M7 & M8 G codes

- lucky phil

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

22 May 2016 12:21 #74942

by lucky phil

M7 & M8 G codes was created by lucky phil

Hi all

I have just connected a couple of air/lube line to solenoid on my router for tool tip cooling/lubrication.

I am using the flood coolant(m8) & mist(m7) to operate them.

Two questions:

1. Is there a way to turn them on or off while I have a program running for the times that I forget to have it written in my code.

2.with the coolant mist, I want to pulse it on and off so as to just spray a small amount of lube time to suit what I'm cutting, I have started coding an Arduino to do the pulsing but thought LinuxCNC may be able to do it for me but have not found any info for it.

Ultimately I would like the pulsing to be approx .5 second on & 5-10 seconds off.

any info would be great

Philip

I have just connected a couple of air/lube line to solenoid on my router for tool tip cooling/lubrication.

I am using the flood coolant(m8) & mist(m7) to operate them.

Two questions:

1. Is there a way to turn them on or off while I have a program running for the times that I forget to have it written in my code.

2.with the coolant mist, I want to pulse it on and off so as to just spray a small amount of lube time to suit what I'm cutting, I have started coding an Arduino to do the pulsing but thought LinuxCNC may be able to do it for me but have not found any info for it.

Ultimately I would like the pulsing to be approx .5 second on & 5-10 seconds off.

any info would be great

Philip

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

22 May 2016 13:15 #74945

by Todd Zuercher

Replied by Todd Zuercher on topic M7 & M8 G codes

1, Yes, when properly configured the mist/lube buttons can override durring a run (I think haven't used them)

2, Yes Linuxcnc could do that with a little HAL logic, no extra hardware required. You could even set up a little vcp screen where you could adjust the frequency/duration.

2, Yes Linuxcnc could do that with a little HAL logic, no extra hardware required. You could even set up a little vcp screen where you could adjust the frequency/duration.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

22 May 2016 15:28 - 22 May 2016 15:32 #74950

by cncbasher

Replied by cncbasher on topic M7 & M8 G codes

yes you can pulse the output either by gcode using o words subs

are you trying to run a lube pump ? or as a coolant , either way there are a few options

such as the lube pump comp , would be ideal for this

forum.linuxcnc.org/forum/47-hal-examples/10935-lube-pump

are you trying to run a lube pump ? or as a coolant , either way there are a few options

such as the lube pump comp , would be ideal for this

forum.linuxcnc.org/forum/47-hal-examples/10935-lube-pump

Last edit: 22 May 2016 15:32 by cncbasher.

Please Log in or Create an account to join the conversation.

- lucky phil

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

23 May 2016 07:28 #74969

by lucky phil

Replied by lucky phil on topic M7 & M8 G codes

Thanks

I am not using a pump, I have a pressurised container with lube in it, what I want to do is pulse a solenoid which will let the lube flow, I would like to be able to adjust the on & off times occasionally depending what material I am cutting/engraving. I like the sound of being able to have a VCP screen.

The M8 code should be on and left on when engraving to keep the cutter clear of chips, I have a needle valve on the side of my air line which will inject lube into the air stream by turning on M7.

I am not using a pump, I have a pressurised container with lube in it, what I want to do is pulse a solenoid which will let the lube flow, I would like to be able to adjust the on & off times occasionally depending what material I am cutting/engraving. I like the sound of being able to have a VCP screen.

The M8 code should be on and left on when engraving to keep the cutter clear of chips, I have a needle valve on the side of my air line which will inject lube into the air stream by turning on M7.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

23 May 2016 11:32 - 23 May 2016 11:32 #74976

by BigJohnT

Replied by BigJohnT on topic M7 & M8 G codes

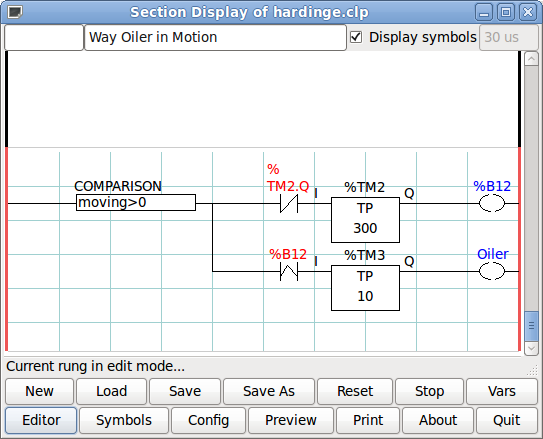

I run my lube pump with classicladder. It's easy to set up a pulse timer circuit.

JT

JT

Last edit: 23 May 2016 11:32 by BigJohnT.

Please Log in or Create an account to join the conversation.

- lucky phil

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

31 May 2016 12:28 #75283

by lucky phil

Replied by lucky phil on topic M7 & M8 G codes

Hi JT

so with classic ladder am I able to put some buttons on my screen to turn on & off p/pin 14 & 16 while code is running and have a couple of buttons to adjust the on & off time on one of then(0.25-1.0 second on and 1.0-10.0 seconds off.

Any code snippets to help me would be appreciated as I am just learning linux.

Philip

so with classic ladder am I able to put some buttons on my screen to turn on & off p/pin 14 & 16 while code is running and have a couple of buttons to adjust the on & off time on one of then(0.25-1.0 second on and 1.0-10.0 seconds off.

Any code snippets to help me would be appreciated as I am just learning linux.

Philip

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

31 May 2016 23:16 #75300

by BigJohnT

Replied by BigJohnT on topic M7 & M8 G codes

What part of the puzzle are you missing?

I have a tutorial here:

gnipsel.com/linuxcnc/ladder/index.html

JT

I have a tutorial here:

gnipsel.com/linuxcnc/ladder/index.html

loadrt mult2 count=3

# Way Oiler

addf mult2.2 servo-thread

# Way Oiler

setp mult2.2.in0 1000

net mult-vel mult2.2.in1 <= motion.current-vel

net in-motion classicladder.0.floatin-00 <= mult2.2.out

net oil-on hm2_5i20.0.gpio.045.out <= classicladder.0.out-07JT

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds