I need help for Comp File programming

- ChironFZ16

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 12

06 Jan 2020 10:56 #154139

by ChironFZ16

I need help for Comp File programming was created by ChironFZ16

Hallo

I have old Comp file for Programming Linuxcnc 2.5.x , they worked until linuxcnc 2.8, but with the newer 2.9 masters I always get error messages and some functions when changing tools do not work anymore.

I would be very grateful if someone could help me.

I have tried a little bit, but I can't see the forest for the trees.

Especially syntax and variables, whether they are correct.

Wekzeugwechsler.comp

Meldung. comp

Spinde.comp

I have old Comp file for Programming Linuxcnc 2.5.x , they worked until linuxcnc 2.8, but with the newer 2.9 masters I always get error messages and some functions when changing tools do not work anymore.

I would be very grateful if someone could help me.

I have tried a little bit, but I can't see the forest for the trees.

Especially syntax and variables, whether they are correct.

Wekzeugwechsler.comp

component WZW " Wechselt Werkzeuge ";

// Ausgänge

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin out bit Klemmung-auf = false " Klemmung öffnen ";

pin out bit Spindel-an = false " Spindel an 150 U/min ";

pin out bit Ausblasen-an = false " WKZKegel Ausblasen starten ";

pin out bit Korb-rauf = false " Korb hoch fahren ";

pin out bit Korb-runter = false " Korb runter fahren ";

pin out bit Alle-WKZ-rauf = false " Alle Werkzeuge nach oben fahren ";

pin out bit WKZ-runter-##[13] = false " Werkzeug ## runterfahren ";

pin out bit WZW-Beendet = false " Beendet den Werkzeugwechsel";

pin out float Meldung = 0 " Ausgang für Meldecodeausgabe ";

// Eingänge

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin in bit IS-MAN = false " Manueller Modus ausgewählt ";

pin in s32 Aktuelle-WKZ-Nummer = 0 " Eingang für das Signal der aktuellen WKZ Nummer ";

pin in s32 Naechste-WKZ-Nummer = 0 " Eingang für das Signal der naechsten WKZ Nummer ";

pin in bit Werkzeugwechsel-Start = false " Eingang für das WZWStartSignal ";

pin in bit Werkzeug-Beladen-Start-Stopp = false " Eingang für das Werkzeug-Beladen Start Signal ";

pin in bit Schluesselschalter = false " Eingang für das Werkzeug-Beladen Sicherheitssignal ";

pin in bit Taster-WKZ-##[13] = false " Grafischer Taster Auswahl Werkzeug 1 ";

pin in bit Sensor-Klemmung-auf = false " Sensor für offene Klemmung ";

pin in bit Sensoren-Korb-unten = false " Sensor für Korb unten ";

pin in bit Sensoren-Korb-oben = false " Sensor für Korb oben ";

pin in bit Sensor-WKZ-##[13] = false " Sensoren der einzelnen Arme für Werkzeug oben ";

pin in bit Sensoren-Ein-WKZ-unten = false " Sensor des gewhlten Werkzeugs untere Endlage ";

pin in bit Sensoren-Alle-WKZ-oben = false " Sensoren aller Werkzeuge obere Endlage ";

pin in float Drehzahl = 0 " aktuelle Spindel Drehzahl ";

pin in float Spindel-Position = 0 " aktuelle Spindel Position ";

// Setp-einstellbare Variablen

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

param rw float Verzoegerung = 1 " Verzögerung in ms bevor Klemmung schließt ";

// Interne Variablen

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

variable int Schrittnummer = 0; // Gibt den aktuellen Schritt an

variable int Werkzeug = 0; // Gibt das nächste Werkzeug an

variable float Pausentimer = 0; // variable Zeitzähler

variable float Fehlerzeit = 0; // Dauer des Vorgangs

variable int Meldecode = 0; // Hilfsvariable zur Fehlerausgabe

variable float Zeit = 0; // Anzeigezeit der Fehlerausgabe

variable float Spindelpos = 0; // Position der Spindel vor dem drehen

// Programmkopf

//////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

option singleton yes;

function _ "Wechselt Werkzeuge";

license "GPL";

;;

enum mystates {WarteSignal=0, Spezialwechsel1, Spezialwechsel2, KlemmungOeffnen, KorbRunterfahren, WerkzeugeHochfahren, WerkzeugRunter, SpezialWerkzeug1, KorbHochfahren, SpezialWerkzeug2, KlemmungSchliesen, WZWBeenden, Fehlerfall};

FUNCTION(_)

{

int co;

// Direkte Signaldurchführungen

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Meldung = Meldecode; // Ausgang = Variable

// Automatik Ablauf

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

switch(Schrittnummer)

{

case WarteSignal:

if(!Werkzeugwechsel_Start)

{

WZW_Beendet = false; //Reset durch das System nach jedem Durchgang

}

if(Werkzeug_Beladen_Start_Stopp && Schluesselschalter && IS_MAN && (Drehzahl <= 120) && !Sensoren_Alle_WKZ_oben && (Aktuelle_WKZ_Nummer <= 12)) //WZW Beladen wird gestartet

{

Schrittnummer = KlemmungOeffnen;

break;

}

if(Werkzeugwechsel_Start && Naechste_WKZ_Nummer && !WZW_Beendet && (Drehzahl <= 10)) //WZW Auto wird gestartet

{

if(((Aktuelle_WKZ_Nummer >= 13) && (Aktuelle_WKZ_Nummer <= 20)) || (Sensoren_Alle_WKZ_oben && Aktuelle_WKZ_Nummer != 21)) //Spezialwechsel

{

Werkzeug = Naechste_WKZ_Nummer;

Spindelpos = Spindel_Position;

Schrittnummer = Spezialwechsel1;

break;

}

else // Normaler wechsel

{

Werkzeug = Naechste_WKZ_Nummer;

Schrittnummer = KlemmungOeffnen;

break;

}

}

break;

case KlemmungOeffnen:

Klemmung_auf = true;

Ausblasen_an = true;

Schrittnummer = KorbRunterfahren;

break;

case KorbRunterfahren:

Fehlerzeit += period * 0.000000001;

if(Sensor_Klemmung_auf)

{

Fehlerzeit = 0;

Korb_runter = true;

Schrittnummer = WerkzeugeHochfahren;

}

break;

case WerkzeugeHochfahren:

Fehlerzeit += period * 0.000000001;

if(Sensoren_Korb_unten)

{

Fehlerzeit = 0;

Korb_runter = false;

Alle_WKZ_rauf = true;

if(Schluesselschalter && IS_MAN) //WZW Beladen Auswahl wird gestartet

{

Ausblasen_an = false;

for(co=0;co<13;co++) //Taster suchen

{

if(Taster_WKZ(co))

{

Werkzeug = co; //Taster wird Werkzeug zugewiesen

Schrittnummer = WerkzeugRunter;

break;

}

}

break;

}

if(Werkzeugwechsel_Start && Werkzeug <= 12)

{

Schrittnummer = WerkzeugRunter;

break;

}

if(Sensoren_Alle_WKZ_oben && ((Werkzeugwechsel_Start && Werkzeug >= 13) && (Werkzeugwechsel_Start && Werkzeug <= 20)))

{

Spindelpos = Spindel_Position;

Korb_rauf = true;

Ausblasen_an = false;

Schrittnummer = SpezialWerkzeug1;

break;

}

if(Werkzeugwechsel_Start && (Werkzeug == 21) && Sensoren_Alle_WKZ_oben)

{

Alle_WKZ_rauf = false;

Schrittnummer = KorbHochfahren;

break;

}

}

break;

case WerkzeugRunter:

Fehlerzeit += period * 0.000000001;

if((Sensoren_Alle_WKZ_oben && Naechste_WKZ_Nummer) || (Sensoren_Alle_WKZ_oben && Schluesselschalter && IS_MAN))

{

Fehlerzeit = 0;

Alle_WKZ_rauf = false;

WKZ_runter(Werkzeug) = true; //Ausgewähltes Werkzeug runterfahren

Schrittnummer = KorbHochfahren;

}

break;

case KorbHochfahren:

if(Sensoren_Ein_WKZ_unten && Naechste_WKZ_Nummer)

{

for(co=0;co<13;co++) WKZ_runter(co) = false; //Werkzeugrunter im Bereich 0-12 reseten

Korb_rauf = true;

Spindel_an = true;

Pausentimer = Verzoegerung;

Schrittnummer = KlemmungSchliesen;

break;

}

if(Sensoren_Ein_WKZ_unten && Schluesselschalter && Werkzeug_Beladen_Start_Stopp && IS_MAN)

{

Ausblasen_an = true;

for(co=0;co<13;co++) WKZ_runter(co) = false; //Werkzeugrunter im Bereich 0-12 reseten

Korb_rauf = true;

Spindel_an = true;

Pausentimer = Verzoegerung;

Schrittnummer = KlemmungSchliesen;

break;

}

if(Sensoren_Ein_WKZ_unten && Schluesselschalter && IS_MAN)

{

Ausblasen_an = false;

for(co=0;co<13;co++) //Taster suchen

{

if(Taster_WKZ(co))

{

Werkzeug = co; //Taster wird Werkzeug zugewiesen

for(co=0;co<13;co++) WKZ_runter(co) = false; //Werkzeugrunter im Bereich 0-12 reseten

Alle_WKZ_rauf = true;

Schrittnummer = WerkzeugRunter;

break;

}

}

}

if(Werkzeug == 21)

{

Korb_rauf = true;

Pausentimer = 0;

Schrittnummer = KlemmungSchliesen;

break;

}

break;

case KlemmungSchliesen:

Fehlerzeit += period * 0.000000001;

if(Sensoren_Korb_oben)

{

Fehlerzeit = 0;

Korb_rauf = false;

if(Pausentimer > 0)

{

Pausentimer -= period * 0.000000001;

break;

}

Klemmung_auf = false;

Schrittnummer = WZWBeenden;

}

break;

case WZWBeenden:

Fehlerzeit += period * 0.000000001;

if(!Sensor_Klemmung_auf)

{

Fehlerzeit = 0;

Ausblasen_an = false;

Spindel_an = false;

WZW_Beendet = true;

Schrittnummer = WarteSignal;

}

break;

// Spezialwerkzeugwechsel ablauf

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

case Spezialwechsel1:

if((Spindel_Position >= (Spindelpos + 0.2)) || (Spindel_Position <= (Spindelpos - 0.2)))

{

Klemmung_auf = true;

Schrittnummer = Spezialwechsel2;

}

break;

case Spezialwechsel2:

if(Sensor_Klemmung_auf && Werkzeug_Beladen_Start_Stopp)

{

Schrittnummer = KlemmungOeffnen;

}

break;

case SpezialWerkzeug1:

if(Sensoren_Korb_oben && ((Spindel_Position >= (Spindelpos + 0.2)) || (Spindel_Position <= (Spindelpos - 0.2))))

{

Korb_rauf = false;

Klemmung_auf = false;

Schrittnummer = SpezialWerkzeug2;

}

break;

case SpezialWerkzeug2:

if(Werkzeug_Beladen_Start_Stopp)

{

Schrittnummer = WZWBeenden;

}

break;

// Fehlerfälle

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

case Fehlerfall:

break;

default: //Fehler!

Schrittnummer = Fehlerfall;

}

// Meldecodeausgabe

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if ((Werkzeug_Beladen_Start_Stopp && (Schrittnummer == WarteSignal)) && (Sensoren_Alle_WKZ_oben || (Aktuelle_WKZ_Nummer >= 13)))

{

Meldecode = 1;

Zeit = 0.5;

}

if (Schrittnummer == Fehlerfall)

{

Meldecode = 2;

Zeit = 0.5;

}

if ((Schrittnummer == KorbHochfahren) && Schluesselschalter && Werkzeug_Beladen_Start_Stopp)

{

Meldecode = 3;

Zeit = 0.5;

}

if (Werkzeug_Beladen_Start_Stopp && !Schluesselschalter && (Schrittnummer == WarteSignal) && (Schrittnummer != SpezialWerkzeug2 || Spezialwechsel2))

{

Meldecode = 4;

Zeit = 0.5;

}

if (Werkzeug_Beladen_Start_Stopp && !IS_MAN && (Schrittnummer != SpezialWerkzeug2 || Spezialwechsel2))

{

Meldecode = 5;

Zeit = 0.5;

}

if (Werkzeug_Beladen_Start_Stopp && (Drehzahl > 120) && (Schrittnummer != SpezialWerkzeug2 || Spezialwechsel2))

{

Meldecode = 6;

Zeit = 0.5;

}

if ((Schrittnummer == KorbRunterfahren) && (Fehlerzeit >= 10))

{

Meldecode = 7;

Zeit = 0.5;

}

if ((Schrittnummer == WerkzeugeHochfahren) && (Fehlerzeit >= 10))

{

Meldecode = 8;

Zeit = 0.5;

}

if ((Schrittnummer == WerkzeugRunter) && (Fehlerzeit >= 10))

{

Meldecode = 9;

Zeit = 0.5;

}

if ((Schrittnummer == KlemmungSchliesen) && (Fehlerzeit >= 10))

{

Meldecode = 10;

Zeit = 0.5;

}

if ((Schrittnummer == WZWBeenden) && (Fehlerzeit >= 10))

{

Meldecode = 11;

Zeit = 0.5;

}

if (Schrittnummer == Spezialwechsel1)

{

Meldecode = 12;

Zeit = 0.5;

}

if (Schrittnummer == Spezialwechsel2)

{

Meldecode = 13;

Zeit = 0.5;

}

if (Schrittnummer == SpezialWerkzeug1)

{

Meldecode = 14;

Zeit = 0.5;

}

if (Schrittnummer == SpezialWerkzeug2)

{

Meldecode = 15;

Zeit = 0.5;

}

if(Zeit > 0)

{

Zeit -= period * 0.000000001;

}

if(Zeit <= 0)

{

Zeit = 0;

Meldecode = 0;

}

}Meldung. comp

component Meldung " Gibt Meldungen aus wenn Fehler anstehen ";

// Eingaenge

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin in bit Not-AUS = false " ( Pin: halui.estop.is-activated ) Not-Aus aktiviert ";

pin in bit Endschalter = false " ( Pin: motion.on-soft-limit ) Endschalter angefahren ";

pin in bit X-Fehler-1 = false " ( Pin: joint_0.error ) Fehler X-Achse ";

pin in bit Y-Fehler-1 = false " ( Pin: joint_1.error ) Fehler Y-Achse ";

pin in bit Z-Fehler-1 = false " ( Pin: joint_2.error ) Fehler Z-Achse ";

pin in bit X-Fehler-2 = false " ( Pin: halui_joint.0.has-fault ) Fehler X-Achse 2 ";

pin in bit Y-Fehler-2 = false " ( Pin: halui_joint.1.has-fault ) Fehler Y-Achse 2 ";

pin in bit Z-Fehler-2 = false " ( Pin: halui_joint.2.has-fault ) Fehler Z-Achse 2 ";

pin in bit X-Endsch-Rechts = false " ( Pin: halui.joint_0.on-soft-max-limit ) X-Achse Endschalter Rechts ";

pin in bit Y-Endsch-Vorne = false " ( Pin: halui.joint_1.on-soft-max-limit ) Y-Achse Endschalter Vorne ";

pin in bit Z-Endsch-Oben = false " ( Pin: halui.joint_2.on-soft-max-limit ) Z-Achse Endschalter Oben ";

pin in bit X-Endsch-Links = false " ( Pin: halui.joint_0.on-soft-min-limit ) X-Achse Endschalter Links ";

pin in bit Y-Endsch-Hinten = false " ( Pin: halui.joint_1.on-soft-min-limit ) Y-Achse Endschalter Hinten ";

pin in bit Z-Endsch-Unten = false " ( Pin: halui.joint_2.on-soft-min-limit ) Z-Achse Endschalter Unten ";

pin in float Spindel-Fehler = 0 " ( Pin: Spindel.Meldung ) Rückmeldepin für den Spindel Fehlercode ";

pin in float WZW-Fehler = 0 " ( Pin: WZW.Meldung ) Rückmeldepin für den WZW Fehlercode ";

pin in float WSW-Fehler = 0 " ( Pin: WSW.Meldung ) Rückmeldepin für den WSW Fehlercode ";

pin in float SF-Fehler = 0 " ( Pin: SF.Meldung ) Rückmeldepin für den SF Fehlercode ";

// Ausgaenge

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin out bit Taster-Fehler-Reset = false " ( Pin: halui.abort ) Taster für Fehler Reset ";

pin out bit Programm-Pause = false " ( Pin: halui.program.pause ) Programm wird pausiert ";

pin out bit Programm-weiter = false " ( Pin: halui.program.resume ) Programm wird fortgesetzt ";

// Interne Variablen

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

variable int Axis_warten1 = true; // Verriegelvariable 1

variable int Axis_warten2 = true; // Verriegelvariable 2

variable int Axis_warten3 = true; // Verriegelvariable 3

variable int Axis_warten4 = true; // Verriegelvariable 4

variable int Axis_warten5 = true; // Verriegelvariable 5

variable int Axis_warten6 = true; // Verriegelvariable 6

variable int Axis_warten7 = true; // Verriegelvariable 7

variable int Axis_warten8 = true; // Verriegelvariable 8

variable int Axis_warten9 = true; // Verriegelvariable 9

variable int Axis_warten10 = true; // Verriegelvariable 10

variable int Axis_warten11 = true; // Verriegelvariable 11

variable int Axis_warten12 = true; // Verriegelvariable 12

variable int Axis_warten13 = true; // Verriegelvariable 13

variable int Axis_warten14 = true; // Verriegelvariable 14

variable int Spindel_warten = true; // Verriegelvariable Spindel

variable int WZW_warten = true; // Verriegelvariable WZW

variable int WZW_warten1 = true; // Verriegelvariable WZW Spezialwechsel

variable int WZW_warten2 = true; // Verriegelvariable WZW Spezialwerkzeug

variable int WSW_warten = true; // Verriegelvariable WSW

variable int SF_warten = true; // Verriegelvariable SF

// Programmkopf

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

option singleton yes;

function _ " Gibt RTAPI Meldungen aus ";

license "GPL";

;;

FUNCTION(_)

{

// Fehler Axis

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (Not_AUS && Axis_warten1)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Not-Aus aktiviert!");

Axis_warten1 = false;

}

if (Endschalter && Axis_warten2)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Endschalter angefahren!");

Axis_warten2 = false;

}

if (X_Fehler_1 && Axis_warten3)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler X-Achse!");

Axis_warten3 = false;

}

if (Y_Fehler_1 && Axis_warten4)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler Y-Achse!");

Axis_warten4 = false;

}

if (Z_Fehler_1 && Axis_warten5)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler Z-Achse!");

Axis_warten5 = false;

}

if (X_Fehler_2 && Axis_warten6)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler X-Achse 2!");

Axis_warten6 = false;

}

if (Y_Fehler_2 && Axis_warten7)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler Y-Achse 2!");

Axis_warten7 = false;

}

if (Z_Fehler_2 && Axis_warten8)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Fehler Z-Achse 2!");

Axis_warten8 = false;

}

if (X_Endsch_Rechts && Axis_warten9)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: X-Achse Endschalter Rechts!");

Axis_warten9 = false;

}

if (X_Endsch_Links && Axis_warten10)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: X-Achse Endschalter Links!");

Axis_warten10 = false;

}

if (Y_Endsch_Vorne && Axis_warten11)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Y-Achse Endschalter Vorne!");

Axis_warten11 = false;

}

if (Y_Endsch_Hinten && Axis_warten12)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Y-Achse Endschalter Hinten!");

Axis_warten12 = false;

}

if (Z_Endsch_Oben && Axis_warten13)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Z-Achse Endschalter Oben!");

Axis_warten13 = false;

}

if (Z_Endsch_Unten && Axis_warten14)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Z-Achse Endschalter Unten!");

Axis_warten14 = false;

}

if (!Not_AUS)

{

Axis_warten1 = true;

}

if (!Endschalter)

{

Axis_warten2 = true;

}

if (!X_Fehler_1)

{

Axis_warten3 = true;

}

if (!Y_Fehler_1)

{

Axis_warten4 = true;

}

if (!Z_Fehler_1)

{

Axis_warten5 = true;

}

if (!X_Fehler_2)

{

Axis_warten6 = true;

}

if (!Y_Fehler_2)

{

Axis_warten7 = true;

}

if (!Z_Fehler_2)

{

Axis_warten8 = true;

}

if (!X_Endsch_Rechts)

{

Axis_warten9 = true;

}

if (!X_Endsch_Links)

{

Axis_warten10 = true;

}

if (!Y_Endsch_Vorne)

{

Axis_warten11 = true;

}

if (!Y_Endsch_Hinten)

{

Axis_warten12 = true;

}

if (!Z_Endsch_Oben)

{

Axis_warten13 = true;

}

if (!Z_Endsch_Unten)

{

Axis_warten14 = true;

}

// Fehler Spindel

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (Spindel_Fehler == 1 && Spindel_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: MAN-Modus nicht angewaehlt!");

Spindel_warten = false;

}

if (Spindel_Fehler == 2 && Spindel_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: M19 P Parameter > 2!");

Spindel_warten = false;

}

if (Spindel_Fehler == 3 && Spindel_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: M19 R Parameter > 360!");

Spindel_warten = false;

}

if (Spindel_Fehler == 4 && Spindel_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Orient Offset zu groß!");

Spindel_warten = false;

}

if (Spindel_Fehler == 5 && Spindel_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Eingegebene Drehzahl zu hoch!");

Spindel_warten = false;

}

if (Spindel_Fehler == 0)

{

Spindel_warten = true;

}

// Fehler WZW

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (WZW_Fehler == 1 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Beladen nicht moeglich Spezialwerkzeug zuerst mit M6 T21 entfernen!");

WZW_warten = false;

}

if (WZW_Fehler == 2 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Falscher Schritt in WZW.comp!");

WZW_warten = false;

}

if (WZW_Fehler == 3 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Zuerst Schluesselschalter abschalten!");

WZW_warten = false;

}

if (WZW_Fehler == 4 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Zuerst Schluesselschalter einschalten!");

WZW_warten = false;

}

if (WZW_Fehler == 5 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Zuerst in manuellen Modus wechseln!");

WZW_warten = false;

}

if (WZW_Fehler == 6 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Zuerst Spindel abschalten!");

WZW_warten = false;

}

if (WZW_Fehler == 7 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Klemmung oeffnet nicht oder Sensor reagiert nicht!");

WZW_warten = false;

}

if (WZW_Fehler == 8 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Korb faehrt nicht runter oder Sensoren reagieren nicht!");

WZW_warten = false;

}

if (WZW_Fehler == 9 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Werkzeuge fahren nicht hoch oder ein Sensor reagiert nicht!");

WZW_warten = false;

}

if (WZW_Fehler == 10 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Korb faehrt nicht hoch oder Sensoren reagieren nicht!");

WZW_warten = false;

}

if (WZW_Fehler == 11 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Klemmung schließt nicht oder Sensor faellt nicht ab!");

WZW_warten = false;

}

if (WZW_Fehler == 12 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Werkzeug entnehmen!");

WZW_warten = false;

}

if (WZW_Fehler == 13 && WZW_warten1)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Entnahme mit Taster WZW Beladen beenden!");

WZW_warten1 = false;

}

if (WZW_Fehler == 14 && WZW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Werkzeug einlegen!");

WZW_warten = false;

}

if (WZW_Fehler == 15 && WZW_warten2)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Einlage mit Taster WZW Beladen beenden!");

WZW_warten2 = false;

}

if (WZW_Fehler == 0)

{

WZW_warten = true;

}

if (WZW_Fehler != 13)

{

WZW_warten1 = true;

}

if (WZW_Fehler != 15)

{

WZW_warten2 = true;

}

// Fehler WSW

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (WSW_Fehler == 1 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Zuerst Schluesselschalter einschalten!");

WSW_warten = false;

}

if (WSW_Fehler == 2 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Seite 1 bereits angewaehlt!");

WSW_warten = false;

}

if (WSW_Fehler == 3 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: Seite 2 bereits angewaehlt!");

WSW_warten = false;

}

if (WSW_Fehler == 4 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Fehler: MAN-Modus erforderlich!");

WSW_warten = false;

}

if (WSW_Fehler == 5 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Z Position zu niedrig Crashgefahr!");

WSW_warten = false;

}

if (WSW_Fehler == 6 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Z nicht referenziert Crashgefahr!");

WSW_warten = false;

}

if (WSW_Fehler == 7 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Tisch entriegelt nicht oder Sensor reagiert nicht!");

WSW_warten = false;

}

if (WSW_Fehler == 8 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Drehbewegung zu langsam evtl. durch Druckmangel oder Sensor reagiert nicht!");

WSW_warten = false;

}

if (WSW_Fehler == 9 && WSW_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: verriegelt nicht oder Sensor reagiert nicht!");

WSW_warten = false;

}

if (WSW_Fehler == 0)

{

WSW_warten = true;

}

// Fehler SF

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (SF_Fehler == 1 && SF_warten)

{

rtapi_print_msg(RTAPI_MSG_ERR, "Achtung: Spaenfoerderer deaktiviert!");

SF_warten = false;

}

if (SF_Fehler == 0)

{

SF_warten = true;

}

}Spinde.comp

component Spindel " Steuert die Spindel an mit Orientieren und manueller Kontrolle ";

// Eingaenge

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin in bit IS-MAN = false " ( Pin: IS-MAN) MAN Modus angewählt ";

pin in bit IS-MDI = false " ( Pin: IS-MDI) MDI Modus angewählt ";

pin in bit IS-AUTO = false " ( Pin: IS-AUTO) AUTO Modus angewählt ";

pin in bit Taster-Spindel-EIN = false " ( Pin: hm2_5i20.x.gpio.0xx.in ) Taster Spindel ein ";

pin in bit Taster-schneller = false " ( Pin: hm2_5i20.x.gpio.0xx.in ) Erhöht die Spindelgeschwindigkeit ";

pin in bit Taster-langsamer = false " ( Pin: hm2_5i20.x.gpio.0xx.in ) Verlangsamt die Spindelgeschwindigkeit ";

pin in bit Spindel-ist-EIN = false " ( Pin: halui.spindle.is-on ) Rückmeldung Spindel ist eingeschaltet ";

pin in bit Spindel-Freigabe = false " ( Pin: motion.spindle-on ) Freigabe für die Spindel ";

pin in float Eingabe-Drehzahl-rpm = 0 " ( Pin: motion.spindle-speed-out ) Eingabe Drehzahl von EMC in Umdrehungen pro Minute ";

pin in float Eingabe-Drehzahl-rps = 0 " ( Pin: motion.spindle-speed-out-rps ) Eingabe Drehzahl von EMC in Umdrehungen pro Sekunde ";

pin in float Ausgabe-Drehzahl-rps = 0 " ( Pin: hm2_5i20.0.encoder.03.velocity ) Ausgabe Drehzahl von EMC ";

pin in float Spindel-Position = 0 " ( Pin: hm2_5i20.0.encoder.03.position ) Aktuelle Spindelposition vom Encoder in Einheiten/Umdrehung ";

pin in s32 Werkzeugnummer = 0 " ( Pin: Aktuelles-Werkzeug ) Aktuelle Werkzeugnummer ";

// Ausgaenge

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

pin out bit Umrichterfreigabe = false " ( Pin: hm2_5i20.x.gpio.0xx.out ) Spindel Umrichter Freigabepin ";

pin out bit manuell-Start = false " ( Pin: halui.spindle.start ) Spindel EIN per Taster manuell ";

pin out bit manuell-Stop = false " ( Pin: halui.spindle.stop ) Spindel AUS per Taster manuell ";

pin out bit OR-schneller = false " ( Pin: halui.spindle-override.increase ) Spindelübersteuerung- wird schneller ";

pin out bit OR-langsamer = false " ( Pin: halui.spindle-override.decrease ) Spindelübersteuerung- wird langsamer ";

pin out float Uebersteuerung = 0 " ( Pin: halui.spindle-override.scale ) Drehzahlübersteuerung ";

pin out float Ausgabe-Drehzahl-rpm = 0 " ( Pin: pyvcp.XXXX ) Drehzahlrückmeldung in rpm für pyvcp ";

pin out bit Drehzahl-erreicht = false " ( Pin: motion.spindle-at-speed ) Rückmelde Pin für Spindle at speed Signal ";

pin out bit PWM-Freigabe = false " ( Pin: hm2_5i20.0.pwmgen.03.enable ) PWM Freigabepin ";

pin out float PWM-Eingabe = 0 " ( Pin: hm2_5i20.0.pwmgen.03.value ) PWM Sollwerteingabe ";

pin out float Meldung = 0 " ( Pin: Meldung.Spindel-Fehler ) Ausgang für Meldecodeausgabe ";

// Setp-einstellbare Variablen

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

param rw float Uebersteuerungsbereich = 1 " Uebersteuerungsbereich Drehzahl ";

// Interne Variablen

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

variable int Meldecode = 0; // Hilfsvariable zur Fehlerausgabe

variable float Entprellen = 0; // Zeitvariable zum entprellen

variable float Zeit = 0; // Anzeigezeit der Fehlerausgabe

variable float Drehzahlabweichung = 0; // Aktuelle Drehazhlabweichung

variable float PositionV = 0; // Aktuelle Spindelposition in grad

// Programmkopf

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

option singleton yes;

option fp yes;

function _ "Steuert die Spindel an mit Orientieren und manueller Kontrolle";

license "GPL";

;;

FUNCTION(_)

{

// Direkte Signaldurchführungen

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Ausgabe_Drehzahl_rpm = Ausgabe_Drehzahl_rps * 60 * 1; // Umdrehungen pro Sekunde => Umdrehungen pro Minute

Uebersteuerung = Uebersteuerungsbereich; // Durchführung der Einstellung für das Spindle override scale

Meldung = Meldecode; // Ausgang = Variable

Drehzahlabweichung = Eingabe_Drehzahl_rps - (Ausgabe_Drehzahl_rps * 1);

// Spindelfreigabe

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if ((Werkzeugnummer != 13) && Spindel_Freigabe)

{

PWM_Freigabe = true;

Umrichterfreigabe = true;

}

if (!Spindel_Freigabe)

{

PWM_Freigabe = false;

Umrichterfreigabe = false;

}

// Manuelle Steuerung der Spindel

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (IS_MAN)

{

if (Taster_Spindel_EIN && !Spindel_ist_EIN && (Entprellen == 0))

{

manuell_Stop = false;

manuell_Start = true;

Entprellen = 0.5;

}

if (Taster_Spindel_EIN && Spindel_ist_EIN && (Entprellen == 0))

{

manuell_Start = false;

manuell_Stop = true;

Entprellen = 0.5;

}

if (Taster_langsamer)

{

OR_langsamer = true;

}

if (Taster_schneller)

{

OR_schneller = true;

}

if (!Taster_langsamer)

{

OR_langsamer = false;

}

if (!Taster_schneller)

{

OR_schneller = false;

}

}

if(Entprellen > 0) // Entprellen > 0

{

Entprellen -= period * 0.000000001; // Zeitablauf Entprellen 1 Sekunde

}

if(Entprellen < 0) // Entprellen < 0

{

Entprellen = 0; // Entprellen zurück auf 0 setzen

}

// IST-Drehzahl Überwachung

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (Spindel_Freigabe)

{

if (Spindel_Freigabe && Eingabe_Drehzahl_rpm <= 4500)

{

PWM_Eingabe = Eingabe_Drehzahl_rpm;

}

if (Spindel_Freigabe && Eingabe_Drehzahl_rpm > 4500)

{

PWM_Eingabe = 4500;

}

if (Drehzahlabweichung * Drehzahlabweichung < 0.1)

{

Drehzahl_erreicht = true;

}

if (Drehzahlabweichung * Drehzahlabweichung > 0.1)

{

Drehzahl_erreicht = false;

}

}

// Meldecodeausgabe

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

if (!IS_MAN && Taster_Spindel_EIN)

{

Meldecode = 1;

Zeit = 0.5;

}

if (Eingabe_Drehzahl_rpm > 4500)

{

Meldecode = 5;

Zeit = 0.5;

}

if(Zeit > 0)

{

Zeit -= period * 0.000000001;

}

if(Zeit <= 0)

{

Zeit = 0;

Meldecode = 0;

}

}

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21256

- Thank you received: 7255

06 Jan 2020 12:24 #154142

by tommylight

Replied by tommylight on topic I need help for Comp File programming

Ales mit "spindle" mus "spindle.0" sein.

The following user(s) said Thank You: ChironFZ16

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

09 Jan 2020 00:27 #154367

by andypugh

Replied by andypugh on topic I need help for Comp File programming

The .comp files should not care about pin names.

(except in the case where there is a pin-name clash)

(except in the case where there is a pin-name clash)

The following user(s) said Thank You: ChironFZ16

Please Log in or Create an account to join the conversation.

- ChironFZ16

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 12

10 Jan 2020 14:38 #154551

by ChironFZ16

Replied by ChironFZ16 on topic I need help for Comp File programming

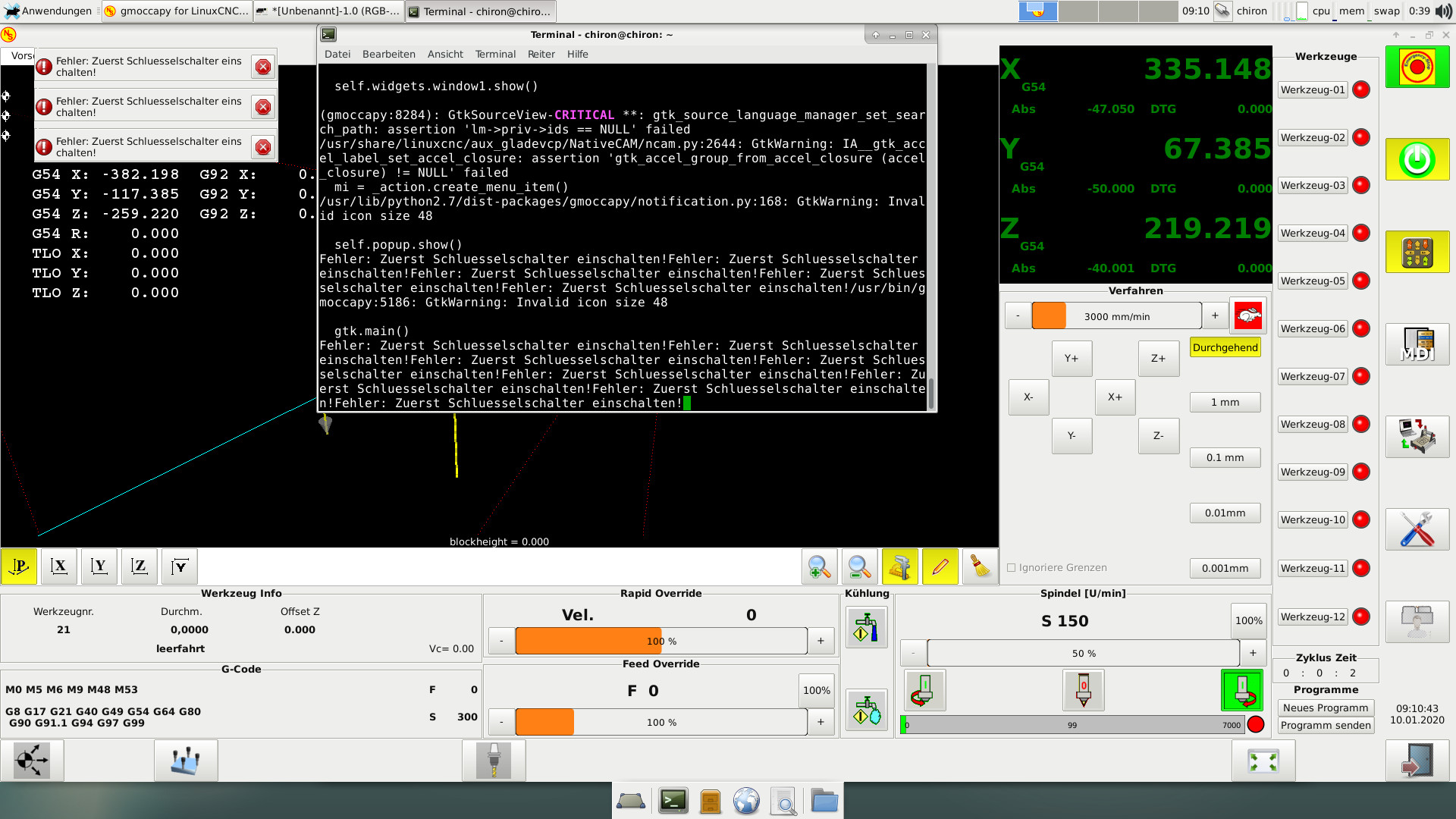

Hallo

Ich bekomme immer diese Fehlermeldungen und weiß nicht mehr weiter, irgendwo ist der Wurm drinnen.

Gibt es Tools/logging für API-Calls aufrufe?

I always get these error messages and don't know what to do, the worm is in there somewhere.

Are there tools/logging calls for API calls?

Any idea ?

Linuxcnc

Turn it on from Konsole

complete errorfile:

Ich bekomme immer diese Fehlermeldungen und weiß nicht mehr weiter, irgendwo ist der Wurm drinnen.

Gibt es Tools/logging für API-Calls aufrufe?

I always get these error messages and don't know what to do, the worm is in there somewhere.

Are there tools/logging calls for API calls?

Any idea ?

Linuxcnc

LINUXCNC - 2.9.0-pre0-939-gadb5ab425Turn it on from Konsole

linuxcnc -d -k -v linuxcnc/configs/chironFZ16/chiron.ini >error21.txtcomplete errorfile:

linuxcnc -d -k -v linuxcnc/configs/chironFZ16/chiron.ini >error21.txt

LINUXCNC - 2.9.0-pre0-939-gadb5ab425

Machine configuration directory is '/home/chiron/linuxcnc/configs/chironFZ16'

Machine configuration file is 'chiron.ini'

Starting LinuxCNC...

[EMCIO] CYCLE_TIME not found in /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini; using default 0.100000

Found file(REL): ./hm2-servo.hal

hm2: loading Mesa HostMot2 driver version 0.15

hm2_pci: loading Mesa AnyIO HostMot2 driver version 0.7

hm2_pci: discovered 5i25 at 0000:04:00.0

hm2/hm2_5i25.0: Low Level init 0.15

hm2/hm2_5i25.0: Smart Serial Firmware Version 43

hm2/hm2_5i25.0: 34 I/O Pins used:

hm2/hm2_5i25.0: IO Pin 000 (P3-01): StepGen #0, pin Direction (Output)

hm2/hm2_5i25.0: IO Pin 001 (P3-14): StepGen #0, pin Step (Output)

hm2/hm2_5i25.0: IO Pin 002 (P3-02): StepGen #1, pin Direction (Output)

hm2/hm2_5i25.0: IO Pin 003 (P3-15): StepGen #1, pin Step (Output)

hm2/hm2_5i25.0: IO Pin 004 (P3-03): StepGen #2, pin Direction (Output)

hm2/hm2_5i25.0: IO Pin 005 (P3-16): StepGen #2, pin Step (Output)

hm2/hm2_5i25.0: IO Pin 006 (P3-04): StepGen #3, pin Direction (Output)

hm2/hm2_5i25.0: IO Pin 007 (P3-17): StepGen #3, pin Step (Output)

hm2/hm2_5i25.0: IO Pin 008 (P3-05): StepGen #4, pin Direction (Output)

hm2/hm2_5i25.0: IO Pin 009 (P3-06): StepGen #4, pin Step (Output)

hm2/hm2_5i25.0: IO Pin 010 (P3-07): IOPort

hm2/hm2_5i25.0: IO Pin 011 (P3-08): IOPort

hm2/hm2_5i25.0: IO Pin 012 (P3-09): IOPort

hm2/hm2_5i25.0: IO Pin 013 (P3-10): IOPort

hm2/hm2_5i25.0: IO Pin 014 (P3-11): IOPort

hm2/hm2_5i25.0: IO Pin 015 (P3-12): IOPort

hm2/hm2_5i25.0: IO Pin 016 (P3-13): IOPort

hm2/hm2_5i25.0: IO Pin 017 (P2-01): IOPort

hm2/hm2_5i25.0: IO Pin 018 (P2-14): IOPort

hm2/hm2_5i25.0: IO Pin 019 (P2-02): IOPort

hm2/hm2_5i25.0: IO Pin 020 (P2-15): IOPort

hm2/hm2_5i25.0: IO Pin 021 (P2-03): IOPort

hm2/hm2_5i25.0: IO Pin 022 (P2-16): IOPort

hm2/hm2_5i25.0: IO Pin 023 (P2-04): IOPort

hm2/hm2_5i25.0: IO Pin 024 (P2-17): IOPort

hm2/hm2_5i25.0: IO Pin 025 (P2-05): IOPort

hm2/hm2_5i25.0: IO Pin 026 (P2-06): IOPort

hm2/hm2_5i25.0: IO Pin 027 (P2-07): IOPort

hm2/hm2_5i25.0: IO Pin 028 (P2-08): IOPort

hm2/hm2_5i25.0: IO Pin 029 (P2-09): IOPort

hm2/hm2_5i25.0: IO Pin 030 (P2-10): IOPort

hm2/hm2_5i25.0: IO Pin 031 (P2-11): IOPort

hm2/hm2_5i25.0: IO Pin 032 (P2-12): IOPort

hm2/hm2_5i25.0: IO Pin 033 (P2-13): IOPort

hm2/hm2_5i25.0: registered

hm2_5i25.0: initialized AnyIO board at 0000:04:00.0

hm2_pci: discovered 5i20 at 0000:06:00.0

hm2/hm2_5i20.0: Low Level init 0.15

hm2/hm2_5i20.0: 72 I/O Pins used:

hm2/hm2_5i20.0: IO Pin 000 (P2-01): PWMGen #0, pin Not-Enable (Output)

hm2/hm2_5i20.0: IO Pin 001 (P2-03): Muxed Encoder #0, pin Muxed A (Input)

hm2/hm2_5i20.0: IO Pin 002 (P2-05): Muxed Encoder #0, pin Muxed B (Input)

hm2/hm2_5i20.0: IO Pin 003 (P2-07): Muxed Encoder #0, pin Muxed Index (Input)

hm2/hm2_5i20.0: IO Pin 004 (P2-09): Muxed Encoder #1, pin Muxed A (Input)

hm2/hm2_5i20.0: IO Pin 005 (P2-11): Muxed Encoder #1, pin Muxed B (Input)

hm2/hm2_5i20.0: IO Pin 006 (P2-13): Muxed Encoder #1, pin Muxed Index (Input)

hm2/hm2_5i20.0: IO Pin 007 (P2-15): Muxed Encoder #2, pin Muxed A (Input)

hm2/hm2_5i20.0: IO Pin 008 (P2-17): Muxed Encoder #2, pin Muxed B (Input)

hm2/hm2_5i20.0: IO Pin 009 (P2-19): Muxed Encoder #2, pin Muxed Index (Input)

hm2/hm2_5i20.0: IO Pin 010 (P2-21): Muxed Encoder Select #0, pin Mux Select 0 (Output)

hm2/hm2_5i20.0: IO Pin 011 (P2-23): PWMGen #0, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 012 (P2-25): PWMGen #0, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 013 (P2-27): PWMGen #1, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 014 (P2-29): PWMGen #1, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 015 (P2-31): PWMGen #2, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 016 (P2-33): PWMGen #2, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 017 (P2-35): PWMGen #3, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 018 (P2-37): PWMGen #3, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 019 (P2-39): PWMGen #4, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 020 (P2-41): PWMGen #4, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 021 (P2-43): PWMGen #5, pin Out0 (PWM or Up) (Output)

hm2/hm2_5i20.0: IO Pin 022 (P2-45): PWMGen #5, pin Out1 (Dir or Down) (Output)

hm2/hm2_5i20.0: IO Pin 023 (P2-47): PWMGen #0, pin Not-Enable (Output)

hm2/hm2_5i20.0: IO Pin 024 (P3-01): IOPort

hm2/hm2_5i20.0: IO Pin 025 (P3-03): IOPort

hm2/hm2_5i20.0: IO Pin 026 (P3-05): IOPort

hm2/hm2_5i20.0: IO Pin 027 (P3-07): IOPort

hm2/hm2_5i20.0: IO Pin 028 (P3-09): IOPort

hm2/hm2_5i20.0: IO Pin 029 (P3-11): IOPort

hm2/hm2_5i20.0: IO Pin 030 (P3-13): IOPort

hm2/hm2_5i20.0: IO Pin 031 (P3-15): IOPort

hm2/hm2_5i20.0: IO Pin 032 (P3-17): IOPort

hm2/hm2_5i20.0: IO Pin 033 (P3-19): IOPort

hm2/hm2_5i20.0: IO Pin 034 (P3-21): IOPort

hm2/hm2_5i20.0: IO Pin 035 (P3-23): IOPort

hm2/hm2_5i20.0: IO Pin 036 (P3-25): IOPort

hm2/hm2_5i20.0: IO Pin 037 (P3-27): IOPort

hm2/hm2_5i20.0: IO Pin 038 (P3-29): IOPort

hm2/hm2_5i20.0: IO Pin 039 (P3-31): IOPort

hm2/hm2_5i20.0: IO Pin 040 (P3-33): IOPort

hm2/hm2_5i20.0: IO Pin 041 (P3-35): IOPort

hm2/hm2_5i20.0: IO Pin 042 (P3-37): IOPort

hm2/hm2_5i20.0: IO Pin 043 (P3-39): IOPort

hm2/hm2_5i20.0: IO Pin 044 (P3-41): IOPort

hm2/hm2_5i20.0: IO Pin 045 (P3-43): IOPort

hm2/hm2_5i20.0: IO Pin 046 (P3-45): IOPort

hm2/hm2_5i20.0: IO Pin 047 (P3-47): IOPort

hm2/hm2_5i20.0: IO Pin 048 (P4-01): IOPort

hm2/hm2_5i20.0: IO Pin 049 (P4-03): IOPort

hm2/hm2_5i20.0: IO Pin 050 (P4-05): IOPort

hm2/hm2_5i20.0: IO Pin 051 (P4-07): IOPort

hm2/hm2_5i20.0: IO Pin 052 (P4-09): IOPort

hm2/hm2_5i20.0: IO Pin 053 (P4-11): IOPort

hm2/hm2_5i20.0: IO Pin 054 (P4-13): IOPort

hm2/hm2_5i20.0: IO Pin 055 (P4-15): IOPort

hm2/hm2_5i20.0: IO Pin 056 (P4-17): IOPort

hm2/hm2_5i20.0: IO Pin 057 (P4-19): IOPort

hm2/hm2_5i20.0: IO Pin 058 (P4-21): IOPort

hm2/hm2_5i20.0: IO Pin 059 (P4-23): IOPort

hm2/hm2_5i20.0: IO Pin 060 (P4-25): IOPort

hm2/hm2_5i20.0: IO Pin 061 (P4-27): IOPort

hm2/hm2_5i20.0: IO Pin 062 (P4-29): IOPort

hm2/hm2_5i20.0: IO Pin 063 (P4-31): IOPort

hm2/hm2_5i20.0: IO Pin 064 (P4-33): IOPort

hm2/hm2_5i20.0: IO Pin 065 (P4-35): IOPort

hm2/hm2_5i20.0: IO Pin 066 (P4-37): IOPort

hm2/hm2_5i20.0: IO Pin 067 (P4-39): IOPort

hm2/hm2_5i20.0: IO Pin 068 (P4-41): IOPort

hm2/hm2_5i20.0: IO Pin 069 (P4-43): IOPort

hm2/hm2_5i20.0: IO Pin 070 (P4-45): IOPort

hm2/hm2_5i20.0: IO Pin 071 (P4-47): IOPort

hm2/hm2_5i20.0: registered

hm2_5i20.0: initialized AnyIO board at 0000:06:00.0

hm2_pci: discovered 5i20 at 0000:06:01.0

hm2/hm2_5i20.1: Low Level init 0.15

hm2/hm2_5i20.1: 72 I/O Pins used:

hm2/hm2_5i20.1: IO Pin 000 (P2-01): IOPort

hm2/hm2_5i20.1: IO Pin 001 (P2-03): IOPort

hm2/hm2_5i20.1: IO Pin 002 (P2-05): IOPort

hm2/hm2_5i20.1: IO Pin 003 (P2-07): IOPort

hm2/hm2_5i20.1: IO Pin 004 (P2-09): IOPort

hm2/hm2_5i20.1: IO Pin 005 (P2-11): IOPort

hm2/hm2_5i20.1: IO Pin 006 (P2-13): IOPort

hm2/hm2_5i20.1: IO Pin 007 (P2-15): IOPort

hm2/hm2_5i20.1: IO Pin 008 (P2-17): IOPort

hm2/hm2_5i20.1: IO Pin 009 (P2-19): IOPort

hm2/hm2_5i20.1: IO Pin 010 (P2-21): IOPort

hm2/hm2_5i20.1: IO Pin 011 (P2-23): IOPort

hm2/hm2_5i20.1: IO Pin 012 (P2-25): IOPort

hm2/hm2_5i20.1: IO Pin 013 (P2-27): IOPort

hm2/hm2_5i20.1: IO Pin 014 (P2-29): IOPort

hm2/hm2_5i20.1: IO Pin 015 (P2-31): IOPort

hm2/hm2_5i20.1: IO Pin 016 (P2-33): IOPort

hm2/hm2_5i20.1: IO Pin 017 (P2-35): IOPort

hm2/hm2_5i20.1: IO Pin 018 (P2-37): IOPort

hm2/hm2_5i20.1: IO Pin 019 (P2-39): IOPort

hm2/hm2_5i20.1: IO Pin 020 (P2-41): IOPort

hm2/hm2_5i20.1: IO Pin 021 (P2-43): IOPort

hm2/hm2_5i20.1: IO Pin 022 (P2-45): IOPort

hm2/hm2_5i20.1: IO Pin 023 (P2-47): IOPort

hm2/hm2_5i20.1: IO Pin 024 (P3-01): IOPort

hm2/hm2_5i20.1: IO Pin 025 (P3-03): IOPort

hm2/hm2_5i20.1: IO Pin 026 (P3-05): IOPort

hm2/hm2_5i20.1: IO Pin 027 (P3-07): IOPort

hm2/hm2_5i20.1: IO Pin 028 (P3-09): IOPort

hm2/hm2_5i20.1: IO Pin 029 (P3-11): IOPort

hm2/hm2_5i20.1: IO Pin 030 (P3-13): IOPort

hm2/hm2_5i20.1: IO Pin 031 (P3-15): IOPoFound file(REL): ./ios.hal

Found file(REL): ./loadrt.hal

Found file(REL): ./Maschine.hal

Found file(REL): ./Spindel.hal

Found file(REL): ./Bedienfeld.hal

Found file(REL): ./Werkstueckwechsler.hal

Found file(REL): ./Werkzeugwechsler.hal

Found file(REL): ./Handrad.hal

Found file(REL): ./Meldung.hal

Found file(REL): ./6i25.hal

Starting TASK program: milltask

Starting DISPLAY program: gmoccapy

+ for KILL_PID in $KILL_PIDS

+ /bin/ps -o comm= 8874

+ /bin/grep -q '<defunct>'

+ /bin/kill 8874

+ WAIT=20

+ '[' 20 -gt 1 ']'

++ /bin/ps -o comm= 8874

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=0

+ '[' 0 -gt 0 ']'

+ WAIT=0

+ '[' 0 -gt 1 ']'

+ '[' 0 -gt 0 ']'

+ '[' 0 -gt 0 ']'

+ KILL_PIDS=

+ KILL_TASK=

+ for KILL_TASK in linuxcncsvr milltask

+ /bin/pidof -x milltask

8946

+ KillTaskWithTimeout

+ '[' '!' -n '' ']'

++ /bin/pidof -x milltask

+ KILL_PIDS=8946

+ '[' '!' -n 8946 ']'

+ local NPROCS

+ for KILL_PID in $KILL_PIDS

+ /bin/ps -o comm= 8946

+ /bin/grep -q '<defunct>'

+ /bin/kill 8946

+ WAIT=20

+ '[' 20 -gt 1 ']'

++ /bin/ps -o comm= 8946

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=1

+ '[' 1 -gt 0 ']'

+ WAIT=19

+ sleep .1

+ '[' 19 -gt 1 ']'

++ /bin/ps -o comm= 8946

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=0

+ '[' 0 -gt 0 ']'

+ WAIT=0

+ '[' 0 -gt 1 ']'

+ '[' 0 -gt 0 ']'

+ '[' 0 -gt 0 ']'

+ KILL_PIDS=

+ KILL_TASK=

+ echo 'Stopping realtime threads'

Stopping realtime threads

+ halcmd -k stop

+ echo 'Unloading hal components'

Unloading hal components

+ halcmd -k unload all

RTAPI_PCI: Unmapped 65536 bytes at 0x7ff771b40000

RTAPI_PCI: Unmapped 65536 bytes at 0x7ff771b30000

RTAPI_PCI: Unmapped 65536 bytes at 0x7ff77199f000

++ seq 10

+ for i in `seq 10`

++ wc -w

++ halcmd -k list comp

+ '[' 3 = 1 ']'

+ sleep .2

+ for i in `seq 10`

++ halcmd -k list comp

++ wc -w

+ '[' 3 = 1 ']'

+ sleep .2

+ for i in `seq 10`

++ halcmd -k list comp

++ wc -w

+ '[' 1 = 1 ']'

+ break

+ echo 'Removing HAL_LIB, RTAPI, and Real Time OS modules'

+ /etc/init.d/realtime stop

Note: Using POSIX realtime

+ echo 'Removing NML shared memory segments'

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1001

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1002

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1003

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1004

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1005

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ '[' -f /tmp/linuxcnc.lock ']'

+ rm /tmp/linuxcnc.lock

+ exit 0

+ ErrorCheck

+ result=0

+ '[' '!' -z :0.0 ']'

+ echo 'catch {send -async popimage destroy .}; destroy .'

+ /usr/bin/wish8.6

+ '[' 0 -ne 0 ']'

+ rm -f /dev/fd/2 /dev/fd/1

+ exit 0

chiron@chiron:~$ linuxcnc -d -k -v linuxcnc/configs/chironFZ16/chiron.ini >error21.txt

Debug mode on

+ getopts dvlhkr opt

+ case "$opt" in

+ DASHK=-k

+ getopts dvlhkr opt

+ case "$opt" in

+ tty -s

+ PRINT_FILE=/dev/fd/1

+ echo 'Verbose mode on'

+ getopts dvlhkr opt

+ shift 3

+ case "" in

+ '[' -z ']'

+ tty -s

+ trap ErrorCheck EXIT

+ '[' '!' -z linuxcnc/configs/chironFZ16/chiron.ini ']'

+ case "$1" in

++ pwd

+ INIFILE=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ shift

+ EXTRA_ARGS=

+ RUN_IN_PLACE=no

+ echo RUN_IN_PLACE=no

+ LINUXCNCVERSION=2.9.0-pre0-939-gadb5ab425

+ export LINUXCNCVERSION

+ INIVAR=inivar

+ HALCMD='halcmd -k'

+ PICKCONFIG='/usr/bin/wish8.6 /usr/lib/tcltk/linuxcnc/bin/pickconfig.tcl'

+ LINUXCNC_EMCSH=/usr/bin/wish8.6

+ echo LINUXCNC_DIR=

+ echo LINUXCNC_BIN_DIR=/usr/bin

+ echo LINUXCNC_TCL_DIR=/usr/lib/tcltk/linuxcnc

+ echo LINUXCNC_SCRIPT_DIR=

+ echo LINUXCNC_RTLIB_DIR=/usr/lib/linuxcnc/modules

+ echo LINUXCNC_CONFIG_DIR=

+ echo LINUXCNC_LANG_DIR=/usr/lib/tcltk/linuxcnc/msgs

+ echo INIVAR=inivar

+ echo HALCMD=halcmd -k

+ echo LINUXCNC_EMCSH=/usr/bin/wish8.6

+ export LINUXCNC_TCL_DIR

+ export LINUXCNC_EMCSH

+ export LINUXCNC_HELP_DIR

+ export LINUXCNC_LANG_DIR

+ export REALTIME

+ export HALCMD

+ export LINUXCNC_NCFILES_DIR

+ '[' -z ']'

+ echo 'LINUXCNC - 2.9.0-pre0-939-gadb5ab425'

+ '[' '!' -z '' ']'

+ '[' '!' -n /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini ']'

+ '[' '!' -n /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini ']'

++ handle_includes /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ hdr='# handle_includes():'

++ inifile=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+++ dirname /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ cd /home/chiron/linuxcnc/configs/chironFZ16

++ /bin/grep '^#INCLUDE' /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ status=1

++ '[' 1 -ne 0 ']'

++ echo /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ return 0

+ INIFILE=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ INI_NAME=chiron.ini

+ INI_DIR=/home/chiron/linuxcnc/configs/chironFZ16

+ CONFIG_DIR=/home/chiron/linuxcnc/configs/chironFZ16

+ export CONFIG_DIR

+ export PATH=/home/chiron/linuxcnc/configs/chironFZ16/bin:/usr/bin:/usr/local/bin:/usr/bin:/bin:/usr/local/games:/usr/games

+ PATH=/home/chiron/linuxcnc/configs/chironFZ16/bin:/usr/bin:/usr/local/bin:/usr/bin:/bin:/usr/local/games:/usr/games

+ '[' -z ']'

+ echo 'Machine configuration directory is '\''/home/chiron/linuxcnc/configs/chironFZ16'\'''

+ echo 'Machine configuration file is '\''chiron.ini'\'''

+ '[' '!' -f /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini ']'

+ echo INIFILE=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ retval=

+ GetFromIni VERSION EMC

+ name=VERSION

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var VERSION -sec EMC

+ retval=1.1

+ '[' '!' -n VERSION ']'

+ echo VERSION=1.1

+ '[' 1.1 '!=' 1.1 ']'

+ /usr/bin/tclsh8.6 /usr/share/linuxcnc/hallib/check_config.tcl /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ exitval=0

+ case "$exitval" in

+ GetFromIni PARAMETER_FILE RS274NGC

+ name=PARAMETER_FILE

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var PARAMETER_FILE -sec RS274NGC

+ retval=hm2-servo.var

+ '[' '!' -n PARAMETER_FILE ']'

+ echo PARAMETER_FILE=hm2-servo.var

+ RS274NGC_PARAMFILE=hm2-servo.var

+ GetFromIniEx MOT MOT EMCMOT EMCMOT motmod

+ original_var='[MOT]MOT'

+ '[' 5 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var MOT -sec MOT

+ retval=

+ shift 2

+ '[' 3 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var EMCMOT -sec EMCMOT

+ retval=motmod

+ return

+ EMCMOT=motmod.so

+ GetFromIniEx IO IO EMCIO EMCIO io

+ original_var='[IO]IO'

+ '[' 5 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var IO -sec IO

+ retval=

+ shift 2

+ '[' 3 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var EMCIO -sec EMCIO

+ retval=io

+ return

+ EMCIO=io

+ GetFromIni TASK TASK

+ name=TASK

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var TASK -sec TASK

+ retval=milltask

+ '[' '!' -n TASK ']'

+ echo TASK=milltask

+ EMCTASK=milltask

+ '[' milltask = emctask ']'

+ EMCSERVER=linuxcncsvr

+ GetFromIniQuiet HALUI HAL

+ name=HALUI

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALUI -sec HAL

+ retval=halui

+ '[' '!' -n HALUI ']'

+ echo HALUI=halui

+ HALUI=halui

+ GetFromIni DISPLAY DISPLAY

+ name=DISPLAY

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var DISPLAY -sec DISPLAY

+ retval=gmoccapy

+ '[' '!' -n DISPLAY ']'

+ echo DISPLAY=gmoccapy

++ set -- gmoccapy

++ echo gmoccapy

+ EMCDISPLAY=gmoccapy

++ set -- gmoccapy

++ shift

++ echo

+ EMCDISPLAYARGS=

+ case $EMCDISPLAY in

+ GetFromIniEx NML_FILE LINUXCNC NML_FILE EMC /usr/share/linuxcnc/linuxcnc.nml

+ original_var='[LINUXCNC]NML_FILE'

+ '[' 5 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var NML_FILE -sec LINUXCNC

+ retval=

+ shift 2

+ '[' 3 -ge 2 ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var NML_FILE -sec EMC

+ retval=

+ shift 2

+ '[' 1 -ge 2 ']'

+ '[' 1 -eq 0 ']'

+ retval=/usr/share/linuxcnc/linuxcnc.nml

+ NMLFILE=/usr/share/linuxcnc/linuxcnc.nml

+ export NMLFILE

+ GetFromIni COORDINATES TRAJ

+ name=COORDINATES

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var COORDINATES -sec TRAJ

+ retval='X Y Z'

+ '[' '!' -n COORDINATES ']'

+ echo 'COORDINATES=X Y Z'

+ TRAJ_COORDINATES='X Y Z'

+ export TRAJ_COORDINATES

+ GetFromIni KINEMATICS KINS

+ name=KINEMATICS

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var KINEMATICS -sec KINS

+ retval=trivkins

+ '[' '!' -n KINEMATICS ']'

+ echo KINEMATICS=trivkins

+ KINS_KINEMATICS=trivkins

+ export KINS_KINEMATICS

+ KILL_TASK=

+ KILL_TIMEOUT=20

+ LOCKFILE=/tmp/linuxcnc.lock

+ '[' -f /tmp/linuxcnc.lock ']'

+ echo Starting LinuxCNC...

+ trap 'Cleanup ; exit 0' SIGINT SIGTERM

+ cd /home/chiron/linuxcnc/configs/chironFZ16

+ touch /tmp/linuxcnc.lock

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var INTRO_GRAPHIC -sec DISPLAY

+ img=linuxcnc.gif

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var INTRO_TIME -sec DISPLAY

+ imgtime=2

+ '[' 2 = '' ']'

+ '[' linuxcnc.gif '!=' '' ']'

+ '[' -e linuxcnc.gif ']'

+ '[' -e /home/chiron/linuxcnc/configs/chironFZ16/linuxcnc.gif ']'

+ '[' -e /usr/share/linuxcnc/linuxcnc.gif ']'

+ img=/usr/share/linuxcnc/linuxcnc.gif

+ '[' /usr/share/linuxcnc/linuxcnc.gif '!=' '' ']'

+ '[' -x /usr/lib/tcltk/linuxcnc/bin/popimage ']'

+ /usr/lib/tcltk/linuxcnc/bin/popimage /usr/share/linuxcnc/linuxcnc.gif 2

+ echo 'Starting LinuxCNC server program: linuxcncsvr'

+ program_available linuxcncsvr

+ type -path linuxcncsvr

+ export INI_FILE_NAME=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ INI_FILE_NAME=/home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ linuxcncsvr -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ echo 'Loading Real Time OS, RTAPI, and HAL_LIB modules'

+ /etc/init.d/realtime start

+ export HAL_RTMOD_DIR=/usr/lib/linuxcnc/modules

+ HAL_RTMOD_DIR=/usr/lib/linuxcnc/modules

+ '[' io '!=' '' ']'

+ echo 'Starting LinuxCNC IO program: io'

+ program_available io

+ type -path io

+ halcmd -k loadusr -Wn iocontrol io -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

+ '[' -n halui ']'

+ echo 'Starting HAL User Interface program: halui'

+ program_available halui

+ type -path halui

+ halcmd -k loadusr -Wn halui halui -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var TWOPASS -sec HAL -num 1

+ TWOPASS=

+ '[' -n '' ']'

+ NUM=1

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 1

+ CFGFILE=hm2-servo.hal

+ '[' -n hm2-servo.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=hm2-servo.hal

+ '[' -z hm2-servo.hal ']'

+ '[' hm2-servo.hal '!=' hm2-servo.hal ']'

+ '[' h = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./hm2-servo.hal

+ '[' -r ./hm2-servo.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./hm2-servo.hal'

+ break

+ '[' -d ./hm2-servo.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./hm2-servo.hal' ']'

+ echo 'Found file(REL): ./hm2-servo.hal'

+ CFGFILE=./hm2-servo.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./hm2-servo.hal

Note: Using POSIX realtime

+ NUM=2

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 2

+ CFGFILE=ios.hal

+ '[' -n ios.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=ios.hal

+ '[' -z ios.hal ']'

+ '[' ios.hal '!=' ios.hal ']'

+ '[' i = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./ios.hal

+ '[' -r ./ios.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./ios.hal'

+ break

+ '[' -d ./ios.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./ios.hal' ']'

+ echo 'Found file(REL): ./ios.hal'

+ CFGFILE=./ios.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./ios.hal

+ NUM=3

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 3

+ CFGFILE=loadrt.hal

+ '[' -n loadrt.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=loadrt.hal

+ '[' -z loadrt.hal ']'

+ '[' loadrt.hal '!=' loadrt.hal ']'

+ '[' l = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./loadrt.hal

+ '[' -r ./loadrt.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./loadrt.hal'

+ break

+ '[' -d ./loadrt.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./loadrt.hal' ']'

+ echo 'Found file(REL): ./loadrt.hal'

+ CFGFILE=./loadrt.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./loadrt.hal

+ NUM=4

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 4

+ CFGFILE=Maschine.hal

+ '[' -n Maschine.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Maschine.hal

+ '[' -z Maschine.hal ']'

+ '[' Maschine.hal '!=' Maschine.hal ']'

+ '[' M = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Maschine.hal

+ '[' -r ./Maschine.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Maschine.hal'

+ break

+ '[' -d ./Maschine.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Maschine.hal' ']'

+ echo 'Found file(REL): ./Maschine.hal'

+ CFGFILE=./Maschine.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Maschine.hal

+ NUM=5

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 5

+ CFGFILE=Spindel.hal

+ '[' -n Spindel.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Spindel.hal

+ '[' -z Spindel.hal ']'

+ '[' Spindel.hal '!=' Spindel.hal ']'

+ '[' S = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Spindel.hal

+ '[' -r ./Spindel.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Spindel.hal'

+ break

+ '[' -d ./Spindel.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Spindel.hal' ']'

+ echo 'Found file(REL): ./Spindel.hal'

+ CFGFILE=./Spindel.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Spindel.hal

+ NUM=6

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 6

+ CFGFILE=Bedienfeld.hal

+ '[' -n Bedienfeld.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Bedienfeld.hal

+ '[' -z Bedienfeld.hal ']'

+ '[' Bedienfeld.hal '!=' Bedienfeld.hal ']'

+ '[' B = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Bedienfeld.hal

+ '[' -r ./Bedienfeld.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Bedienfeld.hal'

+ break

+ '[' -d ./Bedienfeld.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Bedienfeld.hal' ']'

+ echo 'Found file(REL): ./Bedienfeld.hal'

+ CFGFILE=./Bedienfeld.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Bedienfeld.hal

+ NUM=7

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 7

+ CFGFILE=Werkstueckwechsler.hal

+ '[' -n Werkstueckwechsler.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Werkstueckwechsler.hal

+ '[' -z Werkstueckwechsler.hal ']'

+ '[' Werkstueckwechsler.hal '!=' Werkstueckwechsler.hal ']'

+ '[' W = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Werkstueckwechsler.hal

+ '[' -r ./Werkstueckwechsler.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Werkstueckwechsler.hal'

+ break

+ '[' -d ./Werkstueckwechsler.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Werkstueckwechsler.hal' ']'

+ echo 'Found file(REL): ./Werkstueckwechsler.hal'

+ CFGFILE=./Werkstueckwechsler.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Werkstueckwechsler.hal

+ NUM=8

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 8

+ CFGFILE=Werkzeugwechsler.hal

+ '[' -n Werkzeugwechsler.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Werkzeugwechsler.hal

+ '[' -z Werkzeugwechsler.hal ']'

+ '[' Werkzeugwechsler.hal '!=' Werkzeugwechsler.hal ']'

+ '[' W = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Werkzeugwechsler.hal

+ '[' -r ./Werkzeugwechsler.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Werkzeugwechsler.hal'

+ break

+ '[' -d ./Werkzeugwechsler.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Werkzeugwechsler.hal' ']'

+ echo 'Found file(REL): ./Werkzeugwechsler.hal'

+ CFGFILE=./Werkzeugwechsler.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Werkzeugwechsler.hal

+ NUM=9

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 9

+ CFGFILE=Handrad.hal

+ '[' -n Handrad.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Handrad.hal

+ '[' -z Handrad.hal ']'

+ '[' Handrad.hal '!=' Handrad.hal ']'

+ '[' H = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Handrad.hal

+ '[' -r ./Handrad.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Handrad.hal'

+ break

+ '[' -d ./Handrad.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Handrad.hal' ']'

+ echo 'Found file(REL): ./Handrad.hal'

+ CFGFILE=./Handrad.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Handrad.hal

+ NUM=10

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 10

+ CFGFILE=Meldung.hal

+ '[' -n Meldung.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=Meldung.hal

+ '[' -z Meldung.hal ']'

+ '[' Meldung.hal '!=' Meldung.hal ']'

+ '[' M = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./Meldung.hal

+ '[' -r ./Meldung.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./Meldung.hal'

+ break

+ '[' -d ./Meldung.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./Meldung.hal' ']'

+ echo 'Found file(REL): ./Meldung.hal'

+ CFGFILE=./Meldung.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./Meldung.hal

+ NUM=11

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 11

+ CFGFILE=6i25.hal

+ '[' -n 6i25.hal ']'

+ IFS='\ '

+ read CFGFILE CFGFILE_ARGS

+ foundmsg=

+ saveIFS='

'

+ IFS=:

+ explicit_file_in_hallib=6i25.hal

+ '[' -z 6i25.hal ']'

+ '[' 6i25.hal '!=' 6i25.hal ']'

+ '[' 6 = / ']'

+ for pathdir in $HALLIB_PATH

+ foundfile=./6i25.hal

+ '[' -r ./6i25.hal ']'

+ '[' . = . ']'

+ foundmsg='Found file(REL): ./6i25.hal'

+ break

+ '[' -d ./6i25.hal ']'

+ IFS='

'

+ '[' -z 'Found file(REL): ./6i25.hal' ']'

+ echo 'Found file(REL): ./6i25.hal'

+ CFGFILE=./6i25.hal

+ case $CFGFILE in

+ halcmd -k -i /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -f ./6i25.hal

+ NUM=12

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALFILE -sec HAL -num 12

+ CFGFILE=

+ '[' -n '' ']'

+ echo 'Starting TASK program: milltask'

+ program_available milltask

+ type -path milltask

+ NUM=1

+ halcmd loadusr -Wn inihal milltask -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var HALCMD -sec HAL -num 1

+ HALCOMMAND=

+ '[' -n '' ']'

+ halcmd -k start

+ run_applications

+ NUM=1

++ inivar -tildeexpand -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var APP -sec APPLICATIONS -num 1

+ APPFILE=

+ '[' -z '' ']'

+ return

+ echo 'Starting DISPLAY program: gmoccapy'

+ result=0

+ case $EMCDISPLAY in

+ program_available gmoccapy

+ type -path gmoccapy

+ gmoccapy -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini

/usr/bin/gmoccapy:325: GtkWarning: Invalid icon size 48

self.widgets.window1.show()

(gmoccapy:9203): GtkSourceView-CRITICAL **: gtk_source_language_manager_set_search_path: assertion 'lm->priv->ids == NULL' failed

+ result=0

+ Cleanup

+ echo 'Shutting down and cleaning up LinuxCNC...'

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x linuxcncpanel

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x iosh

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x linuxcncsh

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x linuxcncrsh

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x linuxcnctop

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x mdi

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x debuglevel

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x gmoccapy

+ for KILL_TASK in linuxcncpanel iosh linuxcncsh linuxcncrsh linuxcnctop mdi debuglevel gmoccapy gscreen

+ /bin/pidof -x gscreen

+ program_available axis-remote

+ type -path axis-remote

+ '[' '!' -z :0.0 ']'

+ axis-remote --ping

+ '[' '' = other ']'

++ inivar -ini /home/chiron/linuxcnc/configs/chironFZ16/chiron.ini -var SHUTDOWN -sec HAL

+ SHUTDOWN=

+ '[' -n '' ']'

+ for KILL_TASK in linuxcncsvr milltask

+ /bin/pidof -x linuxcncsvr

9127

+ KillTaskWithTimeout

+ '[' '!' -n '' ']'

++ /bin/pidof -x linuxcncsvr

+ KILL_PIDS=9127

+ '[' '!' -n 9127 ']'

+ local NPROCS

+ for KILL_PID in $KILL_PIDS

+ /bin/ps -o comm= 9127

+ /bin/grep -q '<defunct>'

+ /bin/kill 9127

+ WAIT=20

+ '[' 20 -gt 1 ']'

++ /bin/ps -o comm= 9127

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=0

+ '[' 0 -gt 0 ']'

+ WAIT=0

+ '[' 0 -gt 1 ']'

+ '[' 0 -gt 0 ']'

+ '[' 0 -gt 0 ']'

+ KILL_PIDS=

+ KILL_TASK=

+ for KILL_TASK in linuxcncsvr milltask

+ /bin/pidof -x milltask

9199

+ KillTaskWithTimeout

+ '[' '!' -n '' ']'

++ /bin/pidof -x milltask

+ KILL_PIDS=9199

+ '[' '!' -n 9199 ']'

+ local NPROCS

+ for KILL_PID in $KILL_PIDS

+ /bin/ps -o comm= 9199

+ /bin/grep -q '<defunct>'

+ /bin/kill 9199

+ WAIT=20

+ '[' 20 -gt 1 ']'

++ /bin/ps -o comm= 9199

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=1

+ '[' 1 -gt 0 ']'

+ WAIT=19

+ sleep .1

+ '[' 19 -gt 1 ']'

++ /bin/ps -o comm= 9199

++ /bin/grep -v '<defunct>'

++ wc -l

+ NPROCS=0

+ '[' 0 -gt 0 ']'

+ WAIT=0

+ '[' 0 -gt 1 ']'

+ '[' 0 -gt 0 ']'

+ '[' 0 -gt 0 ']'

+ KILL_PIDS=

+ KILL_TASK=

+ echo 'Stopping realtime threads'

Stopping realtime threads

+ halcmd -k stop

+ echo 'Unloading hal components'

Unloading hal components

+ halcmd -k unload all

RTAPI_PCI: Unmapped 65536 bytes at 0x7fad44eeb000

RTAPI_PCI: Unmapped 65536 bytes at 0x7fad44edb000

RTAPI_PCI: Unmapped 65536 bytes at 0x7fad44d4a000

++ seq 10

+ for i in `seq 10`

++ wc -w

++ halcmd -k list comp

+ '[' 4 = 1 ']'

+ sleep .2

+ for i in `seq 10`

++ halcmd -k list comp

++ wc -w

+ '[' 1 = 1 ']'

+ break

+ echo 'Removing HAL_LIB, RTAPI, and Real Time OS modules'

+ /etc/init.d/realtime stop

Note: Using POSIX realtime

+ echo 'Removing NML shared memory segments'

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1001

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1002

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1003

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1004

+ read b x t x x x x x x m x

+ case $b$t in

+ ipcrm -M 1005

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ case $b$t in

+ read b x t x x x x x x m x

+ '[' -f /tmp/linuxcnc.lock ']'

+ rm /tmp/linuxcnc.lock

+ exit 0