[solved] Using motorless B-axis in HAL only

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

19 Apr 2020 11:54 - 19 Apr 2020 16:54 #164629

by Aciera

[solved] Using motorless B-axis in HAL only was created by Aciera

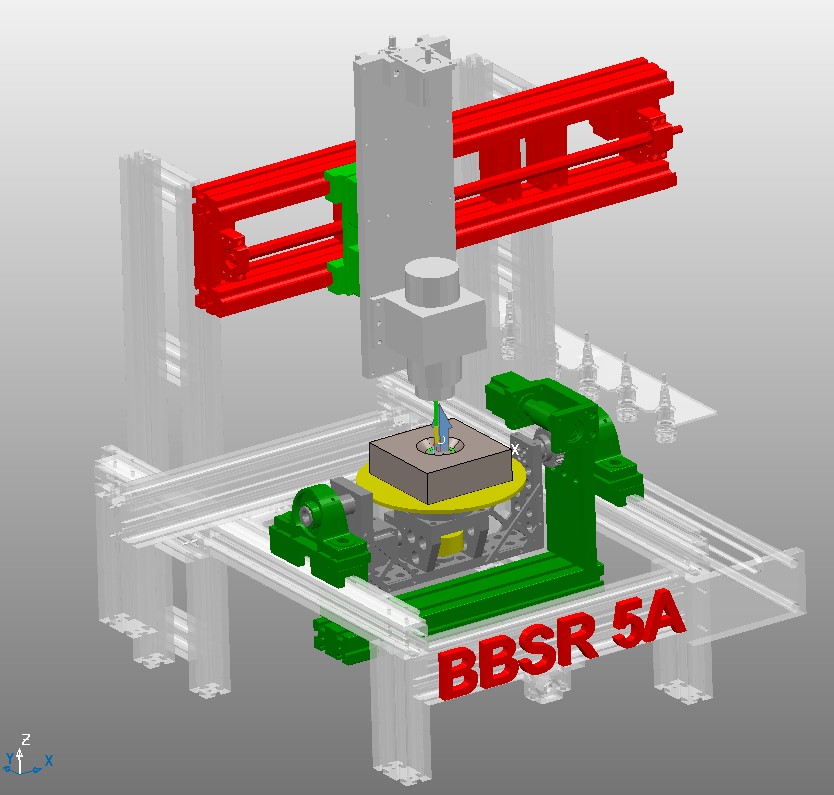

I'm working on a mill with a manual swivel head, an indexing b-axis without a motor. We use this with 5-axis xyzbc-kinematics to mill pockets at preset angles of the tool in reference to the table like in the image below but without the rotary table.

It's all working with the B-axis connected to a stepgen on a MESA 7i76e that does not have an actual motor connected to that particular output connector. I can command say G0 B30 and the DRO for the B-axis counts up to 30 and that is then used in the kinematic to calculate the movement of the X- and Z-axis.

So as it is the loop gets closed on the MESA board.

Now I would like to use that stepgen on the MESA board for another axis and have the b-axis working only in software.

I'm guessing I need to somehow provide the pid with a position feedback to get the DRO to function.

Does anybody have an idea if it is possible to close that loop in HAL and get the DRO to function?

It's all working with the B-axis connected to a stepgen on a MESA 7i76e that does not have an actual motor connected to that particular output connector. I can command say G0 B30 and the DRO for the B-axis counts up to 30 and that is then used in the kinematic to calculate the movement of the X- and Z-axis.

#*******************

# AXIS B

#*******************

setp pid.b.Pgain [JOINT_3]P

setp pid.b.Igain [JOINT_3]I

setp pid.b.Dgain [JOINT_3]D

setp pid.b.bias [JOINT_3]BIAS

setp pid.b.FF0 [JOINT_3]FF0

setp pid.b.FF1 [JOINT_3]FF1

setp pid.b.FF2 [JOINT_3]FF2

setp pid.b.deadband [JOINT_3]DEADBAND

setp pid.b.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.b.error-previous-target true

setp pid.b.maxerror .0005

net b-index-enable <=> pid.b.index-enable

net b-enable => pid.b.enable

net b-pos-cmd => pid.b.command

net b-vel-cmd => pid.b.command-deriv

net b-pos-fb <= pid.b.feedback

net b-output => pid.b.output

# Step Gen signals/setup

setp hm2_7i76e.0.stepgen.04.dirsetup [JOINT_3]DIRSETUP

setp hm2_7i76e.0.stepgen.04.dirhold [JOINT_3]DIRHOLD

setp hm2_7i76e.0.stepgen.04.steplen [JOINT_3]STEPLEN

setp hm2_7i76e.0.stepgen.04.stepspace [JOINT_3]STEPSPACE

setp hm2_7i76e.0.stepgen.04.position-scale [JOINT_3]STEP_SCALE

setp hm2_7i76e.0.stepgen.04.step_type 0

setp hm2_7i76e.0.stepgen.04.control-type 1

setp hm2_7i76e.0.stepgen.04.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp hm2_7i76e.0.stepgen.04.maxvel [JOINT_3]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net b-pos-cmd <= joint.3.motor-pos-cmd

net b-vel-cmd <= joint.3.vel-cmd

net b-output => hm2_7i76e.0.stepgen.04.velocity-cmd

net b-pos-fb <= hm2_7i76e.0.stepgen.04.position-fb

net b-pos-fb => joint.3.motor-pos-fb

net b-enable <= joint.3.amp-enable-out

net b-enable => hm2_7i76e.0.stepgen.04.enableSo as it is the loop gets closed on the MESA board.

Now I would like to use that stepgen on the MESA board for another axis and have the b-axis working only in software.

I'm guessing I need to somehow provide the pid with a position feedback to get the DRO to function.

Does anybody have an idea if it is possible to close that loop in HAL and get the DRO to function?

Last edit: 19 Apr 2020 16:54 by Aciera.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

19 Apr 2020 12:01 - 19 Apr 2020 12:10 #164631

by bbsr_5a

Replied by bbsr_5a on topic Using motorless B-axis in HAL only

as you say manuel it is not a 5Axis Kinetics

just 3+2 as of Fusion360

so Just use Trivial kinetics as it cand move on Auto at all

a Post 5Axis will move all axis simultan like Powermill

and as you set 5axis kinetics it uses RTCP Rotating Tool Center Pos that the machine cand do

so you will be in real trouble if the joints are not there

YOU shoudt go for a 4AXIs only

use GEOMETRY XYZC and you are fine

you can try to HACK with a own component

LOOK at THCUD it hacks the Z axis

z_pos_out = z_pos_in;

z_fb_out = z_pos_in; // keep axis motor position fb from being confused

just feed the Component with your B Axis

just 3+2 as of Fusion360

so Just use Trivial kinetics as it cand move on Auto at all

a Post 5Axis will move all axis simultan like Powermill

and as you set 5axis kinetics it uses RTCP Rotating Tool Center Pos that the machine cand do

so you will be in real trouble if the joints are not there

YOU shoudt go for a 4AXIs only

use GEOMETRY XYZC and you are fine

you can try to HACK with a own component

LOOK at THCUD it hacks the Z axis

z_pos_out = z_pos_in;

z_fb_out = z_pos_in; // keep axis motor position fb from being confused

just feed the Component with your B Axis

Attachments:

Last edit: 19 Apr 2020 12:10 by bbsr_5a. Reason: false info

Please Log in or Create an account to join the conversation.

- Aciera

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 4628

- Thank you received: 2049

19 Apr 2020 12:15 - 19 Apr 2020 12:27 #164632

by Aciera

Replied by Aciera on topic Using motorless B-axis in HAL only

I know my setup is not 5 axis simultaneous but rather 3+1.

However using trivial kinematics does not work here. It would work if the table were tilted as in your example. Then the tool would be perpendicular to the x and y joint/axis and circular interpolation would be possible with trivial kinematics.

But since we are tilting the tool in reference to the joints of the x and y- axis the interpolation plane is tilted by the angle of the swivel head and movements in x require two joints as do movements in z.

But anyway that was just to illustrate what I'm working on. The question was if it is possible to close the stepper loop in HAL or software and thus free up the needed step generator on the MESA board.

However using trivial kinematics does not work here. It would work if the table were tilted as in your example. Then the tool would be perpendicular to the x and y joint/axis and circular interpolation would be possible with trivial kinematics.

But since we are tilting the tool in reference to the joints of the x and y- axis the interpolation plane is tilted by the angle of the swivel head and movements in x require two joints as do movements in z.

But anyway that was just to illustrate what I'm working on. The question was if it is possible to close the stepper loop in HAL or software and thus free up the needed step generator on the MESA board.

Last edit: 19 Apr 2020 12:27 by Aciera.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7227

19 Apr 2020 12:44 #164635

by tommylight

Replied by tommylight on topic Using motorless B-axis in HAL only

This should work, you can set up a software stepgen with a base thread and use that for the axis that has not motor.

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

19 Apr 2020 21:49 #164675

by PCW

Replied by PCW on topic [solved] Using motorless B-axis in HAL only

You do not need the PID or stepgen to get the DRO to function

if you are displaying actual positions, you just need to loop the

commanded position back to the feedback position for the B axis:

net b-pos-loopback <= joint.3.motor-pos-cmd => joint.3.motor-pos-fb

if you are displaying actual positions, you just need to loop the

commanded position back to the feedback position for the B axis:

net b-pos-loopback <= joint.3.motor-pos-cmd => joint.3.motor-pos-fb

The following user(s) said Thank You: Aciera

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7227

19 Apr 2020 23:07 #164688

by tommylight

Thank you for confirming that.

Replied by tommylight on topic [solved] Using motorless B-axis in HAL only

I thought so but i was not sure, so i did not mention it.You do not need the PID or stepgen to get the DRO to function

if you are displaying actual positions, you just need to loop the

commanded position back to the feedback position for the B axis:

net b-pos-loopback <= joint.3.motor-pos-cmd => joint.3.motor-pos-fb

Thank you for confirming that.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

28 Aug 2020 11:34 #179815

by andypugh

I have been meaning to do this for years. How is it working out?

It might be worth configuring the swivel head as a locking indexer. Then you could use a slightly-modified hal_manualtoolchange to pop up a dialog box to ask for a new angle, and then continue the G-code.

See the joint-unlock pins here: linuxcnc.org/docs/2.8/html/man/man9/axis.9.html which would be used a bit like tool-change / tool-changed

Replied by andypugh on topic [solved] Using motorless B-axis in HAL only

I'm working on a mill with a manual swivel head, an indexing b-axis without a motor.

I have been meaning to do this for years. How is it working out?

It might be worth configuring the swivel head as a locking indexer. Then you could use a slightly-modified hal_manualtoolchange to pop up a dialog box to ask for a new angle, and then continue the G-code.

See the joint-unlock pins here: linuxcnc.org/docs/2.8/html/man/man9/axis.9.html which would be used a bit like tool-change / tool-changed

Please Log in or Create an account to join the conversation.

Time to create page: 0.181 seconds