Lathe retrofitting help

- hareedy

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

A friend of mine have a Mascot 1600 lathe and he asked me to convert it to a cnc lathe, now as i'm a big fan of linux i decided to go with linuxcnc over mach, so i dug into mesa store and man they have plenty of cards over there, now i have some questions i hope someone would help me answering them:

1- Are the Ethernet cards from mesa reliable?

2- If i'm gonna use 5i25+7i76 combo, what's the maximum parallel cable length i can use?

3- Is there a kernel speed limitation as in mach3 (100 khz max)?

4- Is the parallel port sufficient enough to drive a plasma machine or must i go with the mesa setup as well?

Thank you guys.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

That's a big lathe (and a lovely one). I suspect that steppers might not be powerful enough. You will need to actually measure some control forces and do some calculations I think.A friend of mine have a Mascot 1600 lathe and he asked me to convert it to a cnc lathe,

I think that even Mach3 users will generally agree that LinuxCNC does lathes a little better than Mach3 does.now as i'm a big fan of linux i decided to go with linuxcnc over mach,

Yes, though not quite 100% mainstream yet.1- Are the Ethernet cards from mesa reliable?

Be aware that whilst it is a cable intended for parallel data it isn't actually carrying normal parallel port signals. As well as the step/dir signals there is some 2.5Mb serial data being transferred.If i'm gonna use 5i25+7i76 combo, what's the maximum parallel cable length i can use?

Not with a Mesa card, unless 10MHz limits you.Is there a kernel speed limitation as in mach3 (100 khz max)?

No, the parport has enough IO for a Plasma cutter, though you may run out of step rate.Is the parallel port sufficient enough to drive a plasma machine or must i go with the mesa setup as well?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21345

- Thank you received: 7284

2. The length of the cable is proportional to the shielding built into them, i have so high quality 3 meter long cables that do work properly, i also had one 5 meter long, and often i use extension cables for the parallel port and i never have problems even at 7 meters, but i aslo had a 1.5 meter that was useles as it had no shielding except one naked wire connected to both connectors. It was fine until i switched on a compressor or god forbid my plasma cutter, it would do all kinds of crazy.

3. 100kHz???? oh hell no, parallel port can do 25kHz easily, 35 to 45 if pushed and on never hardware, anything more and you are asking for trouble. On some computers with low latency i can manage up to 50 but i refrain from going that high. Again if using mesa cards, you do not need to bother with that, they have hardware step generation an some can do up to 1mHz (1000kHz).

4. I have all my plasma machines and some other modified ones running from parallel port with THC without any trouble at all ever, some for over 5 or 6 years.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- hareedy

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

As for the Mascot god yeah it's a pretty big machine, i have some big steppers about 20 N-m that i'm gonna start with, if it's a fiasco i'm gonna go servo,

So what's the maximum step rate the 5i25 can generate?

and Tommy, what kind THC are you using?, and if you are using the THCAD from mesa does it need an external voltage divider?

Thanks again guys and sorry if i'm bugging you with this all questions.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

The maximum step rate is a lot more than any 20Nm stepper will be able to follow. About 10MHz.As for the Mascot god yeah it's a pretty big machine, i have some big steppers about 20 N-m that i'm gonna start with, if it's a fiasco i'm gonna go servo,

So what's the maximum step rate the 5i25 can generate?

I have heard good reports on the closed-loop stepper systems: www.ebay.co.uk/itm/121516261126

However, if the chap has room for a Mascot, and the electrical power for a Mascot, then he might be better swapping it for an industrial CNC lathe and retrofiting the control on that.

There are at last two ways to convert a lathe to CNC, Are you planning to retain the hand controls? Do you plan to swap to ballscrews? Using the leadscrew for all feeds might not be the best long-term plan.

There are two variants, one with a built-in divider and one without.if you are using the THCAD from mesa does it need an external voltage divider?

Please Log in or Create an account to join the conversation.

- hareedy

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

He already own the Mascot and as you know most of us are on budget

However, if the chap has room for a Mascot, and the electrical power for a Mascot, then he might be better swapping it for an industrial CNC lathe and retrofiting the control on that.

Do you plan to swap to ballscrews? Using the leadscrew for all feeds might not be the best long-term plan.

Yes, he is planning to use ballscrews, actually i'll only carry out the electrics and controls and he will handle the mechanics.

one more thing about the THCAD, i was looking at the THC models for mach and even the stand alone modules such as the ones from Proma and man these things are very very pricey compared to the THCAD, is there any reason for that?

Thank you again Andy

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Yes, he is planning to use ballscrews, actually i'll only carry out the electrics and controls and he will handle the mechanics.

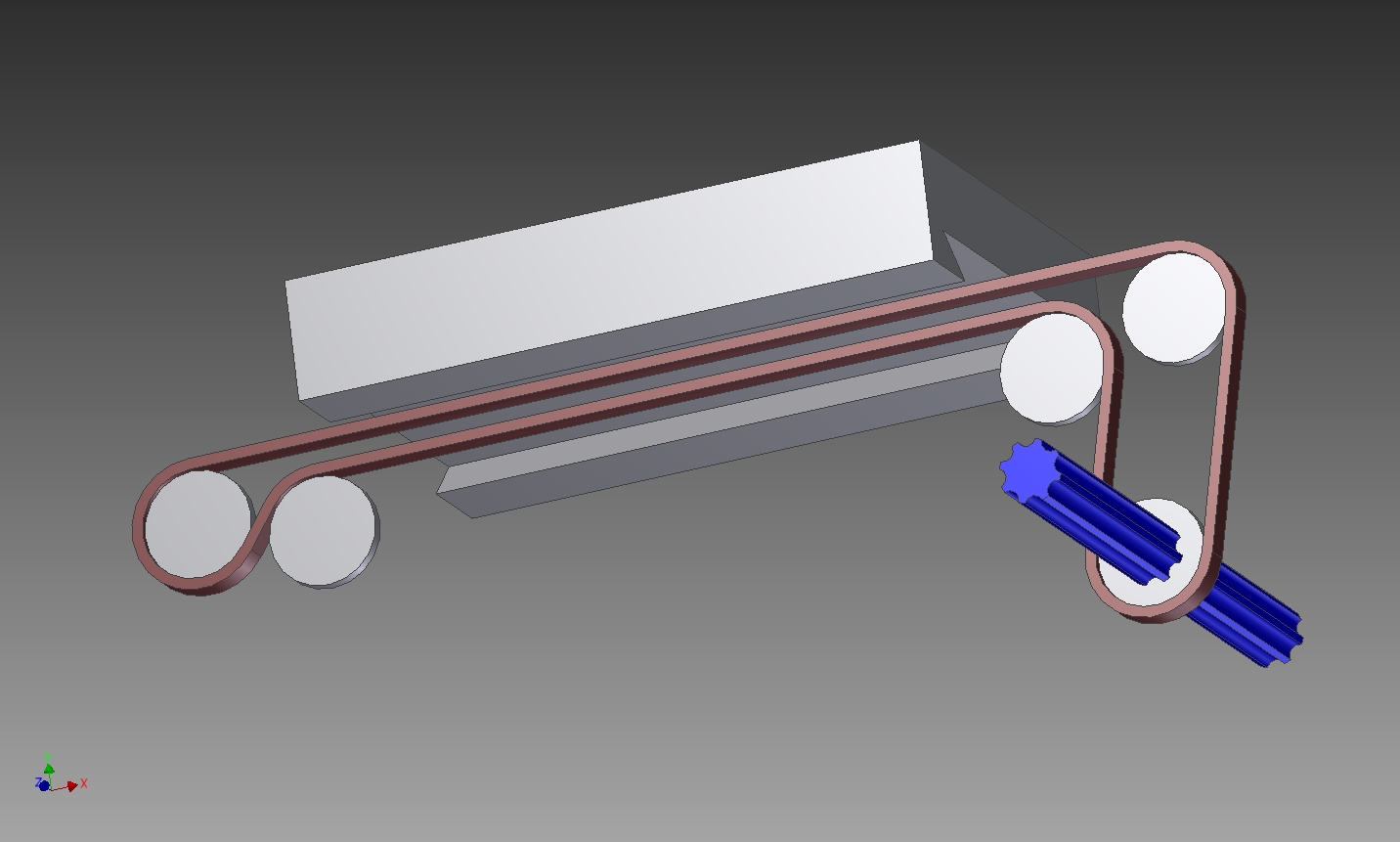

You can't simply put a ballscrew where the leadscrew is without modifying the apron to place a ballnut where the clasp-nut would normally be. The power-shaft becomes redundant, though one option that I have considered is to replace the power shaft with a ball-spline and move the tool slide with a belt or chain drive. This might avoid the common difficulty with fitting a ballnut in the tool slide.

The weakness with this design might be that the torsional stiffness of the splined shaft will decrease as the saddle moves further from the drive end.

I am currently engaged in converting a manual Holbrook lathe into a CNC lathe. I am using a number of custom-designed iron castings in an attempt to do the job to my own satisfaction. Castings are somewhat cheaper than you might guess.

The story so far is at bodgesoc.blogspot.co.uk/search/label/Hol...20to%20go%20Forwards and bodgesoc.blogspot.co.uk/search/label/Hol...3%20Pattern%20Making

I think it is worth at least considering this for the Mascot. You might note that I have a 1kW servo motor for the Z axis. I expect this to be more than adequate, but commercial CNC lathes use even larger servos.

Please Log in or Create an account to join the conversation.

- hareedy

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

Again thanks for your help

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Nice work Andy, i'll tell my friend to consider all what you've mentioned.

On further reflection I think that the splined shaft idea is fundamentally flawed, as any departure from exact straightness in the splines would translate to a diameter error.

Please Log in or Create an account to join the conversation.