AASD Servo driver and torque problem

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

17 Jan 2024 17:45 - 18 Jan 2024 11:13 #290970

by Gnevko

AASD Servo driver and torque problem was created by Gnevko

Hello everyone,

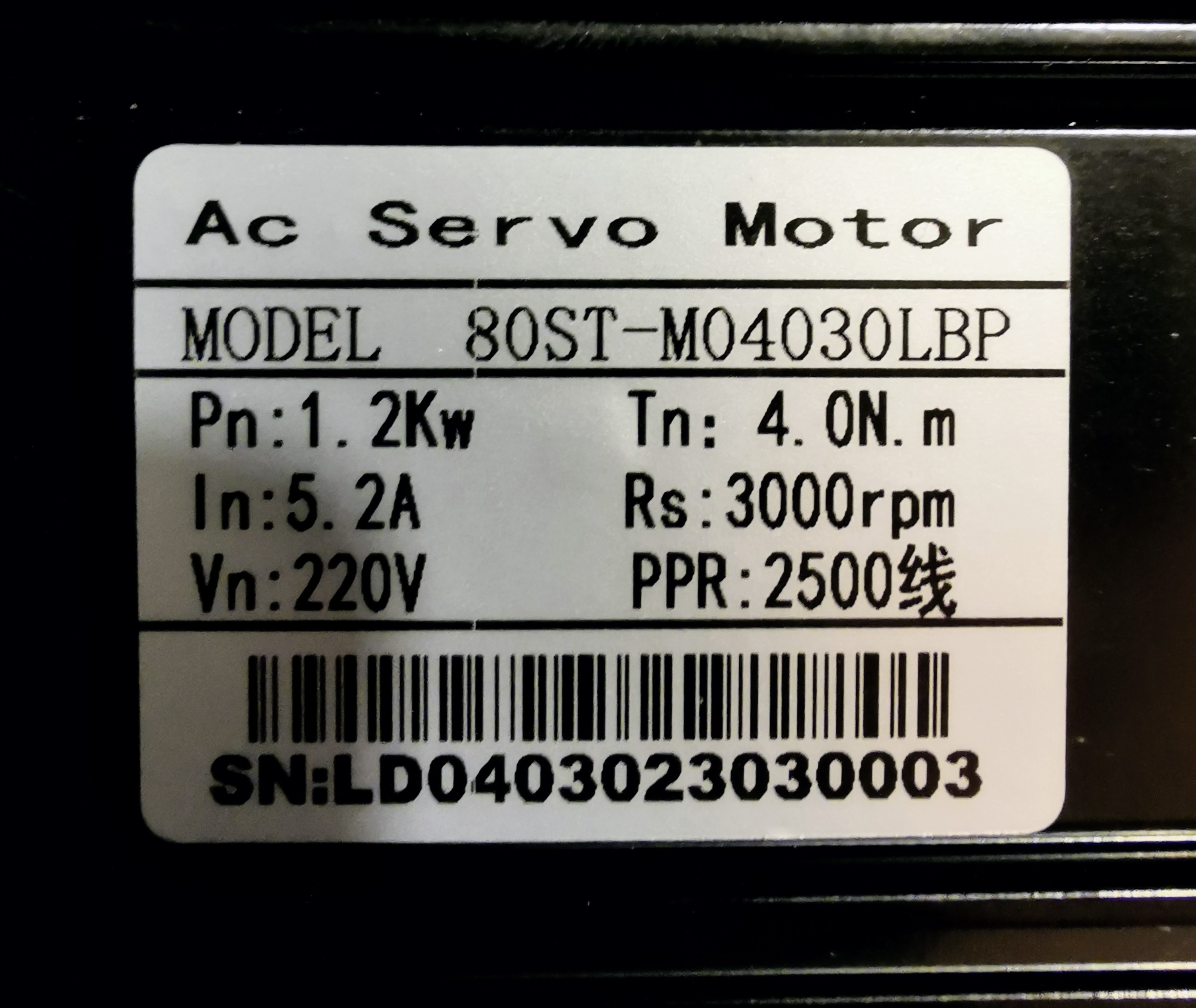

I recently decided to change the spindle on my milling machine and also switch to a servo motor. However, I'm facing an issue: at low speeds, the motor doesn't seem to deliver its full 1.2 kW of power. It can practically be stopped with bare hands, which makes tasks like threading impossible. Is such behavior normal for a servo motor? I've tried searching for a solution online and on this forum but haven't had much luck.

Additional details:

I recently decided to change the spindle on my milling machine and also switch to a servo motor. However, I'm facing an issue: at low speeds, the motor doesn't seem to deliver its full 1.2 kW of power. It can practically be stopped with bare hands, which makes tasks like threading impossible. Is such behavior normal for a servo motor? I've tried searching for a solution online and on this forum but haven't had much luck.

Additional details:

- the spindle is controlled by a MESA 7I95 in step mode (Pn002=2);

- Pn098 = 20;

- the motor also has a strange behavior in maintaining speed - it fluctuates within quite large ranges, both when controlled by MESA and when using the driver's internal control Fn002.

- I tryed to play with Pn259 + Pn257 but without big success.

Links to videos:

photos.app.goo.gl/PPnikUve9ojGVg2q6

photos.app.goo.gl/xt18cd4i8q22xdtWA

Thank you for your help!

Last edit: 18 Jan 2024 11:13 by Gnevko.

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

17 Jan 2024 19:05 #290973

by PCW

Replied by PCW on topic AASD Servo driver and tourque problem

Is there a tuning utility for the drive? Sounds like it is not tuned and/or has a low torque limit setting

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

17 Jan 2024 19:33 #290974

by Gnevko

Replied by Gnevko on topic AASD Servo driver and tourque problem

Attachments:

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 57

18 Jan 2024 00:32 #290981

by COFHAL

Replied by COFHAL on topic AASD Servo driver and tourque problem

You have feedback the encoder the servo?

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

18 Jan 2024 06:52 - 18 Jan 2024 06:57 #290996

by besriworld

Replied by besriworld on topic AASD Servo driver and tourque problem

Error code AL-04 :

1: Check the motor line U, V, W and

encoder line is normal.

2: Turn the power off half an hour,

electricity again, if the alarm is still there,

may be internal power module is damaged,

please replace the servo amplifier.

3: Speed loop and current loop pid

parameter Settings.

Maybe the problem is in point 3?

What happens at 0 speed and applied axle force?

1: Check the motor line U, V, W and

encoder line is normal.

2: Turn the power off half an hour,

electricity again, if the alarm is still there,

may be internal power module is damaged,

please replace the servo amplifier.

3: Speed loop and current loop pid

parameter Settings.

Maybe the problem is in point 3?

What happens at 0 speed and applied axle force?

Last edit: 18 Jan 2024 06:57 by besriworld.

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

18 Jan 2024 09:37 #291011

by Gnevko

photos.app.goo.gl/9fnouKu1NwuBShxn9

Replied by Gnevko on topic AASD Servo driver and tourque problem

Yes, I utilized the LinuxCNC HAL oscilloscope and observed all the relevant signals: A, B, and Index. However, what's intriguing is that the motor speed appears to be inconsistent, even when using the jog function (Fn002). For instance, if I set the speed to 100 RPM, the displayed speed value fluctuates between 85 and 125 RPM. This is why the encoder pulses also vary in length.You have feedback the encoder the servo?

In this scenario, I am able to slightly rotate the motor shaft (more easily in a counterclockwise direction than clockwise), but I am unable to trigger the Al-04 error. During this process, the display value of Dn002 increases to between 70 and 80 and then stabilizes, regardless of the amount of force applied. Additionally, when observing the same Dn002 value during the motor's operation at 100 RPM, the value also rises to 74, but this is immediately followed by the Al-04 error code.Maybe the problem is in point 3?

What happens at 0 speed and applied axle force?

photos.app.goo.gl/9fnouKu1NwuBShxn9

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Jan 2024 14:27 #291032

by andypugh

Replied by andypugh on topic AASD Servo driver and tourque problem

4Nm is quite a small torque. Maybe try setting a torque wrench to that level to calibrate your hands and see if the motor is genereating a similar torque at low speeds.

However, looking at this tapping torque calculator, 4Nm should be enough for M16(!) in Aluminium, so it sounds like you probably are low on torque.

A servo motor should make rated torque at 0 rpm. That's prety much their job.

However, looking at this tapping torque calculator, 4Nm should be enough for M16(!) in Aluminium, so it sounds like you probably are low on torque.

A servo motor should make rated torque at 0 rpm. That's prety much their job.

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

18 Jan 2024 17:54 - 18 Jan 2024 18:08 #291047

by besriworld

Replied by besriworld on topic AASD Servo driver and tourque problem

Hello, the revs should not play. Are the values of the pid regulator default?

This is my other 1kw motor with a hard setting on the pid regulator.

ps: the watch has a resolution of 0.002uM, a belt drive of 1:1 and a screw pitch of 10mm. The motor has 2500 rpm

From 22 seconds I apply great force.

This is my other 1kw motor with a hard setting on the pid regulator.

ps: the watch has a resolution of 0.002uM, a belt drive of 1:1 and a screw pitch of 10mm. The motor has 2500 rpm

From 22 seconds I apply great force.

Last edit: 18 Jan 2024 18:08 by besriworld.

Please Log in or Create an account to join the conversation.

- Gnevko

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 10

21 Jan 2024 20:04 #291279

by Gnevko

Replied by Gnevko on topic AASD Servo driver and tourque problem

After conducting numerous experiments, I have established the following parameters:

Pn259 = 6

Pn275 = 1.20

Pn020 = 3000

Pn098 = 20

These settings enable the motor shaft, when connected to the spindle, to operate comfortably up to 1500 RPM with manageable noise levels. However, beyond 1500 RPM, the noise becomes extremely loud and problematic. Another issue arises when attempting to decelerate the spindle from 1500 RPM to 0 RPM. During such attempts, the servo driver immediately displays the well-known error from my first post - AL-04. To avoid this, I need to first reduce the speed to 1000 RPM, then to 500 RPM, before I can safely stop it without triggering the error.

Pn259 = 6

Pn275 = 1.20

Pn020 = 3000

Pn098 = 20

These settings enable the motor shaft, when connected to the spindle, to operate comfortably up to 1500 RPM with manageable noise levels. However, beyond 1500 RPM, the noise becomes extremely loud and problematic. Another issue arises when attempting to decelerate the spindle from 1500 RPM to 0 RPM. During such attempts, the servo driver immediately displays the well-known error from my first post - AL-04. To avoid this, I need to first reduce the speed to 1000 RPM, then to 500 RPM, before I can safely stop it without triggering the error.

Please Log in or Create an account to join the conversation.

- 0x2102

-

- Offline

- Elite Member

-

Less

More

- Posts: 214

- Thank you received: 78

21 Jan 2024 22:02 #291287

by 0x2102

Replied by 0x2102 on topic AASD Servo driver and tourque problem

Are you running your spindle server in position or speed mode?

I run mine (Lathe) in speed mode - set PN002 = 1 (speed mode) or 3 (position/speed mode).

The last option will allow you to switch (via input signal) between modes in certain situations.

Then look at your settings PN146 etc (speed control parameter) and define your acceleration / deceleration times.

I run mine (Lathe) in speed mode - set PN002 = 1 (speed mode) or 3 (position/speed mode).

The last option will allow you to switch (via input signal) between modes in certain situations.

Then look at your settings PN146 etc (speed control parameter) and define your acceleration / deceleration times.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.155 seconds