linuxcnc+ethercat drives the AKD servo motor it cannot be moved

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 07:51 - 30 Jun 2021 07:56 #213316

by wang

linuxcnc+ethercat drives the AKD servo motor it cannot be moved was created by wang

hi everyone

linuxcnc+ethercat drives the AKD servo motor. After configuring ini, xml, hal files, it cannot be moved and the following deviation level fault occurs.

I think that because the motor cannot be rotated, but the position command can be executed, there is a deviation between the two (F439 follow-up deviation level fault)

Below is my configuration file

xml

<masters>

<master idx="0" appTimePeriod="1000000" refClockSyncCycles="5">

<slave idx="0" type="generic" vid="0000006a" pid="0x00414b44" configPdos="true">

<sdoConfig idx="6060" subIdx="0">

<sdoDataRaw data="08"/>

</sdoConfig>

<sdoConfig idx="60C2" subIdx="1">

<sdoDataRaw data="02"/>

</sdoConfig>

<syncManager idx="0" dir="out"></syncManager>

<syncManager idx="1" dir="in"></syncManager>

<syncManager idx="2" dir="out">

<pdo idx="1725">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="drivecontrol" halType="bit"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="poscommand" halType="float" scale="1000"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1B26">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="drivestatus" halType="bit"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="pos" halType="float" scale="1000"/>

</pdo>

</syncManager>

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="250000"/>

</slave>

</master>

</masters>

ini

# EMC controller parameters for a simulated machine.

# General note: Comments can either be preceded with a # or ; - either is

# acceptable, although # is in keeping with most linux config files.

# General section

[EMC]

# Version of this INI file

VERSION = 1.1

# Name of machine, for use with display, etc.

MACHINE = LinuxCNC-HAL-SIM-AXIS

# Debug level, 0 means no messages. See src/emc/nml_int/emcglb.h for others

#DEBUG = 0x7FFFFFFF

DEBUG = 0

# Sections for display options

[DISPLAY]

# Name of display program, e.g., axis

DISPLAY = axis

# Cycle time, in seconds, that display will sleep between polls

CYCLE_TIME = 0.100

# Path to help file

HELP_FILE = doc/help.txt

# Initial display setting for position, RELATIVE or MACHINE

POSITION_OFFSET = RELATIVE

# Initial display setting for position, COMMANDED or ACTUAL

POSITION_FEEDBACK = ACTUAL

# Highest value that will be allowed for feed override, 1.0 = 100%

MAX_FEED_OVERRIDE = 1.2

MAX_SPINDLE_OVERRIDE = 1.0

MAX_LINEAR_VELOCITY = 5

DEFAULT_LINEAR_VELOCITY = .25

DEFAULT_SPINDLE_SPEED = 200

# Prefix to be used

PROGRAM_PREFIX = ../../nc_files/

# Introductory graphic

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

#EDITOR = gedit

TOOL_EDITOR = tooledit

INCREMENTS = 1 in, 0.1 in, 10 mil, 1 mil, 1mm, .1mm, 1/8000 in

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Grayscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

# Task controller section

[TASK]

# Name of task controller program, e.g., milltask

TASK = milltask

# Cycle time, in seconds, that task controller will sleep between polls

CYCLE_TIME = 0.001

# Part program interpreter section

[RS274NGC]

# File containing interpreter variables

PARAMETER_FILE = sim.var

# Motion control section

[EMCMOT]

EMCMOT = motmod

# Timeout for comm to emcmot, in seconds

COMM_TIMEOUT = 1.0

# BASE_PERIOD is unused in this configuration but specified in core_sim.hal

BASE_PERIOD = 0

# Servo task period, in nano-seconds

SERVO_PERIOD = 1000000

# section for main IO controller parameters

[EMCIO]

# Name of IO controller program, e.g., io

EMCIO = io

# cycle time, in seconds

CYCLE_TIME = 0.100

# tool table file

TOOL_TABLE = sim.tbl

TOOL_CHANGE_POSITION = 0 0 0

TOOL_CHANGE_QUILL_UP = 1

# Hardware Abstraction Layer section

[HAL]

# The run script first uses halcmd to execute any HALFILE

# files, and then to execute any individual HALCMD commands.

#

# list of hal config files to run through halcmd

# files are executed in the order in which they appear

HALFILE = core_sim.hal

HALFILE = sim_spindle_encoder.hal

HALFILE = axis_manualtoolchange.hal

HALFILE = simulated_home.hal

HALFILE = check_xyz_constraints.hal

HALFILE = deltaPos.hal

# list of halcmd commands to execute

# commands are executed in the order in which they appear

#HALCMD = save neta

# Single file that is executed after the GUI has started. Only supported by

# AXIS at this time (only AXIS creates a HAL component of its own)

#POSTGUI_HALFILE = test_postgui.hal

HALUI = halui

# Trajectory planner section

[TRAJ]

COORDINATES = X Y Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 4

DEFAULT_LINEAR_ACCELERATION = 100

MAX_LINEAR_ACCELERATION = 100

POSITION_FILE = position.txt

[KINS]

KINEMATICS = trivkins

JOINTS = 3

# Axes sections

[AXIS_X]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

[AXIS_Y]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

[AXIS_Z]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -8.0

MAX_LIMIT = 0.12

# Joints sections

[JOINT_0]

TYPE = LINEAR

HOME = 0.000

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

FERROR = 0.050

MIN_FERROR = 0.010

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 1

HOME_IS_SHARED = 1

[JOINT_1]

TYPE = LINEAR

HOME = 0.000

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

FERROR = 0.050

MIN_FERROR = 0.010

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 1

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

MIN_LIMIT = -8.0

# Normally the Z max should be 0.000!

# The only reason it's greater than 0 here is so that the splash screen

# gcode will run.

MAX_LIMIT = 0.12

FERROR = 0.050

MIN_FERROR = 0.010

HOME_OFFSET = 1.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 0

HOME_IS_SHARED = 1

hal

loadusr -W lcec_conf /home/qxh-wyk/linuxcnc-dev/configs/sim/axis/deltaPos.xml

loadrt lcec

addf lcec.read-all servo-thread

addf lcec.write-all servo-thread

setp lcec.0.0.drivecontrol-1 1

setp lcec.0.0.drivecontrol-2 1

#net Xachse_fb lcec.0.0.pos => joint.0.motor-pos-fb

net Xpos => lcec.0.0.poscommand

net Xachse_AF joint.0.amp-enable-out => lcec.0.0.drivecontrol-0

net Xachse_AF => lcec.0.0.drivecontrol-3

net Xachse_AF => lcec.0.0.drivecontrol-5

I know my configuration is a bit simple, because I am a novice and need some help

At present, I can use the axis interface of linuxcnc to control the switch of AKD through ethercat, but I cannot control the motor rotation freely.

linuxcnc+ethercat drives the AKD servo motor. After configuring ini, xml, hal files, it cannot be moved and the following deviation level fault occurs.

I think that because the motor cannot be rotated, but the position command can be executed, there is a deviation between the two (F439 follow-up deviation level fault)

Below is my configuration file

xml

Warning: Spoiler!

<masters>

<master idx="0" appTimePeriod="1000000" refClockSyncCycles="5">

<slave idx="0" type="generic" vid="0000006a" pid="0x00414b44" configPdos="true">

<sdoConfig idx="6060" subIdx="0">

<sdoDataRaw data="08"/>

</sdoConfig>

<sdoConfig idx="60C2" subIdx="1">

<sdoDataRaw data="02"/>

</sdoConfig>

<syncManager idx="0" dir="out"></syncManager>

<syncManager idx="1" dir="in"></syncManager>

<syncManager idx="2" dir="out">

<pdo idx="1725">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="drivecontrol" halType="bit"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="poscommand" halType="float" scale="1000"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1B26">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="drivestatus" halType="bit"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="pos" halType="float" scale="1000"/>

</pdo>

</syncManager>

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="250000"/>

</slave>

</master>

</masters>

ini

Warning: Spoiler!

# EMC controller parameters for a simulated machine.

# General note: Comments can either be preceded with a # or ; - either is

# acceptable, although # is in keeping with most linux config files.

# General section

[EMC]

# Version of this INI file

VERSION = 1.1

# Name of machine, for use with display, etc.

MACHINE = LinuxCNC-HAL-SIM-AXIS

# Debug level, 0 means no messages. See src/emc/nml_int/emcglb.h for others

#DEBUG = 0x7FFFFFFF

DEBUG = 0

# Sections for display options

[DISPLAY]

# Name of display program, e.g., axis

DISPLAY = axis

# Cycle time, in seconds, that display will sleep between polls

CYCLE_TIME = 0.100

# Path to help file

HELP_FILE = doc/help.txt

# Initial display setting for position, RELATIVE or MACHINE

POSITION_OFFSET = RELATIVE

# Initial display setting for position, COMMANDED or ACTUAL

POSITION_FEEDBACK = ACTUAL

# Highest value that will be allowed for feed override, 1.0 = 100%

MAX_FEED_OVERRIDE = 1.2

MAX_SPINDLE_OVERRIDE = 1.0

MAX_LINEAR_VELOCITY = 5

DEFAULT_LINEAR_VELOCITY = .25

DEFAULT_SPINDLE_SPEED = 200

# Prefix to be used

PROGRAM_PREFIX = ../../nc_files/

# Introductory graphic

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

#EDITOR = gedit

TOOL_EDITOR = tooledit

INCREMENTS = 1 in, 0.1 in, 10 mil, 1 mil, 1mm, .1mm, 1/8000 in

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Grayscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

# Task controller section

[TASK]

# Name of task controller program, e.g., milltask

TASK = milltask

# Cycle time, in seconds, that task controller will sleep between polls

CYCLE_TIME = 0.001

# Part program interpreter section

[RS274NGC]

# File containing interpreter variables

PARAMETER_FILE = sim.var

# Motion control section

[EMCMOT]

EMCMOT = motmod

# Timeout for comm to emcmot, in seconds

COMM_TIMEOUT = 1.0

# BASE_PERIOD is unused in this configuration but specified in core_sim.hal

BASE_PERIOD = 0

# Servo task period, in nano-seconds

SERVO_PERIOD = 1000000

# section for main IO controller parameters

[EMCIO]

# Name of IO controller program, e.g., io

EMCIO = io

# cycle time, in seconds

CYCLE_TIME = 0.100

# tool table file

TOOL_TABLE = sim.tbl

TOOL_CHANGE_POSITION = 0 0 0

TOOL_CHANGE_QUILL_UP = 1

# Hardware Abstraction Layer section

[HAL]

# The run script first uses halcmd to execute any HALFILE

# files, and then to execute any individual HALCMD commands.

#

# list of hal config files to run through halcmd

# files are executed in the order in which they appear

HALFILE = core_sim.hal

HALFILE = sim_spindle_encoder.hal

HALFILE = axis_manualtoolchange.hal

HALFILE = simulated_home.hal

HALFILE = check_xyz_constraints.hal

HALFILE = deltaPos.hal

# list of halcmd commands to execute

# commands are executed in the order in which they appear

#HALCMD = save neta

# Single file that is executed after the GUI has started. Only supported by

# AXIS at this time (only AXIS creates a HAL component of its own)

#POSTGUI_HALFILE = test_postgui.hal

HALUI = halui

# Trajectory planner section

[TRAJ]

COORDINATES = X Y Z

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 4

DEFAULT_LINEAR_ACCELERATION = 100

MAX_LINEAR_ACCELERATION = 100

POSITION_FILE = position.txt

[KINS]

KINEMATICS = trivkins

JOINTS = 3

# Axes sections

[AXIS_X]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

[AXIS_Y]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

[AXIS_Z]

MAX_VELOCITY = 4

MAX_ACCELERATION = 100.0

MIN_LIMIT = -8.0

MAX_LIMIT = 0.12

# Joints sections

[JOINT_0]

TYPE = LINEAR

HOME = 0.000

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

FERROR = 0.050

MIN_FERROR = 0.010

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 1

HOME_IS_SHARED = 1

[JOINT_1]

TYPE = LINEAR

HOME = 0.000

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

FERROR = 0.050

MIN_FERROR = 0.010

MIN_LIMIT = -10.0

MAX_LIMIT = 10.0

HOME_OFFSET = 0.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 1

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

MAX_VELOCITY = 5

MAX_ACCELERATION = 50.0

BACKLASH = 0.000

INPUT_SCALE = 4000

OUTPUT_SCALE = 1.000

MIN_LIMIT = -8.0

# Normally the Z max should be 0.000!

# The only reason it's greater than 0 here is so that the splash screen

# gcode will run.

MAX_LIMIT = 0.12

FERROR = 0.050

MIN_FERROR = 0.010

HOME_OFFSET = 1.0

HOME_SEARCH_VEL = 20.0

HOME_LATCH_VEL = 20.0

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = NO

HOME_SEQUENCE = 0

HOME_IS_SHARED = 1

hal

Warning: Spoiler!

loadusr -W lcec_conf /home/qxh-wyk/linuxcnc-dev/configs/sim/axis/deltaPos.xml

loadrt lcec

addf lcec.read-all servo-thread

addf lcec.write-all servo-thread

setp lcec.0.0.drivecontrol-1 1

setp lcec.0.0.drivecontrol-2 1

#net Xachse_fb lcec.0.0.pos => joint.0.motor-pos-fb

net Xpos => lcec.0.0.poscommand

net Xachse_AF joint.0.amp-enable-out => lcec.0.0.drivecontrol-0

net Xachse_AF => lcec.0.0.drivecontrol-3

net Xachse_AF => lcec.0.0.drivecontrol-5

I know my configuration is a bit simple, because I am a novice and need some help

At present, I can use the axis interface of linuxcnc to control the switch of AKD through ethercat, but I cannot control the motor rotation freely.

Last edit: 30 Jun 2021 07:56 by wang.

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

30 Jun 2021 09:01 #213321

by db1981

Replied by db1981 on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

Hi,

is linuxcnc showing the correct position if you turn the motor shaft by hand (scaling...)

please show your complete halfile.

is linuxcnc showing the correct position if you turn the motor shaft by hand (scaling...)

please show your complete halfile.

The following user(s) said Thank You: wang

Please Log in or Create an account to join the conversation.

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 09:09 #213322

by wang

Replied by wang on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

No, rotate the motor manually, linuxcnc has no feedback

The above hal is my completed hal file

I am a newbie and look forward to your guidance

The above hal is my completed hal file

I am a newbie and look forward to your guidance

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

30 Jun 2021 10:50 - 30 Jun 2021 10:52 #213327

by db1981

Replied by db1981 on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

hi,

you have to move this lines:

loadusr -W lcec_conf /home/qxh-wyk/linuxcnc-dev/configs/sim/axis/deltaPos.xml

loadrt lcec

addf lcec.read-all servo-thread

addf lcec.write-all servo-thread

to the core_sim.hal. At the actual placement in your hal structure, the values from ethercat are not recognized by linuxcnc's motion part...

put "addf lcec.read-all servo-thread" as the first line in front of all others addf's commands. and "addf lcec.write-all servo-thread" as the last.

read here : forum.linuxcnc.org/24-hal-components/223...er?start=1270#212470

you have to move this lines:

loadusr -W lcec_conf /home/qxh-wyk/linuxcnc-dev/configs/sim/axis/deltaPos.xml

loadrt lcec

addf lcec.read-all servo-thread

addf lcec.write-all servo-thread

to the core_sim.hal. At the actual placement in your hal structure, the values from ethercat are not recognized by linuxcnc's motion part...

put "addf lcec.read-all servo-thread" as the first line in front of all others addf's commands. and "addf lcec.write-all servo-thread" as the last.

read here : forum.linuxcnc.org/24-hal-components/223...er?start=1270#212470

Last edit: 30 Jun 2021 10:52 by db1981.

The following user(s) said Thank You: wang

Please Log in or Create an account to join the conversation.

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 11:04 #213328

by wang

Replied by wang on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

Thank you for your guidance, I will try it, thank you very much

Please Log in or Create an account to join the conversation.

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 11:33 - 30 Jun 2021 11:36 #213332

by wang

Replied by wang on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

hi

According to your guidance I will

These lines are moved to core_sim.hal

Is still placed in deltaPos.hal

Although the rotation is not controlled, it is obvious that the shaft is braked. This is different from the previous feeling. Thank you for your guidance.

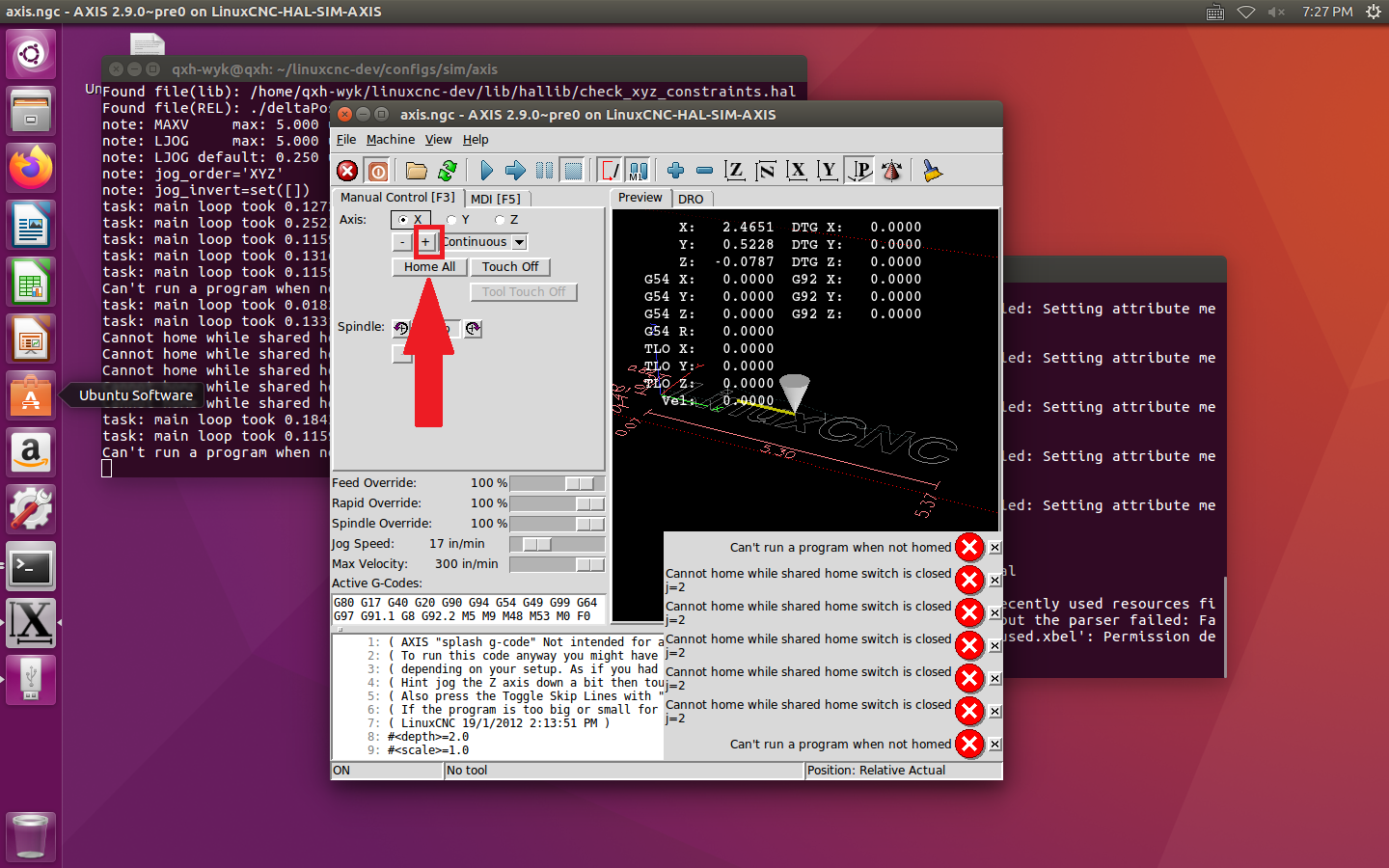

For single-axis testing, should I click this plus sign to see if the motor turns

According to your guidance I will

loadusr -W lcec_conf /home/qxh-wyk/linuxcnc-dev/configs/sim/axis/deltaPos.xml

loadrt lcec addf

lcec.read-all servo-threadThese lines are moved to core_sim.hal

addf lcec.write-all servo-threadAlthough the rotation is not controlled, it is obvious that the shaft is braked. This is different from the previous feeling. Thank you for your guidance.

For single-axis testing, should I click this plus sign to see if the motor turns

Attachments:

Last edit: 30 Jun 2021 11:36 by wang.

Please Log in or Create an account to join the conversation.

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 11:39 #213334

by wang

Replied by wang on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

By the way, my operating environment is

Ubuntu16.04+manually build linuxcnc2.9

Ubuntu16.04+manually build linuxcnc2.9

Please Log in or Create an account to join the conversation.

- wang

- Offline

- Premium Member

-

Less

More

- Posts: 85

- Thank you received: 0

30 Jun 2021 19:40 #213357

by wang

Replied by wang on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

The following is part of the results of dmesg, whether there is an error that caused the motor to be unable to control the rotation

Attachments:

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

30 Jun 2021 20:11 #213363

by db1981

Replied by db1981 on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

dmesg reads ok ....

i think its an scaling problem.

do you get position feedback if you start linuxcnc (do not enable the motor) and turn the shaft by hand?

i think its an scaling problem.

do you get position feedback if you start linuxcnc (do not enable the motor) and turn the shaft by hand?

Please Log in or Create an account to join the conversation.

- db1981

- Offline

- Platinum Member

-

Less

More

- Posts: 790

- Thank you received: 276

30 Jun 2021 20:30 #213367

by db1981

Replied by db1981 on topic linuxcnc+ethercat drives the AKD servo motor it cannot be moved

normaly scaling should be so:

-reading (posfeedback)

scale = 0.001 (1000 incs = 1 Machine Unit)

inside lcec : sint_to_float -> raw_value; raw_value * scale =hal_value

-writing (pos command)

scale = 1000 (1 Machine Unit = 1000 incs [enc_counts])

inside lcec : hal_value * scale = raw_value; raw_value ->float_to_sint

-reading (posfeedback)

scale = 0.001 (1000 incs = 1 Machine Unit)

inside lcec : sint_to_float -> raw_value; raw_value * scale =hal_value

-writing (pos command)

scale = 1000 (1 Machine Unit = 1000 incs [enc_counts])

inside lcec : hal_value * scale = raw_value; raw_value ->float_to_sint

Please Log in or Create an account to join the conversation.

Time to create page: 0.164 seconds