Round Corners

- creisey

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 16

- Thank you received: 1

29 Sep 2020 14:40 #184299

by creisey

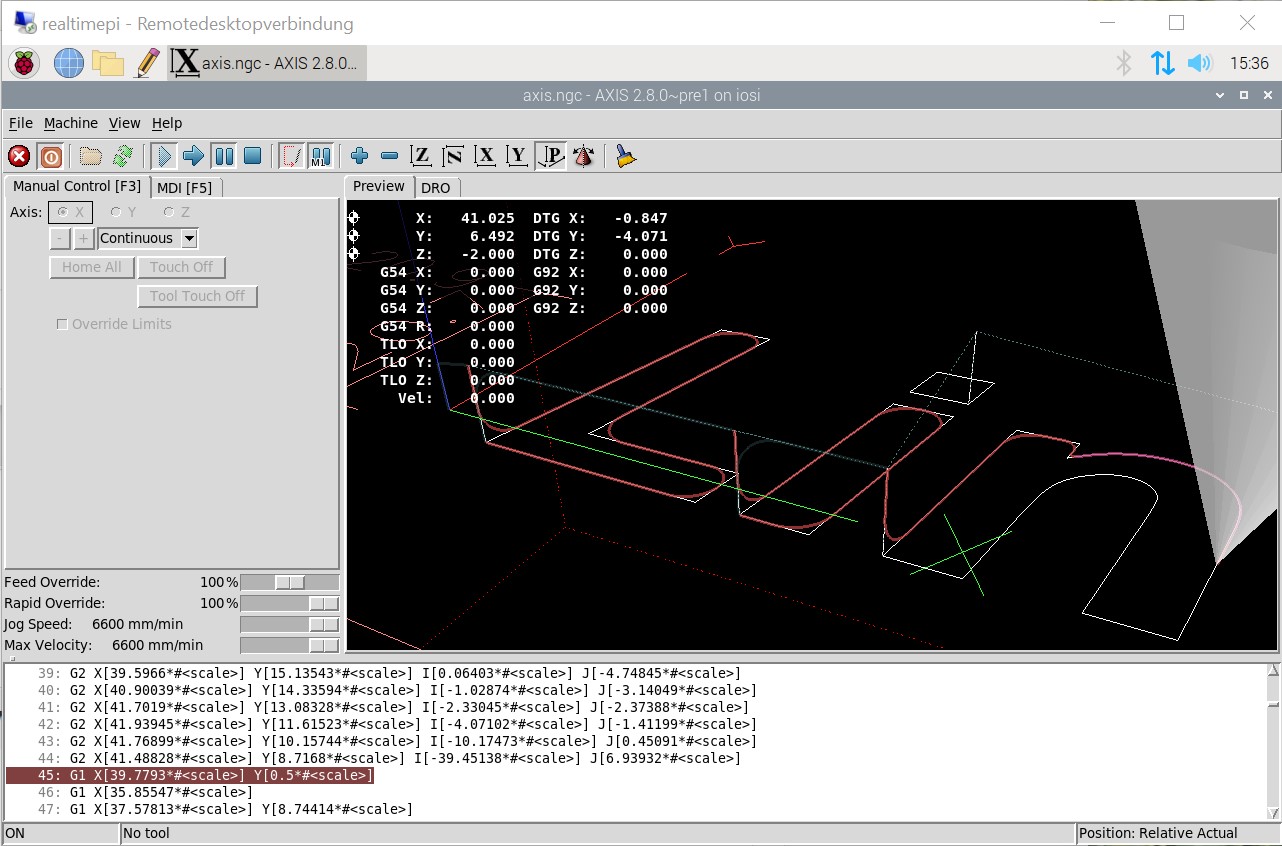

Round Corners was created by creisey

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20929

- Thank you received: 7132

29 Sep 2020 16:20 #184307

by tommylight

Replied by tommylight on topic Round Corners

Raise the acceleration in the ini file.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

29 Sep 2020 19:04 - 29 Sep 2020 19:15 #184321

by Todd Zuercher

Replied by Todd Zuercher on topic Round Corners

The reason the machine is slowing down is because at a corner one axis must decelerate to a stop and the other must accelerate from stopped to the feed rate, but at the point there will be an instant of full stopped.

The G64 Pn setting sets a tolerance to how close the movement must come to the programmed path. G64 with no P tolerance is infinite blending and the corners will be rounded to their maximum for the machines acceleration settings.

It is simple physics and geometry you can't make a square corner without stopping. If you round the corner you can go faster, and the faster you can accelerate the less rounded the corner must be to maintain a certain speed around it.

You have to work out a compromise to determine what G64Pn setting will give you the fastest possible speed, yet still maintain an acceptable tolerance for your work. The larger Pn is the faster and more rounded the machine can go around the corners, if Pn is smaller the rounding will be less, but it will take more time.

G64Pn where n=the minimum resolution of the machine (such as 0.0001inches), might be a good setting for extremely precise work. 50-100 times that is usually a pretty good compromise that usually won't make noticeable deviations on a machine like a wood router.

The G64 Pn setting sets a tolerance to how close the movement must come to the programmed path. G64 with no P tolerance is infinite blending and the corners will be rounded to their maximum for the machines acceleration settings.

It is simple physics and geometry you can't make a square corner without stopping. If you round the corner you can go faster, and the faster you can accelerate the less rounded the corner must be to maintain a certain speed around it.

You have to work out a compromise to determine what G64Pn setting will give you the fastest possible speed, yet still maintain an acceptable tolerance for your work. The larger Pn is the faster and more rounded the machine can go around the corners, if Pn is smaller the rounding will be less, but it will take more time.

G64Pn where n=the minimum resolution of the machine (such as 0.0001inches), might be a good setting for extremely precise work. 50-100 times that is usually a pretty good compromise that usually won't make noticeable deviations on a machine like a wood router.

Last edit: 29 Sep 2020 19:15 by Todd Zuercher.

The following user(s) said Thank You: tommylight, creisey, fernandosf

Please Log in or Create an account to join the conversation.

Time to create page: 0.074 seconds