I need super basic Help with Hardware choices

- Twizzlermill

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 5

I kinda feel stupid, because this feels like a super basic question and I already did a lot of research, but maybe in the wrong places… I hope this is the right one.

In short, I have a CNC machine I'm currently working on and I need it to move (duh). It's just that somehow, I really don't know what hardware I need and how to find this out.

What I have/want:

1.: A Raspberry Pi 4 as a computer (with all the other stuff of course).

2.: 4 JMC Closed Loop Stepper motors(Model IHSS60-36-30-21-38); the y-axis will need two.

What I have a hard time understanding is everything I need to somehow get those two parts to communicate. Maybe it's a matter of how it is worded, but looking at vendors, it seems like a lot of their hardware is application specific and I would have a hard time getting it to work.

There also seem to be some out-of-the-box solutions, but I'd rather use LinuxCNC or bCNC than pay-ware on Windows 7…

So, TL;DR:

I need help understanding what I need to get the computer to move the steppers; assume I'm five years old.

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

- Posts: 204

- Thank you received: 45

Some more limited than others.

1 just use the RPI4 and its built in gpio thats the headers on the board to connect to your stepper motor drivers.

This is cheapest but will have max speed limits and limited expansion and possibly features. it will also lack any protection incase a mistakes happens you could fry the RPI4.

2. Mesa cards, these are card built to control cnc machines there are 2 options with the rpi4 a Ethernett based one or a SPI card based,

This option will have the most support here and have lots of ability to expand.

3. Use a project called Remora that allows the RPI4 to use a 3d printer controller board such as a skr1.4

This option is the second lowest cost, has much more function vs using just the RPI but it is new and has less users who have used it.

i must say i have used it and i like it very much the creator has even added features to it for my machine such as a high speed spindle encoder able to track my spindle at 5k rpm.

4. the last option is how i started i found an old computer that had the big parallel port and bought a cheap break out board

the usb is only there for power it works via the big port. this port was common back in the day for printers and other devices.

This could get you up and running very fast for little cost.

linux cnc has a built in config tool to make a config to use one of these.

This might be the best way to learn and understand linux cnc or at least it was for me.

There is an option to install a port add on card but there are only some that work and for people starting out a second port is not needed. also some old laptops have this port as well and you can try to use them but some have reduced voltage and or power and the break out boards dont always like them. but at sub 10$ for the boards its worth a shot.

the basic control scheme of the www.jmc-motor.com/product/954.html

is 3 pins 1 to enable the motors aka the on switch.

next is the direction pin if its on it turns one way off another.

And finally the step pin. when this pin is turn on and off the motor will turn one step. a step is normally 1.8deg There are options on a motor to turn on micro stepping so half step would be 0.9deg and quarter would be 0.45 and so on.

So depending on your machine and how many features you want and the speeds you want it to hit will help you decide what you will want to use.

What type of machine wiil this be?

Is it a self built router with a large cutting area?

A converted manual mill?

Maybe a cnc machine that had dead controls and you are going to replace the controls.

What are you going to cut?

More info and pictures will help.

Please Log in or Create an account to join the conversation.

- Twizzlermill

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 5

I'll parse your suggestions when my brain is less preoccupied, so here's just a quick overview of what I'm doing:

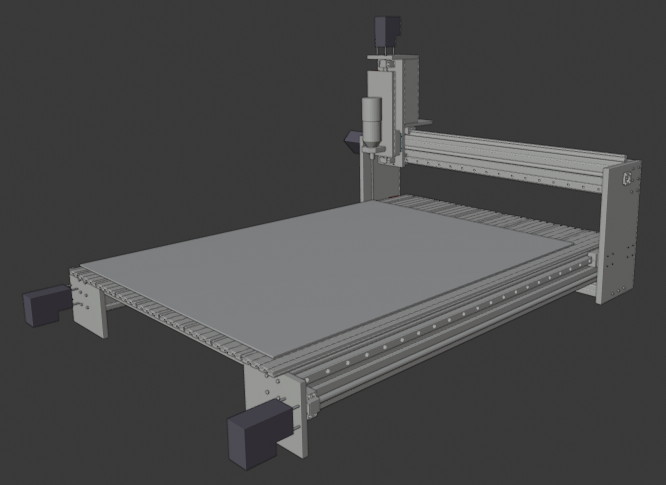

It's a self-built CNC router with a working area of roughly 120 x 95 x 18 centimeters, mostly made out of aluminum profiles and plates. 16/5 mm spindles, the longest will be 140 cm. Rail guides. The plates are rectangles because my access to a router is limited, so, I'll build it like this for now and maybe use the machine to improve itself.

It will mostly cut MDF, acrylic and wood, but since I've got a grant to build it (and I can only use the money on this specific project), I decided to build it as beefy and upgradeable as possible. Also, having such a beefy machine, I'd like to play with working aluminum as well, but it won't be a focus.

The main choice of materials to work on suggests that I might be able to run the router relatively quickly, which I'd be interested in.

Apart from speed, I want to use closed loop steppers. Does that change anything regarding what I need to look for to use them?

Also, I totally forgot endstops, which I obviously also need.

For now, it'll move a 1.5kw Suhner router, which is mostly due to me not willing to introduce more complexity and that my working space's fuses won't allow running a too powerful router plus dust collection.

Here's a rough sketch of what I'm working on. the blank space is the working area.

Attachments:

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

- Posts: 204

- Thank you received: 45

Is this a tool for learning mostly?

Given the size you would want something capable of good rapid travel speeds to help speed up cycle times.

You could get by without but jogging around would be slow.

So I would look towards option 2 and 3

But if you want to hit the ground running fast to start learning while you make a long term option 1 and 4 and going to be a great start. I would go for number 4 as it's a safe and easy starting point.

End switches/ home can be any mechanical momentary switch. Even ones for 3d printers will work. Avoid optical as dust and cutting debris will cause problems. A relay for your spindle would be a good idea.

www.amazon.com/SSR-40DA-Solid-Output-24-...id=1623121809&sr=8-4

These are not actually 20a more like 10 to 15a

But I would get one for the spindle and one for your dust collection system.

These take a low voltage signal from one of the control boards or pc and allow it to turn on and off a mains powered device.

Please Log in or Create an account to join the conversation.

- Twizzlermill

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 5

Is this for hobby or production?

Is this a tool for learning mostly?

Given the size you would want something capable of good rapid travel speeds to help speed up cycle times.

You could get by without but jogging around would be slow.

It's definitely more for production. It's not that I don't enjoy the building process and I'm eager to learn, but I need it to work rather than indefinitely fiddling around with it.

Speed is a factor for me as well, because you are right, it's a big machine and I intend on using it to its full size (well, maybe not along the z-axis, but we'll see).

However, due to the material craziness, I have to wait at least a month for my profiles, so I have ample time to play around with steppers. I ordered a cheap breakout board and will just see how far I get.

Thanks for the suggestion regarding relays, by the way. It's definitely something I'll consider.

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

- Posts: 204

- Thank you received: 45

Again as i said the usb is only for power.

alot of old pc from the dual core E8xxxx and pentium 4 and Celerons have this.

You could also use that breakout board with a RPI4 as a protection circuit.

You would need to make your own cable to adapt the gpio on the rpi4 to the parallel port the break out board uses.

also dont try and use a usb to parallel port adapter those will not work.

usb timings are not tight enough and have other problems. must be a built in port to the mobo or a pci card based one.

Please Log in or Create an account to join the conversation.

- Twizzlermill

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 5

Do you have an old pc with the right ports to work with the break out board?

I got some old laptops lying around, some from 2006-ish.

Yeah, I already read somewhere else that USB options seem to exist, but are considered a bad choice.

I think for now, I'll just get some hardware and have a go at it, but I have one last relatively unrelated question:

The motors I want to use are rated at up to 50V, but according to JMC, are typically used with 36V. I already read somewhere else that running them at their rated maximum (so 50V) would be a bad idea (If I understood correctly, this has to do with the motors turning into dynamos when the machine brakes – or was that with servos?Plus a chance of overheating, I guess.), but how do I decide what's the right voltage for me? Should I go as high as possible, but with some "reserve"? If yes, how big should that reserve be?

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

- Posts: 204

- Thank you received: 45

yes when the machine slows down its possible for the motor to feed back voltage.

This is also why in alot of system i have seen they dont use switching power supplies but big transformer based ones for the drive motors.

more voltage will allow you to go faster to a point but heat dissipation from the motor can become a problem and may need an active cooling solution.

I would stick around or just under 40V DC.

you might leave a bit of speed on the table but i doubt it will be that much the extra few volts will get you vs the problems that may come in the long term of running up against the rated max.

Its no fun in the middle of a 7 hour part a drive motor overheats and kicks off but the machine keeps going.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21176

- Thank you received: 7235

If those are the Nema23 ones with the drive attached to one side on the motor, those are servos that use step/dir control, not steppers.

Usually servos are better, but that highly depends on what they are used for.

Please Log in or Create an account to join the conversation.

- Twizzlermill

- Offline

- Senior Member

-

- Posts: 40

- Thank you received: 5

Just to be on the safe side, are you sure those are steppers as i have not seen those made bu JMC, but i never looked closely.

If those are the Nema23 ones with the drive attached to one side on the motor, those are servos that use step/dir control, not steppers.

Usually servos are better, but that highly depends on what they are used for.

JMC makes both servos(e.g. iHSV57) and closed loop steppers(e.g. IHSS60), which look pretty much the same.

I decided not to fuss with servos, because they seem to need more active calibration and from what I gathered, the size of my router (more specifically the length of the spindles) limits travel speed anyway.

I would stick around or just under 40V DC.

you might leave a bit of speed on the table but i doubt it will be that much the extra few volts will get you vs the problems that may come in the long term of running up against the rated max.

Its no fun in the middle of a 7 hour part a drive motor overheats and kicks off but the machine keeps going.

Thanks, thinking about it a little more, that's what I assumed as well. In the end, 90% of what I'll be working on will be MDF, so I can live with a little less power.

Please Log in or Create an account to join the conversation.