Tool table set up.

- usert_l

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 2

06 Oct 2019 16:59 #147271

by usert_l

Tool table set up. was created by usert_l

Hello,

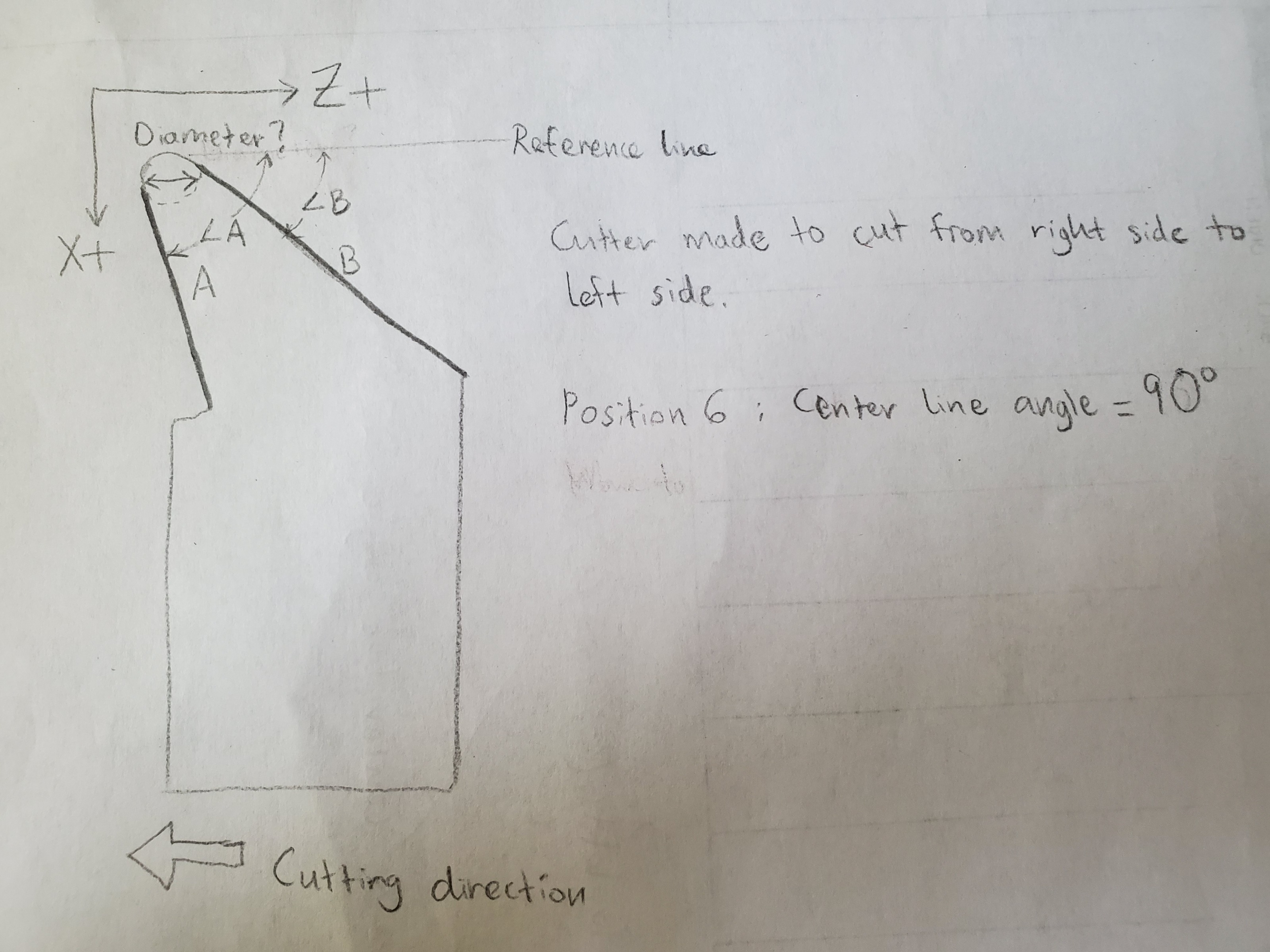

Regarding the tool table setup, I am still a little confused about how to determine which side of the cutting tool makes for the front angle and which side makes up for the back angle. I do understand the tool position and center line angle; those seem pretty straightforward based on the Figure 3.33 in the LinuxCNC document.

I attached a drawing for a tool mounted on the lathe's cross slide. It's a normal tool mounted in front to the stock and cut from right side to left side. In this case, how to I determine which of A or B is the front and the other is the back so that I can figure out the frontangle and backangle? Also, the diameter of the tool is just simply the diameter of the cutting tip, does that sound correct?

Regarding the tool table setup, I am still a little confused about how to determine which side of the cutting tool makes for the front angle and which side makes up for the back angle. I do understand the tool position and center line angle; those seem pretty straightforward based on the Figure 3.33 in the LinuxCNC document.

I attached a drawing for a tool mounted on the lathe's cross slide. It's a normal tool mounted in front to the stock and cut from right side to left side. In this case, how to I determine which of A or B is the front and the other is the back so that I can figure out the frontangle and backangle? Also, the diameter of the tool is just simply the diameter of the cutting tip, does that sound correct?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

09 Oct 2019 03:47 #147528

by andypugh

Replied by andypugh on topic Tool table set up.

I think your diagram is correct, with A as frontangle and B as backangle.

It isn't particularly critical at the moment, as they only matter for the graphical preview, LinuxCNC does not currently use them for anything (but may in future, there are experimental G71 routines out there that use the angles.

The diameter does matter if you are using cutter compensation, but even then only for cuts that are not pure X or pure Z. With the wrong tool tip radius fillets and radii will have fractionally wrong radius sizes. Though this very rarely maters.

It isn't particularly critical at the moment, as they only matter for the graphical preview, LinuxCNC does not currently use them for anything (but may in future, there are experimental G71 routines out there that use the angles.

The diameter does matter if you are using cutter compensation, but even then only for cuts that are not pure X or pure Z. With the wrong tool tip radius fillets and radii will have fractionally wrong radius sizes. Though this very rarely maters.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.381 seconds