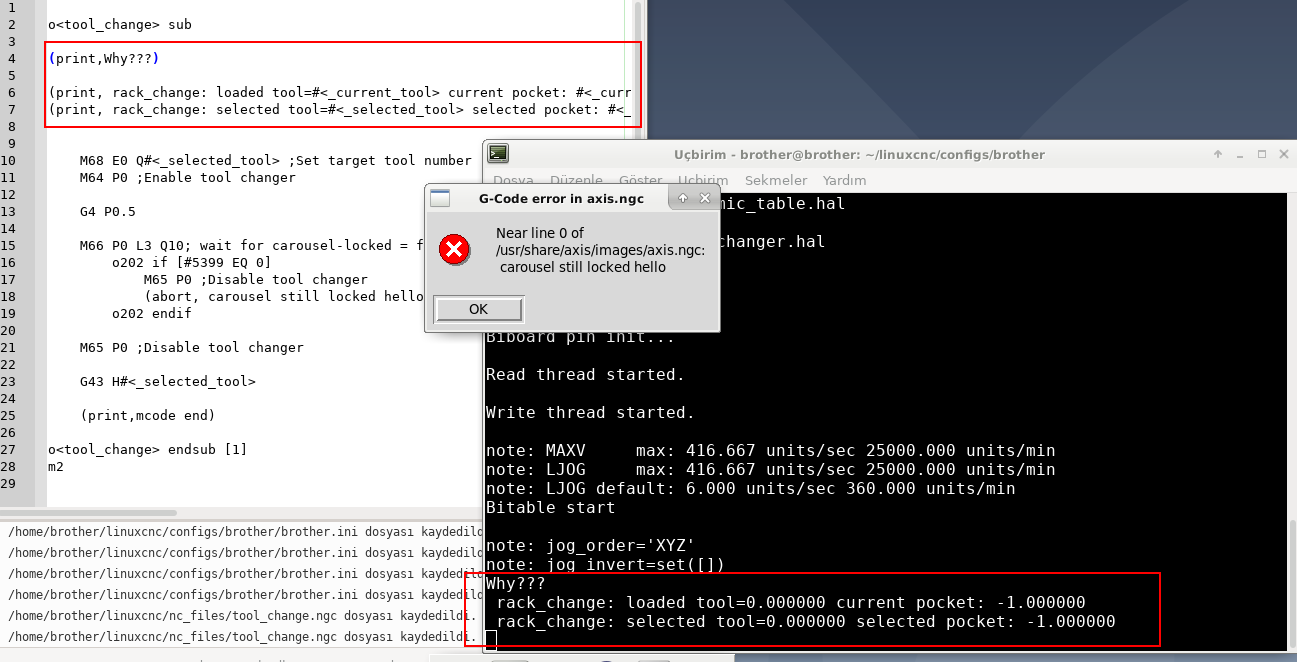

[REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

28 Aug 2021 11:36 - 28 Aug 2021 11:42 #218983

by mugurlu

[REMAP FOR M6] Why does linuxcnc run the .ngc file on startup? was created by mugurlu

Attachments:

Last edit: 28 Aug 2021 11:42 by mugurlu.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

28 Aug 2021 11:47 #218985

by andypugh

Replied by andypugh on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

Do you by any chance have an M6 in the [RS274NGC]STARTHUP_GCODES in the .ini file?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4616

- Thank you received: 2043

28 Aug 2021 11:55 - 28 Aug 2021 12:14 #218986

by Aciera

Replied by Aciera on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

Not sure why it's running at startup.

But as to why you have a tool offset but no tool loaded:

In line 23 of your 'tool_change.ngc' you are only telling the controller to enable tool length compensation using the tool length offset value of the 'selected_tool' but you never actually tell the controller to change the tool.

Note that you can actually use M6 inside a custom remap:

Have a look at section 5.6 here:

linuxcnc.org/docs/html/remap/remap.html#...lated_codes_t_m6_m61

So maybe changing line 23 to this will do what you want:

T#<_selected_tool> M6 G43

But as to why you have a tool offset but no tool loaded:

In line 23 of your 'tool_change.ngc' you are only telling the controller to enable tool length compensation using the tool length offset value of the 'selected_tool' but you never actually tell the controller to change the tool.

Note that you can actually use M6 inside a custom remap:

Have a look at section 5.6 here:

linuxcnc.org/docs/html/remap/remap.html#...lated_codes_t_m6_m61

So maybe changing line 23 to this will do what you want:

T#<_selected_tool> M6 G43

Last edit: 28 Aug 2021 12:14 by Aciera.

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

28 Aug 2021 12:57 - 28 Aug 2021 13:01 #218995

by mugurlu

# Generated by PNCconf at Sun Feb 21 11:35:31 2021

# Using LinuxCNC version: 2.8

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = brother

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/brother/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 416.666666

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

PYVCP = spindle.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

HAL_PIN_VARS = 1

NO_DOWNCASE_OWORD = 1

# turn on all optional features except RETAIN_G43

FEATURES= 30

REMAP=M06 modalgroup=6 ngc=tool_change

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

CARD0=hm2_5i25.0

[HAL]

HALUI = halui

HALFILE = brother.hal

HALFILE = custom.hal

HALFILE = jog_pendant.hal

HALFILE = spindle.hal

HALFILE = dynamic_table.hal

HALFILE = toolchanger.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 41.67

MAX_LINEAR_VELOCITY = 416.67

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

MIN_LIMIT = -85.0

MAX_LIMIT = 580.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

BACKLASH=0.025

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 460

STEPGEN_MAXACCEL = 400

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 500

MIN_LIMIT = -85.0

MAX_LIMIT = 580.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -50.0

HOME_LATCH_VEL = -5.00

HOME_FINAL_VEL = -5.00

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

MIN_LIMIT = -70.0

MAX_LIMIT = 220.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

BACKLASH=0.02

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 460

STEPGEN_MAXACCEL = 400

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 500

MIN_LIMIT = -70.0

MAX_LIMIT = 220.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -50.0

HOME_LATCH_VEL = -5.00

HOME_FINAL_VEL = -5.00

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 333

MAX_ACCELERATION = 100

MIN_LIMIT = -190.0

MAX_LIMIT = 190.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 333

MAX_ACCELERATION = 100

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 350

STEPGEN_MAXACCEL = 200

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 1000

MIN_LIMIT = -190.0

MAX_LIMIT = 190.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 50.0

HOME_LATCH_VEL = 5.00

HOME_FINAL_VEL = 5.00

HOME_SEQUENCE = 0

#******************************************

[SPINDLE_0]

P = 100

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 500

# Step/Dir

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEPGEN_MAXACCEL = 30000

STEPGEN_MAXVEL = 50000

ENCODER_SCALE = 1024

# 1024/60 17.0666

OUTPUT_SCALE = 1

ACCELERATION = 2000

MAX_ERROR = 0.2

OFF_DELAY = 1.5

[PYTHON]

#TOPLEVEL= /home/brother/linuxcnc/configs/brother/python/toplevel.py

#PATH_APPEND= /home/brother/linuxcnc/configs/brother/python

Replied by mugurlu on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

No, my ini file:Do you by any chance have an M6 in the [RS274NGC]STARTHUP_GCODES in the .ini file?

Warning: Spoiler!

# Generated by PNCconf at Sun Feb 21 11:35:31 2021

# Using LinuxCNC version: 2.8

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = brother

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/brother/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 416.666666

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

PYVCP = spindle.xml

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

HAL_PIN_VARS = 1

NO_DOWNCASE_OWORD = 1

# turn on all optional features except RETAIN_G43

FEATURES= 30

REMAP=M06 modalgroup=6 ngc=tool_change

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

BASE_PERIOD = 100000

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

CARD0=hm2_5i25.0

[HAL]

HALUI = halui

HALFILE = brother.hal

HALFILE = custom.hal

HALFILE = jog_pendant.hal

HALFILE = spindle.hal

HALFILE = dynamic_table.hal

HALFILE = toolchanger.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 41.67

MAX_LINEAR_VELOCITY = 416.67

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

MIN_LIMIT = -85.0

MAX_LIMIT = 580.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

BACKLASH=0.025

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 460

STEPGEN_MAXACCEL = 400

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 500

MIN_LIMIT = -85.0

MAX_LIMIT = 580.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -50.0

HOME_LATCH_VEL = -5.00

HOME_FINAL_VEL = -5.00

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

MIN_LIMIT = -70.0

MAX_LIMIT = 220.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 416

MAX_ACCELERATION = 100

BACKLASH=0.02

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 460

STEPGEN_MAXACCEL = 400

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 500

MIN_LIMIT = -70.0

MAX_LIMIT = 220.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = -50.0

HOME_LATCH_VEL = -5.00

HOME_FINAL_VEL = -5.00

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 333

MAX_ACCELERATION = 100

MIN_LIMIT = -190.0

MAX_LIMIT = 190.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 5

MIN_FERROR = 1

MAX_VELOCITY = 333

MAX_ACCELERATION = 100

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 350

STEPGEN_MAXACCEL = 200

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 250

STEPSPACE = 50

STEP_SCALE = 1000

MIN_LIMIT = -190.0

MAX_LIMIT = 190.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 50.0

HOME_LATCH_VEL = 5.00

HOME_FINAL_VEL = 5.00

HOME_SEQUENCE = 0

#******************************************

[SPINDLE_0]

P = 100

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 500

# Step/Dir

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

STEPGEN_MAXACCEL = 30000

STEPGEN_MAXVEL = 50000

ENCODER_SCALE = 1024

# 1024/60 17.0666

OUTPUT_SCALE = 1

ACCELERATION = 2000

MAX_ERROR = 0.2

OFF_DELAY = 1.5

[PYTHON]

#TOPLEVEL= /home/brother/linuxcnc/configs/brother/python/toplevel.py

#PATH_APPEND= /home/brother/linuxcnc/configs/brother/python

Last edit: 28 Aug 2021 13:01 by mugurlu.

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

28 Aug 2021 13:02 #218997

by mugurlu

Replied by mugurlu on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

28 Aug 2021 14:05 - 28 Aug 2021 14:11 #219004

by mugurlu

Answer:

linuxcnc.org/docs/html/remap/remap.html#...lated_codes_t_m6_m61 [Step 1]

Section :4. Upgrading an existing configuration for remapping

Create stdglue.py file.

[Step]

Section 5.3. Specifying the M6 replacement

I edited stdglue.py for two headers as below;

everything is fine so far

However,

I can't find the answer to the question in the title.

What should I do to prevent tool change every time the machine is turned on? (M6 why are you working?)

Best regards,

mugurlu

Replied by mugurlu on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

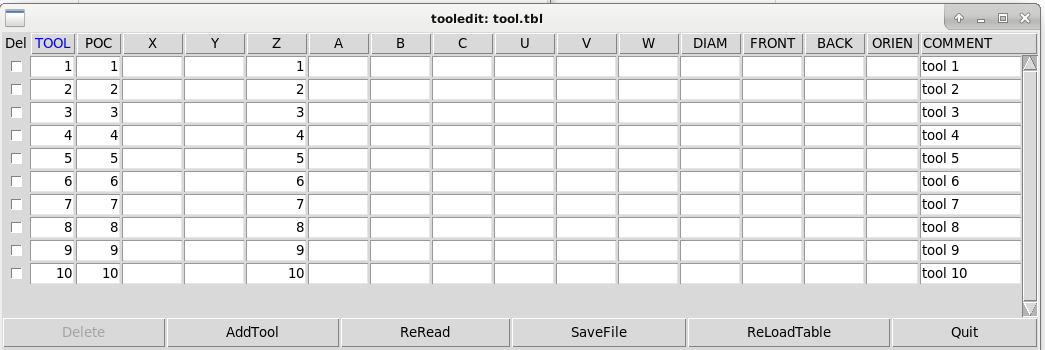

Why does it stay in No Tool status? (P3 ... P4.png P5.png)

Answer:

linuxcnc.org/docs/html/remap/remap.html#...lated_codes_t_m6_m61 [Step 1]

Section :4. Upgrading an existing configuration for remapping

Create stdglue.py file.

[Step]

Section 5.3. Specifying the M6 replacement

I edited stdglue.py for two headers as below;

def change_prolog(self, **words):

try:

if self.selected_pocket < 0:

return "M6: no tool prepared"

if self.cutter_comp_side:

return "Cannot change tools with cutter radius compensation on"

self.params["tool_in_spindle"] = self.current_tool

self.params["selected_tool"] = self.selected_tool

self.params["current_pocket"] = self.current_pocket

self.params["selected_pocket"] = self.selected_pocket

return INTERP_OK

except Exception, e:

return "M6/change_prolog: %s" % (e)

def change_epilog(self, **words):

try:

if self.return_value > 0.0:

# commit change

self.selected_pocket = int(self.params["selected_pocket"])

emccanon.CHANGE_TOOL(self.selected_pocket)

# cause a sync()

self.tool_change_flag = True

self.set_tool_parameters()

return INTERP_OK

else:

return "M6 aborted (return code %.1f)" % (self.return_value)

except Exception, e:

return "M6/change_epilog: %s" % (e)everything is fine so far

However,

I can't find the answer to the question in the title.

What should I do to prevent tool change every time the machine is turned on? (M6 why are you working?)

Best regards,

mugurlu

Last edit: 28 Aug 2021 14:11 by mugurlu.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

28 Aug 2021 14:17 - 28 Aug 2021 14:28 #219006

by bevins

Replied by bevins on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

You have to test for milltask mode in ypur remap and return if it is not so it doesnt run the remap and move the machine. When Lcnc loads a file it is in preview mode. Thats the best way I can explain it. Maybe someone can chime in.

if self.task==0:

return INTERP_OK

Last edit: 28 Aug 2021 14:28 by bevins.

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

28 Aug 2021 14:41 #219007

by mugurlu

Replied by mugurlu on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

Hi,

but i use to .ngc file...Where should I add the part you mentioned?

but i use to .ngc file...

REMAP=M6 modalgroup=6 prolog=change_prolog ngc=tool_change epilog=change_epilogif self.task==0:

return INTERP_OKPlease Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

28 Aug 2021 14:54 - 28 Aug 2021 14:55 #219009

by bevins

Replied by bevins on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

/Edit Sorry I didnt see that. Your remap line up farther didnt show it.

Last edit: 28 Aug 2021 14:55 by bevins.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4616

- Thank you received: 2043

28 Aug 2021 14:55 - 28 Aug 2021 15:41 #219010

by Aciera

Replied by Aciera on topic [REMAP FOR M6] Why does linuxcnc run the .ngc file on startup?

Unrelated: Note that the FEATURES tag in the [RS274NGC] Section does no longer work in Version 2.8 and up.

linuxcnc.org/docs/html/config/ini-config...l#gcode:ini-features

linuxcnc.org/docs/html/config/ini-config...l#gcode:ini-features

Last edit: 28 Aug 2021 15:41 by Aciera.

Please Log in or Create an account to join the conversation.

Time to create page: 0.308 seconds