Looking for advice retrofitting older CNC

- NtroP

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

26 Feb 2025 23:18 #322759

by NtroP

Looking for advice retrofitting older CNC was created by NtroP

Greetings.

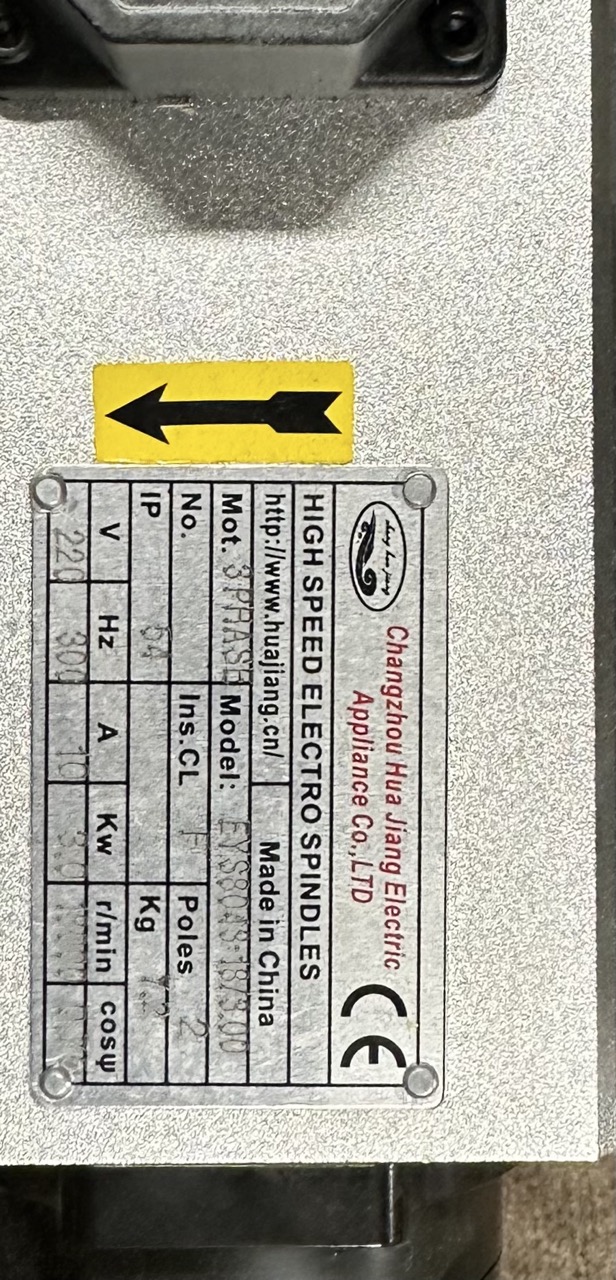

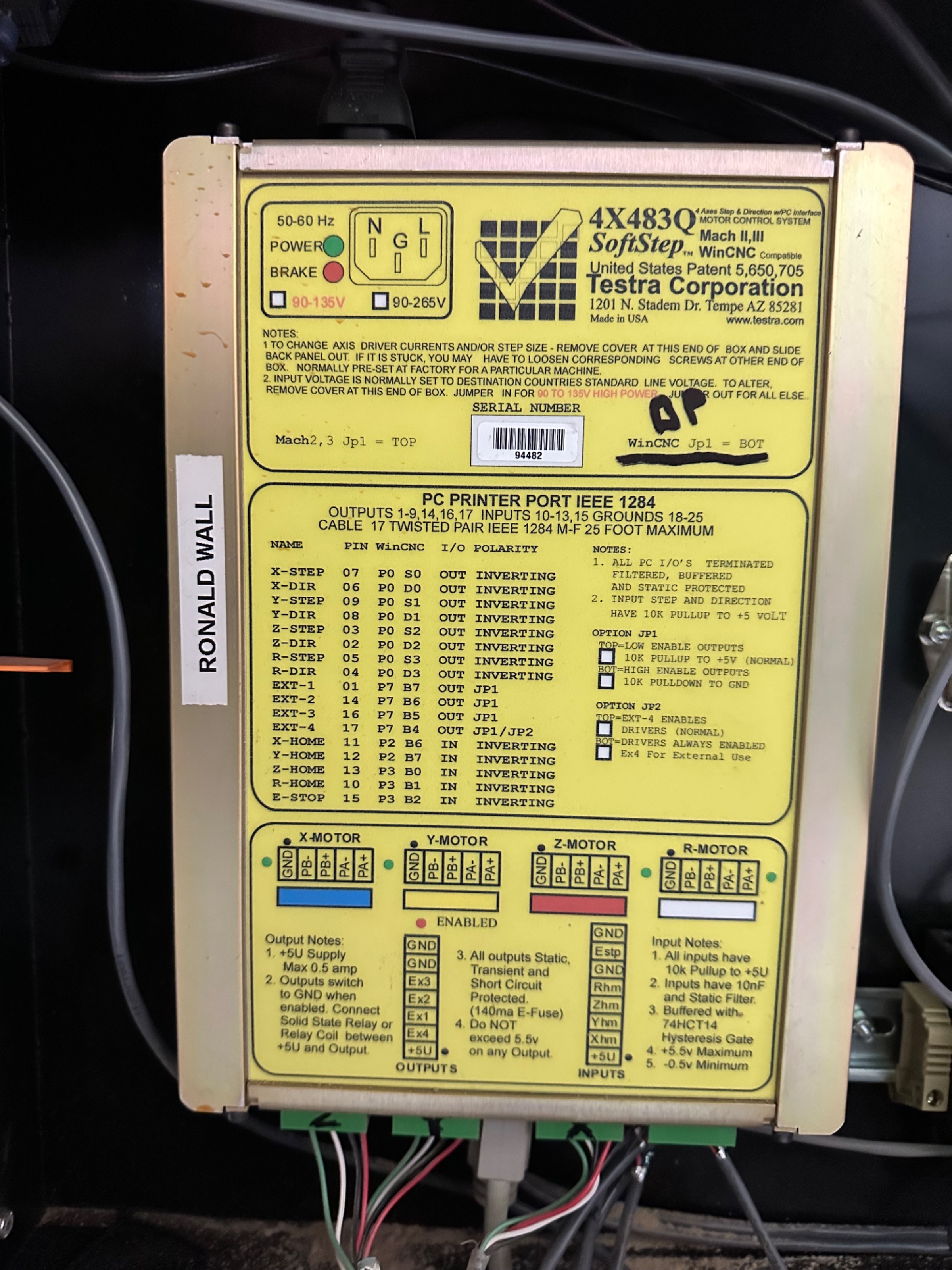

I'm new to linuxCNC (and CNC in general). I've been "gifted" a Stinger CNC after the owner upgraded to a newer machine because he was having problems with the software on this one. It came with an OLD tower PC running WinXP and WinCNC. This was connected via parallel port to another box that housed the controller and other electronics like the emergency shutoff switch, etc. The controller it uses is a Testra 4x483Q. I've purchased a mini-pc with a parallel port and loaded linuxCNC on it. I've begun trying to get it configured to talk to the controller but it's not natively compatible and it's been giving me some issues. Frankly, I'd just as soon put new controllers into the box that are natively supported by LinuxCNC but before I go spending hundreds of dollars on what would be a stab in the dark for me, I thought I'd ask for some advice. Oh, I've also purchased a 3-phase, 220V (chinesium) spindle with an H100-series "High Performance Vector Control Inverter" to replace the router it came with so I'd like/need to be able to control that as well. Any help or advice you can offer will be appreciated. Do I keep fighting with getting the old controller to talk to LinuxCNC or do I get a new set of controllers, power supplies, etc that are known to work with LinuxCNC and build it back up myself (and hopefully learn something along the way?). Recommendations for controllers and power supplies would be great.

Thanks!

I'm new to linuxCNC (and CNC in general). I've been "gifted" a Stinger CNC after the owner upgraded to a newer machine because he was having problems with the software on this one. It came with an OLD tower PC running WinXP and WinCNC. This was connected via parallel port to another box that housed the controller and other electronics like the emergency shutoff switch, etc. The controller it uses is a Testra 4x483Q. I've purchased a mini-pc with a parallel port and loaded linuxCNC on it. I've begun trying to get it configured to talk to the controller but it's not natively compatible and it's been giving me some issues. Frankly, I'd just as soon put new controllers into the box that are natively supported by LinuxCNC but before I go spending hundreds of dollars on what would be a stab in the dark for me, I thought I'd ask for some advice. Oh, I've also purchased a 3-phase, 220V (chinesium) spindle with an H100-series "High Performance Vector Control Inverter" to replace the router it came with so I'd like/need to be able to control that as well. Any help or advice you can offer will be appreciated. Do I keep fighting with getting the old controller to talk to LinuxCNC or do I get a new set of controllers, power supplies, etc that are known to work with LinuxCNC and build it back up myself (and hopefully learn something along the way?). Recommendations for controllers and power supplies would be great.

Thanks!

Attachments:

Please Log in or Create an account to join the conversation.

- NtroP

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

26 Feb 2025 23:23 #322761

by NtroP

Replied by NtroP on topic Looking for advice retrofitting older CNC

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17710

- Thank you received: 5183

27 Feb 2025 00:06 #322765

by PCW

Replied by PCW on topic Looking for advice retrofitting older CNC

Looks like that should be relatively easy to get working

with a parallel port and LinuxCNC + StepConf since

it was designed for a standard parallel port interface.

What issues did you have?

with a parallel port and LinuxCNC + StepConf since

it was designed for a standard parallel port interface.

What issues did you have?

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 50

27 Feb 2025 05:05 - 27 Feb 2025 05:32 #322772

by timo

Replied by timo on topic Looking for advice retrofitting older CNC

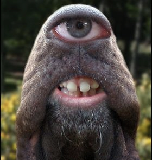

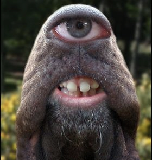

Haha, you are in luck that someone bothered to print information on that thing.

I would

Chances are that you can drive the VFD via PWM directly. (maybe a digital potentiometer is an easy way to do) A 2nd parallel port can be added if there is not enough IO left for the VFD.

I would

- provided nothing damaged on the machine, not touch its electrics.

- get it running without integrating the spindle into the control. (safe that machine configuration)

- start working on spindle integration with another machine configuration (that way you can take your time to figure it out and still use the machine to cut something)

Chances are that you can drive the VFD via PWM directly. (maybe a digital potentiometer is an easy way to do) A 2nd parallel port can be added if there is not enough IO left for the VFD.

Last edit: 27 Feb 2025 05:32 by timo.

The following user(s) said Thank You: NtroP

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17710

- Thank you received: 5183

27 Feb 2025 15:20 #322795

by PCW

Replied by PCW on topic Looking for advice retrofitting older CNC

Yes, that label with all the specifications is great!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21306

- Thank you received: 7277

27 Feb 2025 21:38 #322825

by tommylight

Replied by tommylight on topic Looking for advice retrofitting older CNC

The pin numbers on that label are the exact pin numbers on a parallel port, so enter those in the StepConf wizard.

As for spindle, almost all new VFD's will accept 0-5V or 0-10V that can be set, so setting it to 5V and using a resistor and a capacitor will give you roughly 0-4.5V of analog voltage from a 5V parallel port, or 0-3V from a 3.3V parallel port.

As for spindle, almost all new VFD's will accept 0-5V or 0-10V that can be set, so setting it to 5V and using a resistor and a capacitor will give you roughly 0-4.5V of analog voltage from a 5V parallel port, or 0-3V from a 3.3V parallel port.

The following user(s) said Thank You: timo, NtroP

Please Log in or Create an account to join the conversation.

- NtroP

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

28 Feb 2025 21:18 #322888

by NtroP

Replied by NtroP on topic Looking for advice retrofitting older CNC

Thanks for the information. One of the issues I'm running into is something to do with needing an "enable" signal or something. Still working through that.

I did the latency test. It came out around 150 nanoseconds if I remember correctly.

I did the latency test. It came out around 150 nanoseconds if I remember correctly.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21306

- Thank you received: 7277

28 Feb 2025 22:08 #322893

by tommylight

Replied by tommylight on topic Looking for advice retrofitting older CNC

Option JP2 on the label, set it to always on for now.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.188 seconds