PWM/frequency signal as input to Mesa card

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

07 Jun 2024 02:32 #302502

by Unlogic

Replied by Unlogic on topic PWM/frequency signal as input to Mesa card

After running some prolonged milling sessions with my mill I've decided to go a different route here.

I'm going completely replace the VFD, the gigantic 2kw AC spindle motor and the noisy 6 speed transmission.

I'll be replacing the whole setup with a Delta B3 2kw 400v AC servo rated for max 6000 RPM and use a belt drive with 1:1 ratio pulleys to drive the spindle directly.

This should give me plenty of low end torque, a built in encoder and double the max RPM of what I had before at much lower noise level.

But I just realized that the question of how to read the spindle load from the servo drive still remains. The load is available from the Delta servo drive either as an analog signal or via Modbus.

As I'm using a Mesa 7i96S + 7i84 combo I have no analog inputs available and the Modbus capable RS422/485 port is already used for the 7i84.

What's the best way around this?

Do I try to source a Mesa 7i76EU which has a few analog inputs and replace the Mesa 7i96S board?

Can I use the FPGA expansion port in some clever way without adding too many expansion cards?

I'm going completely replace the VFD, the gigantic 2kw AC spindle motor and the noisy 6 speed transmission.

I'll be replacing the whole setup with a Delta B3 2kw 400v AC servo rated for max 6000 RPM and use a belt drive with 1:1 ratio pulleys to drive the spindle directly.

This should give me plenty of low end torque, a built in encoder and double the max RPM of what I had before at much lower noise level.

But I just realized that the question of how to read the spindle load from the servo drive still remains. The load is available from the Delta servo drive either as an analog signal or via Modbus.

As I'm using a Mesa 7i96S + 7i84 combo I have no analog inputs available and the Modbus capable RS422/485 port is already used for the 7i84.

What's the best way around this?

Do I try to source a Mesa 7i76EU which has a few analog inputs and replace the Mesa 7i96S board?

Can I use the FPGA expansion port in some clever way without adding too many expansion cards?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

07 Jun 2024 03:25 #302505

by tommylight

Replied by tommylight on topic PWM/frequency signal as input to Mesa card

1. get a Mesa THCAD, it can do pretty good analog to digital, should be more than enough for spindle load, but that would also require an encoder input to Mesa 7i96S, in case the spindle is already using it.

That might still be usable if the spindle does not require the index pin as THCAD requires only a single pin.

Or wire the THCAD to the IDC26 connector, might need firmware flashing.

2. Get a LM331 chip, some resistors and capacitors, and build a voltage to frequency converter, 8 pin chip, 1-3$ a piece, info here:

www.ti.com/lit/ds/symlink/lm231.pdf?ts=1...Fwww.google.com%252F

3. same as 2 but get a ready made module, under 10$ usually.

That might still be usable if the spindle does not require the index pin as THCAD requires only a single pin.

Or wire the THCAD to the IDC26 connector, might need firmware flashing.

2. Get a LM331 chip, some resistors and capacitors, and build a voltage to frequency converter, 8 pin chip, 1-3$ a piece, info here:

www.ti.com/lit/ds/symlink/lm231.pdf?ts=1...Fwww.google.com%252F

3. same as 2 but get a ready made module, under 10$ usually.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17581

- Thank you received: 5142

07 Jun 2024 03:50 #302506

by PCW

Replied by PCW on topic PWM/frequency signal as input to Mesa card

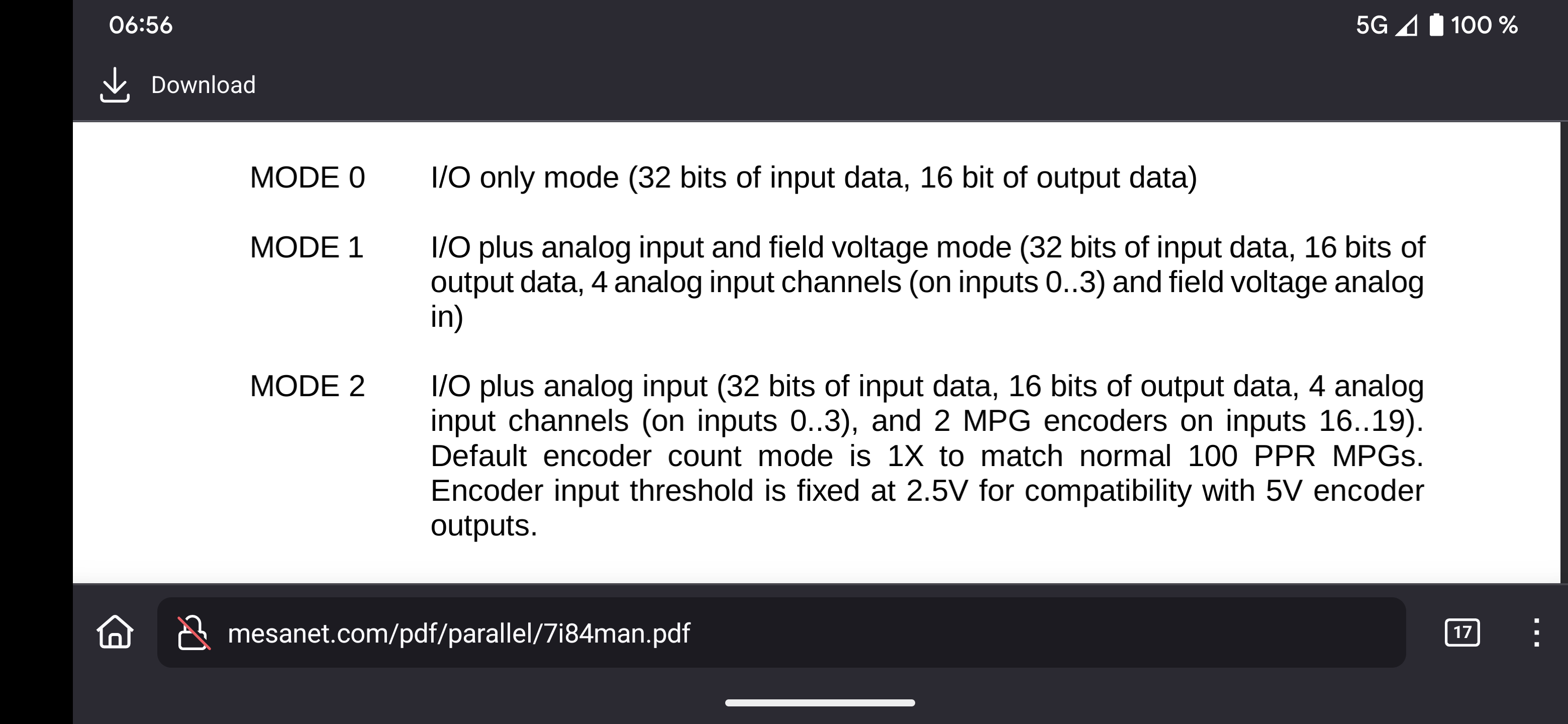

There are 4 analog inputs on the 7I84

The following user(s) said Thank You: Unlogic

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

07 Jun 2024 05:00 - 07 Jun 2024 05:04 #302509

by Unlogic

I had no idea about how that, how could I have missed the mode setting.

Replied by Unlogic on topic PWM/frequency signal as input to Mesa card

PCW to the rescue!There are 4 analog inputs on the 7I84

I had no idea about how that, how could I have missed the mode setting.

Attachments:

Last edit: 07 Jun 2024 05:04 by Unlogic.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

07 Jun 2024 12:57 #302531

by tommylight

Replied by tommylight on topic PWM/frequency signal as input to Mesa card

4. use existing analog inputs on Mesa 7i84.

-

Cr@p, forgot about that, getting to damn old, sorry.

-

Cr@p, forgot about that, getting to damn old, sorry.

Please Log in or Create an account to join the conversation.

- Unlogic

- Offline

- Elite Member

-

Less

More

- Posts: 238

- Thank you received: 118

14 Sep 2024 07:43 #310123

by Unlogic

Replied by Unlogic on topic PWM/frequency signal as input to Mesa card

A final update to this thread, using the anslog inputs on the Mesa 7i84 worked like a charm and I now have spindle load reading in Probe Basic.

While doing the setup I noticed that the four analog inputs on the 7i84 in mode 1 can still be used as normal digital inputs which makes the change from mode 0 to mode 1 very simple.

It's hard to not fall in love with these Mesa cards. So far they have managed to handle everything I've thrown at them.

While doing the setup I noticed that the four analog inputs on the 7i84 in mode 1 can still be used as normal digital inputs which makes the change from mode 0 to mode 1 very simple.

It's hard to not fall in love with these Mesa cards. So far they have managed to handle everything I've thrown at them.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

14 Sep 2024 12:33 #310139

by tommylight

Replied by tommylight on topic PWM/frequency signal as input to Mesa card

All that, and the best support on planet earth from PCW.

While doing the setup I noticed that the four analog inputs on the 7i84 in mode 1 can still be used as normal digital inputs which makes the change from mode 0 to mode 1 very simple.

It's hard to not fall in love with these Mesa cards. So far they have managed to handle everything I've thrown at them.

Please Log in or Create an account to join the conversation.

- vre

- Offline

- Platinum Member

-

Less

More

- Posts: 609

- Thank you received: 17

14 Sep 2024 15:14 #310150

by vre

Replied by vre on topic PWM/frequency signal as input to Mesa card

I have also 7i84 and didn't know these analog inputs.

can use these inputs to read 0-9v analog plasma arc voltage?

can use these inputs to read 0-9v analog plasma arc voltage?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

14 Sep 2024 16:07 #310153

by tommylight

Replied by tommylight on topic PWM/frequency signal as input to Mesa card

7i84 should also have 4 analog inputs that can do up to VCC, so yes you can use it to measure 9V, but at low resolution and at low speeds.

Although speed might not be much of an issue for slow cutting with plasma, the resolution is as it will cause big jumps when correcting.

Buy a THCAD.

Or make a THC using a "voltage to frequency converter" chip, plenty of those around and quite cheap, until you figure out you need high voltage isolation and care with wiring and stuff, so it really does not pay off to build one, given the price of THCAD is really low for what you get.

Although speed might not be much of an issue for slow cutting with plasma, the resolution is as it will cause big jumps when correcting.

Buy a THCAD.

Or make a THC using a "voltage to frequency converter" chip, plenty of those around and quite cheap, until you figure out you need high voltage isolation and care with wiring and stuff, so it really does not pay off to build one, given the price of THCAD is really low for what you get.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17581

- Thank you received: 5142

14 Sep 2024 18:15 #310159

by PCW

Replied by PCW on topic PWM/frequency signal as input to Mesa card

One big issue with reading the plasma voltage is that the GND connection

will have large (possibly 50V or more) high frequency transients when the

torch fires. This makes is very easy to damage connected devices. This is why

the THCAD is fully isolated and has only a few pF of capacitance between the

plasma side and the control side.

Funny aside: We had to change the name of the THCAD on a invoice for a

shipment to Brazil as anything with the letters THC gets held up in customs...

will have large (possibly 50V or more) high frequency transients when the

torch fires. This makes is very easy to damage connected devices. This is why

the THCAD is fully isolated and has only a few pF of capacitance between the

plasma side and the control side.

Funny aside: We had to change the name of the THCAD on a invoice for a

shipment to Brazil as anything with the letters THC gets held up in customs...

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.094 seconds