Lathe project needs a turret

- CaliusOptimus

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 4

24 Oct 2025 18:50 #337080

by CaliusOptimus

Lathe project needs a turret was created by CaliusOptimus

Hi all, new user long time lurker. My first linuxcnc experience was a sherline and a parallel port some 10 years ago. That turned into a pair of tormachs, now a vf2ssyt, and more if I had the space. Anyway...I picked up this lathe some time ago. It was originally cnc and converted to linuxcnc by the previous owner. I got it in a sort of working state. Everything was hooked up and moving but needed some refinement. At some point the PC died of unknown causes so I decided to start from scratch with trixie, kde and 2.9.6. I've got the servo thread running solid at 0.5ms, the motors all tuned and running well, the spindle drive is now controlled through modbus rather than analog, and I've added a few handy things with pyvcp. It's running fast and holding size.Now it's ready for a turret, and I'm hoping to get a recommendation. I currently have a neat manual turret but... manual is no fun. I've browsed alibaba and seen some affordable options. Also checked ebay and the pickings were slim, ancient and beat to death. I considered a tormach turret since it works so well on my sl15 but it would be nice to beat the $5k price tag.Also searching for an automatic collet closer or some sort of automatic chuck. It would be amazing to have a 16c or a 3j automatic collet... sounds like a huge amount of work if I can't find something to retrofit. Any ideas?

The following user(s) said Thank You: besriworld, COFHAL

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

24 Oct 2025 20:31 - 24 Oct 2025 20:32 #337086

by andypugh

Replied by andypugh on topic Lathe project needs a turret

The manual turret looks like a prime candidate for motorisation...

Or get an industrial robot arm to operate the manual tool changer for you.

Or get an industrial robot arm to operate the manual tool changer for you.

Last edit: 24 Oct 2025 20:32 by andypugh.

Please Log in or Create an account to join the conversation.

- MusicCityMfg

-

- Offline

- New Member

-

Less

More

- Posts: 10

- Thank you received: 1

03 Nov 2025 18:04 - 03 Nov 2025 18:05 #337773

by MusicCityMfg

Replied by MusicCityMfg on topic Lathe project needs a turret

@CaliusOptimus, check out the ALTAROS Automatic Turret Head:

www.altaros.cz/content/53-automatic-turret-head

CNC4XR7 on YouTube installed one and has a few videos on it.

www.altaros.cz/content/53-automatic-turret-head

CNC4XR7 on YouTube installed one and has a few videos on it.

Last edit: 03 Nov 2025 18:05 by MusicCityMfg.

Please Log in or Create an account to join the conversation.

- CaliusOptimus

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 4

08 Nov 2025 12:13 #338078

by CaliusOptimus

Replied by CaliusOptimus on topic Lathe project needs a turret

What a neat little turret! Cool company too, I've got one of their booster pumps.

That turret is too small unfortunately. Will be taking some decent cuts on this lathe so I ordered a tormach turret. Pricey, but those guys are so great with tech support... one call and they were willing to explain all of the electrical details I needed to integrate it.

That turret is too small unfortunately. Will be taking some decent cuts on this lathe so I ordered a tormach turret. Pricey, but those guys are so great with tech support... one call and they were willing to explain all of the electrical details I needed to integrate it.

Please Log in or Create an account to join the conversation.

- CaliusOptimus

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 4

12 Nov 2025 22:49 #338295

by CaliusOptimus

Replied by CaliusOptimus on topic Lathe project needs a turret

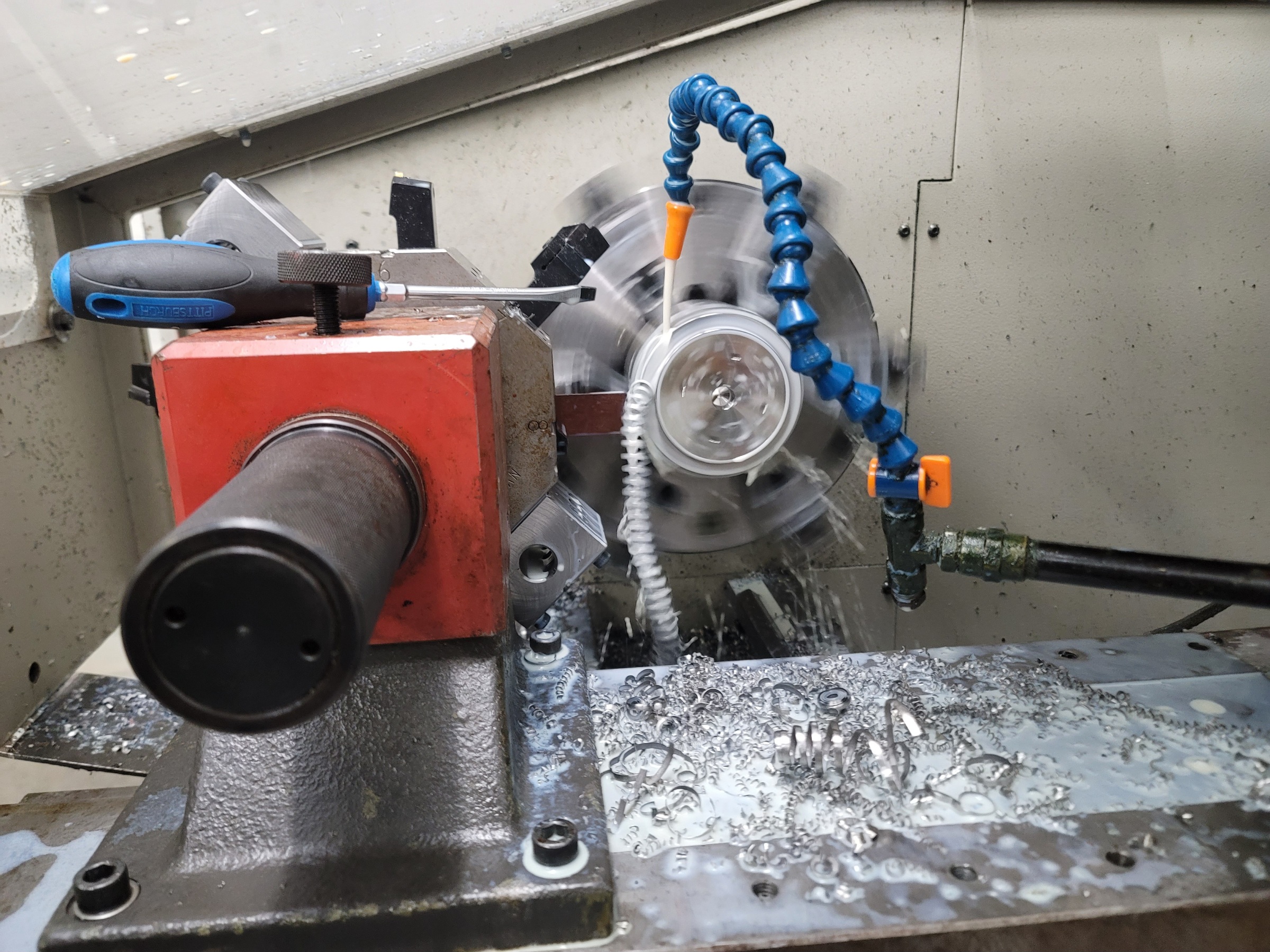

First real job for this lathe-

Parting off from a 4" 304 bar, then facing back side of the part.

Had some extreme and abnormal chatter at first so I looked around for loose components. Tightened up the X gibs, tried again, nope. Put a bar in the chuck and an indiciator on the spindle, gave it a push and a shove and saw .004" TIR. Ended up having to tighten the spindle preload and good to go.

Parting off from a 4" 304 bar, then facing back side of the part.

Had some extreme and abnormal chatter at first so I looked around for loose components. Tightened up the X gibs, tried again, nope. Put a bar in the chuck and an indiciator on the spindle, gave it a push and a shove and saw .004" TIR. Ended up having to tighten the spindle preload and good to go.

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- CaliusOptimus

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 4

03 Dec 2025 16:59 - 03 Dec 2025 17:00 #339690

by CaliusOptimus

Replied by CaliusOptimus on topic Lathe project needs a turret

The turret is up and running!

Not too bad getting it set up. The turret control board from tormach has NPN outputs and the mesa 7i77 needs PNP so I had to add some pullup resistors. One of the relays on the turret board also bit the dust right away (maybe my fault but not sure)... which led to a lot of confusion while programming the hal. I rigged it to use a couple of ice cube relays instead of the tiny, soldered in, DIP relays. Good to go.

Here's a vid of the first part I made with the turret. Just a little delrin spacer:

Not too bad getting it set up. The turret control board from tormach has NPN outputs and the mesa 7i77 needs PNP so I had to add some pullup resistors. One of the relays on the turret board also bit the dust right away (maybe my fault but not sure)... which led to a lot of confusion while programming the hal. I rigged it to use a couple of ice cube relays instead of the tiny, soldered in, DIP relays. Good to go.

Here's a vid of the first part I made with the turret. Just a little delrin spacer:

Last edit: 03 Dec 2025 17:00 by CaliusOptimus. Reason: Youtube link not working

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.187 seconds