Problem G-code?

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

24 Jul 2025 17:17 #332271

by Todd Zuercher

Problem G-code? was created by Todd Zuercher

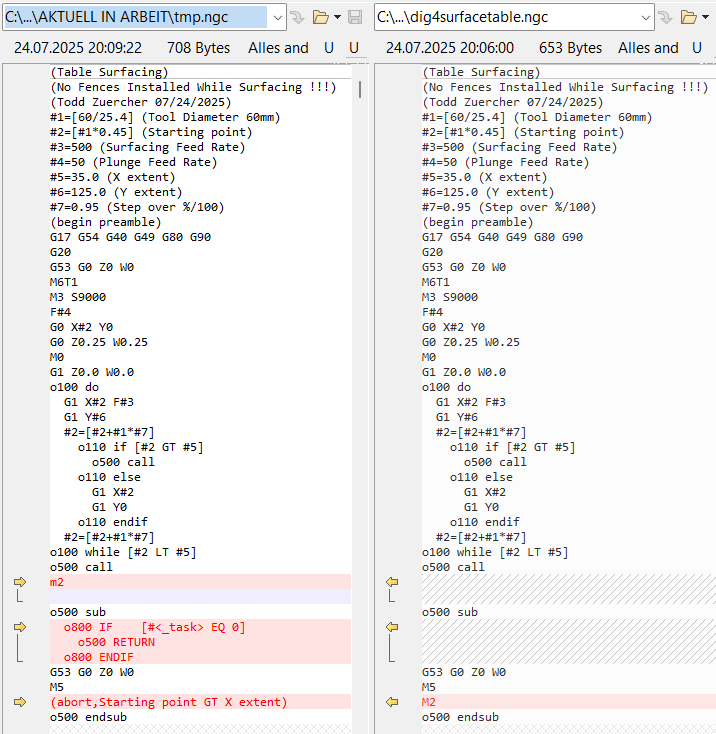

I wrote this parametric G-code program and it seems to run fine on my simulation machine. But when I try to run it on the real machine it stops at line 20 and gives (Does not exicute line 20) no feedback as to why. However my simulation machine is running Linuxcnc 2.9, and the real machine is only on 2.7.

Attachments:

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 484

- Thank you received: 206

24 Jul 2025 17:44 #332274

by MaHa

Replied by MaHa on topic Problem G-code?

Line 20 has M0, but normally the next line is the problem, the first G1 move in the routine. Is spindle.0.at-speed true?

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 484

- Thank you received: 206

24 Jul 2025 18:13 #332276

by MaHa

Replied by MaHa on topic Problem G-code?

Attachments:

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

25 Jul 2025 10:49 #332300

by Todd Zuercher

Replied by Todd Zuercher on topic Problem G-code?

It wasn't spindle at speed, I had checked that first thing. It wasn't the M0 pause, I had tried running it with that line deleted with the same result. Starting the program rhe machine would raise the spindles, start the spindles, move to the starting point, lower the spindles down to 0.25, and pause, At this point clicking the pause button or pressing the next line buttons would have no effect. I tried debugging the parameter that was setting the feed rate before Line 20, and it was what it was supposed to be. I tried deleting the parameter for the feed and expicitly setting the F term with the real feed number, no effect. Deleting the M0 only changed that the pause button on the menu bar wouldn't toggle on, but the machine still would not proceed beyond line 20.

I still don't know what the real problem was, but I restarted the Linuxcnc from the command line to try to see if there were any messages there, and then it ran fine. weird

I still don't know what the real problem was, but I restarted the Linuxcnc from the command line to try to see if there were any messages there, and then it ran fine. weird

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21088

- Thank you received: 7201

25 Jul 2025 11:57 #332302

by tommylight

Replied by tommylight on topic Problem G-code?

Axis GUI?

Did you accidentally press the 0 on the keyboard? That would set the feed rate to 0 and would do exactly as you describe, namely start and go to the first cut and stop there waiting.

Did you accidentally press the 0 on the keyboard? That would set the feed rate to 0 and would do exactly as you describe, namely start and go to the first cut and stop there waiting.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

25 Jul 2025 11:59 #332304

by Todd Zuercher

Replied by Todd Zuercher on topic Problem G-code?

I'm sorry I don't understand what the point of checking to see if #_task> is equal to 0 in my sub program that is intended to end the program. And maybe that isn't the best way to do that. I basically have two branches, the surfacing program can end either at the front or back of the machine depending on where it runs out of space. Then it needs to raise the spindles, turn them off, and end the program. Maybe it would have been better to end it like this.

(Table Surfacing)

(No Fences Installed While Surfacing !!!)

(Todd Zuercher 07/24/2025)

#1=[60/25.4] (Tool Diameter 60mm)

#2=[#1*0.45] (Starting point)

#3=500 (Surfacing Feed Rate)

#4=50 (Plunge Feed Rate)

#5=35.0 (X extent)

#6=125.0 (Y extent)

#7=0.95 (Step over %/100)

(begin preamble)

G17 G54 G40 G49 G80 G90

G20

G53 G0 Z0 W0

M6T1

M3 S9000

F#4

G0 X#2 Y0

G0 Z0.25 W0.25

M0

G1 Z0.0 W0.0

o100 do

G1 X#2 F#3

G1 Y#6

#2=[#2+#1*#7]

o110 if [#2 GT #5]

o100 break

o110 else

G1 X#2

G1 Y0

o110 endif

#2=[#2+#1*#7]

o100 while [#2 LT #5]

G53 G0 Z0 W0

M5

M2Please Log in or Create an account to join the conversation.

Time to create page: 0.071 seconds