motion.adaptive-feed

- ghislain.vdwalle

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 2

07 Oct 2017 14:46 #100045

by ghislain.vdwalle

motion.adaptive-feed was created by ghislain.vdwalle

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

10 Oct 2017 22:32 #100170

by andypugh

Replied by andypugh on topic motion.adaptive-feed

I am not very clear what you are trying to do, but the PyVCP scale should be able to connect to any floating-point signal.

You need to make the connections in a postgui hal file. What HAL code fails? (And can you give the _exact_ error message)

You need to make the connections in a postgui hal file. What HAL code fails? (And can you give the _exact_ error message)

Please Log in or Create an account to join the conversation.

- ghislain.vdwalle

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 2

11 Oct 2017 05:52 #100195

by ghislain.vdwalle

Replied by ghislain.vdwalle on topic motion.adaptive-feed

Thank you andypugh for giving attention to our post.

No error messages whatsoever, MUX4, MUX8 and the bar in PYVCP all working fine.

We are talking Wire EDM.

When eroding the gap voltage between the wire and the workpiece is inverse proportional towards the distance between both.

I mean, when erosion takes place, the nearer the wire gets to the workpiece, the lower the generator voltage becomes.

We detect this voltage in a "gap detector" an put out a 3 bit signal over an IO board towards HAL.

This detection goes through MUX8 and gives an adaptive feed to the wire.

This is what the creator of the motion.adaptive-feed meant in creating this pin.

So far, so good.

Our handicap, at this moment, is that the decision making of the gap detector is that fast, that it is difficult to follow with the eye.

A visualisation bar in PYVCP would help a lot. The equivalent is present in all Wire EDM's like AGIE, Charmilles and GF+.

This bar helps the operator in the decision making to hold or change the generator settings.

In LinuxCNC terms:

by using MUX8 we occupy the hal pin motion.adaptive-feed. Once used, it can't be used once again to visualise a bar in PYVCP.

One way out, would probably be to use the inverse pins of our IO board ;to use a separate MUX8 and channel this to the visualisation bar.

Any help greatly appreciated.

kind regards,

Ghislain

No error messages whatsoever, MUX4, MUX8 and the bar in PYVCP all working fine.

We are talking Wire EDM.

When eroding the gap voltage between the wire and the workpiece is inverse proportional towards the distance between both.

I mean, when erosion takes place, the nearer the wire gets to the workpiece, the lower the generator voltage becomes.

We detect this voltage in a "gap detector" an put out a 3 bit signal over an IO board towards HAL.

This detection goes through MUX8 and gives an adaptive feed to the wire.

This is what the creator of the motion.adaptive-feed meant in creating this pin.

So far, so good.

Our handicap, at this moment, is that the decision making of the gap detector is that fast, that it is difficult to follow with the eye.

A visualisation bar in PYVCP would help a lot. The equivalent is present in all Wire EDM's like AGIE, Charmilles and GF+.

This bar helps the operator in the decision making to hold or change the generator settings.

In LinuxCNC terms:

by using MUX8 we occupy the hal pin motion.adaptive-feed. Once used, it can't be used once again to visualise a bar in PYVCP.

One way out, would probably be to use the inverse pins of our IO board ;to use a separate MUX8 and channel this to the visualisation bar.

Any help greatly appreciated.

kind regards,

Ghislain

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

11 Oct 2017 10:38 #100200

by andypugh

If you have a line in HAL like

net signalname mux8.0.out motion.adaptive-feed-in

Then you can connect the PyVCP bar to the same signal:

net signalname pyvcp.motion-adaptive-feed-float

A pin can only connect to one signal, but any number of pins can connect to the same signal.

Replied by andypugh on topic motion.adaptive-feed

by using MUX8 we occupy the hal pin motion.adaptive-feed. Once used, it can't be used once again to visualise a bar in PYVCP.

If you have a line in HAL like

net signalname mux8.0.out motion.adaptive-feed-in

Then you can connect the PyVCP bar to the same signal:

net signalname pyvcp.motion-adaptive-feed-float

A pin can only connect to one signal, but any number of pins can connect to the same signal.

Please Log in or Create an account to join the conversation.

- ghislain.vdwalle

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 2

11 Oct 2017 13:02 #100204

by ghislain.vdwalle

Replied by ghislain.vdwalle on topic motion.adaptive-feed

Hello Andypugh,

thank you very much for the help. This works indeed.

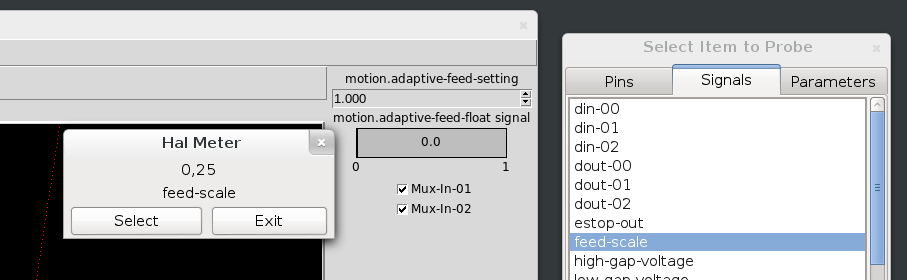

For the sake of being complete: In the attachments you will find a copy of the XML file, an extract of the custom_postgui.hal file

As proof you can watch the workings on:https://youtu.be/95cdyaj2RBM

thanks once again,

Ghislain

thank you very much for the help. This works indeed.

For the sake of being complete: In the attachments you will find a copy of the XML file, an extract of the custom_postgui.hal file

As proof you can watch the workings on:https://youtu.be/95cdyaj2RBM

thanks once again,

Ghislain

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

11 Oct 2017 14:13 #100207

by andypugh

Replied by andypugh on topic motion.adaptive-feed

Are you aware of the experimental reverse-run?

(Negative adaptive feed moves backwards through the G-code)

(Negative adaptive feed moves backwards through the G-code)

Please Log in or Create an account to join the conversation.

- ghislain.vdwalle

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 2

11 Oct 2017 16:25 #100216

by ghislain.vdwalle

Replied by ghislain.vdwalle on topic motion.adaptive-feed

Hello Andypugh,

I am aware of the experimental reverse-run initiative, although I must admit, we never tried it but it is definitely on our to do list.

tell a long story short:

I am the founder of the workshop at:http://www.vdwalle.com.

In 2012 we retrofitted a huge VMC; look at www.vdwalle.com/Norte

In 2015 we built a new plasma cutter; look at www.vdwalle.com/Cutty Spark

Both machines run on Ubuntu/LinuxCNC to our satifaction.

In this process all desktops became Linux.

We have an Agiecut 300 (a big iron of 1993) and a Charmilles Robofil190 (a small machine of 2003).

Since that time all brass wire machine builders have changed their process to under water cutting.

We particularly do not like this, because this type of machine becomes "unreachable for the operator" and look like a huge aquarium.

Sodick just made us an offer of 320.000 Euro for an aquarium of 3000 liter water to replace our Agie.

On the other hand there is a lot going on on the WEDM market in the far east.

They use molybdenum wire--rewinding their wire.

The nice thing of it; cost are going down and the speed is hugely going up; they claim speed x5 or even x10.

They are not that precise though; while a brass classic WEDM claims a precision in the 0.001 of a mm, Moly EDM is in the range of 0.01mm.

So I just want to see it for myself; the visum is applied for; once we have it, we fly over there and look for it ourselves.

On the other hand when I put an oscilloscope on our WEDM machines, talk to other people in the WEDM praxis, I hear a lot of fables and quasi truths.

Please have a look at:https://www.youtube.com/watch?v=kJNpy_HmPvw

When this Polish guy succeeds to run and "rape" this moly wire on LinuxCNC just using motion.enable, even running at 20mm/min

pulling and not breaking or shorting the wire, succes cannot be that far of.

So we started a small project building a generator and a gap detector to master the process in a trial setup, before building or retrofitting a machine. I am sure the reverse-run initiative will be integrated at its due time.

kind regards,

Ghislain

I am aware of the experimental reverse-run initiative, although I must admit, we never tried it but it is definitely on our to do list.

tell a long story short:

I am the founder of the workshop at:http://www.vdwalle.com.

In 2012 we retrofitted a huge VMC; look at www.vdwalle.com/Norte

In 2015 we built a new plasma cutter; look at www.vdwalle.com/Cutty Spark

Both machines run on Ubuntu/LinuxCNC to our satifaction.

In this process all desktops became Linux.

We have an Agiecut 300 (a big iron of 1993) and a Charmilles Robofil190 (a small machine of 2003).

Since that time all brass wire machine builders have changed their process to under water cutting.

We particularly do not like this, because this type of machine becomes "unreachable for the operator" and look like a huge aquarium.

Sodick just made us an offer of 320.000 Euro for an aquarium of 3000 liter water to replace our Agie.

On the other hand there is a lot going on on the WEDM market in the far east.

They use molybdenum wire--rewinding their wire.

The nice thing of it; cost are going down and the speed is hugely going up; they claim speed x5 or even x10.

They are not that precise though; while a brass classic WEDM claims a precision in the 0.001 of a mm, Moly EDM is in the range of 0.01mm.

So I just want to see it for myself; the visum is applied for; once we have it, we fly over there and look for it ourselves.

On the other hand when I put an oscilloscope on our WEDM machines, talk to other people in the WEDM praxis, I hear a lot of fables and quasi truths.

Please have a look at:https://www.youtube.com/watch?v=kJNpy_HmPvw

When this Polish guy succeeds to run and "rape" this moly wire on LinuxCNC just using motion.enable, even running at 20mm/min

pulling and not breaking or shorting the wire, succes cannot be that far of.

So we started a small project building a generator and a gap detector to master the process in a trial setup, before building or retrofitting a machine. I am sure the reverse-run initiative will be integrated at its due time.

kind regards,

Ghislain

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

11 Oct 2017 23:20 #100243

by andypugh

You could try asking about this on the mailing list, a couple of people there seem to know a lot about the subject.

sourceforge.net/p/emc/mailman/emc-users/...ail.com/#msg35181840

Replied by andypugh on topic motion.adaptive-feed

So we started a small project building a generator and a gap detector to master the process in a trial setup, before building or retrofitting a machine. I am sure the reverse-run initiative will be integrated at its due time.

You could try asking about this on the mailing list, a couple of people there seem to know a lot about the subject.

sourceforge.net/p/emc/mailman/emc-users/...ail.com/#msg35181840

Please Log in or Create an account to join the conversation.

- ghislain.vdwalle

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 2

14 Oct 2017 08:57 #100344

by ghislain.vdwalle

Replied by ghislain.vdwalle on topic motion.adaptive-feed

Hello Andypugh,

I have a question, motion.adaptive-feed related.

On our AGIE wire EDM we have beside the generator indicators and progressions bars an indication in mm/min how fast the wire progressed in the workpiece, updated every 5 seconds.

Just looking at the workpiece being eroded, the operator never can judge about the real progress the wire makes.

Visually a progress of 0.15mm/min is nothing different as a progress of 1.15mm/min.

Using this indicator, we adapt pulse voltage, pulse width, frequency and duty factor in the generator.

I have added a picture of the screen of the Agie in the attachment.

Talking LinuxCNC, how can this be built? Should I ask the programmers for it, or is it possible to use HAL and PYVCP or GladeVCP?

kind regards,

I have a question, motion.adaptive-feed related.

On our AGIE wire EDM we have beside the generator indicators and progressions bars an indication in mm/min how fast the wire progressed in the workpiece, updated every 5 seconds.

Just looking at the workpiece being eroded, the operator never can judge about the real progress the wire makes.

Visually a progress of 0.15mm/min is nothing different as a progress of 1.15mm/min.

Using this indicator, we adapt pulse voltage, pulse width, frequency and duty factor in the generator.

I have added a picture of the screen of the Agie in the attachment.

Talking LinuxCNC, how can this be built? Should I ask the programmers for it, or is it possible to use HAL and PYVCP or GladeVCP?

kind regards,

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

14 Oct 2017 17:53 #100351

by andypugh

Replied by andypugh on topic motion.adaptive-feed

Please Log in or Create an account to join the conversation.

Time to create page: 0.107 seconds