Starting from scratch (again) - Spindle encoder Question

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

15 Dec 2019 03:02 #152671

by mooser

Starting from scratch (again) - Spindle encoder Question was created by mooser

Planning a mach to linuxcnc conversion and with a ton of help here have made it up to the spindle encoder.

Currently the machine has a disc with a single slot read by a c3 pulse index card fed to an c11g control board.

New system is using a 6i25 and 7i76

I've been reading a lot about different encoders being used and I'm not sure if what I'm wanting and what I'm needing are matching up.

1, need to thread on the lathe so an index is needed.

I believe the single slot disc that's currently on the machine could simple be used to supply that basically the way it is. The c3 card really seemed to be a signal conditioning thing more or less so I could probably dump that in the conversion.

Spindle speed... here's where I'm not so sure. I would certainly like to have some RPM feedback (and hopefully linuxcnc can do some closed loop type work for me to maintain speeds?)

The machine has a 6 speed gearbox (low and high range with 3 steps in each) but it seems that where mach had a place to setup gear easily, linuxcnc has only 2, I haven't really looked too far into that yet, I'm hoping it's not a deal breaker this far in.

Anyway, the spindle is a through hole style so I can't mount a normal (cheap) quad encoder but I could machine a new slotted or drilled disc to fit onto the outside of the rear spindle tube with X number of slots/holes (have read 60 or 100 or 120, I'll have to see what the smallest slot / hole I could get away with would be I guess) and could probably add another sensor in a different path to pick up an index slot/hole

Would this be sufficient or do I need something else? Benefits? drawbacks?

Can the 7i76 / linuxcnc deal with two sensors (speed-RPM and index for threading)

Looking at the manual it says one channel encoder with index which I'm thinking I should be able to feed one sensor to encoder A and the other to Index or am I completely under-thinking that?

Guess it's time to deal with the gears as well

M

Currently the machine has a disc with a single slot read by a c3 pulse index card fed to an c11g control board.

New system is using a 6i25 and 7i76

I've been reading a lot about different encoders being used and I'm not sure if what I'm wanting and what I'm needing are matching up.

1, need to thread on the lathe so an index is needed.

I believe the single slot disc that's currently on the machine could simple be used to supply that basically the way it is. The c3 card really seemed to be a signal conditioning thing more or less so I could probably dump that in the conversion.

Spindle speed... here's where I'm not so sure. I would certainly like to have some RPM feedback (and hopefully linuxcnc can do some closed loop type work for me to maintain speeds?)

The machine has a 6 speed gearbox (low and high range with 3 steps in each) but it seems that where mach had a place to setup gear easily, linuxcnc has only 2, I haven't really looked too far into that yet, I'm hoping it's not a deal breaker this far in.

Anyway, the spindle is a through hole style so I can't mount a normal (cheap) quad encoder but I could machine a new slotted or drilled disc to fit onto the outside of the rear spindle tube with X number of slots/holes (have read 60 or 100 or 120, I'll have to see what the smallest slot / hole I could get away with would be I guess) and could probably add another sensor in a different path to pick up an index slot/hole

Would this be sufficient or do I need something else? Benefits? drawbacks?

Can the 7i76 / linuxcnc deal with two sensors (speed-RPM and index for threading)

Looking at the manual it says one channel encoder with index which I'm thinking I should be able to feed one sensor to encoder A and the other to Index or am I completely under-thinking that?

Guess it's time to deal with the gears as well

M

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 569

- Thank you received: 110

15 Dec 2019 14:38 #152688

by JohnnyCNC

Replied by JohnnyCNC on topic Starting from scratch (again) - Spindle encoder Question

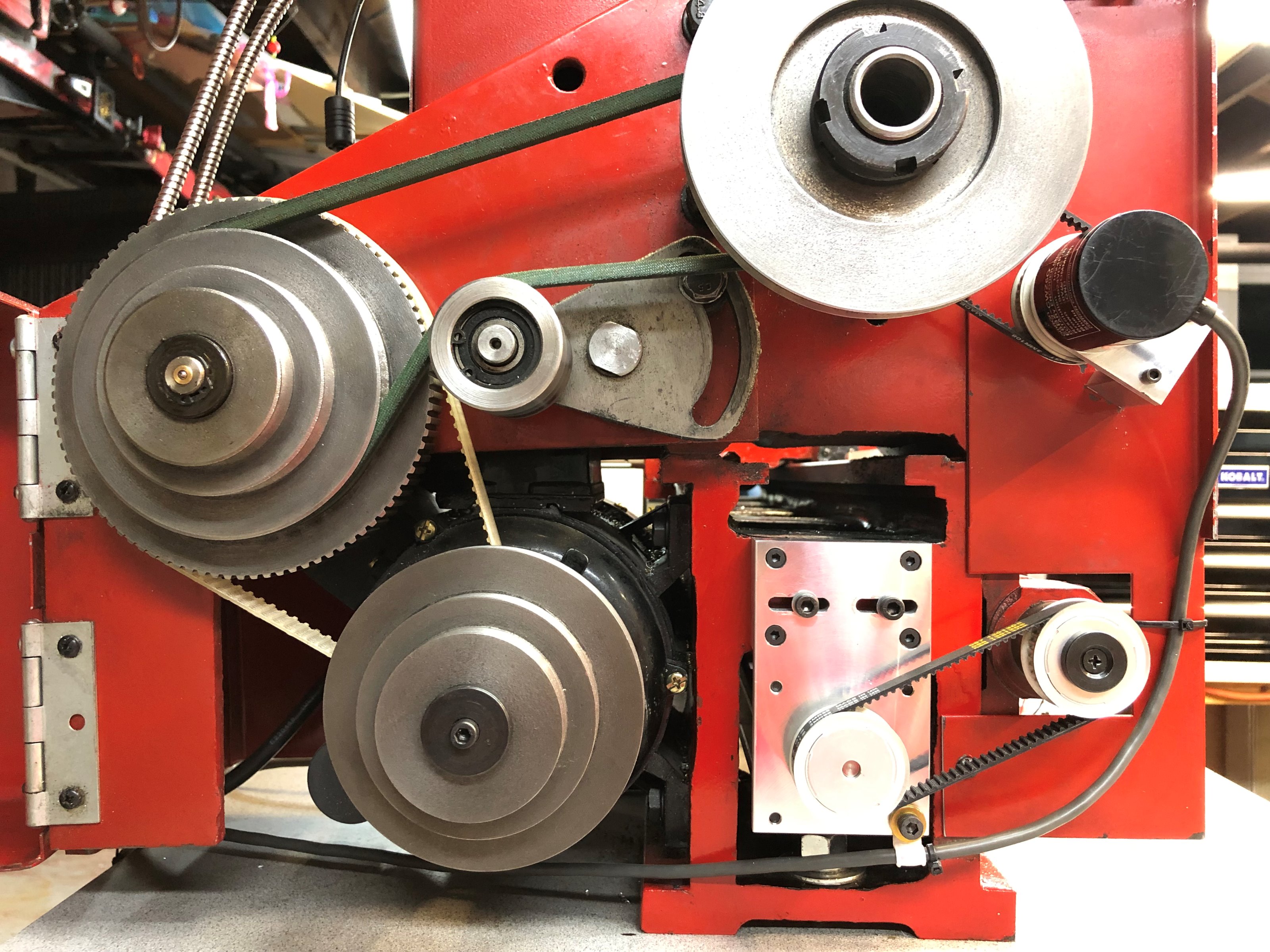

Attachments:

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

15 Dec 2019 16:09 #152692

by mooser

Replied by mooser on topic Starting from scratch (again) - Spindle encoder Question

Attachments:

Please Log in or Create an account to join the conversation.

- ississ

-

- Offline

- Senior Member

-

Less

More

- Posts: 68

- Thank you received: 25

02 Jan 2020 09:12 #153778

by ississ

Replied by ississ on topic Starting from scratch (again) - Spindle encoder Question

I have 5i25 + 7i76 on my lathe. And a 1024 pulse/rev encoder with an index.

Max spindle speed 6300rpm, only "manual gears" by changing pulleys when needed.

The original belt broke up (from 1992) and I couldn't find a replacement so I made new pulleys from aluminium pulley stock (T5 50 tooth, ~78mm outer diameter).

Probably there is space somewhere around the spindle to mount the encoder ( picture showing a larger area will help us others ).

You can buy a suitable encoder and make a pulley that fits around the spindle shaft. There is not much forces when driving only a pulley and an encoder so make a bit tight fit and use a couple of top screws to keep the pulley where it should be. Possibly file a small flat area on the shaft for one of the screws.

And forget the original index signal.

Max spindle speed 6300rpm, only "manual gears" by changing pulleys when needed.

The original belt broke up (from 1992) and I couldn't find a replacement so I made new pulleys from aluminium pulley stock (T5 50 tooth, ~78mm outer diameter).

Probably there is space somewhere around the spindle to mount the encoder ( picture showing a larger area will help us others ).

You can buy a suitable encoder and make a pulley that fits around the spindle shaft. There is not much forces when driving only a pulley and an encoder so make a bit tight fit and use a couple of top screws to keep the pulley where it should be. Possibly file a small flat area on the shaft for one of the screws.

And forget the original index signal.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 569

- Thank you received: 110

02 Jan 2020 22:20 #153829

by JohnnyCNC

Replied by JohnnyCNC on topic Starting from scratch (again) - Spindle encoder Question

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

02 Jan 2020 23:11 #153834

by mooser

Replied by mooser on topic Starting from scratch (again) - Spindle encoder Question

I've got a handful of extra bits around the spindle that were related to the original feed mechanisms. Once I get it vaguely running (I've now taken enough of the old system apart that it'll not run and there's no turning back (pun intended) I'm going to see if I can remove some of those pieces and free up enough room to install an encoder something along the lines you have.

I've got two small US digital encoders here (1000 point) that I can hopefully use but I'll have to deal with a ratio no matter what.

More questions to follow once I get there

Thanks again

M

I've got two small US digital encoders here (1000 point) that I can hopefully use but I'll have to deal with a ratio no matter what.

More questions to follow once I get there

Thanks again

M

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2202

- Thank you received: 482

02 Jan 2020 23:27 #153836

by Clive S

Replied by Clive S on topic Starting from scratch (again) - Spindle encoder Question

Attachments:

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

02 Jan 2020 23:36 #153838

by mooser

Replied by mooser on topic Starting from scratch (again) - Spindle encoder Question

That's the other option. The exiting one was made from delrin and then I had to cover all the slots except one (I can't remember exactly why but no doubt it was for indexing / threading in mach)

First will be just to get it running again

M

First will be just to get it running again

M

Please Log in or Create an account to join the conversation.

- mooser

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 12

02 Jan 2020 23:38 #153839

by mooser

Replied by mooser on topic Starting from scratch (again) - Spindle encoder Question

I see the index slot but just noticed the 3rd sensor,

Please elaborate, is it quad or directional?

Thanks

M

Please elaborate, is it quad or directional?

Thanks

M

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 569

- Thank you received: 110

03 Jan 2020 04:03 #153859

by JohnnyCNC

Replied by JohnnyCNC on topic Starting from scratch (again) - Spindle encoder Question

I put the smallest pulley I could fit on the spindle and then just used that same size pulley on the encoder to get a 1:1 ratio.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.208 seconds