Best Ethernet Based Board in 2020

- EverydayDiesel

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

I plan on using these power supplies

www.teknic.com/products/servo-motor-dc-power-supply/

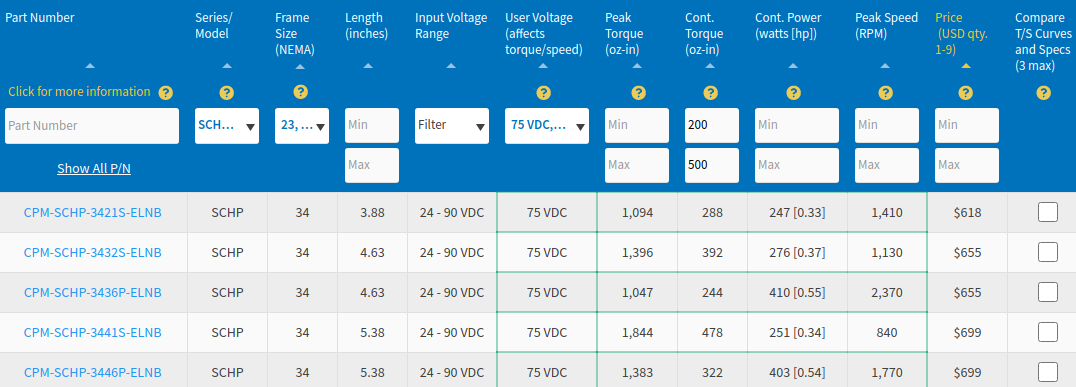

One of these motors (they have an API

Will these SC (software control) line of the teknic work with linuxcnc?

www.teknic.com/clearpath-accessories-guide/

will the 7i76e workr with these motors with the built in controllers or is there another option to look at?

Attachments:

Please Log in or Create an account to join the conversation.

- EverydayDiesel

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

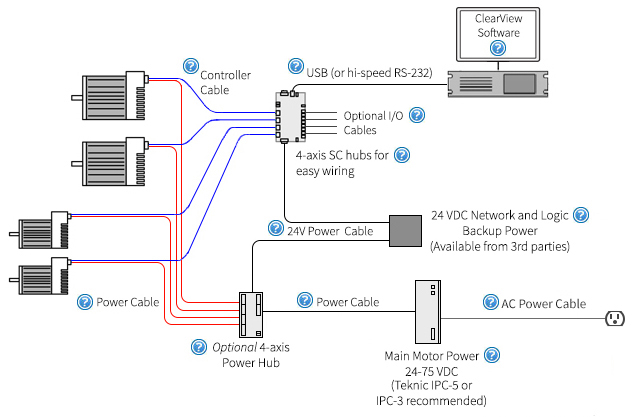

computer --> 7i76e --> SC4-HUB --> servos (with built in controller) [of course also connected to power supply]

Communication Hub for ClearPath-SC Series

Part Number: SC4-HUB

Input: 15-30 volts

Connectors: See drawing

Dimensions, in (mm): 3.56 x 5.31 (90.4 x 134.9)

Certifications: UL, CE (pending)

www.teknic.com/images/sc_hub_lightbox_drawing_3.jpg

EDIT: Maybe i dont need the SC4-HUB at all and the new data flow can be

computer --> 7i76e --> servos (with built in controller)

I can buy these cables to connect the motor to the 7i76e

Controller Cable, 10 ft

Part Number: CPM-CABLE-CTRL-MU120

Connectors: 8-pin Molex Mini-fit to 8-pin Molex Mini-fit (one connector is overmolded)

Length: 3.05 m (10 ft)

This cable connects your digital control signals (from switches, buttons, PLCs, etc.) to your ClearPath motor. The overmolded Molex connector connects to the motor (which allows an IP-65 sealed connection when used with dielectric grease), and the other end can be plugged into a breakout board (or for ClearPath-SC, the SC communication hub), or cut off to create flying leads to allow you to wire into any control device you may use.

www.teknic.com/images/accessories/329_lg.jpg

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11668

- Thank you received: 3932

Those are designed for industrial use, convyers etc.

Please Log in or Create an account to join the conversation.

- EverydayDiesel

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Nitram

-

- Offline

- Elite Member

-

- Posts: 210

- Thank you received: 15

The attached pdf helped immensely.

Please Log in or Create an account to join the conversation.

- EverydayDiesel

- Offline

- New Member

-

- Posts: 14

- Thank you received: 0

NO for CNC you need to use their SD (step and direction) drives so they can be controlled by Linuxcnc (or other similar systems.

Those are designed for industrial use, convyers etc.

You were right. I reached out to the company with several questions and this was the response...

I'm an applications engineer with Teknic. I was recently forwarded your contact request regarding the differences between the SC and SD ClearPath servo motors.

In short - you can use SC motors to take in step and direction, but I wouldn't recommend it. The MES 717rE should be a pretty good fit (I have seen customers use it in the past, and LinuxCNC is a good choice for the CNC control software.

That being said, if you are looking for the motor drive to interface with step and direction signals (generated by the G-code), it's best to use a CNC software that is configured to accept the signals CNC controllers generally output. Creating your own trajectory generator that interfaces with G-code is a non-trivial task, although it is possible to do so.

Essentially, the SD motors come configured to work in CNC applications with little programming (other than configuration) with the motors themselves. They simple wire to a controller and breakout-board. The SC motors can take in step and direction commands, but you would need to program the operational mode completely from scratch. With that, you would also need to setup a host PC (single board computer) that interfaces with serial communication in order to input the step and direction signals into the motor inputs.

Please Log in or Create an account to join the conversation.