Halscope tuning servos Question

- jamby

- Offline

- Elite Member

-

- Posts: 235

- Thank you received: 6

I have been reading your tutorial on "Servo Tuning Tutorial" and I am afraid between it and the "Hal Tutorial" I have been pushed into the group named : Thick as a Brick.

Background:

Mill is a 1985 Alliant knee mill (bridgeport clone),

SEM servo motors w/tacho, westamp boards, anilam A-10

glass scales. Mesa 5i25-7i77

GA-J1900n mobo, Wheezy, realtime-3.4-9-rtai-686-pae,

Linuxcnc from github master.

Axis 2.8.0-pre1.4032-g7626740

Now I open Linuxcnc and goto machine>halscope and start it. Accept Select Sample Rate by pressing OK and the Halscope opens. I pick Channel 1 and the list of channel selections opens. But here's the rub, the list I am seeing under pins, signals, and parameters doesn't seem to include any of the values shown in the tutorial.

I've been unable to find axis.1.joint-vel-cmd or any of the others? Is there some other list that i should be looking to?

Once halscope is set up and in use are you using a trigger or is the machine being used by jog or MDI to create the input?

Thanks

Jim

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

For the most part, I think most of the pin names you are looking for and can't find will have been renamed with the "axis" at the begining renamed to "joint".

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

- Posts: 235

- Thank you received: 6

Thanks I did find these joint items under "pins" that look like them:

axis.1.joint-vel-cmd : joint.0.vel-cmd

axis.1.f-error : joint.0.f-error

axis.1.motor-pos-cmd : joint.0.motor-pos-cmd

axis.1.motor-fb : joint.0.motor-fb

Note: the joint.0 is for X on my machine joint.1 is Y

I'll continue trying this tomorrow.

Jim

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

github.com/LinuxCNC/linuxcnc/blob/master...ipts/update_ini#L370

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

- Posts: 235

- Thank you received: 6

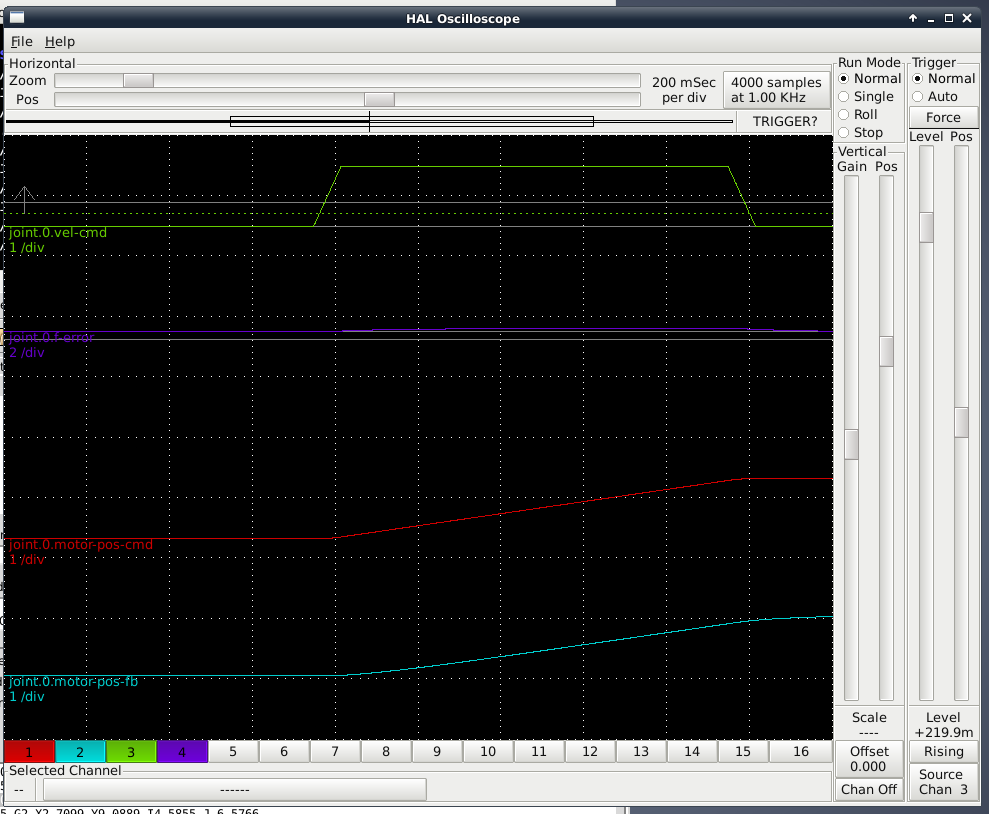

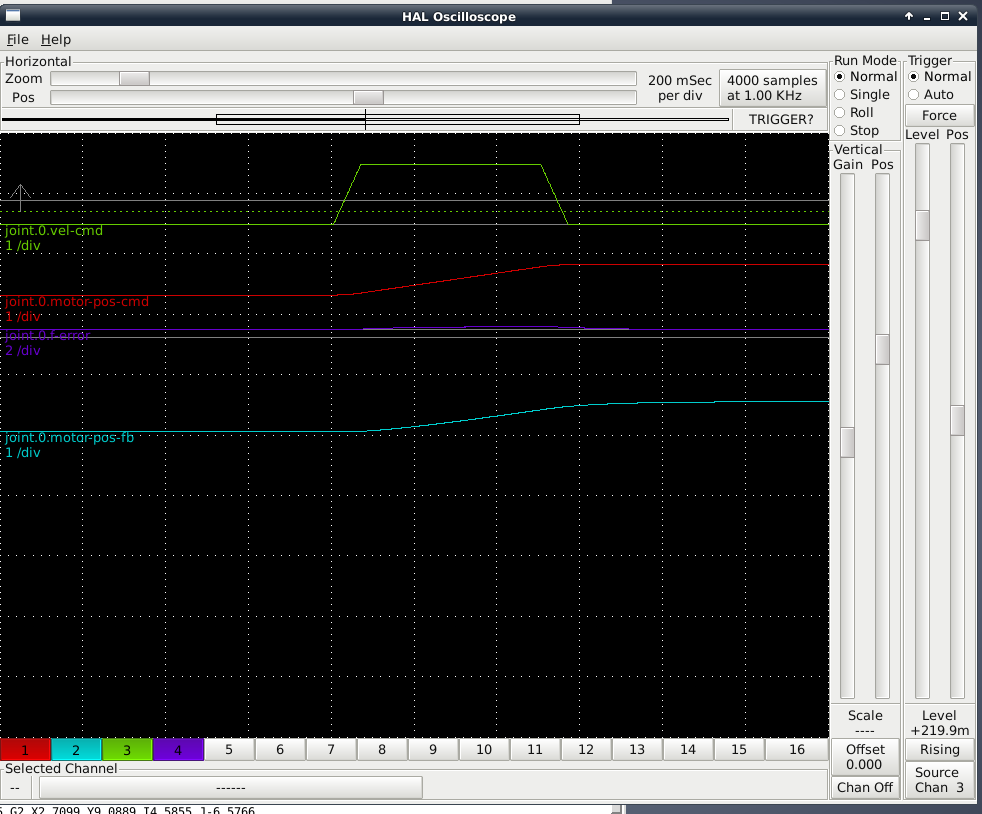

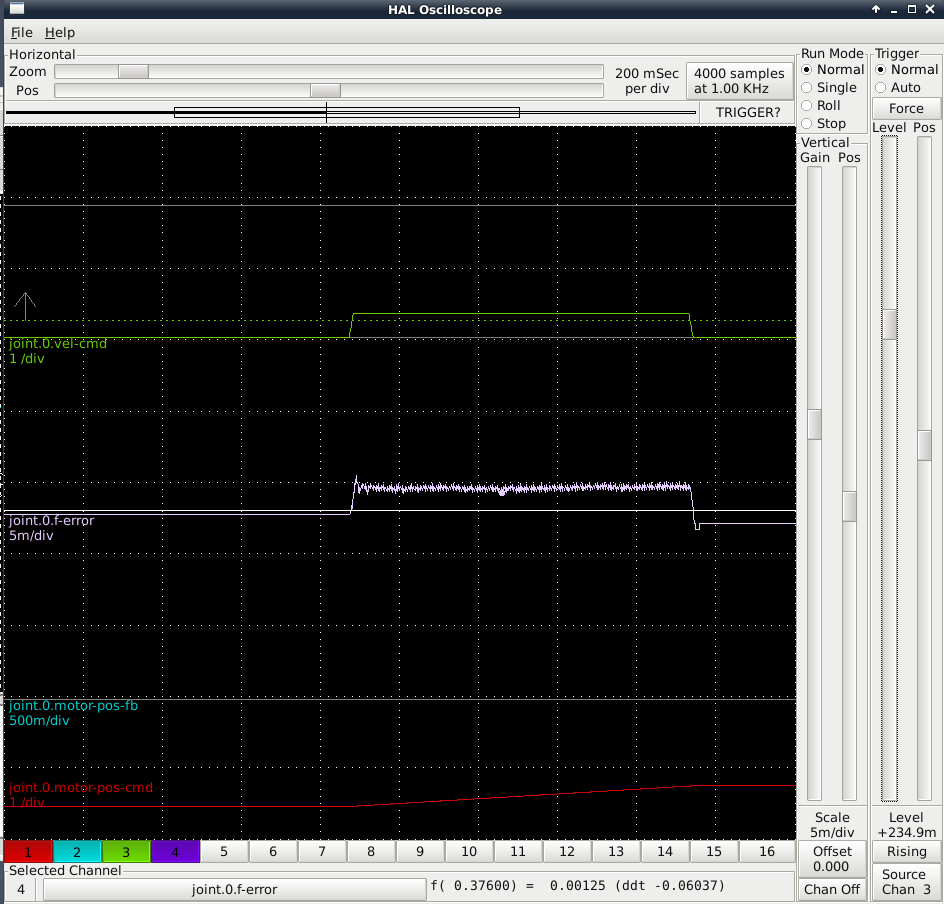

Okay I went out to the shop and played with the halscope and used these PINs

joint.0.motor-pos-cmd

joint.0.motor-fb

joint.0.vel-cmd

joint.0.f-error

these are for X axis on my machine and the readings below are with 1.0 inch at rapid / 60 ipm and 0.5 inch same fedrat.

Oddly the oscilloscope only responded to + movements.

It took me a while to learn which sliders to use to get the correct, well to match the example in "Servo Tuning Tutorial" but this is as close as I could get

I still can figure out what to do to get a channel back if I push the "Chan Off" button? yes I just had to push it.

I recovered by deleting the autosave file

1.0 inches in X axis at rapid/60 inch per minute. G0 G91 X1

0.5 inches in X axis at rapid/60 inch per minute. G0 G91 X0.5

They look good to me but what do I know?

Thanks guys

Jim

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 22

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 22

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

- Posts: 235

- Thank you received: 6

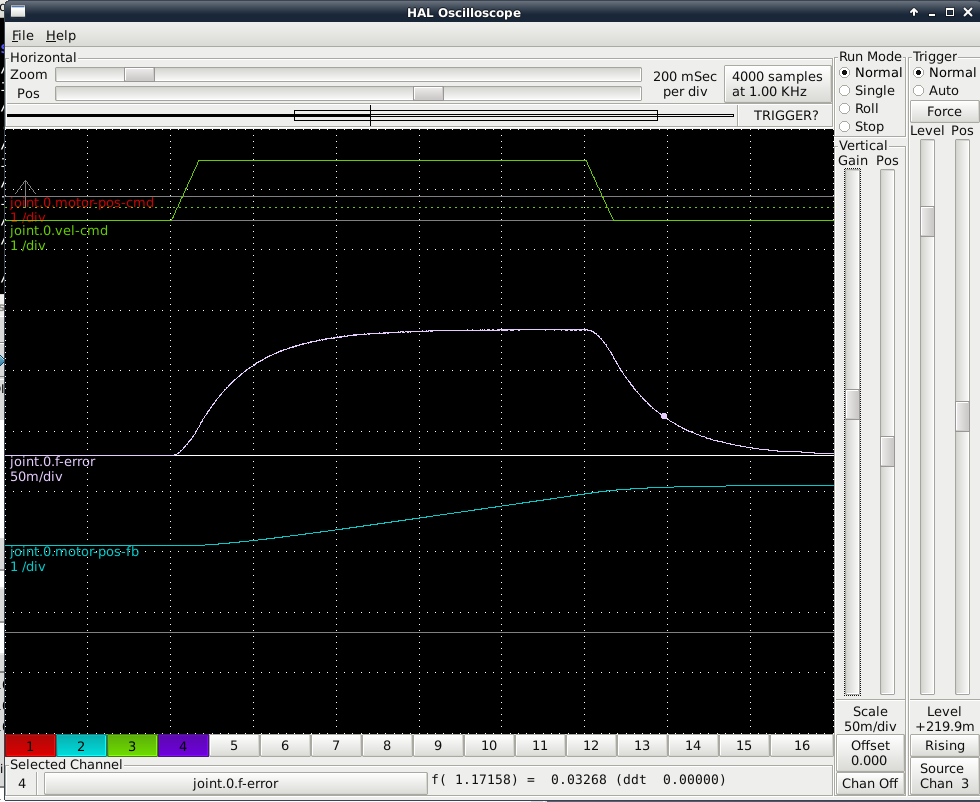

I reran the scope and paid attention to having the trigger set to channel 3 and then to select channel 4 joint.0.f-error so its the active one. Once I ran the machine again and a new plot returned I found I could move the gain slider up and down and see the curve generated from different angles.

Here's the better one.

I also learned to save a file for each axis so I didn't have to keep reloading the channels.

Thanks for the help

Jim

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17728

- Thank you received: 5186

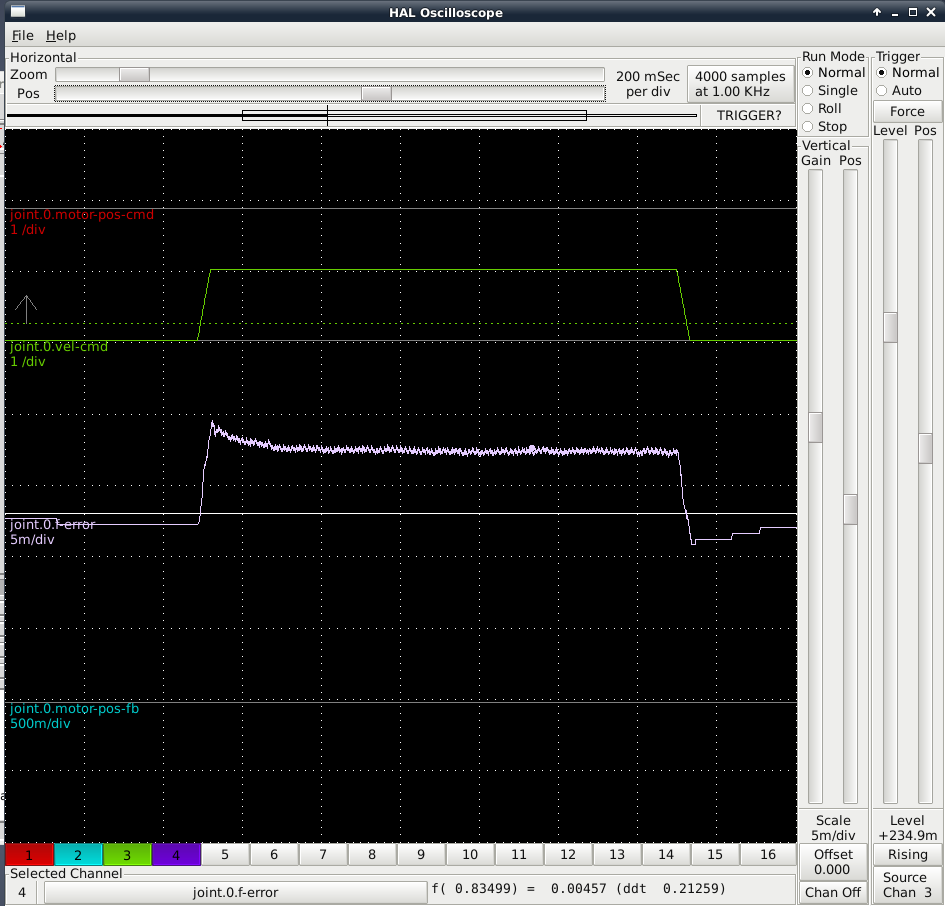

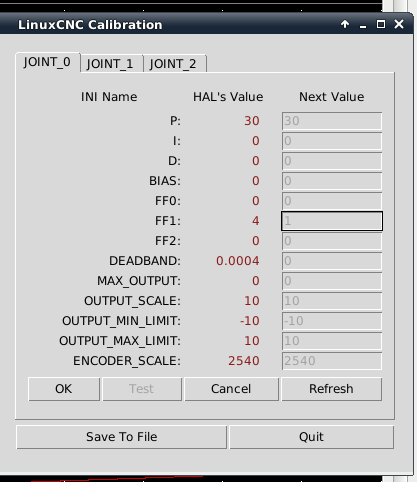

1. Higher FF1 ( adjust for 0 error during constant speed motion )

(if the following error is in the direction of velocity you need more FF1,

if the following error is in the opposite direction of velocity, you need less FF1 )

2. Higher P term ( adjust till its unstable then back off maybe 30% )

Easiest way to adjust things live is via the calibrate menu

Please Log in or Create an account to join the conversation.

- jamby

- Offline

- Elite Member

-

- Posts: 235

- Thank you received: 6

Well I've been playing with the halscope and I am feeling better about what I am seeing.

My Machine

a 1985 Alliant knee mill (bridgeport clone),

SEM servo motors w/tacho, westamp boards, anilam A-10

glass scales. Mesa 5i25-7i77

GA-J1900n mobo, Wheezy, realtime-3.4-9-rtai-686-pae,

Linuxcnc from github master.

Axis 2.8.0-pre1.4032-g7626740

Because of the old anilam glass scales the axis have a "dither" of about .0004 which the current setting seems to help and since this is a hobby machine I am not nearly as picky as a production machine.

Here's some current scopes:

this is at 20 ipm (short jog)

this is at 7 ipm (short jog)

this is the calibration screen

Thanks

Jim

Please Log in or Create an account to join the conversation.