Sherline Lathe Conversion ?

- currinh

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 1

I've been thinking of the interface to a parallel port, but that is not the case. The Gecko G540 is doing some interfacing and I'm not sure, from the manual, just what. I emailed Gecko but they haven't gotten back to me. The manual shows the G540 input switches (i.e. limit switches) directly switching the input pins to ground. I have a G540 so I measured an input pin to ground. Open voltage is 11 V and the shorted current is 7 mA. I think it should be OK to directly connect the encoder or slotted optical switches, both open collector, directly to the G540. We'll see when the parts show up.

Iron-Man: As I said, I ordered the e-Bay encoder from China. Right or wrong we'll see if it works.

I want to see the encoder before going too far with the mounting design. I have some XL pinion stock what I plan to cut the pulleys from. Likely just use a set screw on the encoder pulley and screw the spindle pulley to the Sherline pulley using a bolt circle. That's the plan but haven't looked at sizes yet. Worse comes to worse I'll order two pulleys and a belt from SPD/SI. Should be OK as long as the two pulleys are the same diameter / # teeth.

Thank you both for your help. Great instructions and I haven't even gotten to the Linuxcnc configuration yet.

Thanks.

Hugh

Klamath Falls, OR, USA

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

I want to see the encoder before going too far with the mounting design. I have some XL pinion stock what I plan to cut the pulleys from. Likely just use a set screw on the encoder pulley and screw the spindle pulley to the Sherline pulley

I have wondered if a speedometer drive would work:

www.beedspeed.com/images/Speedo_drive_kit_metal.gif

The problem would be to find one that was exactly 1:1, but the dissimilar sizes of driver and driven might be useful.

Please Log in or Create an account to join the conversation.

- currinh

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 1

I have wondered if a speedometer drive would work:

www.beedspeed.com/images/Speedo_drive_kit_metal.gif

The problem would be to find one that was exactly 1:1, but the dissimilar sizes of driver and driven might be useful.

Hmm. For a spindle, the P/R of standard encoders seems in the ball park. How would slowing, or speeding, the sensor shaft help? I always think of gears as introducing backlash, but for a spindle only rotating one direction it wouldn't matter. One could put a hall effect or optical sensor directly on the spindle for a Z pulse. You'd want a constant pulse stream so consider this when picking a gear ratio. As an extreme example consider a speed ratio of 1.111 (20:18 gears) and a 4 P/R encoder. This gives 4.444 P/R at the spindle which gives one uneven pulse using a Z on the spindle. A 1.25 radio (20:16) would give 5 P/R for an even pulse spacing. I don't know enough about LinucCNC to know if this is a potential problem or not.

Thanks.

Hugh

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Hmm. For a spindle, the P/R of standard encoders seems in the ball park. How would slowing, or speeding, the sensor shaft help?

It would rarely help. Running at half-speed would be OK, as the index would still happen at a consistent angle, you might just have to wait longer for one. Anything non-integer would require a separate index from a sensor on the spindle.

This gives 4.444 P/R at the spindle which gives one uneven pulse using a Z on the spindle. A 1.25 radio (20:16) would give 5 P/R for an even pulse spacing. I don't know enough about LinucCNC to know if this is a potential problem or not

In practice it wouldn't matter except, possibly for gear hobbing.

For threading the encoder is zeroed at the start of each pass. The calculations are done in double-precision floating-point, with at least 15 digits of precision. For any plausible length of thread you would not see the rounding errors. But the HA/INI file should probably have at least 8 digits for non-integer scales.

Please Log in or Create an account to join the conversation.

- currinh

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 1

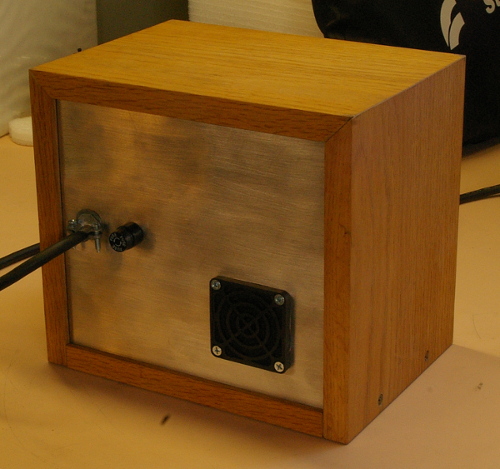

The separate DB25 plug at the upper right brings out the G540 terminal block and 5v supply.

The Lathe is so far a plain vanilla Sherline CNC conversion.

I'll likely build a stand and then decide how far I have to extend the stepper leads. Also decide lengths for the encoder and limit switch leads.

I ordered some slotted optical switches before ordering the encoder. These arrived from Newark a day or two ago. I hooked up the LED side to the 5V supply with a 250 ohm resistor (20mA). Then connected the open collector output directly to one of the G540 inputs and its ground. Using HALmeter I was able to monitor the parallel port line and see that it was switching. There was joy. Sounds simple, but with dumb wiring errors and other trial & error it took me some time.

I'm sure I'll have LinuxCNC questions once the encoder is mounted. I'm also starting to believe running a CNC lathe isn't trivial either, so I'll likely have some questions there also.

Thanks.

Hugh

Klamath Falls, OR, USA

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

JT

Please Log in or Create an account to join the conversation.

- currinh

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 1

I've made some progress, mostly in learning how to run a CNC lathe. Seems a different ball game than a mill. It's only two axes, instead of three, so how could it be difficult? I set off learning the new turning portion of CamBam. It's not nearly as polished as the milling portion but eventually seemed workable. I couldn't get the roughing lead in moves to work, but that's a topic for the CamBam Forum. CamBam came with a LinuxCNC-turn post processor which I used without modification.

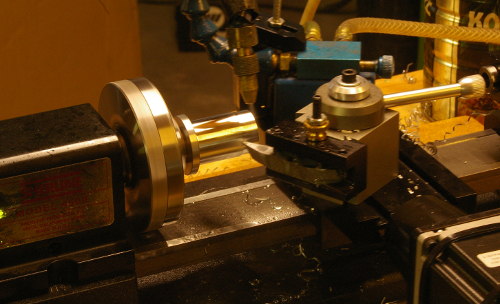

I had some learning difficulties, such as grabbing a scrap round of AL 1.5" diam saying that'll be large enough. The CAM was developed assuming a 1.25" stock. It didn't take too long to remember I had to cut the stock to 1.25". Then I had to come to grips with the Sherline. I have a 14" Goodway manual lathe and it took some experimenting to discover just how much less the Sherline can take off. After that it worked well. Here's a shot of the lathe during first cut.

The resulting part is one post of a towel rack for our trailer. There's a bobble around the flange, but I'm declaring it a good part.

The slow boat from China did show up on our shores delivering a new encoder.

It is the same one mentioned above. It'll take some time to design and build the mounting, too many things getting in the way. But that is the plan. Then wire in the Sherline spindle speed control and maybe homing switches, although I may be OK without the switches. One step at a time.

I need to write this up if it isn't a know issue. I loaded LinuxCNC in simulation mode trying to track down some CamBam/G-Code questions. It seemed that LinuxCNC was rounding corners during rapid moves. I didn't notice it while machining but it was disconcerting to notice in simulation. The arcs are much bigger than a tool compensation would account for and the G Code had only sharp corners. If this seems unusual let me know and I'll start a thread on it.

Thanks.

Hugh

Klamath Falls, OR, USA

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

I need to write this up if it isn't a know issue. I loaded LinuxCNC in simulation mode trying to track down some CamBam/G-Code questions. It seemed that LinuxCNC was rounding corners during rapid moves

It does that. The degree to which it does it is partly governed by the acceleration settings of the machine, and perhaps those are low in the simulator config you were looking at. I think that the G64 (etc) settings can also have a bearing on this, even in rapid moves.

Please Log in or Create an account to join the conversation.

- currinh

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 60

- Thank you received: 1

I have thought about it. What's stopped me is the cost of ball screws/etc, not having a lathe during the retrofit, the concept of cramming a ball screw into the cross slide, and not knowing if a cnc lathe is worthwhile for one off hobby use. The Sherline is a test to see if one is worthwhile. If worthwhile, and the Sherline is too small, I'll likely start again with an 8" class lathe. Ha, you asked so there.For your next trick, convert the Goodway to CNC

It does that. The degree to which it does it is partly governed by the acceleration settings of the machine, and perhaps those are low in the simulator config you were looking at. I think that the G64 (etc) settings can also have a bearing on this, even in rapid moves.I loaded LinuxCNC in simulation mode trying to track down some CamBam/G-Code questions. It seemed that LinuxCNC was rounding corners during rapid moves

OK, not a problem then. I guess rounding corners on rapids shouldn't hurt anything. It was a surprise when I noticed it though.

Thanks.

Hugh

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

What's stopped me is the cost of ball screws/etc, not having a lathe during the retrofit, the concept of cramming a ball screw into the cross slide, and not knowing if a cnc lathe is worthwhile for one off hobby use.

I think it is. So much so that I am part-way through my second conversion.

The first was a Chinese 9x20 lathe done on-the-cheap with steppers.

This time I am doing it "right" and have spent more on castings alone than the entire Chinese conversion cost.

I am blogging the process: bodgesoc.blogspot.co.uk/2015/08/holbrook1.html

Please Log in or Create an account to join the conversation.