G33.1 right hand tapping weird behavior H E L P !

- tkamsker

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 1

18 Feb 2015 18:04 #56071

by tkamsker

G33.1 right hand tapping weird behavior H E L P ! was created by tkamsker

Hi,

i am almost finished with my bridgeport retrofit now at training stage i found out that G33.1 (because i normally don't use it ) doesn't behave as it should.

i have also prepared an python drill script generator which i donate when we solve that -

-

So i go to lets say g0 x0 y0 z0.5

S200 M3

G33.1 Z-3 K1.5

i would expect that it does go down to Z-3 in the needed speed to achieve 1.5 per revolution

so far so good (i looks that i have a glitch from motor to spindle it is a 1:2 ratio but ,.. )

so i use a bigger number in K to achieve the ratio )

but when the system reaches Z-3 it reverses the spindle also ok

but then it proceeds i stopped it then at Z-30

so has anyone seen that behavior and how can i check what i probably have done wrong ?

or if someone has an Working G84 script which i can remap would also help a lot

i use now the latest live cd and do updates

so any hint welcome

thx

thomas kamsker

i am almost finished with my bridgeport retrofit now at training stage i found out that G33.1 (because i normally don't use it ) doesn't behave as it should.

i have also prepared an python drill script generator which i donate when we solve that

So i go to lets say g0 x0 y0 z0.5

S200 M3

G33.1 Z-3 K1.5

i would expect that it does go down to Z-3 in the needed speed to achieve 1.5 per revolution

so far so good (i looks that i have a glitch from motor to spindle it is a 1:2 ratio but ,.. )

so i use a bigger number in K to achieve the ratio )

but when the system reaches Z-3 it reverses the spindle also ok

but then it proceeds i stopped it then at Z-30

so has anyone seen that behavior and how can i check what i probably have done wrong ?

or if someone has an Working G84 script which i can remap would also help a lot

i use now the latest live cd and do updates

so any hint welcome

thx

thomas kamsker

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

18 Feb 2015 21:58 #56075

by andypugh

Replied by andypugh on topic G33.1 right hand tapping weird behavior H E L P !

but when the system reaches Z-3 it reverses the spindle also ok

but then it proceeds i stopped it then at Z-30 /quote]

Does your spindle encoder definitely count both up and down? It sounds to me like you might be in counter-mode and the system thinks that the spindle is still moving in the same direction.

The following user(s) said Thank You: tkamsker

Please Log in or Create an account to join the conversation.

- tkamsker

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 1

19 Feb 2015 00:45 #56083

by tkamsker

Replied by tkamsker on topic G33.1 right hand tapping weird behavior H E L P !

Hi andy,

Thank you for the fast answer

i think the encoder can not count backwards because i only have Z and A signal on the same pin

i thought because of the reverse spindle it should "know" that it is backwards.

Is there any known configuration which makes this possible or do i have to mount an B signal 90° from the A signal ?

this is something we could manage would that help ?

i then would have A and Index on one signal and B on an 2nd 90° apart

thomas

Thank you for the fast answer

i think the encoder can not count backwards because i only have Z and A signal on the same pin

i thought because of the reverse spindle it should "know" that it is backwards.

Is there any known configuration which makes this possible or do i have to mount an B signal 90° from the A signal ?

this is something we could manage would that help ?

i then would have A and Index on one signal and B on an 2nd 90° apart

thomas

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

19 Feb 2015 00:59 #56085

by andypugh

Just because a spindle reversal has been requested does not mean that the spindle has actually changed direction.

I am afraid that there probably is no alternative to adding a second sensor.

It doesn't have to be at 90 degrees, 360+90 or 720+90 etc all work too.

Replied by andypugh on topic G33.1 right hand tapping weird behavior H E L P !

i thought because of the reverse spindle it should "know" that it is backwards.

Is there any known configuration which makes this possible or do i have to mount an B signal 90° from the A signal ?

Just because a spindle reversal has been requested does not mean that the spindle has actually changed direction.

I am afraid that there probably is no alternative to adding a second sensor.

It doesn't have to be at 90 degrees, 360+90 or 720+90 etc all work too.

The following user(s) said Thank You: tkamsker

Please Log in or Create an account to join the conversation.

- tkamsker

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 1

11 Mar 2015 23:19 #56699

by tkamsker

Replied by tkamsker on topic G33.1 right hand tapping weird behavior H E L P !

Hi andy

i now build an 2nd Probe to my config and can get some better insights

My question which values does the 33 command take in consideration ?

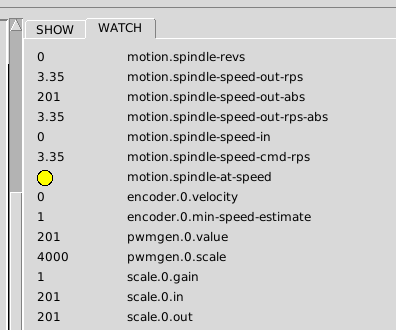

This is an example where i have 201 as RPM and 3,35 as Rev/Sek

And when i turn the direction i is negative

Is that correct ?

Is there an example to work from ?

thx

thomas

i now build an 2nd Probe to my config and can get some better insights

My question which values does the 33 command take in consideration ?

This is an example where i have 201 as RPM and 3,35 as Rev/Sek

And when i turn the direction i is negative

Is that correct ?

Is there an example to work from ?

thx

thomas

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

11 Mar 2015 23:56 #56704

by andypugh

G33 uses the value of motion.spindle-revs (revolutions, not rpm)

You need to set up the encoder scale so that one rotation clockwise of the spindle gives an increase of exactly 1.0 in motion.spindle-revs and one rotation anticlockwise makes it _reduce_ by exactly 1.0.

Replied by andypugh on topic G33.1 right hand tapping weird behavior H E L P !

My question which values does the 33 command take in consideration ?

G33 uses the value of motion.spindle-revs (revolutions, not rpm)

You need to set up the encoder scale so that one rotation clockwise of the spindle gives an increase of exactly 1.0 in motion.spindle-revs and one rotation anticlockwise makes it _reduce_ by exactly 1.0.

The following user(s) said Thank You: tkamsker

Please Log in or Create an account to join the conversation.

- tkamsker

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 1

15 Mar 2015 01:56 #56820

by tkamsker

Replied by tkamsker on topic G33.1 right hand tapping weird behavior H E L P !

Hi,

I have an question

I have switched of count of course

have connected A and Z and B is extra so one Revolution of the spindle brings

A and Z

then B

and next revolution the same

And i think that brings me in trouble ,..

I can get Speed rps rpm fine but then revs is 0 -1 or 1

so do i have to attach an encoder which gives AB AB AB AB and so on and only 1 Z per revolution ?

It seems they revs start after 2nd revolution

When i switch counter on and use A and Z (z then on former B ) to have an 90° offset i get everything

but revs keep on counting (when i do G33.1 it starts nice then reverses the spindle but ,... )

So if anybody has some experience with tha minimized setup it would be nice

The bridgeport has done ist somehow by one Pin anyway ,..

but that is another story

thx

thomas

I have an question

I have switched of count of course

have connected A and Z and B is extra so one Revolution of the spindle brings

A and Z

then B

and next revolution the same

And i think that brings me in trouble ,..

I can get Speed rps rpm fine but then revs is 0 -1 or 1

so do i have to attach an encoder which gives AB AB AB AB and so on and only 1 Z per revolution ?

It seems they revs start after 2nd revolution

When i switch counter on and use A and Z (z then on former B ) to have an 90° offset i get everything

but revs keep on counting (when i do G33.1 it starts nice then reverses the spindle but ,... )

So if anybody has some experience with tha minimized setup it would be nice

The bridgeport has done ist somehow by one Pin anyway ,..

but that is another story

thx

thomas

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17676

- Thank you received: 5170

15 Mar 2015 06:56 - 15 Mar 2015 06:56 #56828

by PCW

Replied by PCW on topic G33.1 right hand tapping weird behavior H E L P !

Rigid tapping requires a full A/B/IDX encoder, in addition it needs one with fairly good resolution

in order to accurately "gear" the Z axis to the spindle rotation. One pin is fine for getting

spindle velocity, no so fine for determining exactly when reversal occurs

in order to accurately "gear" the Z axis to the spindle rotation. One pin is fine for getting

spindle velocity, no so fine for determining exactly when reversal occurs

Last edit: 15 Mar 2015 06:56 by PCW.

The following user(s) said Thank You: tkamsker

Please Log in or Create an account to join the conversation.

- tkamsker

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 1

15 Mar 2015 15:59 #56833

by tkamsker

Replied by tkamsker on topic G33.1 right hand tapping weird behavior H E L P !

Hi PCW ,

thank you for you answer i hoped that i can do it without big changes on the bridgeport

my idea was (because on the original

here my adaption ) to use only one "ping"

i now learned that this is not enough

So Plan "B" i build an test on my mill

where 2 "Probes" are 90° separated and only 1 steel plate is doing the signal so i hoped to get an A/ B Signal (which i do ) which gives me perfect speed .

but revs are not counted !!! i denn put the index signal to A and later to b signal then the revs never get bigger than 1 or -1

So my conclusion would be to put more metal plates (just for test ) on the spindle to get lets say 4 a/b per revolution and i add an longer metal plate and mount a 3rd "probe" to get the index signal

this would lead to an poor mans encoder ,..

so if someone had done ist similar i would go that route because i have everything at hand (but time)

or if you say encoder i have some AMT 101 Encoders on stock ( www.digikey.at/product-detail/en/AMT102-V/102-1307-ND/827015 ) but the mount on the Bridgeport will be very complicated ( on my lathe i am on the way to do that but that is next task )

So if someone can lead me in the right direction this would help me big times

last resort would be to go the Encoder route

thanx

thomas kamsker

thank you for you answer i hoped that i can do it without big changes on the bridgeport

my idea was (because on the original

here my adaption ) to use only one "ping"

i now learned that this is not enough

So Plan "B" i build an test on my mill

where 2 "Probes" are 90° separated and only 1 steel plate is doing the signal so i hoped to get an A/ B Signal (which i do ) which gives me perfect speed .

but revs are not counted !!! i denn put the index signal to A and later to b signal then the revs never get bigger than 1 or -1

So my conclusion would be to put more metal plates (just for test ) on the spindle to get lets say 4 a/b per revolution and i add an longer metal plate and mount a 3rd "probe" to get the index signal

this would lead to an poor mans encoder ,..

so if someone had done ist similar i would go that route because i have everything at hand (but time)

or if you say encoder i have some AMT 101 Encoders on stock ( www.digikey.at/product-detail/en/AMT102-V/102-1307-ND/827015 ) but the mount on the Bridgeport will be very complicated ( on my lathe i am on the way to do that but that is next task )

So if someone can lead me in the right direction this would help me big times

last resort would be to go the Encoder route

thanx

thomas kamsker

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

15 Mar 2015 16:37 #56834

by andypugh

You probably want more than 4 pulses. Home-made encoders normally have 50+ slots and commercial ones have 1000+

Do you know what the response time of you sensors is? At high speeds they may start missing edges.

Replied by andypugh on topic G33.1 right hand tapping weird behavior H E L P !

So my conclusion would be to put more metal plates (just for test ) on the spindle to get lets say 4 a/b per revolution and i add an longer metal plate and mount a 3rd "probe" to get the index signal

You probably want more than 4 pulses. Home-made encoders normally have 50+ slots and commercial ones have 1000+

Do you know what the response time of you sensors is? At high speeds they may start missing edges.

The following user(s) said Thank You: tkamsker

Please Log in or Create an account to join the conversation.

Time to create page: 0.129 seconds