how to correct generate cnc files with Fusion 360

- geostein8888

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

23 Aug 2023 17:06 #278809

by geostein8888

how to correct generate cnc files with Fusion 360 was created by geostein8888

Hello,

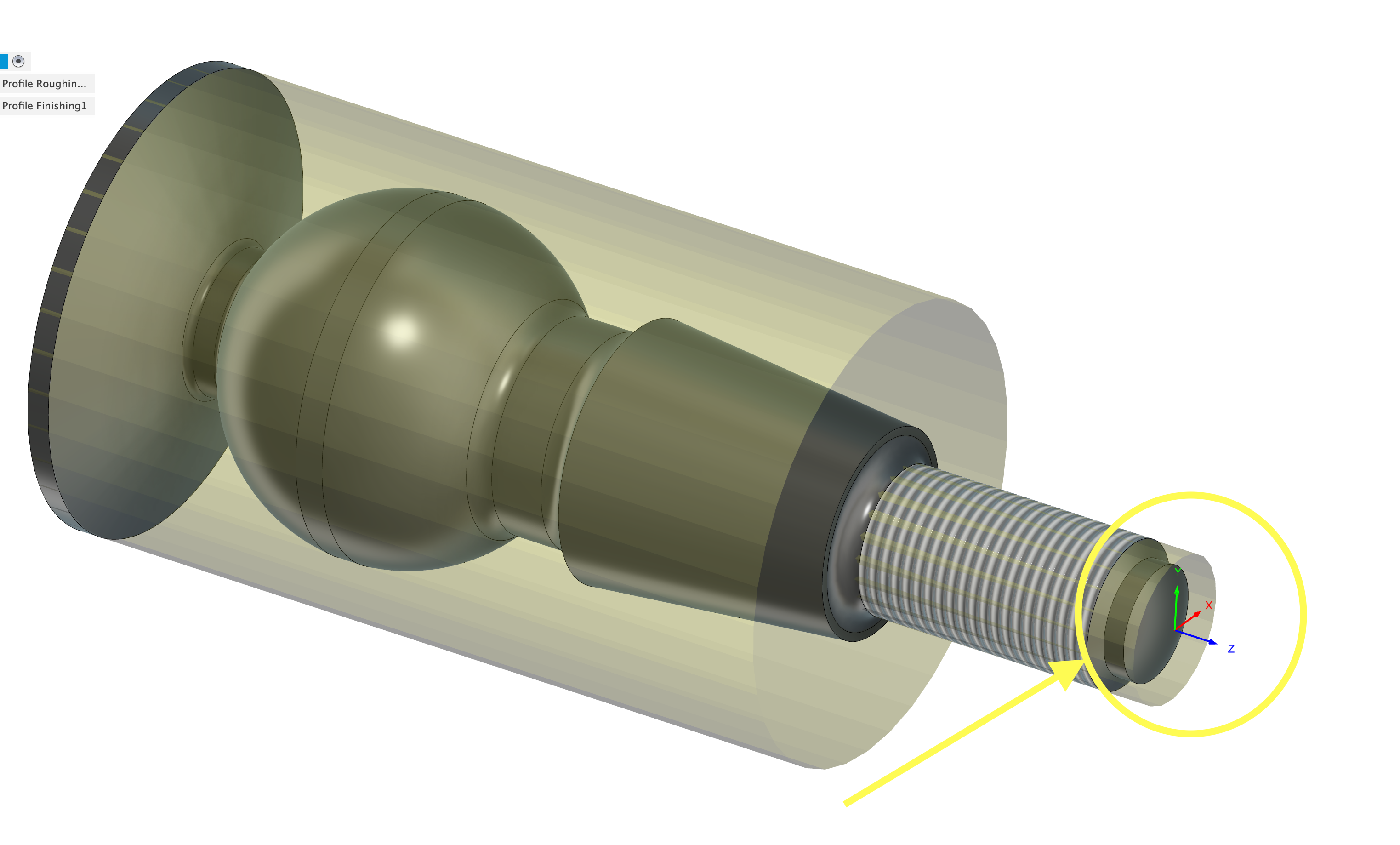

when i generate a cnc file with fusion360 and the linuxcnc turning post processor, the result is also not matching my work piece, It looks like its taking the diameter instead of the radios somehow, in all case when i touch off my work piece in this way(perhaps here the problem is situated):

going to the start of the work piece outer right side and outside corner and set x and z to zero, when i start now the file, its always starting around the radius towards me in the air in stead of the work pieces surface.

when i generate a cnc file with fusion360 and the linuxcnc turning post processor, the result is also not matching my work piece, It looks like its taking the diameter instead of the radios somehow, in all case when i touch off my work piece in this way(perhaps here the problem is situated):

going to the start of the work piece outer right side and outside corner and set x and z to zero, when i start now the file, its always starting around the radius towards me in the air in stead of the work pieces surface.

%

(CHESS_)

N10 G7

N11 G90 G18

N12 G21

(WHEN USING FUSION 360 FOR PERSONAL USE, THE FEEDRATE OF)

(RAPID MOVES IS REDUCED TO MATCH THE FEEDRATE OF CUTTING)

(MOVES, WHICH CAN INCREASE MACHINING TIME. UNRESTRICTED RAPID)

(MOVES ARE AVAILABLE WITH A FUSION 360 SUBSCRIPTION.)

N13 G53 G0 X0.

N14 G53 G0 Z0.

(PROFIL-SCHRUPPEN1)

N15 T2 M6

N17 G90 G94 G18

N18 G54

N19 G97 S1463 M3

N20 G0 X43.5 Z7.

N21 G96 D3500 S200 M3

N22 G1 Z1.5 F65.

N23 X21.5

N24 Z-50.132

N25 X23.5

N26 X25.5 Z-49.132

N27 Z1.5

N28 X19.5

N29 Z-38.373

N30 G3 Z-42.682 R8.7

N31 G1 Z-49.185

N32 X20.189 Z-50.132

N33 X21.5

N34 X23.5 Z-49.132

N35 Z1.5

N36 X17.5

N37 Z-32.608

N38 G3 Z-34.925 R3.

N39 G1 Z-36.

N40 G3 X19.5 Z-38.373 R8.7

N41 G1 X21.5 Z-37.373

N42 Z1.5

N43 X15.5

N44 Z-31.342

N45 G3 X17.5 Z-32.608 R3.

N46 G1 X19.5 Z-31.608

N47 Z1.5

N48 X13.5

N49 Z-6.335

N50 X15.051 Z-8.466

N51 Z-13.522

N52 Z-13.524

N53 G3 X13.5 Z-15.762 R3.8

N54 G1 Z-30.866

N55 G3 X15.5 Z-31.342 R3.

N56 G1 X17.5 Z-30.342

N57 Z1.5

N58 X11.5

N59 Z-5.2

N60 G2 X12.861 Z-5.457 R4.7

N61 G1 X13.5 Z-6.335

N62 X15.5 Z-5.335

N63 Z1.5

N64 X9.5

N65 Z-4.567

N66 G2 X11.5 Z-5.2 R4.7

N67 G1 X13.5 Z-4.2

N68 Z1.5

N69 X7.5

N70 Z-3.422

N71 G2 X9.5 Z-4.567 R4.7

N72 G1 X11.5 Z-3.567

N73 Z1.5

N74 X5.5

N75 Z0.1

N76 X6.324

N77 G2 X7.5 Z-3.422 R4.7

N78 G1 X9.5 Z-2.422

N79 Z1.5

N80 X3.5

N81 Z0.1

N82 X5.5

N83 X7.5 Z1.1

N84 Z1.5

N85 X1.55

N86 Z0.1

N87 X3.5

N88 X5.5 Z1.1

N89 Z1.5

N90 X-0.4

N91 Z0.1

N92 X1.55

N93 X3.55 Z1.1

N94 X16.051

N95 Z-15.762

N96 X14.5

N97 X13.5

N98 G3 X12.338 Z-16.372 R3.8

N99 G1 X11.5 Z-16.723

N100 Z-28.688

N101 X12.036 Z-28.955

N102 Z-30.767

N103 G3 X13.5 Z-30.866 R3.

N104 G1 X15.5 Z-29.866

N105 Z-16.723

N106 X12.5

N107 X11.5

N108 X9.646 Z-17.501

N109 Z-27.761

N110 X11.5 Z-28.688

N111 X13.5 Z-27.688

N112 Z-17.501

N113 X10.646

N114 X9.646

N115 X7.793 Z-18.278

N116 Z-26.834

N117 X9.646 Z-27.761

N118 X11.646 Z-26.761

N119 X18.966

N120 Z-34.925

N121 X18.5

N122 X17.5

N123 G3 X16.853 Z-35.507 R3.

N124 X17.5 Z-36. R8.7

N125 G1 X19.5 Z-35.

N126 X21.042

N127 Z-42.682

N128 X20.5

N129 X19.5

N130 G3 X18.176 Z-44.447 R8.7

N131 G1 Z-47.367

N132 X19.5 Z-49.185

N133 X21.5 Z-48.185

N134 Z-44.447

N135 X19.176

N136 X18.176

N137 G3 X16.852 Z-45.548 R8.7

N138 G1 X18.176 Z-47.367

N139 X20.176 Z-46.367

N140 X43.5

N141 Z7.

N142 G97 S1463 M3

N143 M5

N144 G53 G0 X0.

N145 G53 G0 Z0.

N146 M30

%Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

23 Aug 2023 20:29 #278823

by andypugh

Replied by andypugh on topic how to correct generate cnc files with Fusion 360

Attachments:

Please Log in or Create an account to join the conversation.

- geostein8888

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

23 Aug 2023 21:30 #278827

by geostein8888

Replied by geostein8888 on topic how to correct generate cnc files with Fusion 360

do you mean to the diameter of the work piece or the resulting diameter of the finished part?

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.076 seconds