Mesa Card Basics

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19797

- Thank you received: 4607

The FPGA runs a firmware known as " Hostmot2 "

The interface between LinuxCNC and the card is in HAL, but at one level above that which you configure with the parallel port.

So, with a parallel port you connect motion to a stepgen, and then choose which physical pin to use for the step output, with a Mesa card you connect motion to a stepgen input pin on the FPGA interface, and the firmware on the card determines which physical pin is step and which direction.

A parallel port configuration which contained:

net x-pos joint.0.motor-pos-cmd => stepgen.0.position-cmd

net x-step stepgen.0.step => parport.0.pin-01-outnet net x-pos joint.0.motor-pos-cmd => hm2_5i25.0.stepgen.00.position-cmdMesaflash can tell you the physical pin allocation of the installed firmware, but finding a firmware with a specific pin allocation is more difficult. One way is to download the Hostmot2 source file from Mesa and to look through the .vhd files (which are just about human-readable)

Mesa FPGA cards can connect to LinuxCNC through PCI, PCIe , EPP parallel port ( 7i43 , 7i90 ), Ethernet and SPI ( Pi version ) interfaces.

Many FPGA cards can additionally connect to expansion cards using the Mesa "smart serial" interface via CAT5 cables.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

- Posts: 1872

- Thank you received: 358

loadrt hm2_eth board_ip=192.168.1.121 config="num_stepgens=3, num_encoders=0, num_pwmgens=1"

setp hm2_7i92.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i92.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i92.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i92.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i92.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i92.0.stepgen.00.step_type 0

setp hm2_7i92.0.stepgen.00.control-type 0

setp hm2_7i92.0.stepgen.00.maxaccel [JOINT_0]MAX_ACCELERATION

setp hm2_7i92.0.stepgen.00.maxvel [JOINT_0]MAX_VELOCITY

net x-pos-fb joint.0.motor-pos-fb <= hm2_7i92.0.stepgen.00.position-fb

net x-pos-cmd joint.0.motor-pos-cmd => hm2_7i92.0.stepgen.00.position-cmd

net x-enable joint.0.amp-enable-out => hm2_7i92.0.stepgen.00.enable

Attachments:

Please Log in or Create an account to join the conversation.

- KcChris

- Offline

- New Member

-

- Posts: 8

- Thank you received: 1

I'm a newbie and still trying to get my head wrapped around this.

(looking at 7i85 - 5i25 plug-n-go kit)

The 5i25 mesa board takes over control of stepgen? So now the latency of the pc doesn't matter?

Then the 7i85 for take care of sending signals to the stepper drives?

Also a side question, if running dual Y-axis motors, do I need a stepper driver for each or can I just wire the 2 motors together (step and direction)?

Please Log in or Create an account to join the conversation.

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19797

- Thank you received: 4607

The 5i25 mesa board takes over control of stepgen? So now the latency of the pc doesn't matter?

Yes, that's correct. There is an FPGA on the 5i25 that makes steps at very regular rate up to 10Mhz.

The rate is changed by the LinuxCNC serv-thread once every millisecond or so. A great deal of jitter in the millisecond timing can be tolerated as the actual position and step rate runs closed-loop inside LinuxCNC using a PID.

The 7i85 is basically just IO pin protection and voltage conversion. The pins on the 5i25 are only safe to +5V (and something like -0.7) whereas the pins on the 7i85 are protected from -7 to +12V. It also adds handy screw terminals.Then the 7i85 for take care of sending signals to the stepper drives?

If your stepper drivers accept a differential signal then the 7i85S version is a better bet as that has differential line-drivers on board (much more noise tolerant)

You can wire two motors in series, or in parallel. Series guarantees the same current through both, and it probably the safer idea, but back-emf is doubled so for a given supply voltage the top speed will be lower.Also a side question, if running dual Y-axis motors, do I need a stepper driver for each or can I just wire the 2 motors together (step and direction)?

But, it is probably better to use two stepper drivers. Then LinuxCNC can auto-square the gantry to separate home switches and overall control is likely to be better.

Please Log in or Create an account to join the conversation.

- clunc

-

- Offline

- Elite Member

-

- Posts: 245

- Thank you received: 37

Thank you for this. As I read it, I find myself wishing it had comparisons for the spindle PWM and enable signals and home/limit switches and probe i/o as well.

Please Log in or Create an account to join the conversation.

- MarcosK

- Offline

- New Member

-

- Posts: 3

- Thank you received: 1

I have already asked this (newbie question) to Mesa's tech support, but I repeat it here in case someone could drop me some lines on this:

I own a 7i96s card and have read the manual head to tail without being able to find this piece of input: I understand P4 will accept only 5v of DC but I fear that if I do not back up those 5v with enough amperage/current, it might end up drawing too much current and have a possibly lousy PSU collapse.

How much should a PSU (at 5V) be able to provide in terms of current? 2 Amps?, more?

Cheers and thanks again for any help,

Marcos

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17705

- Thank you received: 5177

( Ignoring added Encoder or Expansion board load, the 7I96S only draws about 200 mA)

Please Log in or Create an account to join the conversation.

- Robbin

- Offline

- New Member

-

- Posts: 10

- Thank you received: 0

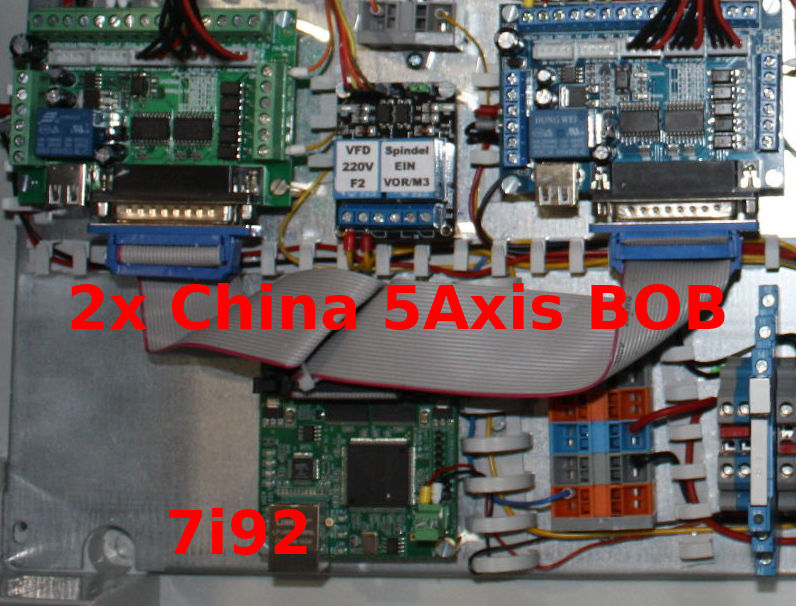

i am a new user of linuxcnc, recently i purchased a Mesa 7i92T card to go with the two 5 Axis Chinese bobs i already had for the plasma machine that it needs to control.

i am bit confused and can't find my answer anywhere.

are the step/dir outputs also capable of being an input? or do i need a different bob for all the end stop/switches etc.?

cheers, Robbin

Please Log in or Create an account to join the conversation.

- Cant do this anymore bye all

-

- Offline

- Platinum Member

-

- Posts: 1200

- Thank you received: 425

Just be sure that the second BoB you get supports changing the 8 pit port to either input or output, other wise you'll be stuck with 12 outputs & 5 inputs per card.

Something such as this is a example:

cnc4pc.com/bi-directional-parallel-port-card.html

This is one I have, unfortunately out os stock:

www.homanndesigns.com/index.php?main_pag...nqrjh2mun1b5lp4aubc2

Please Log in or Create an account to join the conversation.

- Robbin

- Offline

- New Member

-

- Posts: 10

- Thank you received: 0

Please Log in or Create an account to join the conversation.