Newbie on tool changing needs advice

- jcarpenter

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

22 Oct 2014 06:44 #52260

by jcarpenter

Newbie on tool changing needs advice was created by jcarpenter

Is there a way to rezero my Z axis during a program using AXIS? I have a complicated G code program with 4 tool changes. I don’t have the tooling to do preset tools. So I need to manually change the cutters and rezero the Z axis at each requested tool change. Now I could always get out of the G code program auto mode and change the tool and reset Z. I could then Resume execution of the code at the line where the tool change was requested. However in my mind this is equivalent to running 4 separate programs. And it would be simpler and less error prone to just have 4 separate G Code programs to do the machining with each tool. Any suggestions? If I am totally screwing this up please let me know. Won't be the first time.

Thanks,

John C

Thanks,

John C

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

22 Oct 2014 18:40 #52272

by BigJohnT

Replied by BigJohnT on topic Newbie on tool changing needs advice

You should break your program up into one tool per program.

JT

JT

The following user(s) said Thank You: jcarpenter

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 758

22 Oct 2014 22:31 #52280

by ArcEye

Replied by ArcEye on topic Newbie on tool changing needs advice

Hi

This is something that is only possible through remapping of M6 and a lot of python hoop jumping at present.

If you don't have pre-set tool-holders or repeatable methods of tool changing, it really is easier to have 4 programs.

Just look at the effects of M2 / M30 and be aware that you may want to halt the run with a % and preserve offsets, modes etc

regards

This is something that is only possible through remapping of M6 and a lot of python hoop jumping at present.

If you don't have pre-set tool-holders or repeatable methods of tool changing, it really is easier to have 4 programs.

Just look at the effects of M2 / M30 and be aware that you may want to halt the run with a % and preserve offsets, modes etc

regards

The following user(s) said Thank You: jcarpenter

Please Log in or Create an account to join the conversation.

- jcarpenter

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

23 Oct 2014 00:04 #52290

by jcarpenter

Replied by jcarpenter on topic Newbie on tool changing needs advice

Ok, thanks. I broke the program up into parts for each tool. I guess I need to invest in some hardware. Maybe after my next paying job.

John C

John C

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

23 Oct 2014 03:30 #52306

by BigJohnT

Replied by BigJohnT on topic Newbie on tool changing needs advice

In addition a good preamble at the head of each file will eliminate errors that might creep in in between runs when manually mucking about.

gnipsel.com/linuxcnc/g-code/gen01.html

JT

gnipsel.com/linuxcnc/g-code/gen01.html

JT

Please Log in or Create an account to join the conversation.

- jcarpenter

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

31 Oct 2014 03:00 #52601

by jcarpenter

Replied by jcarpenter on topic Newbie on tool changing needs advice

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 758

31 Oct 2014 15:37 #52610

by ArcEye

Replied by ArcEye on topic Newbie on tool changing needs advice

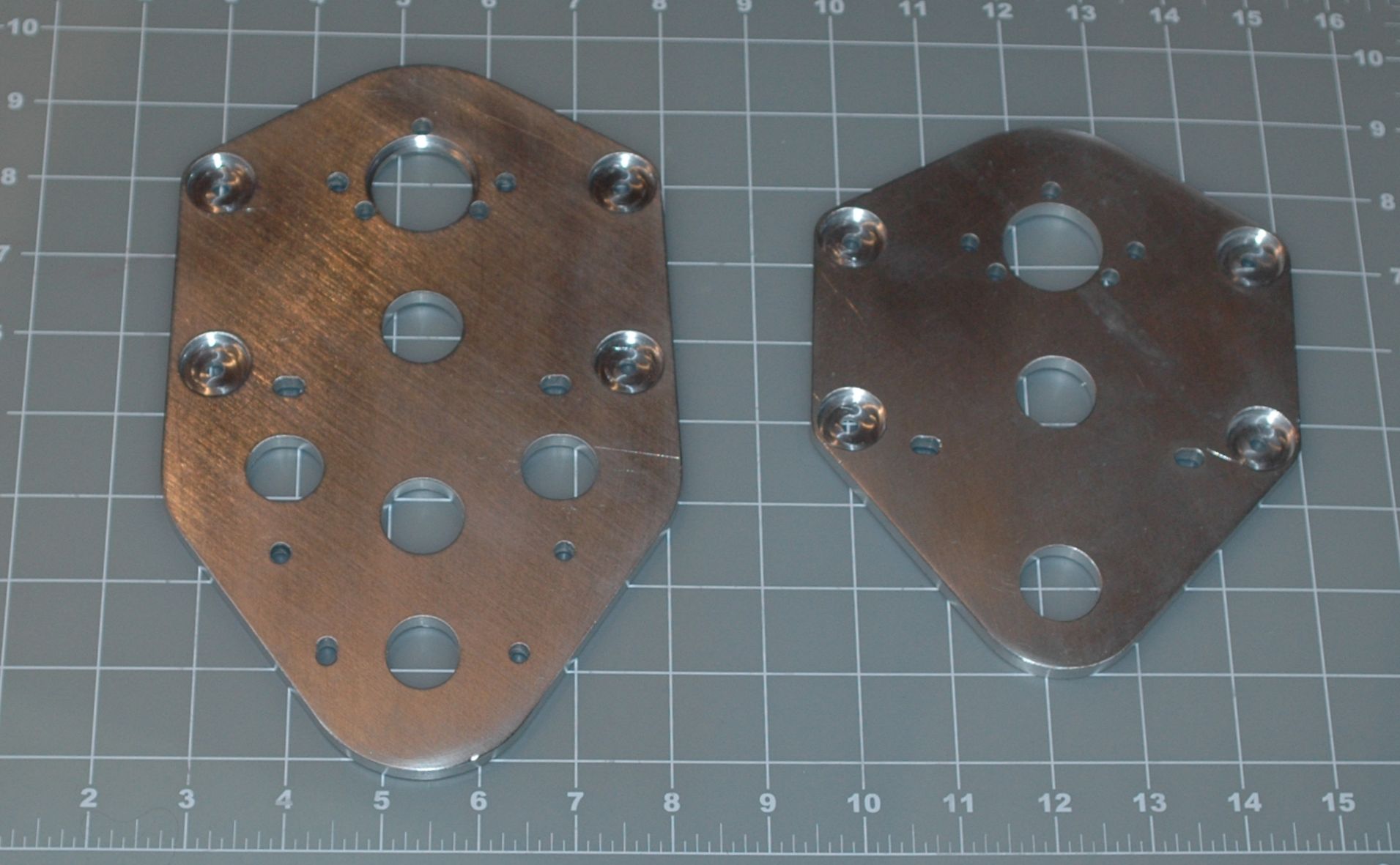

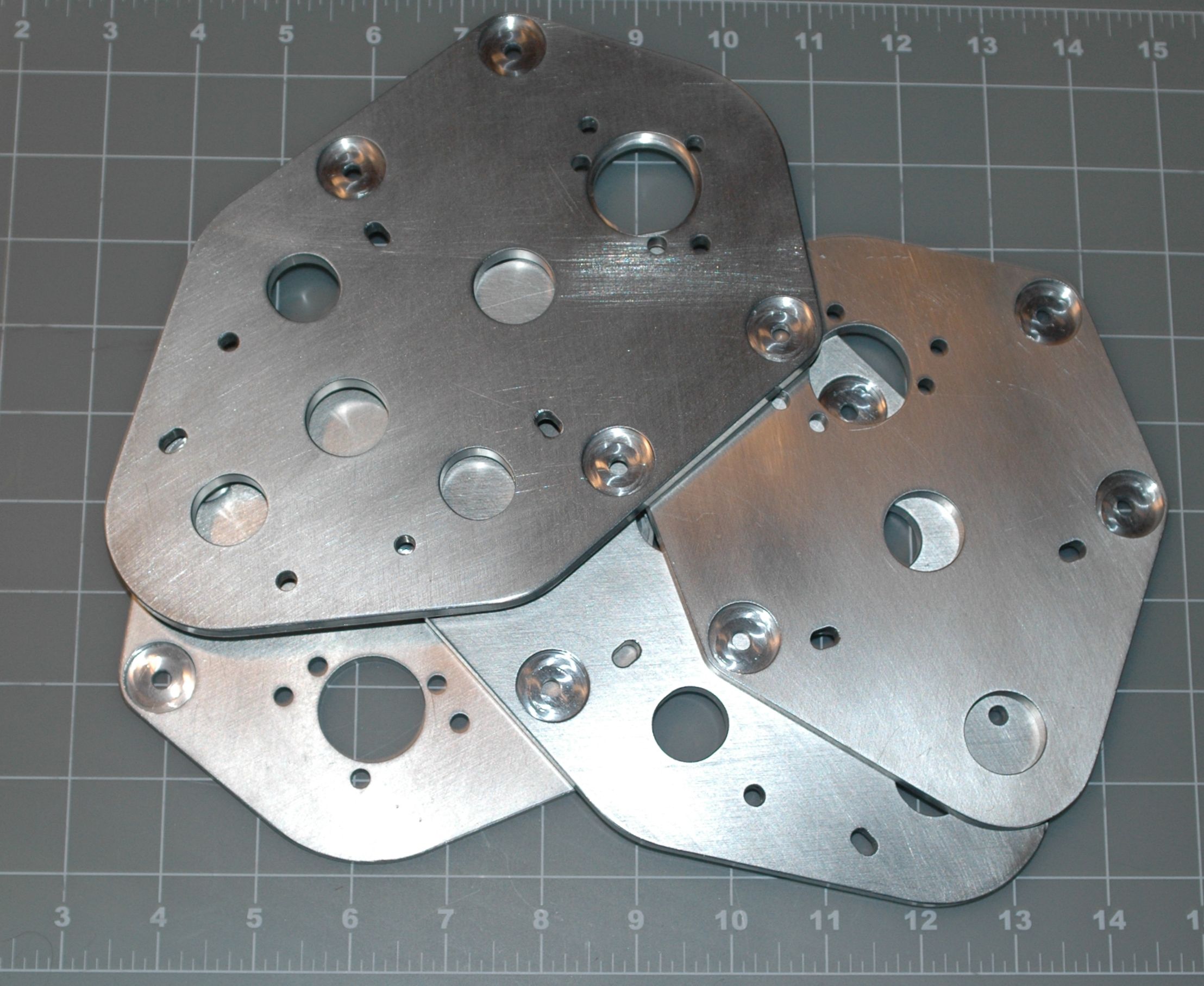

I don't know what they are for, but they are well machined.

Glad you got it sorted.

regards

Glad you got it sorted.

regards

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

01 Nov 2014 20:30 #52655

by BigJohnT

Replied by BigJohnT on topic Newbie on tool changing needs advice

Nice looking parts for sure!

JT

JT

Please Log in or Create an account to join the conversation.

- jcarpenter

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 1

01 Nov 2014 21:40 - 01 Nov 2014 21:42 #52663

by jcarpenter

Replied by jcarpenter on topic Newbie on tool changing needs advice

Thanks for the compliments. Deburring and scotch brite make even ragged machining look pretty. The parts were at the request from a local mentor to a high school First Robotic group. They are the gearbox plates for the robots transmission. Must be a good size robot that they are building. One interesting thing is they sent me a step model only to do the build. Job brought me a little closer to the modern age.

Something I need to investigate. On some of the straight edges that do not line up orthogonal to the axis I get a wavy finish. The scallops are about 3/8 inch apart and can be felt. I have seen in the past some segmentation around a curve but never on a straight. In the G code it is a straight linear X and Y move. It only happens on one side of the plate, never on the corresponding cut on the other side. I am beginning to think that it is something mechanical in the mill. sigh.

John C

Something I need to investigate. On some of the straight edges that do not line up orthogonal to the axis I get a wavy finish. The scallops are about 3/8 inch apart and can be felt. I have seen in the past some segmentation around a curve but never on a straight. In the G code it is a straight linear X and Y move. It only happens on one side of the plate, never on the corresponding cut on the other side. I am beginning to think that it is something mechanical in the mill. sigh.

John C

Last edit: 01 Nov 2014 21:42 by jcarpenter. Reason: i can't spell

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1744

- Thank you received: 288

01 Nov 2014 23:08 #52666

by cncbasher

Replied by cncbasher on topic Newbie on tool changing needs advice

sounds mechanical , and the tools flexing or grabing the aluminum if your running slow etc

and of course if your climb milling or not

and of course if your climb milling or not

Please Log in or Create an account to join the conversation.

Time to create page: 0.115 seconds