Slowdown in arc-line-arc

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

10 Dec 2021 16:19 - 10 Dec 2021 16:29 #228785

by fernandosf

Slowdown in arc-line-arc was created by fernandosf

Mine is a plasma, I have seen some slowdown where it would blend smoothly with G64P0.1 (mm).

I'm new to LinuxCNC.

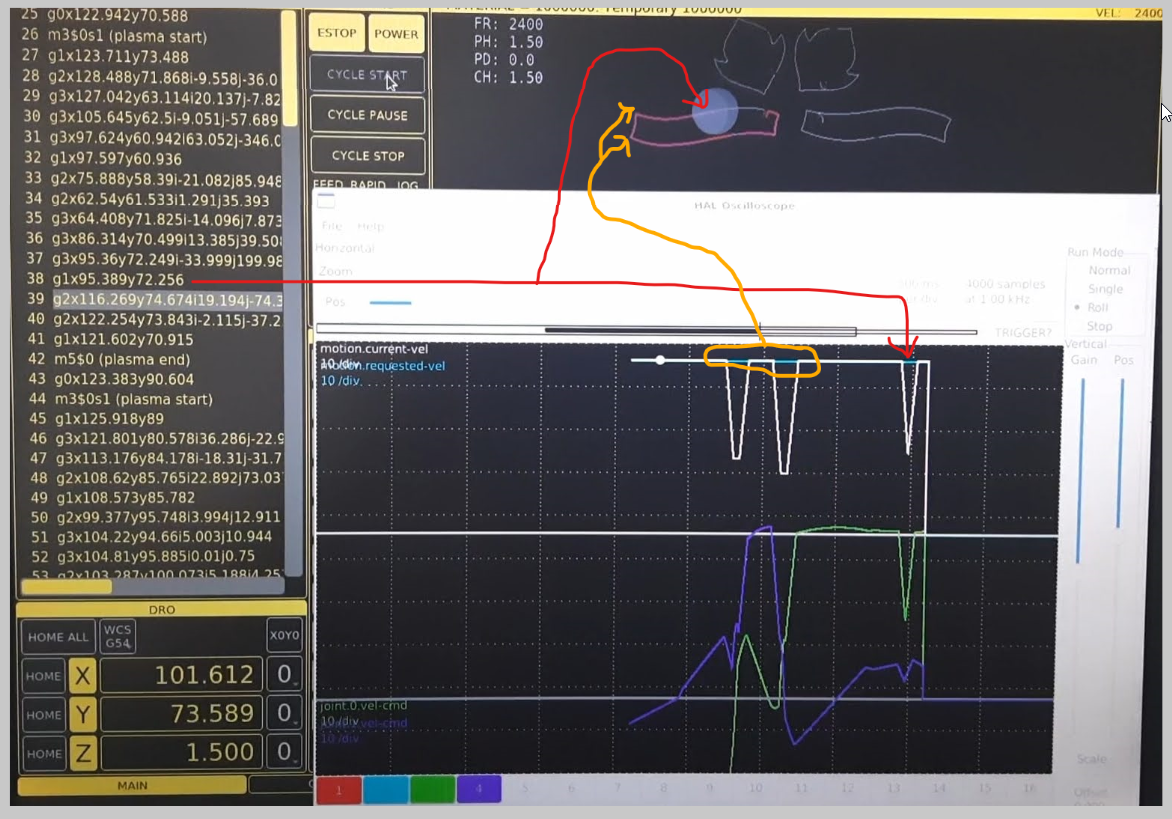

Tried to do a HalScope:

You can see that on sharp corners (orange line) it slows down, ok, that's expected.

But on arc-line (lines 38 and 39 of gcode) I hoped it would blend without loosing speed, but velocity drops to half.

Is this intend behaviour?

It's really bad for plasma cutting, as when cutting thin stainless steel the torch vaporizes surrounding material when it drops speed.

I'm attaching the g-code file, will have to get back to the shop to recover my LinuxCNC .ini file .

I tried to change to G64 P1 Q0.1 and other values, but, or it starts to loose the shape or it has mininum effect on the slowdown.

I'm using LinuxCNC 2.9 and QTPlasmaC, it's a chinese BoB, parallel port.

I'm new to LinuxCNC.

Tried to do a HalScope:

You can see that on sharp corners (orange line) it slows down, ok, that's expected.

But on arc-line (lines 38 and 39 of gcode) I hoped it would blend without loosing speed, but velocity drops to half.

Is this intend behaviour?

It's really bad for plasma cutting, as when cutting thin stainless steel the torch vaporizes surrounding material when it drops speed.

I'm attaching the g-code file, will have to get back to the shop to recover my LinuxCNC .ini file .

I tried to change to G64 P1 Q0.1 and other values, but, or it starts to loose the shape or it has mininum effect on the slowdown.

I'm using LinuxCNC 2.9 and QTPlasmaC, it's a chinese BoB, parallel port.

Attachments:

Last edit: 10 Dec 2021 16:29 by fernandosf. Reason: last line

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

10 Dec 2021 17:14 #228788

by Michael

Replied by Michael on topic Slowdown in arc-line-arc

What type of acceleration does the machine have? The G64 settings will behave differently based on each machines acceleration.

G64 without any modifications will maintain speed as best as possible in corners. But sharp corners will see them cut in an effort to maintain that speed. This setting has the most path deviation.

G64 P and Q values will limit the amount of blending/deviation to maintain speed but will slow down in corners a certain amount.

If you have multiple splines in a design versus one continuous arc you may get some odd behavior as each small segment is interrupted in the blending. Try to redraw the file to have clean lines and arcs with no splines. Often when you convert images to dxf you will get splines which when you zoom in on them are jagged for no reason.

For your design in question the parts highlighted should be only a few lines of g code. The straight line with sharp corner to a large arc and then a different large arc. I would make sure your cam software has smoothing turned off and and check tolerance settings. These settings tend to create multiple small lines/arcs in a gcode file but then get reinterpreted in linuxcnc with it's blending settings.

G64 without any modifications will maintain speed as best as possible in corners. But sharp corners will see them cut in an effort to maintain that speed. This setting has the most path deviation.

G64 P and Q values will limit the amount of blending/deviation to maintain speed but will slow down in corners a certain amount.

If you have multiple splines in a design versus one continuous arc you may get some odd behavior as each small segment is interrupted in the blending. Try to redraw the file to have clean lines and arcs with no splines. Often when you convert images to dxf you will get splines which when you zoom in on them are jagged for no reason.

For your design in question the parts highlighted should be only a few lines of g code. The straight line with sharp corner to a large arc and then a different large arc. I would make sure your cam software has smoothing turned off and and check tolerance settings. These settings tend to create multiple small lines/arcs in a gcode file but then get reinterpreted in linuxcnc with it's blending settings.

Please Log in or Create an account to join the conversation.

- fernandosf

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 69

- Thank you received: 17

10 Dec 2021 18:44 #228793

by fernandosf

Replied by fernandosf on topic Slowdown in arc-line-arc

What do you mean? Those are steppers (open loop).What type of acceleration does the machine have? The G64 settings will behave differently based on each machines acceleration.

I design in Illustrator, then convert to SVG, then input in SheetCam. Illustrator has a "simplify" path that seems to do what you mean, but when I import into SheetCam it gives me those odd lines between arcs, sometimes very tiny ones.If you have multiple splines in a design versus one continuous arc you may get some odd behavior as each small segment is interrupted in the blending. Try to redraw the file to have clean lines and arcs with no splines. Often when you convert images to dxf you will get splines which when you zoom in on them are jagged for no reason.

I'm not sure Sheetcam has such features (smoothness control, I mean)For your design in question the parts highlighted should be only a few lines of g code. The straight line with sharp corner to a large arc and then a different large arc. I would make sure your cam software has smoothing turned off and and check tolerance settings. These settings tend to create multiple small lines/arcs in a gcode file but then get reinterpreted in linuxcnc with it's blending settings.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21259

- Thank you received: 7255

10 Dec 2021 20:16 #228803

by tommylight

Replied by tommylight on topic Slowdown in arc-line-arc

To many points for failure.

Use wizard, do some shapes, post results.

Use wizard, do some shapes, post results.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

10 Dec 2021 20:37 #228810

by Michael

Replied by Michael on topic Slowdown in arc-line-arc

For acceleration on open loop steppers the value is expressed in your ini file. Lower values will cause more dramatic corner cutting in G64. This is because it has to slow down sooner for a corner.

I'm with Tommy. Try doing some simple square patterns that you hand write the gcode for and see if you have the same issues. I have gotten files from illustrator before and when you zoom in on the SVG the lines are all splines and have a lot of garbage/clutter. I have found inkscape makes a more useable SVG but with steep learning curve. All my cad and cam is done in fusion360 so I can't help much with your setup.

I'm with Tommy. Try doing some simple square patterns that you hand write the gcode for and see if you have the same issues. I have gotten files from illustrator before and when you zoom in on the SVG the lines are all splines and have a lot of garbage/clutter. I have found inkscape makes a more useable SVG but with steep learning curve. All my cad and cam is done in fusion360 so I can't help much with your setup.

Please Log in or Create an account to join the conversation.

Time to create page: 0.082 seconds