Gould Gettys Servo Amplifier Drifting User Guide

- rmavalente

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

07 Jan 2025 18:10 #318319

by rmavalente

Gould Gettys Servo Amplifier Drifting User Guide was created by rmavalente

Hello Mates,

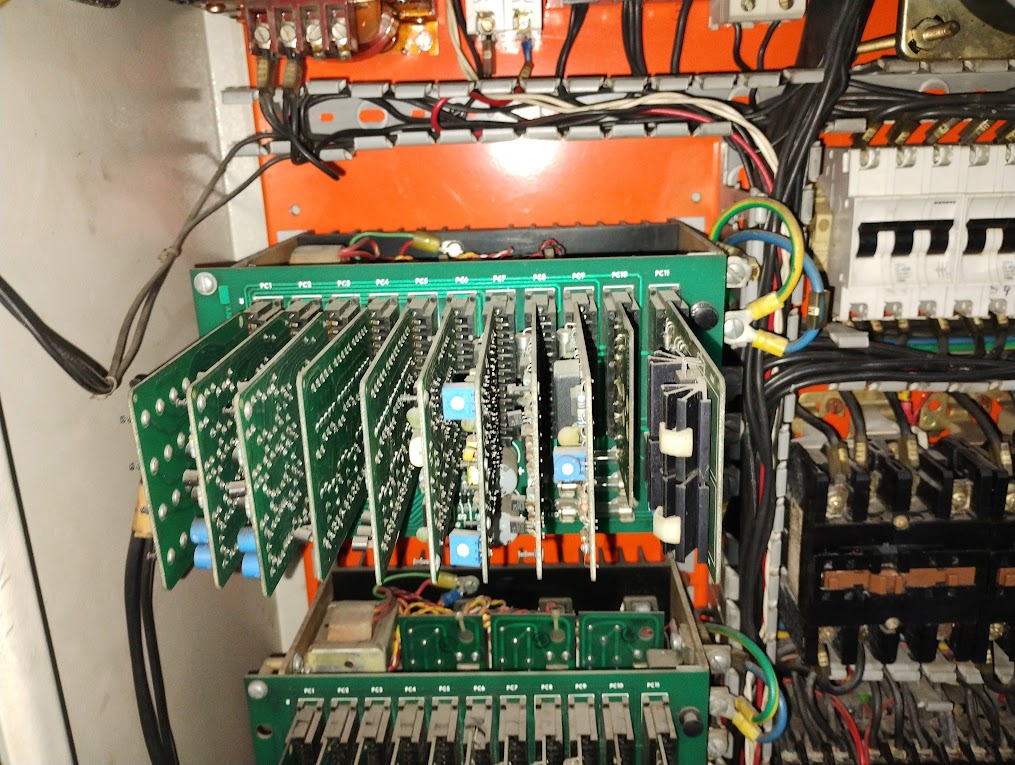

my milling machine is based on 3 N360 / A121 (I guess) servo amplifiers from gould. I believe they need a little adjustment to reduce drift (about 12 to 16V whe 0V at analog in). Thing is I can not find their manuals anywhere! Gould gettys has been dissolved, their tech support could no care less about my request. There is a guy selling one manual on ebay, but he will not ship to Brazil. Can anyone help?

Greetings!

my milling machine is based on 3 N360 / A121 (I guess) servo amplifiers from gould. I believe they need a little adjustment to reduce drift (about 12 to 16V whe 0V at analog in). Thing is I can not find their manuals anywhere! Gould gettys has been dissolved, their tech support could no care less about my request. There is a guy selling one manual on ebay, but he will not ship to Brazil. Can anyone help?

Greetings!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21162

- Thank you received: 7226

07 Jan 2025 18:25 #318322

by tommylight

Replied by tommylight on topic Gould Gettys Servo Amplifier Drifting User Guide

Do NOT fix drift!

All analog servo systems will have a bit of drift at 0V input.

Wire the control, it takes care of it when encoders are in use.

All analog servo systems will have a bit of drift at 0V input.

Wire the control, it takes care of it when encoders are in use.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

08 Jan 2025 19:40 #318453

by jmelson

Jon

Replied by jmelson on topic Gould Gettys Servo Amplifier Drifting User Guide

Well, I wouldn't go that far. Make sure the velocity DAC is outputting zero, and then adjust the "balance" or velocity offset put to get minimum drift. You will not be able to get it down to absolute zero, but any drift in the amp will offset your position when not commanding movement. If you really have 12 - 16 V output to the motor with zero in, then something is QUITE wrong! That could be an open connection to the tachometers. If the machine has been sitting a long time, the commutator of the tachs might be oxidized, maybe running the motors a bit might clean them. Or, it could be a dirty connector contact.Do NOT fix drift!

All analog servo systems will have a bit of drift at 0V input.

Wire the control, it takes care of it when encoders are in use.

Jon

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.092 seconds