Myford Super 7 Lathe CNC Conversion anyone?

- racedirector

- Offline

- Elite Member

-

- Posts: 231

- Thank you received: 42

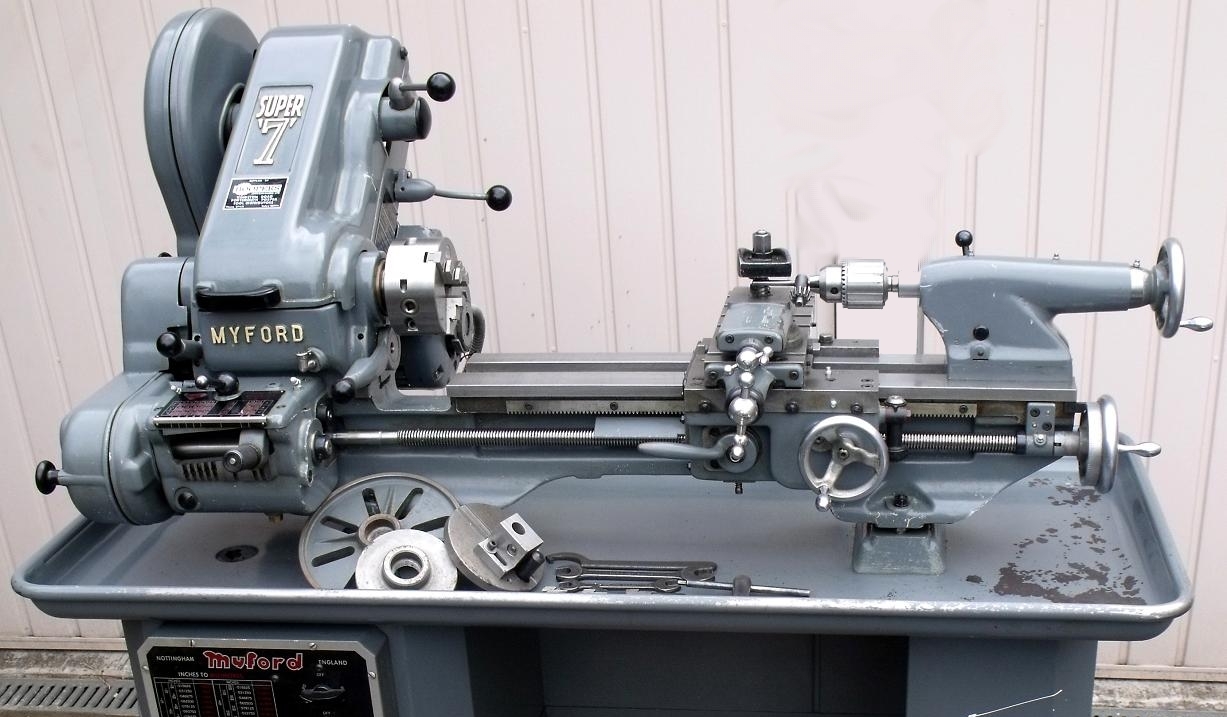

Today I scored a Myford Super 7 lathe for free, I pick it up on Thursday this week. Immediately I thought of converting it to CNC and found some info on it at this site: www.jeffree.co.uk/modelengineering.html

The pic attached is just a general one I found on the web, not my actual machine.

Of course I plan to use LCNC under Pathpilot to run it instead of Mach3 so I was wondering if anyone has completed a conversion on one of these lathes? Would be interested in any feedback anyone could offer.

Cheers

Bruce

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11526

- Thank you received: 3860

www.jeffree.co.uk/pages/ml7-cnc/part-1-files/myfordcncpt1.htm

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

- Posts: 231

- Thank you received: 42

I have 4x 425oz-in Nema 23's from my old router, just need some controllers to run them and would probably use my PMDX-126 on it once I get my 5i25 and 7i76 to run my router. My wife thinks it s great idea to CNC the lathe, she doesn't particularly like the idea of a spinning chuck and a sliding tool controlled by me

Please Log in or Create an account to join the conversation.

- Einar

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 1

The backlash is much smaller. You may even come out cheaper, as the ballscrews have a much lower friction.

So you can get away with smaller steppers and drives. Or, alternatively get more acceleration and speed from the same size stepper & drive. Both come in handy when screwcutting.

Controlled by you!? I'm not so sure about that. I had a tool crash today on the CNC lathe. I cannot remember last time I had one on my manual lathes. Probably >40 years ago. After forgetting the G43 after a toolchange, never issue a G0!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19717

- Thank you received: 4573

Would be interested in any feedback anyone could offer.

Myford lathes seem to have a value quite out of proportion to their utility.

It might be better to clean up and fix the Myford (if needed) and buy something else to convert with the money.

The "something else" should not be a brand-new Chinese lathe, trust me on this

Basllscrews are cheap enough that there really isn't a good reason not to use them:

www.zappautomation.co.uk/mechanical-prod...t3-fsid-ballnut.html

If you convert the Myford, don't mess about. Just plan on totally replacing the feeds gearbox and the apron.

If you can make wooden patterns then one-off iron castings are probably cheaper than you think. You can probably have a custom CNC apron for £30

This is the write-up of my Holbrook conversion. But note that I was doing it for fun, and many of the choices I made were barely rational. bodgesoc.blogspot.co.uk/search/label/Hol...20Phase%20Conversion (and the other 7 installments)

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

- Posts: 231

- Thank you received: 42

I have seen quite a few of them for sale in the UK at what look like expensive pricing but I have never seen one for sale in Australia. Lathes here, even second hand, are horribly expensive which is why I was so quick to pick this one up for free. Having never owned one, and the last time I used one was in school 40+ years ago, this is more of a learning tool. Once I get it home and see what condition it is in I will decide what comes next.Myford lathes seem to have a value quite out of proportion to their utility.

Oh yea, I know what that means and fully trust you on that one!The "something else" should not be a brand-new Chinese lathe, trust me on this

I actually have a couple of 16mm ballscrews I was going to use on my old router and they have been just sitting there waiting for something to do. I also want to add a VFD to allow LCNC control of that too.Basllscrews are cheap enough that there really isn't a good reason not to use them:

www.zappautomation.co.uk/mechanical-prod...t3-fsid-ballnut.html

If you convert the Myford, don't mess about. Just plan on totally replacing the feeds gearbox and the apron.

Have never done any casting in my life, not sure where to start with that one.If you can make wooden patterns then one-off iron castings are probably cheaper than you think. You can probably have a custom CNC apron for £30

I found a site that sells parts and kits for actually CNCing the Super 7, its a British guy but the prices are serious money: cncyourmyford.com

If anything I would buy the spindle speed encoder from him but at around $500 AUD its a little out of my league right now.

Thanks for that, will have a good read of what you did.This is the write-up of my Holbrook conversion. But note that I was doing it for fun, and many of the choices I made were barely rational. bodgesoc.blogspot.co.uk/search/label/Hol...20Phase%20Conversion (and the other 7 installments)

Cheers

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

- Posts: 231

- Thank you received: 42

I have a couple of 16mm ballscrews already from a forgotten project on my previous router just waiting to be used.Go for ballscrews! Even if getting a cheap chinese one.

The backlash is much smaller. You may even come out cheaper, as the ballscrews have a much lower friction.

So you can get away with smaller steppers and drives. Or, alternatively get more acceleration and speed from the same size stepper & drive. Both come in handy when screw cutting.

Ouch! something to take note of!Controlled by you!? I'm not so sure about that. I had a tool crash today on the CNC lathe. I cannot remember last time I had one on my manual lathes. Probably >40 years ago. After forgetting the G43 after a toolchange, never issue a G0!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11526

- Thank you received: 3860

Anyway, if you did decide to sell it, stick it on eBay with $0.99c starting bid and it will go crazy I am sure! I did this with my old lathe and made sure I had a mate to help it along if it did not get to $500 but he never needed to make a bid. It went for $1k and that was what I paid for it a few years earlier.Once it gets off the ground, and people see a few bids on it, they get carried away....

I have the Chinese AL320G which is a 13" swing and 38mm spindle and once you get up to that size, they are surprisingly accurate and robust. I just did not have the floor space to go up another size which would have given me the DI4 chuck which I really wanted. I have seen one CNC'd somewhere.

Anyway I digress, If I was going to make a new saddle for a lathe, I think I would buy a slab of cast Iron. I bought a couple of slices 165mm dia x 30mm thick and it cost $25 a piece. Machined very quickly (in a very messy sort of way). I got it from George Weston in Brissy but not sure if they are in other states.

If you can make a pattern, talk to White Industries in Dalby, QLD. I've been talking to them about casting a part recently and while we have not finalised the design, the cost did not sound too scary (but I'm selling 20-30 a month)...

Please Log in or Create an account to join the conversation.

- racedirector

- Offline

- Elite Member

-

- Posts: 231

- Thank you received: 42

Had a quick look on the local eBay and found 1 Super 7 that he wants $2800 for.... no bids but 31 watchers!

As I have said this is the first lathe I will have ever owned and, to be honest, I am not sure what I am going to do with it. I do plan to bore out some new pinions for my Mechmate plus bore some more pullies for my belt drives to 12.7mm. Other than that I don't have a lot of plans for it.... but you never know. Maybe I can use it in conjunction with my woodworking.

Still interested in possibly CNC it so far......

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11526

- Thank you received: 3860

Thanks Rod

Had a quick look on the local eBay and found 1 Super 7 that he wants $2800 for.... no bids but 31 watchers!

Yes, thats where people go wrong on eBay. Everybody wants a bargain but there are so many bidders there are none! So if he had faith in the auction system, with that number of watchers he would have sold it at or beyond his ask... the watchers would have been happy becasue they would have had at least 1 bid each!

I did think of taking up pen turning on my lathe. Plenty of stuff on Youtube. Just an idea...

Please Log in or Create an account to join the conversation.