WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

08 Mar 2025 11:33 - 08 Mar 2025 11:36 #323507

by Surmetall

WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT? was created by Surmetall

Hello all,

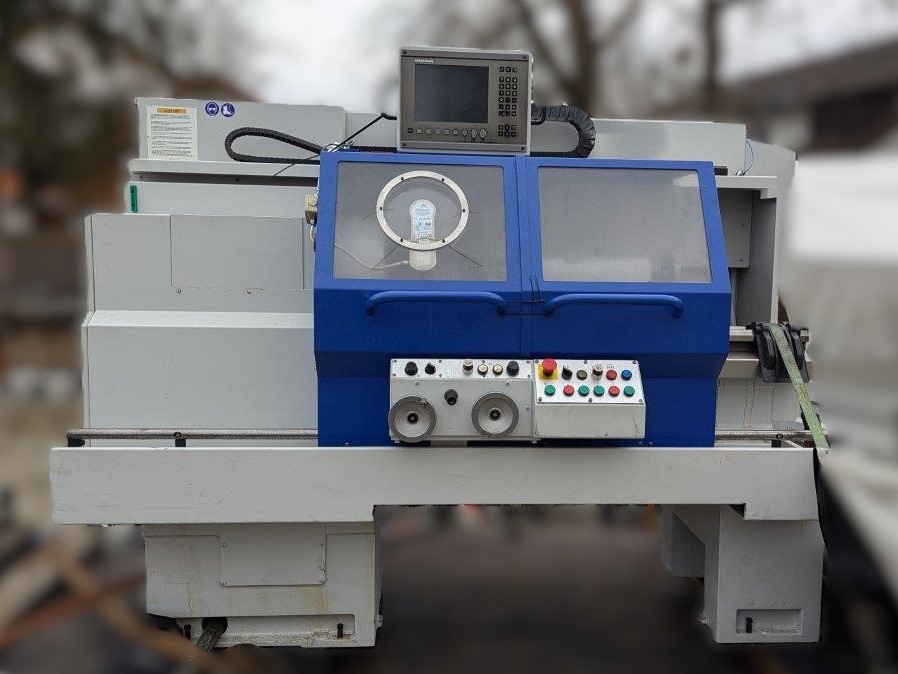

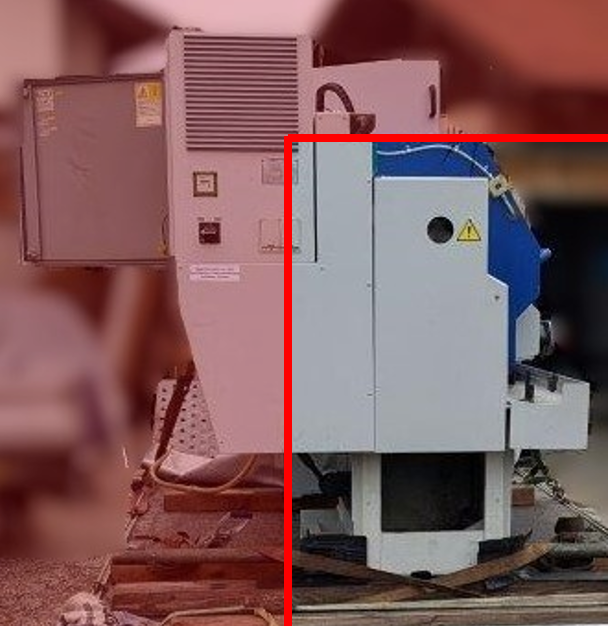

I have taken on a 2.2-ton heavy problem and started a new project: a CNC lathe from WEMAS, or Kovosvit MAS, built in 2000. So, it’s a 25-year-old German-Czech machine. History of the machine: This machine was purchased by a larger company in 2000 and was used in prototype production until around 2004. Then, it encountered an issue with the electronics. After an internal move—after which it was never repaired—it was slated for scrapping. But that was far too good of a machine to throw away! Luckily, a dear friend stepped in to prevent that and played a significant role in getting it to me (thanks again, you know who you are!). To summarize: 2.2 tons, incredibly top-heavy, difficult to move, barely liftable, and broken... why would anyone take this on? Fortunately, I had professional help from my family for the (not-so-simple) transport, and it was soon safely at home. We disassembled it while it was still on the trailer to make it more manageable. It’s a massive cabinet made of robust 3mm steel sheet—very sturdy and maintenance-friendly, but it takes up a lot of space and isn’t exactly hobbyist-friendly. Plus, the weather wasn’t on my side, so I had to make it smaller quickly despite various challenges.

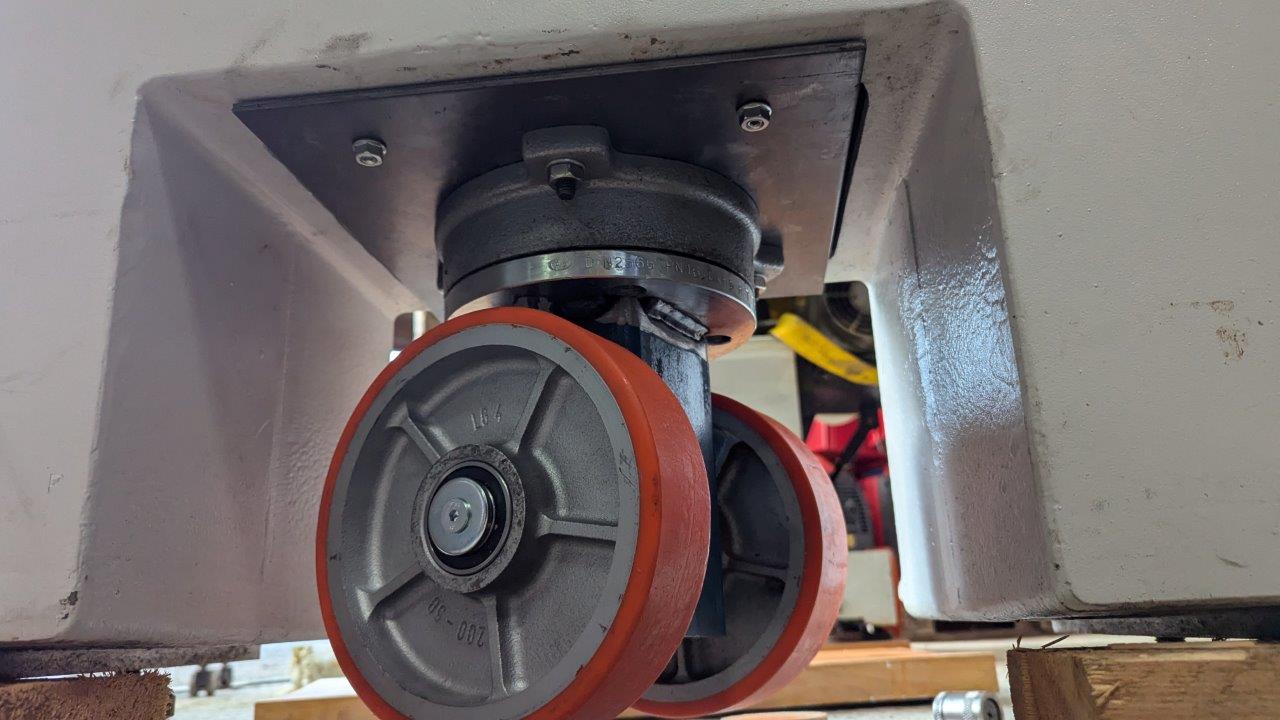

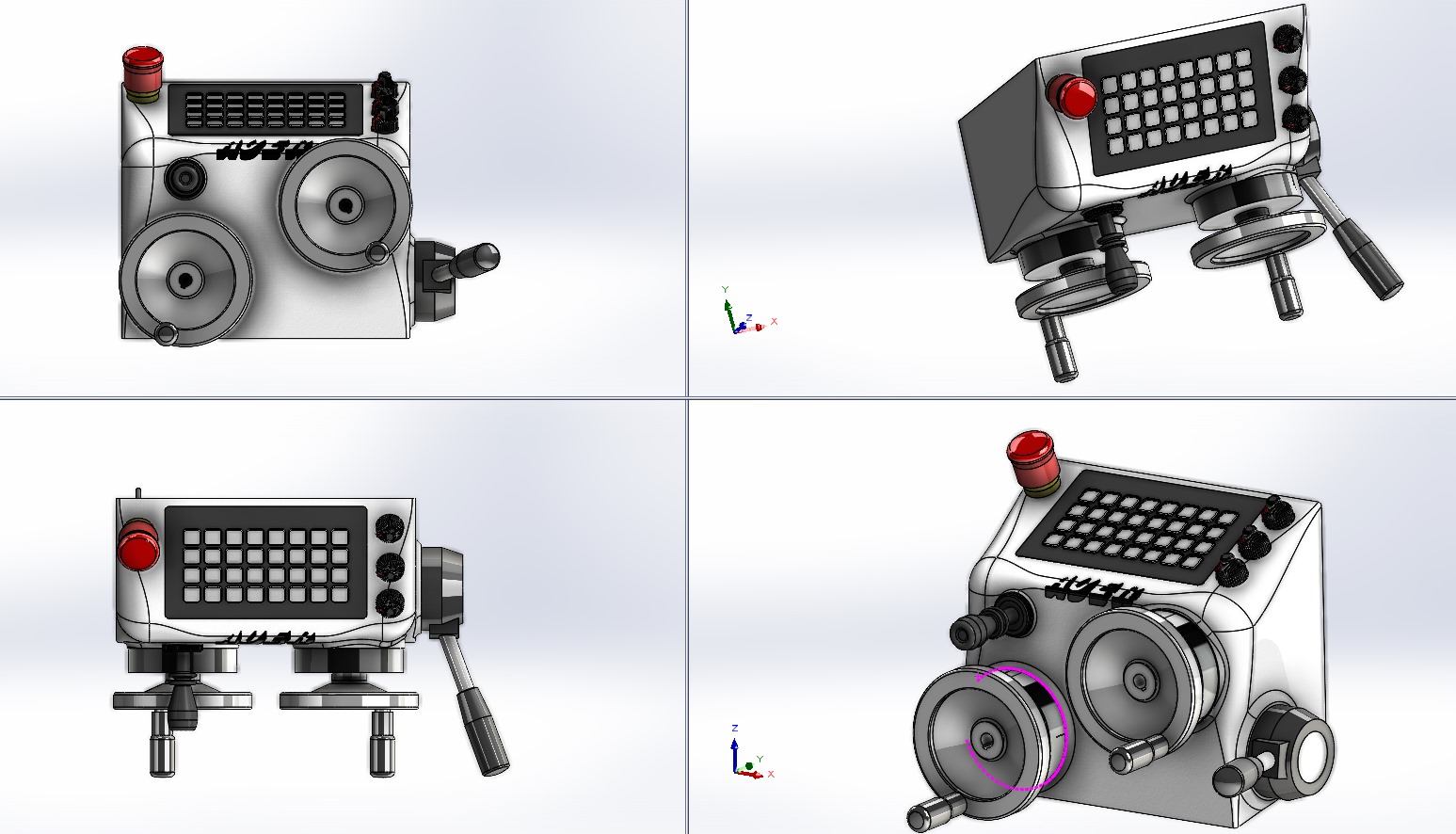

Here’s a first look at its inner beauty. It stands there nearly smallish without the cabinet (I’d compare it roughly to a Weiler B Condor). To move it without hydraulics or a crane, I built a chassis from scrap parts (a broken flange and the lower part of a vice plate) using some hardware and heavy-duty wheels.With this setup, it can be maneuvered easily and very precisely with one person. it’s now flexible enough for the casing modifications. I’ve also given it a bit of a clean.

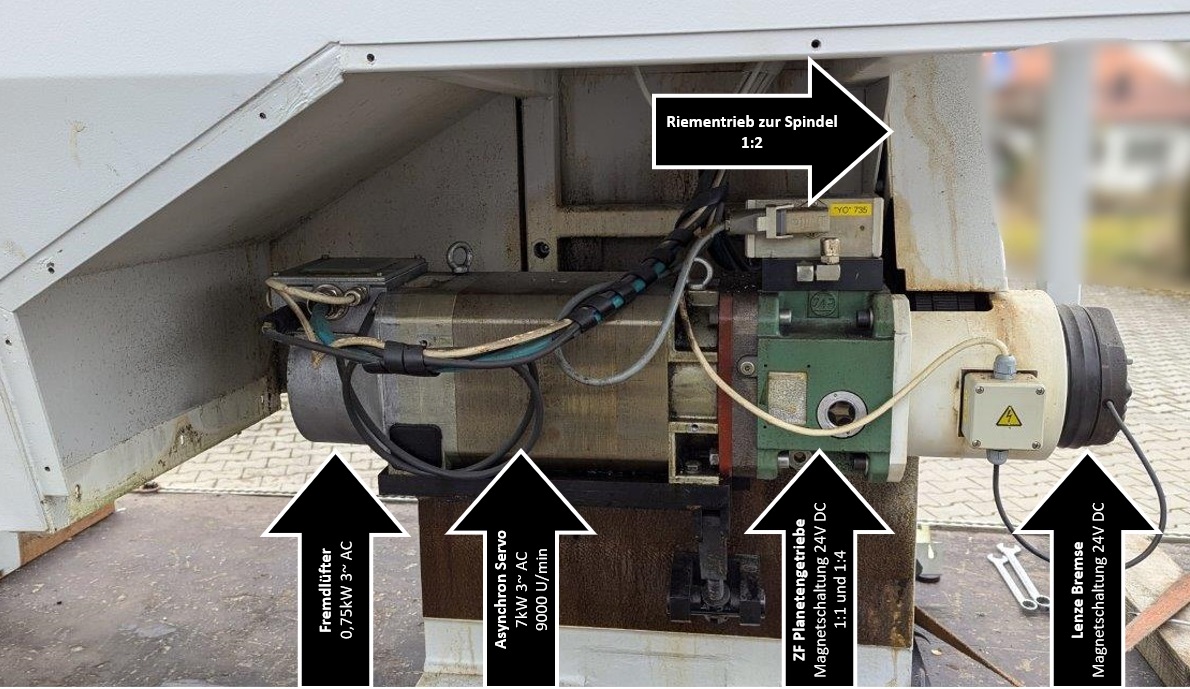

Next step is planning and buying hardware for the conversion to LinuxCNC. I’d like to continue using the servo motors, as I believe they are definitely worth preserving. In particular, the spindle drive is fantastic. It’s a SIEMENS asynchronous servo motor with an external fan, brake, and a two-speed planetary gearbox. The motor can reach up to about 9000 RPM. Through the belt drive, I have spindle speeds of 0 to 1000 and 0 to 4000 RPM. Given the well-designed bearings and the belt in between, I’m hoping for excellent Surface-results.

Unfortunately, the large motor is both a blessing and a curse. The Heidenhain compact inverter is actually brilliantly small designed and should still work fine. However, it seems that the folks in Traunreut have turned it into a complex project, and it looks like you can only connect this thing to HH controllers. Documentation on this is almost non-existent, which is frustrating. So, finding a suitable (small) inverter for the spindle servo is not easy, and it’s not cheap either. The best option might be to go with a SIEMENS S120. However, the software, namely TIA Portal, is a significant hurdle for me.

I’ve been mulling over this for a few weeks now; if it weren’t for these issues, the machine would probably already be moving. I might even take the plunge into EtherCAT. That way, it could be easier to buy new motors and drivers for the X and Z axes directly (with absolute encoders and position feedback).

Finding a suitable driver for the large SIEMENS 1PH7105 servo is quite challenging. Perhaps something from Beckhoff, like an AX51? Or again a SIEMENS S120, which can sometimes be found very cheaply on eBay, although it’s primarily designed for ProfiBUS. There is an EtherCAT adapter available, but I fear that no one has tried it with LinuxCNC yet, and I don’t have the skills to tackle that.

Unfortunately, LinuxCNC and EtherCAT are still a bit of a mystery to me. I’m looking forward to hearing your thoughts and tips!

Best regards,

Tom

I have taken on a 2.2-ton heavy problem and started a new project: a CNC lathe from WEMAS, or Kovosvit MAS, built in 2000. So, it’s a 25-year-old German-Czech machine. History of the machine: This machine was purchased by a larger company in 2000 and was used in prototype production until around 2004. Then, it encountered an issue with the electronics. After an internal move—after which it was never repaired—it was slated for scrapping. But that was far too good of a machine to throw away! Luckily, a dear friend stepped in to prevent that and played a significant role in getting it to me (thanks again, you know who you are!). To summarize: 2.2 tons, incredibly top-heavy, difficult to move, barely liftable, and broken... why would anyone take this on? Fortunately, I had professional help from my family for the (not-so-simple) transport, and it was soon safely at home. We disassembled it while it was still on the trailer to make it more manageable. It’s a massive cabinet made of robust 3mm steel sheet—very sturdy and maintenance-friendly, but it takes up a lot of space and isn’t exactly hobbyist-friendly. Plus, the weather wasn’t on my side, so I had to make it smaller quickly despite various challenges.

Here’s a first look at its inner beauty. It stands there nearly smallish without the cabinet (I’d compare it roughly to a Weiler B Condor). To move it without hydraulics or a crane, I built a chassis from scrap parts (a broken flange and the lower part of a vice plate) using some hardware and heavy-duty wheels.With this setup, it can be maneuvered easily and very precisely with one person. it’s now flexible enough for the casing modifications. I’ve also given it a bit of a clean.

Next step is planning and buying hardware for the conversion to LinuxCNC. I’d like to continue using the servo motors, as I believe they are definitely worth preserving. In particular, the spindle drive is fantastic. It’s a SIEMENS asynchronous servo motor with an external fan, brake, and a two-speed planetary gearbox. The motor can reach up to about 9000 RPM. Through the belt drive, I have spindle speeds of 0 to 1000 and 0 to 4000 RPM. Given the well-designed bearings and the belt in between, I’m hoping for excellent Surface-results.

Unfortunately, the large motor is both a blessing and a curse. The Heidenhain compact inverter is actually brilliantly small designed and should still work fine. However, it seems that the folks in Traunreut have turned it into a complex project, and it looks like you can only connect this thing to HH controllers. Documentation on this is almost non-existent, which is frustrating. So, finding a suitable (small) inverter for the spindle servo is not easy, and it’s not cheap either. The best option might be to go with a SIEMENS S120. However, the software, namely TIA Portal, is a significant hurdle for me.

I’ve been mulling over this for a few weeks now; if it weren’t for these issues, the machine would probably already be moving. I might even take the plunge into EtherCAT. That way, it could be easier to buy new motors and drivers for the X and Z axes directly (with absolute encoders and position feedback).

Finding a suitable driver for the large SIEMENS 1PH7105 servo is quite challenging. Perhaps something from Beckhoff, like an AX51? Or again a SIEMENS S120, which can sometimes be found very cheaply on eBay, although it’s primarily designed for ProfiBUS. There is an EtherCAT adapter available, but I fear that no one has tried it with LinuxCNC yet, and I don’t have the skills to tackle that.

Unfortunately, LinuxCNC and EtherCAT are still a bit of a mystery to me. I’m looking forward to hearing your thoughts and tips!

Best regards,

Tom

Attachments:

Last edit: 08 Mar 2025 11:36 by Surmetall. Reason: format...

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

08 Mar 2025 11:45 #323508

by Surmetall

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Attachments:

The following user(s) said Thank You: tommylight, besriworld

Please Log in or Create an account to join the conversation.

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

18 Mar 2025 14:29 #324208

by Surmetall

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Hi everyone,

Since I haven't made much progress with the inverters and electrical hardware (i try to get the SIEMENS S120 running but its hard with linuxCNC ;( ),

I've been working on a concept for the hand-control-panel in the meantime. I dont like the original one that much, so I'm trying to build a new one and keep it as compact as possible.

I like the idea of it being mounted to the bed carriage, similar to a conventional maschines. I plan to design the lever for forward/reverse operation in a way similar to what was done with VDF. In the neutral position, it will lock in place, and to activate it, you’ll need to push it slightly towards the negative Z direction first. Then, you can move it up for left rotation or down for right rotation. All three positions will have a locking mechanism in the center, as mentioned. This is for safety and prevents unintentional movement when you have your head near the spindle and might get caught on something like your clothing.

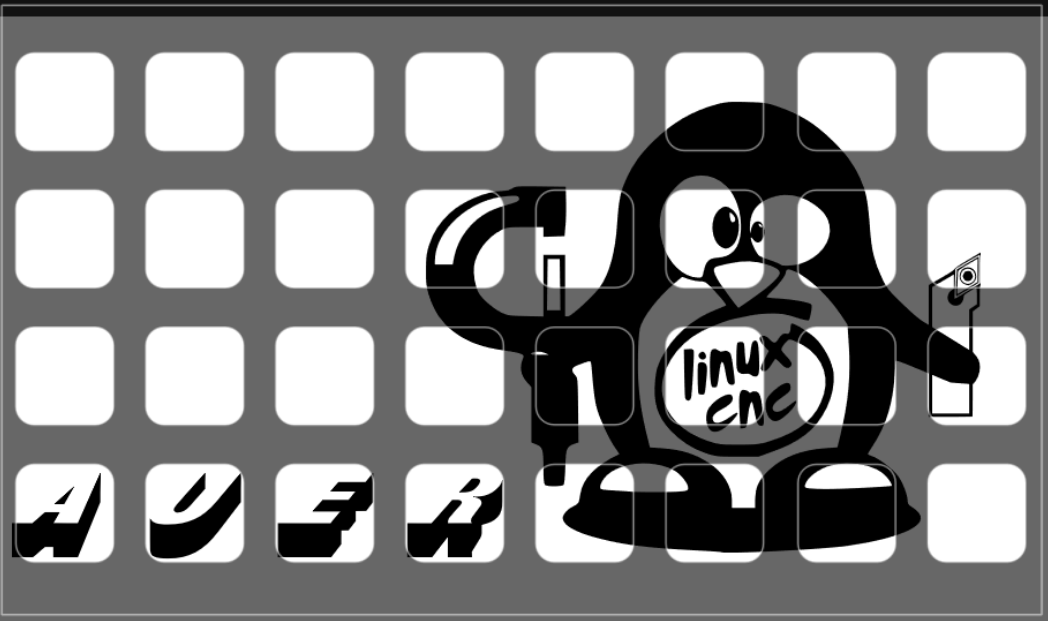

For the keys I'm thinking about adding a Stream Deck instead of real switches. So i can programm different functions to the setup in the future. Could be very handy.

Best regards,

Tom

Since I haven't made much progress with the inverters and electrical hardware (i try to get the SIEMENS S120 running but its hard with linuxCNC ;( ),

I've been working on a concept for the hand-control-panel in the meantime. I dont like the original one that much, so I'm trying to build a new one and keep it as compact as possible.

I like the idea of it being mounted to the bed carriage, similar to a conventional maschines. I plan to design the lever for forward/reverse operation in a way similar to what was done with VDF. In the neutral position, it will lock in place, and to activate it, you’ll need to push it slightly towards the negative Z direction first. Then, you can move it up for left rotation or down for right rotation. All three positions will have a locking mechanism in the center, as mentioned. This is for safety and prevents unintentional movement when you have your head near the spindle and might get caught on something like your clothing.

For the keys I'm thinking about adding a Stream Deck instead of real switches. So i can programm different functions to the setup in the future. Could be very handy.

Best regards,

Tom

Attachments:

Please Log in or Create an account to join the conversation.

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

30 Mar 2025 18:31 #325340

by Surmetall

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

I'm currently taking my first steps with an S120, but SIEMENS isn't making it easy for me. Right now, there are a lot of other priorities, so I hardly have any time to tinker. Whenever I find a spare five minutes, I either clean up a bit or start working on modifying or assembling the casing. I'm also testing alternatives for the missing limb guard. For now, I'm using feeler gauge material to see how it goes; I might end up buying a guard or a bellows from a good supplier in China.

Additionally, I'm continuing to work on the control panel. I'm having a lot of fun with the initial tests of the keypad, and I think it’s going to be really practical. I might even consider getting something similar as an addition to the handwheel on my FP3.

Additionally, I'm continuing to work on the control panel. I'm having a lot of fun with the initial tests of the keypad, and I think it’s going to be really practical. I might even consider getting something similar as an addition to the handwheel on my FP3.

Attachments:

The following user(s) said Thank You: tommylight, besriworld

Please Log in or Create an account to join the conversation.

- endian

-

- Offline

- Elite Member

-

Less

More

- Posts: 302

- Thank you received: 113

24 Apr 2025 19:24 #327010

by endian

Replied by endian on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

hi there,

share photos of electronic which you have...

I have build profibus machine over ethercat and it works in the 2ms synchro ... I can help you if there will be avaible stuff and time

AX5xxx from beckhoff is SoE and it can be pain to create custom .xml which should be editable out of Sachas own .xml files...

I can recommend you ethercat stuff ... S120 over drivecliq is very powerfull tool with 31.25us bus cycle but prices are out of any small shop budget ..

regards

share photos of electronic which you have...

I have build profibus machine over ethercat and it works in the 2ms synchro ... I can help you if there will be avaible stuff and time

AX5xxx from beckhoff is SoE and it can be pain to create custom .xml which should be editable out of Sachas own .xml files...

I can recommend you ethercat stuff ... S120 over drivecliq is very powerfull tool with 31.25us bus cycle but prices are out of any small shop budget ..

regards

The following user(s) said Thank You: besriworld, Surmetall

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11720

- Thank you received: 3968

24 Apr 2025 21:21 #327017

by rodw

Replied by rodw on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

If you wanted to use handwheels, consider Mesa over Ethercat.encoder/counter. Required Ethercat modules are expensive.

The following user(s) said Thank You: Surmetall, endian

Please Log in or Create an account to join the conversation.

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

26 Apr 2025 14:06 #327083

by Surmetall

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Hello and thank you both for the response.

I saw that the ethercat Beckhoff encodermoduls are really not cheap :/ Maybe a mixed setup with mesa would be an option? time will tell. My main Headache toipic is still the drivers for the Motors,

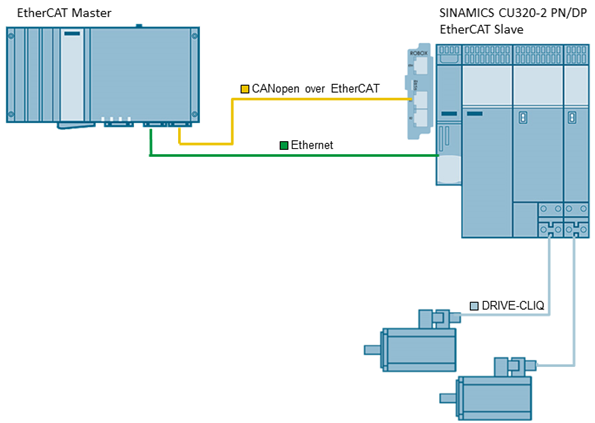

I allready have some parts of the SIEMENS S120

-Single Motors Modul for the spindle

-Double Motor Modul vor the X and Z Servo

-Active lIne modul

-Breakresistor

-Filter

-Motor choke

Now I have to search for CU320-2 on Ebay. and for the Ethercat modul wich is sadly really expensive.

If i dont get the ethercat PCB i think i also could run it with the ans SMC30. but that would mean i only have step dir. All functions form the ethercat world would of course be really cool!

endian, you say: profibus .. over ethercat ... the 2ms synchro ... I dont have a feeling for that. But ms sounds "slow" is that fast enough for Positioning a CNC machine?

Taht sounds really interesting, can you tell me more about it? Is there a Thread with your machine?

Have a great day!

Tom

I saw that the ethercat Beckhoff encodermoduls are really not cheap :/ Maybe a mixed setup with mesa would be an option? time will tell. My main Headache toipic is still the drivers for the Motors,

I allready have some parts of the SIEMENS S120

-Single Motors Modul for the spindle

-Double Motor Modul vor the X and Z Servo

-Active lIne modul

-Breakresistor

-Filter

-Motor choke

Now I have to search for CU320-2 on Ebay. and for the Ethercat modul wich is sadly really expensive.

If i dont get the ethercat PCB i think i also could run it with the ans SMC30. but that would mean i only have step dir. All functions form the ethercat world would of course be really cool!

endian, you say: profibus .. over ethercat ... the 2ms synchro ... I dont have a feeling for that. But ms sounds "slow" is that fast enough for Positioning a CNC machine?

Taht sounds really interesting, can you tell me more about it? Is there a Thread with your machine?

Have a great day!

Tom

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- endian

-

- Offline

- Elite Member

-

Less

More

- Posts: 302

- Thank you received: 113

26 Apr 2025 20:05 #327099

by endian

Replied by endian on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

hi there,

I have a long talk with gentelmen from the beckhoff which are talking that 2ms is for them limit of RT control ... I am experimenting with the 7 axis over profibus and there is latency 1336us, but I have not tested them ever... I have setted them to 2ms

I think for 3 o 4 axis it should be less then 1ms in the optimalized profibus cycle with equidistant mode active... I am running old metronix servopacks over speed loop... Everything works well even homing procedure but I think it is not for extremly precise machines probably I will facing the limits in the future but that servopacks was for 40bugs at locat market place

I have configure CanOpen, profibus, profinet over ethercat too but profinet have terrible delay 4ms which are not enough for anything ... or use the IRT profinet with 31.25us latency(there is limitation of 5 or 6 device on the network) but you will need special interface from continental which is only dealer of them

My machine is running at mesa 7i77 + linear scales, next running kollmorgen packs at 250us + linear scales, next nidec stuff too at 250us{not all stuff integrated as driver build in probing} and now I am experimenting with profibus ...

S120 is profi solution on 31.25us drivecliQ bus but it is soo soo expensive ... EtherCAT should runs at 62.5us but need native stuff and I have never tested them that fast... probably there will be limitations of lcnc latency hw itself

regards

I have a long talk with gentelmen from the beckhoff which are talking that 2ms is for them limit of RT control ... I am experimenting with the 7 axis over profibus and there is latency 1336us, but I have not tested them ever... I have setted them to 2ms

I think for 3 o 4 axis it should be less then 1ms in the optimalized profibus cycle with equidistant mode active... I am running old metronix servopacks over speed loop... Everything works well even homing procedure but I think it is not for extremly precise machines probably I will facing the limits in the future but that servopacks was for 40bugs at locat market place

I have configure CanOpen, profibus, profinet over ethercat too but profinet have terrible delay 4ms which are not enough for anything ... or use the IRT profinet with 31.25us latency(there is limitation of 5 or 6 device on the network) but you will need special interface from continental which is only dealer of them

My machine is running at mesa 7i77 + linear scales, next running kollmorgen packs at 250us + linear scales, next nidec stuff too at 250us{not all stuff integrated as driver build in probing} and now I am experimenting with profibus ...

S120 is profi solution on 31.25us drivecliQ bus but it is soo soo expensive ... EtherCAT should runs at 62.5us but need native stuff and I have never tested them that fast... probably there will be limitations of lcnc latency hw itself

regards

Please Log in or Create an account to join the conversation.

- Surmetall

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

27 Apr 2025 12:25 #327143

by Surmetall

Replied by Surmetall on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

I have a lot of mechanical work on the machine. Cutting and welding on the housing to get it smaller. maybe i will post pictures later if you are interested.

The plan for the drives at the moment is to use the SIEMENS Drivers if i can manage them to run... i think at least the Step Dir Config via SMC30 should be possible. But i would love to use ethterCAT like in this example.

support.industry.siemens.com/cs/document...p-pn-?dti=0&lc=en-WW

I have some experience with Mesa. After learning LCNC and help of great people like Talla83 and many more, my Deckel FP3NC runs really nice with it.

But i am a complete NOOB with EtherCAT. And to be honest, i am a little bit afraid of it.

So i hesitate to buy a used few hundred euro PCB for something i have no glue of

The plan for the drives at the moment is to use the SIEMENS Drivers if i can manage them to run... i think at least the Step Dir Config via SMC30 should be possible. But i would love to use ethterCAT like in this example.

support.industry.siemens.com/cs/document...p-pn-?dti=0&lc=en-WW

I have some experience with Mesa. After learning LCNC and help of great people like Talla83 and many more, my Deckel FP3NC runs really nice with it.

But i am a complete NOOB with EtherCAT. And to be honest, i am a little bit afraid of it.

So i hesitate to buy a used few hundred euro PCB for something i have no glue of

Attachments:

The following user(s) said Thank You: endian

Please Log in or Create an account to join the conversation.

- endian

-

- Offline

- Elite Member

-

Less

More

- Posts: 302

- Thank you received: 113

27 Apr 2025 18:36 #327178

by endian

Replied by endian on topic WEMAS MT 32 CNC Lathe -> LinuxCNC - Mesa or EtherCAT?

Nice nice nice... This document is tasty and it is a new galactic space for everyone from us...

Sinamics are widely used for everything and they are very powerfull..

every shared picture is are helpfull i think if you will need help I am here for everyone.. i will create a dry project in the twincat3 to check configuration ...

i think if you will need help I am here for everyone.. i will create a dry project in the twincat3 to check configuration ...

Sinamics are widely used for everything and they are very powerfull..

every shared picture is are helpfull

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.442 seconds