Radius programming problem in lathe- urgent!

- viski

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 1

25 Sep 2014 14:42 #51555

by viski

Radius programming problem in lathe- urgent! was created by viski

I have simple 90° radius to make but always get an error mesage: arc is zero, can not use K in XY plane , .. and so on (:

I use diameter code :

G90 G95 G7

G96 S90

M4

G0 X75

G1 Z-12 F0.2

G2 X81 Z-15 I3 F0.2

It's 3mm arc.

i have tried adding G90.1 , G91.1 , G17 , G18 , J and K, but no luck.

I use diameter code :

G90 G95 G7

G96 S90

M4

G0 X75

G1 Z-12 F0.2

G2 X81 Z-15 I3 F0.2

It's 3mm arc.

i have tried adding G90.1 , G91.1 , G17 , G18 , J and K, but no luck.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 240

25 Sep 2014 15:29 - 25 Sep 2014 15:38 #51558

by ArcEye

Replied by ArcEye on topic Radius programming problem in lathe- urgent!

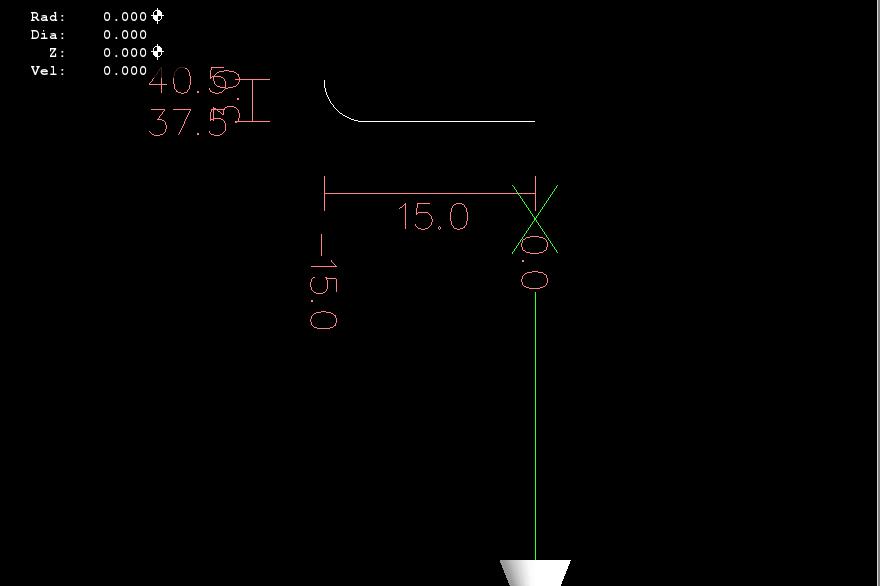

Hi

If you are running in M4 I assume you have a backtool or slant-bed lathe

So do I, so ignore the strange orientation of this plot which comes from running a sim with the system set up to invert the X axis

The code that produces it is

ie modified for metric specifically

I can only assume that your not telling it what planes were operational (lathe or mill) threw the error.

You should get in the habit of heading all your files as above or similar to match.

Historically, this software (and Mach for that matter) was written by Americans with milling machines and the defaults you get will be imperial and XYZ.

regards

If you are running in M4 I assume you have a backtool or slant-bed lathe

So do I, so ignore the strange orientation of this plot which comes from running a sim with the system set up to invert the X axis

The code that produces it is

G18 G21 G40 G49 G54 G80 G95

G90 G7

S600 M4

G0 X75

G1 Z-12 F150

G2 X81 Z-15 I3 F50

m2ie modified for metric specifically

I can only assume that your not telling it what planes were operational (lathe or mill) threw the error.

You should get in the habit of heading all your files as above or similar to match.

Historically, this software (and Mach for that matter) was written by Americans with milling machines and the defaults you get will be imperial and XYZ.

regards

Last edit: 25 Sep 2014 15:38 by ArcEye.

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

25 Sep 2014 16:12 - 25 Sep 2014 16:15 #51560

by Rick G

Replied by Rick G on topic Radius programming problem in lathe- urgent!

As ArcEye said...

It often seems that lathes are considered the weak sister of the mill when it comes to software.

Also note that if you end your program with M2 instead of starting and ending it with % signs it will revert back to the xy plane.

linuxcnc.org/docs/html/gcode/m-code.html#sec:M2-M30

Which can also make for unexpected results when entering MDI commands.

Rick G

Historically, this software (and Mach for that matter) was written by Americans with milling machines and the defaults you get will be imperial and XYZ.

It often seems that lathes are considered the weak sister of the mill when it comes to software.

Also note that if you end your program with M2 instead of starting and ending it with % signs it will revert back to the xy plane.

linuxcnc.org/docs/html/gcode/m-code.html#sec:M2-M30

Which can also make for unexpected results when entering MDI commands.

Rick G

Last edit: 25 Sep 2014 16:15 by Rick G.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 240

25 Sep 2014 19:51 - 25 Sep 2014 19:52 #51561

by ArcEye

Replied by ArcEye on topic Radius programming problem in lathe- urgent!

Rick G wrote:

Just to clarify, Rick means if you don't set your lathe up properly to begin with, it will revert to to a mill setup if you quit the program with M2.

The ini file has a heading [RS274NGC]

under this you should have a string similar to

RS274NGC_STARTUP_CODE = G80 G90 G40 G49 G21 G18 G7

This will cancel any compensation in place, put it in absolute mode, metric, lathe with diameter mode

This is the same command string your programs should begin with, especially if you terminate programs with %, as compensation can carry over to the next program with all sorts of problems otherwise.

regards

Also note that if you end your program with M2 instead of starting and ending it with % signs it will revert back to the xy plane.

linuxcnc.org/docs/html/gcode/m-code.html#sec:M2-M30

Which can also make for unexpected results when entering MDI commands.

Just to clarify, Rick means if you don't set your lathe up properly to begin with, it will revert to to a mill setup if you quit the program with M2.

The ini file has a heading [RS274NGC]

under this you should have a string similar to

RS274NGC_STARTUP_CODE = G80 G90 G40 G49 G21 G18 G7

This will cancel any compensation in place, put it in absolute mode, metric, lathe with diameter mode

This is the same command string your programs should begin with, especially if you terminate programs with %, as compensation can carry over to the next program with all sorts of problems otherwise.

regards

Last edit: 25 Sep 2014 19:52 by ArcEye.

Please Log in or Create an account to join the conversation.

- viski

- Offline

- Senior Member

-

Less

More

- Posts: 44

- Thank you received: 1

26 Sep 2014 01:22 #51574

by viski

Replied by viski on topic Radius programming problem in lathe- urgent!

Thanks guys. I made it  .

.

Yeh, problem was M2 . It returned machine back to mill ( g17 , XY plane ) and i recived message " arc is zero ".

Putting all G80 G90 G40 G49 G21 G18 G7 codes in nc file saved problem.

Regards

Yeh, problem was M2 . It returned machine back to mill ( g17 , XY plane ) and i recived message " arc is zero ".

Putting all G80 G90 G40 G49 G21 G18 G7 codes in nc file saved problem.

Regards

Please Log in or Create an account to join the conversation.

Time to create page: 0.115 seconds