Auto tool measurement options

- guitarcarrot

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

29 Mar 2024 22:11 #297150

by guitarcarrot

Auto tool measurement options was created by guitarcarrot

I'm looking to implement an auto tool measurement routine into my machine, there are a couple of options that I'm aware of, and likely several others that I'm unaware of.

1. Built in gmoccapy tool measurement

This seems a little unintuitive to me, but likely due to ignorance on my part.

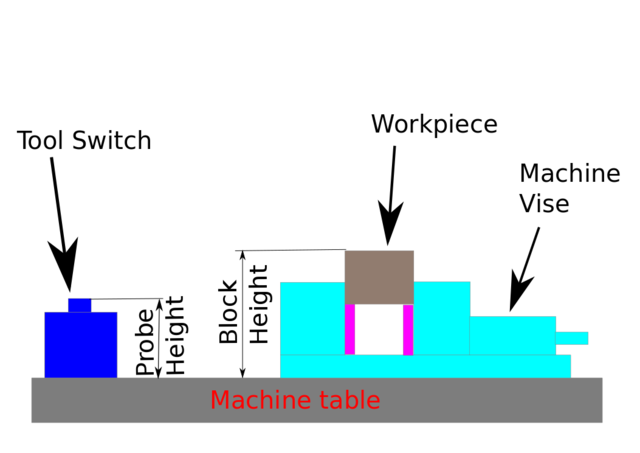

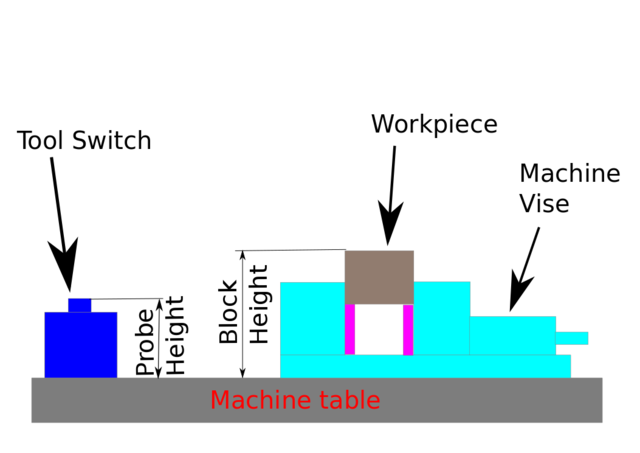

Using the machine table surface as a datum of sorts and measuring block height seems unnecessary to me

2. Orangecat Method (Also detailed here: PrintNC )

This seems much more intuitive to me:Sequence of operations for Running g-code;

In an ideal world I'd like a workflow something like the following, does this exist?

1. Insert probe into spindle, touch off on tool sensor

2. Run probing cycles on the stock

3. Insert the first tool into the spindle, touch off on tool sensor. run code until tool change required

4. Spindle is raised to change position, change tool, touch off on tool sensor, continue until next tool change

5. Repeat as required.

What other options are there?

1. Built in gmoccapy tool measurement

This seems a little unintuitive to me, but likely due to ignorance on my part.

Using the machine table surface as a datum of sorts and measuring block height seems unnecessary to me

2. Orangecat Method (Also detailed here: PrintNC )

This seems much more intuitive to me:Sequence of operations for Running g-code;

- Using a T99, a .250" Rod, touch off X, Y, and Z of WCS as modeled in CAM

- Manually input M600 on MDI screen

- Manually call an M6 T99, tool will touch off on toolsetter and store tool height

- Load program and run, M6 in program will prompt tool change, after changing, tool will touch off and Z will adjust

- Run any and all code using the same desired Z height for the WCS as designed

- For new WCS repeat from Step #1

- Touches each tool off to the tool height sensor.

- The first tool is used as the reference, all subsequent tools adjust the tool offset.

- Tool is moved away by raising Z to _TravelZ before moving towards the Tool Setter XY Coordinates, and when moving back from the switch again moves at height _TravelZ before going straight back down to the original position.

- Sets all necessary modes to ensure correct operation no matter what state the program is in when this is called. We eliminate almost all side effects by saving and restoring the modal state.

In an ideal world I'd like a workflow something like the following, does this exist?

1. Insert probe into spindle, touch off on tool sensor

2. Run probing cycles on the stock

3. Insert the first tool into the spindle, touch off on tool sensor. run code until tool change required

4. Spindle is raised to change position, change tool, touch off on tool sensor, continue until next tool change

5. Repeat as required.

What other options are there?

Please Log in or Create an account to join the conversation.

- zmrdko

-

- Offline

- Elite Member

-

Less

More

- Posts: 185

- Thank you received: 49

13 Apr 2024 20:19 #298200

by zmrdko

Replied by zmrdko on topic Auto tool measurement options

Do you have an ATC spindle? Or do you manually change tools with collets in spindle?

Please Log in or Create an account to join the conversation.

- Hendrixx

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 27

19 Jun 2024 09:24 #303342

by Hendrixx

Replied by Hendrixx on topic Auto tool measurement options

I set up a macro that moves the spindle to a safe place and calls t99. I probe my wcs then press another macro button to get the probe height off the tool setter. Then run the program using a modified post I made that removes any g43 or H codes.

I think you could write all this into a program you added to to the front of your posts that asks you to install probe then asked you to define x with the probe then y then z then set the probe height off the tool setter and was just a part of each program you run.

But that would prolly take some custom m codes and hal magic.

I think you could write all this into a program you added to to the front of your posts that asks you to install probe then asked you to define x with the probe then y then z then set the probe height off the tool setter and was just a part of each program you run.

But that would prolly take some custom m codes and hal magic.

Please Log in or Create an account to join the conversation.

Time to create page: 0.066 seconds