Advice on suitable DC drive

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 702

- Thank you received: 139

19 Oct 2014 18:16 - 19 Oct 2014 18:19 #52186

by emcPT

Advice on suitable DC drive was created by emcPT

Hello.

I have the possibility to acquire a non working machine to retrofit (milling machine).

The drives are not working (not sure if all) but even if they are working they are almost 30 years old, so I prefer to replace them.

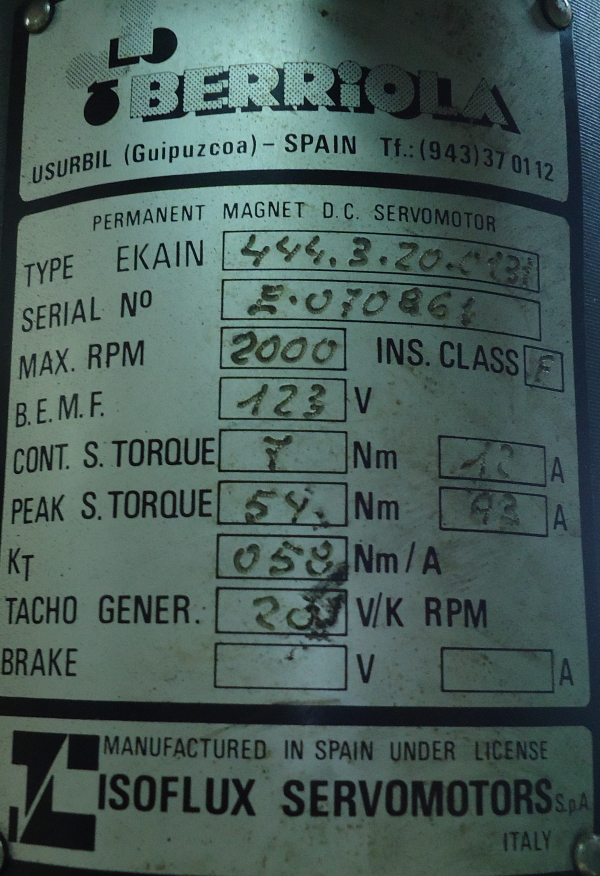

The motors plates are on attachment. I would acquire the machine if I was able to buy new drives (3 units) up to 1500€, this is 500€, each drive.

The machine mechanics are very good, ballscrews 40mm, glass scales on XY axes (on Z I was not able to see it, but probably it also have), so my immediate concern are the motors. I could also acquire motors+drives but for this power I think that the price would be over killing.

Peak torque is 54Nm at 93 Amperes !

Any recommendations?

Thank you.

I have the possibility to acquire a non working machine to retrofit (milling machine).

The drives are not working (not sure if all) but even if they are working they are almost 30 years old, so I prefer to replace them.

The motors plates are on attachment. I would acquire the machine if I was able to buy new drives (3 units) up to 1500€, this is 500€, each drive.

The machine mechanics are very good, ballscrews 40mm, glass scales on XY axes (on Z I was not able to see it, but probably it also have), so my immediate concern are the motors. I could also acquire motors+drives but for this power I think that the price would be over killing.

Peak torque is 54Nm at 93 Amperes !

Any recommendations?

Thank you.

Last edit: 19 Oct 2014 18:19 by emcPT.

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Platinum Member

-

Less

More

- Posts: 446

- Thank you received: 35

20 Oct 2014 18:53 - 20 Oct 2014 18:54 #52205

by DaBit

Replied by DaBit on topic Advice on suitable DC drive

I am not exactly an expert in what kind of motor drives are available, but it seems that Mesa's 7i29 could work as a cost effective solution and you are a reseller of that brand.

Single channel current would be limited to 'only' 22,5A, but that is still good for operation above the continuous torque rating of the motors. Maybe it is possible to parallel the two channels of a 7i29 to obtain 45A current capacity.

The tacho would require something extra, not sure what. I think I would consider replacing the tachos with an encoder or resolver; that would give you accurate velocity information faster than a tacho does.

Single channel current would be limited to 'only' 22,5A, but that is still good for operation above the continuous torque rating of the motors. Maybe it is possible to parallel the two channels of a 7i29 to obtain 45A current capacity.

The tacho would require something extra, not sure what. I think I would consider replacing the tachos with an encoder or resolver; that would give you accurate velocity information faster than a tacho does.

Last edit: 20 Oct 2014 18:54 by DaBit.

The following user(s) said Thank You: emcPT

Please Log in or Create an account to join the conversation.

- emcPT

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 702

- Thank you received: 139

20 Oct 2014 21:10 #52206

by emcPT

Replied by emcPT on topic Advice on suitable DC drive

Thank you, honestly I didn't knew about the 7i29  (I do not stock it). I must consider it.

(I do not stock it). I must consider it.

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

25 Oct 2014 18:03 #52384

by mariusl

Regards

Marius

www.bluearccnc.com

Replied by mariusl on topic Advice on suitable DC drive

The 7i29 with a 5i20 or 5i22 will work well for your application. The 7i29 has an encoder input for every channel.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23451

- Thank you received: 4988

27 Oct 2014 22:27 #52440

by andypugh

In principle you could connect the tachos to store.mesanet.com/index.php?route=produc...input&product_id=126

Though a firmware that supported smart-serial, and a suitable adapter (7i44) would be needed.

You could then run a velocity-controlled servo loop based on the tachos, and then drive that from a position loop on the glass scales.

(ie, two PID loops per axis). This ought to give better results than just using the scales.

The alternative would be to swap the tachos for encoders and run a standard postion loop, but have a second position loop with much lower authority to "tweak" the positions.

Replied by andypugh on topic Advice on suitable DC drive

The tacho would require something extra, not sure what. I think I would consider replacing the tachos with an encoder or resolver; that would give you accurate velocity information faster than a tacho does.

In principle you could connect the tachos to store.mesanet.com/index.php?route=produc...input&product_id=126

Though a firmware that supported smart-serial, and a suitable adapter (7i44) would be needed.

You could then run a velocity-controlled servo loop based on the tachos, and then drive that from a position loop on the glass scales.

(ie, two PID loops per axis). This ought to give better results than just using the scales.

The alternative would be to swap the tachos for encoders and run a standard postion loop, but have a second position loop with much lower authority to "tweak" the positions.

Please Log in or Create an account to join the conversation.

- DaBit

- Offline

- Platinum Member

-

Less

More

- Posts: 446

- Thank you received: 35

27 Oct 2014 23:05 #52445

by DaBit

Replied by DaBit on topic Advice on suitable DC drive

I am using the second approach: encoder on the servo used for primary positioning, low bandwidth Igain-only secondary loop to process the difference between actual position and assumed position. It took a while to optimize for real loads, but it works very well now.

If the scale is used as the only position feedback one has to be very, very sure that there is no lost motion in the system. Not in backlash, not in ballscrew torsion, not in belt springiness, not in scale encoder slide suspension. I tried it just for fun to see if it is really that bad, but the slightest lost motion either makes the system go wild or requires sluggish settings. But that was with the motors in torque mode; in velocity mode (when the tacho is used for feedback) it should be much better.

If the scale is used as the only position feedback one has to be very, very sure that there is no lost motion in the system. Not in backlash, not in ballscrew torsion, not in belt springiness, not in scale encoder slide suspension. I tried it just for fun to see if it is really that bad, but the slightest lost motion either makes the system go wild or requires sluggish settings. But that was with the motors in torque mode; in velocity mode (when the tacho is used for feedback) it should be much better.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.082 seconds