Retrofitting a 3-axis VMC with DC servos - guidance needed

- Japoo_Ness

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 1

07 Aug 2025 11:07 #332999

by Japoo_Ness

Retrofitting a 3-axis VMC with DC servos - guidance needed was created by Japoo_Ness

Hi everyone,

I'm currently working on the retrofit of a 3-axis vertical machining center (from 1995) and have decided to use LinuxCNC with Mesa boards. The machine is in excellent mechanical condition, but the original controller (Fagor 8025M) is beginning to fail. I’m still evaluating whether it’s worth repairing, but I’m leaning toward fully modernizing it instead.

Here are the key technical details of the system:

The machine will be used for both production and toolmaking, so reliability and precision are key. The current system performs interpolation and achieves 0.01 mm precision, and I’d like to match or improve upon that.

I’d like to ask:

- Has anyone here done a similar retrofit with SEM DC motors and Axor drives?

- Is it reasonable to expect similar or better precision from LinuxCNC using KA300 scales and Mesa hardware?

- Are there any specific concerns when using analog ±10 V control with older servo amplifiers?

- Any advice or experience you could share with full closed-loop systems based on linear feedback?

- I’m also interested in your thoughts on encoder scaling, latency tuning, and best practices for safety inputs and interlocks.

Info:

digital-readout.com/wp-content/uploads/2...stallation-guide.pdf

www.axorindustries.com/wp-content/upload...ce-Manual-MS-Eng.pdf

www.mroelectric.com/static/app/product/p...a06b-6044-manual.pdf

forum.linuxcnc.org/media/kunena/attachme...17/MT30R4Extract.pdf

Thanks in advance for any help or tips you can share! I’ve already started digging into the documentation but would really value input from those who’ve done similar projects.

Best regards,

Santiago

I'm currently working on the retrofit of a 3-axis vertical machining center (from 1995) and have decided to use LinuxCNC with Mesa boards. The machine is in excellent mechanical condition, but the original controller (Fagor 8025M) is beginning to fail. I’m still evaluating whether it’s worth repairing, but I’m leaning toward fully modernizing it instead.

Here are the key technical details of the system:

- **Machine type**: 3-axis vertical milling machine

- **Original controller**: Fagor 8025M

- **Motors**: SEM MT30R4-46 brushed DC servos, each with internal tachometers

- **Drives**: Axor analog drives (Miniclamp 140, Minispeed, Minispeed 140, Minispeed 200) with ±10 V control input

- **Spindle drive**: Fanuc A06B-6060-H003#H503 (also analog control)

- **Feedback**:

- **Main feedback**: KA300 linear scales (Extent 570D), 5 µm resolution, differential outputs (A/B/Z, A-/B-/Z-)

- **Velocity loop** is handled inside the servo drives via tachometers

- **Planned control strategy**: Full closed-loop position control via linear scales in LinuxCNC

- **I/O needs**: At least 18 digital inputs for limits, emergency stop, lubrication pump, coolant, etc.

- **Desired precision**: Hundredths of a millimeter (0.01 mm) or better

- **Budget**: About $1500 or less

- **Planned Mesa boards**: Leaning toward a 5i25 (PCIe) + 7i77 for analog servo control and I/O

The machine will be used for both production and toolmaking, so reliability and precision are key. The current system performs interpolation and achieves 0.01 mm precision, and I’d like to match or improve upon that.

I’d like to ask:

- Has anyone here done a similar retrofit with SEM DC motors and Axor drives?

- Is it reasonable to expect similar or better precision from LinuxCNC using KA300 scales and Mesa hardware?

- Are there any specific concerns when using analog ±10 V control with older servo amplifiers?

- Any advice or experience you could share with full closed-loop systems based on linear feedback?

- I’m also interested in your thoughts on encoder scaling, latency tuning, and best practices for safety inputs and interlocks.

Info:

digital-readout.com/wp-content/uploads/2...stallation-guide.pdf

www.axorindustries.com/wp-content/upload...ce-Manual-MS-Eng.pdf

www.mroelectric.com/static/app/product/p...a06b-6044-manual.pdf

forum.linuxcnc.org/media/kunena/attachme...17/MT30R4Extract.pdf

Thanks in advance for any help or tips you can share! I’ve already started digging into the documentation but would really value input from those who’ve done similar projects.

Best regards,

Santiago

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

07 Aug 2025 13:25 #333000

by Todd Zuercher

Replied by Todd Zuercher on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Sounds like it should be a straight forward analog system conversion. What about things like the spindle controls, does it have a tool changer?

Best advice, is first thing e-stop circuits, then get encoder feedback working, then the servo drive enable\disable, then add safeties (limits etc), then confirm directions are correct, finally tune your position loops.

Best advice, is first thing e-stop circuits, then get encoder feedback working, then the servo drive enable\disable, then add safeties (limits etc), then confirm directions are correct, finally tune your position loops.

The following user(s) said Thank You: tommylight, Japoo_Ness

Please Log in or Create an account to join the conversation.

- Japoo_Ness

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 1

07 Aug 2025 16:47 #333008

by Japoo_Ness

Replied by Japoo_Ness on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Excellent, it doesn't have a tool changer, which is a plus. I would like to add one eventually if possible, but that’s more of a future upgrade.

Regarding the spindle control, that’s an area I want to dive deeper into, but I'm not sure where to start.

From what I understand, important aspects would include direction of rotation, speed control, and handling alarms or faults. Is there anything else I should be considering?

Regarding the spindle control, that’s an area I want to dive deeper into, but I'm not sure where to start.

From what I understand, important aspects would include direction of rotation, speed control, and handling alarms or faults. Is there anything else I should be considering?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1540

- Thank you received: 572

08 Aug 2025 08:00 #333035

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

I retrofitted a Maho and kept it's DC servos...

forum.linuxcnc.org/12-milling/33035-retr...ing-a-1986-maho-400e

forum.linuxcnc.org/12-milling/33035-retr...ing-a-1986-maho-400e

The following user(s) said Thank You: Japoo_Ness

Please Log in or Create an account to join the conversation.

- Japoo_Ness

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 1

11 Aug 2025 11:06 #333208

by Japoo_Ness

Replied by Japoo_Ness on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Hi, thanks for sharing your Maho retrofit experience, very interesting project.

my machine uses DC servos with ±10 V analog control.

I’m currently deciding which Mesa hardware to choose, but I’ve noticed that most of the combinations I had in mind are out of stock.

One of my doubts is regarding communication:

Some people suggest parallel-port-based cards for heavy, real-time work.

Others mention Ethernet-based cards might be better for future expansion.

My concern is whether Ethernet introduces more delay or has less data transfer capability for this kind of servo control — or if I’m completely wrong in that assumption.

Could you share your opinion or recommendations on:

Which Mesa cards you would choose for ±10 V DC servos in a retrofit like mine.

Whether you think Ethernet is a good choice for long-term expandability.

Any reliable sources or distributors where I might be able to get the boards (especially in Latin America, but I’m open to others).

Thanks in advance for any insight!

my machine uses DC servos with ±10 V analog control.

I’m currently deciding which Mesa hardware to choose, but I’ve noticed that most of the combinations I had in mind are out of stock.

One of my doubts is regarding communication:

Some people suggest parallel-port-based cards for heavy, real-time work.

Others mention Ethernet-based cards might be better for future expansion.

My concern is whether Ethernet introduces more delay or has less data transfer capability for this kind of servo control — or if I’m completely wrong in that assumption.

Could you share your opinion or recommendations on:

Which Mesa cards you would choose for ±10 V DC servos in a retrofit like mine.

Whether you think Ethernet is a good choice for long-term expandability.

Any reliable sources or distributors where I might be able to get the boards (especially in Latin America, but I’m open to others).

Thanks in advance for any insight!

Please Log in or Create an account to join the conversation.

- Japoo_Ness

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 1

25 Aug 2025 14:57 #333906

by Japoo_Ness

Replied by Japoo_Ness on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Hi everyone, I hope you’re doing well.

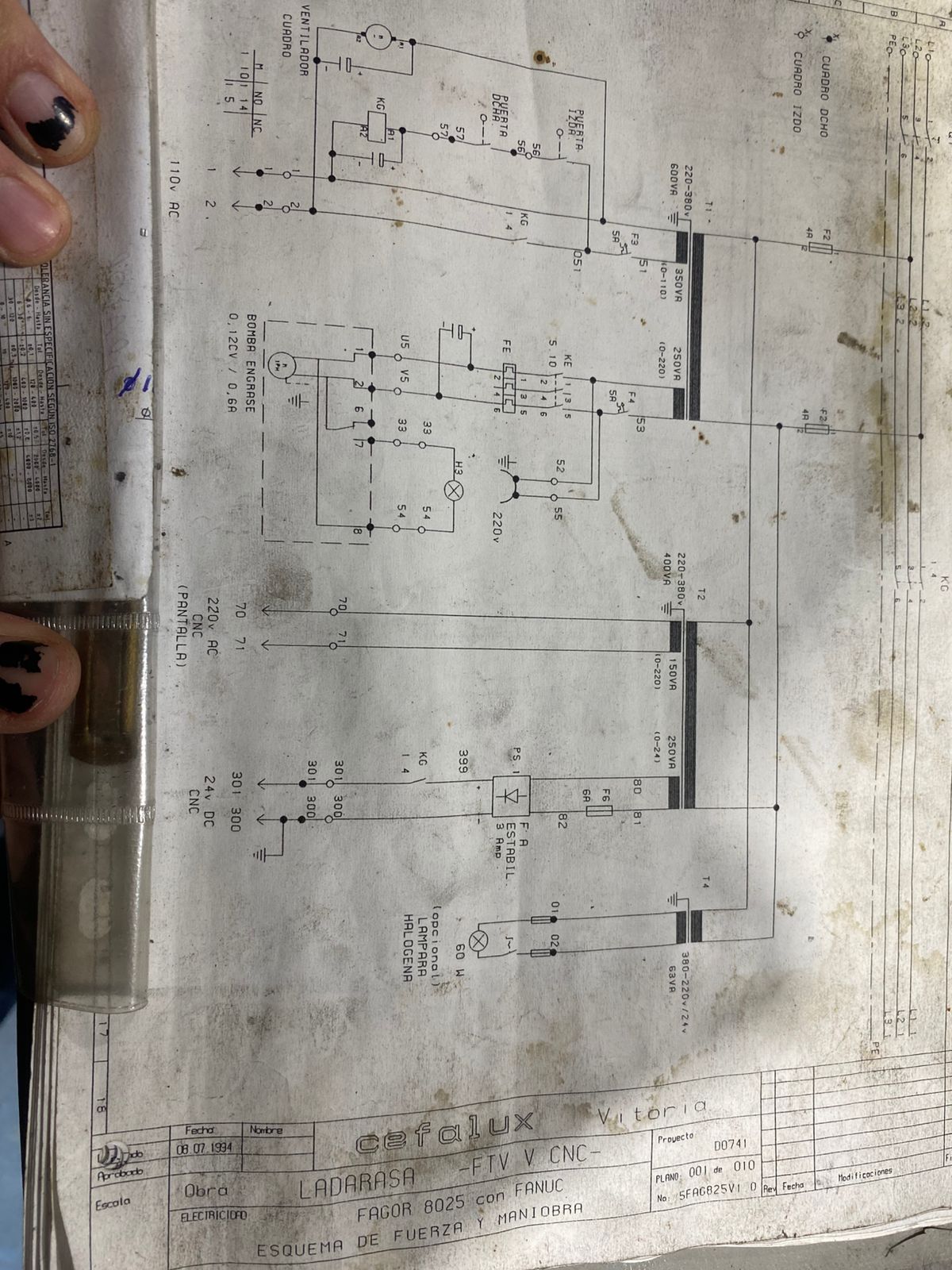

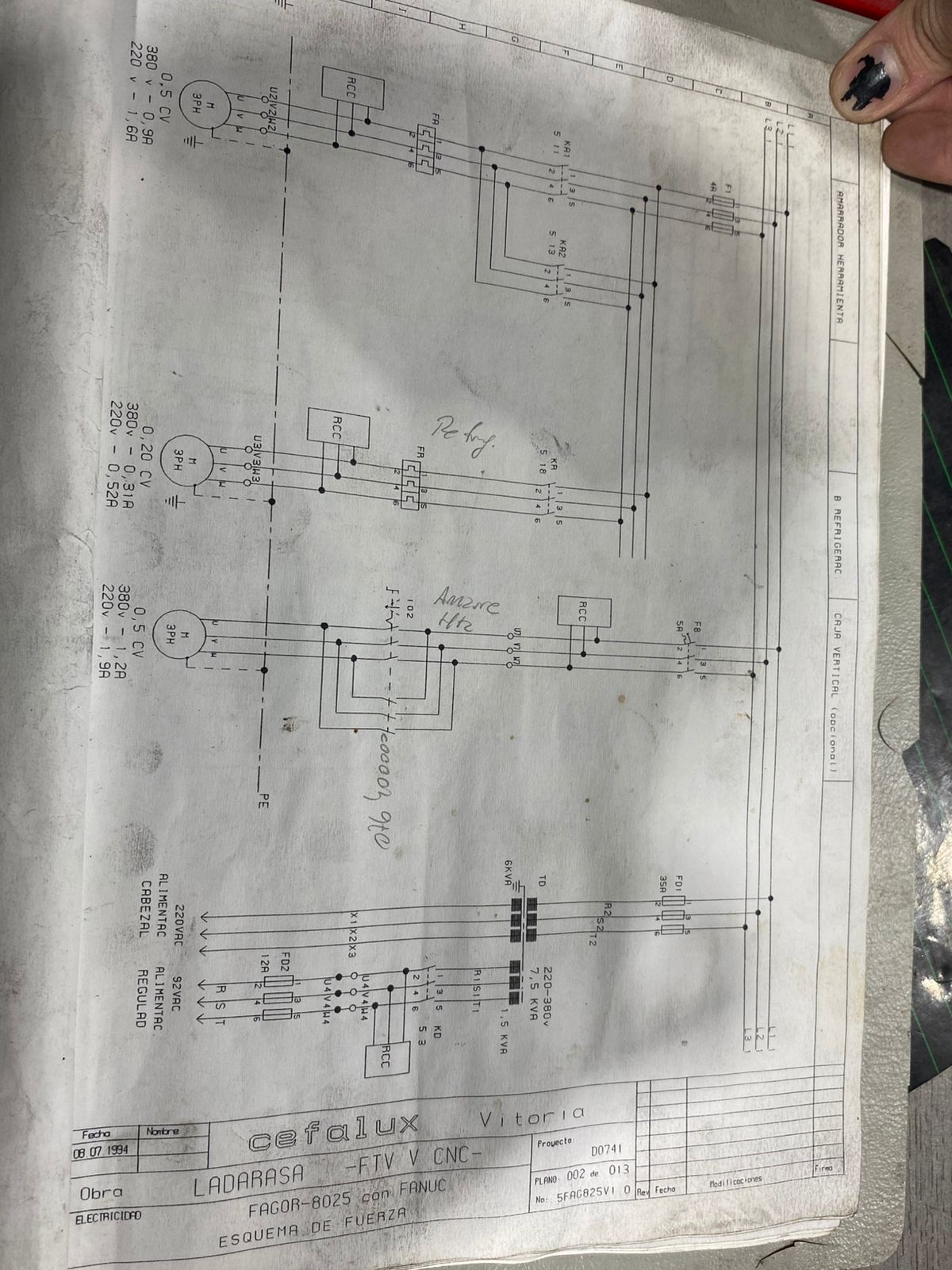

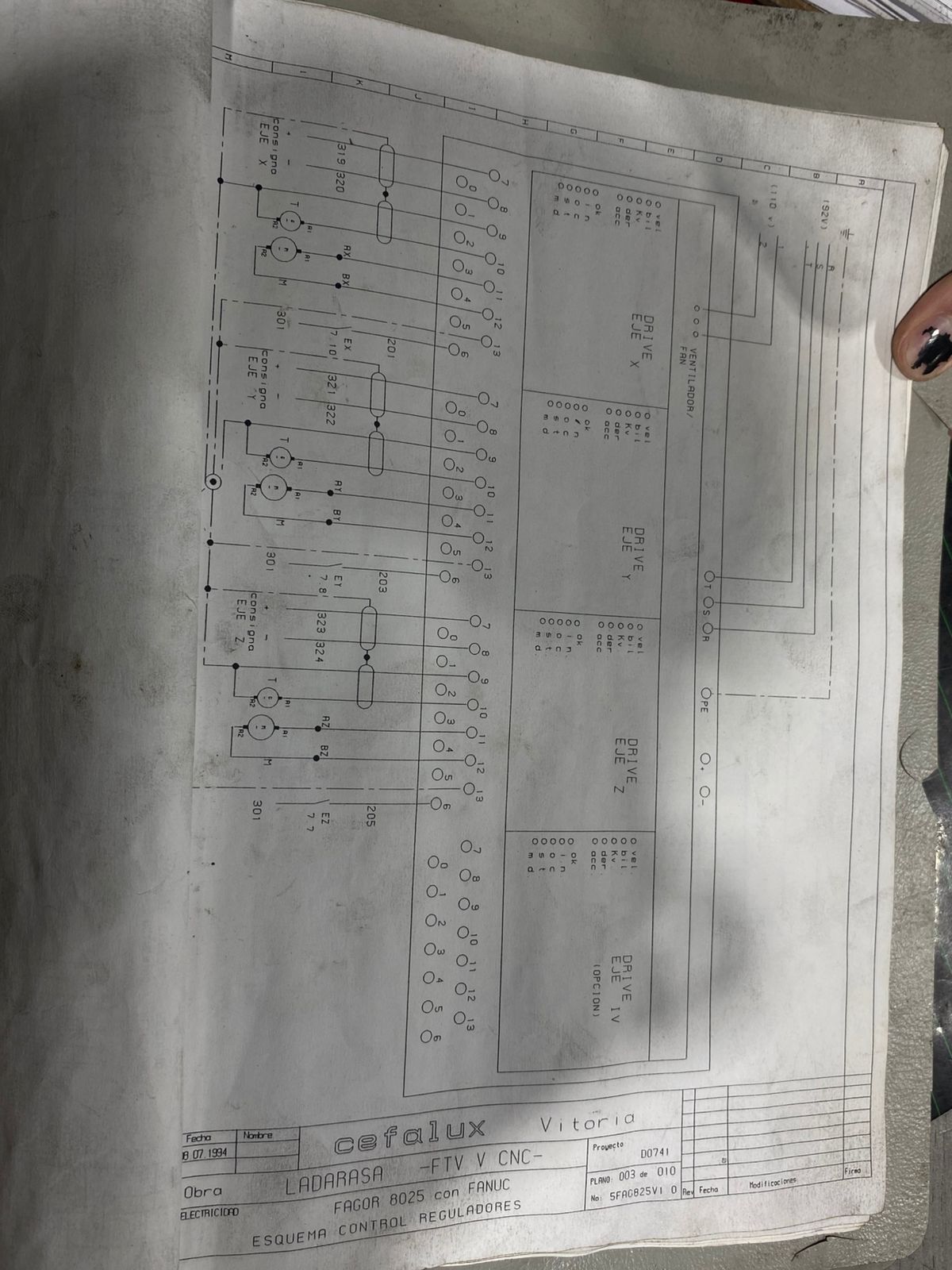

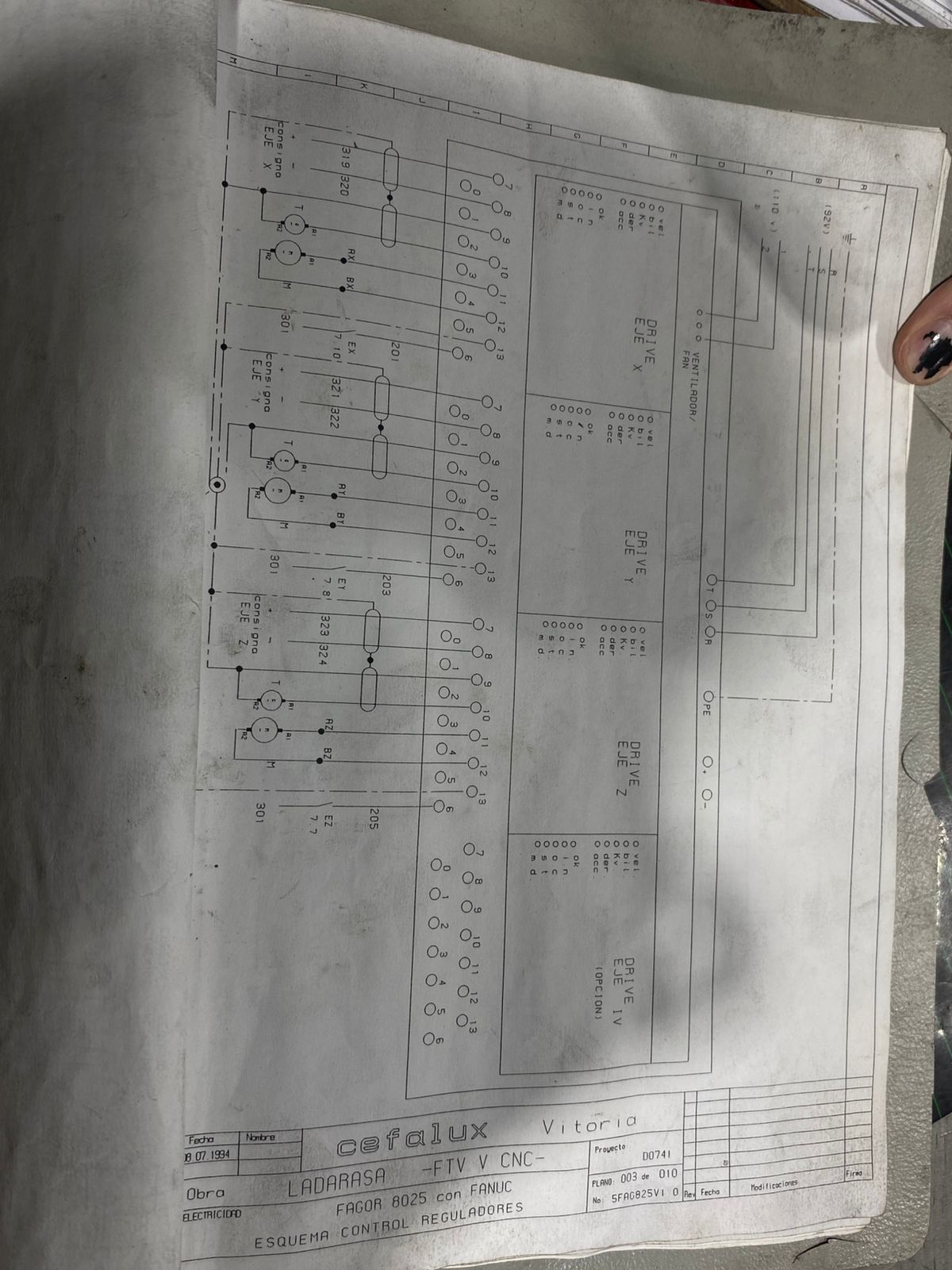

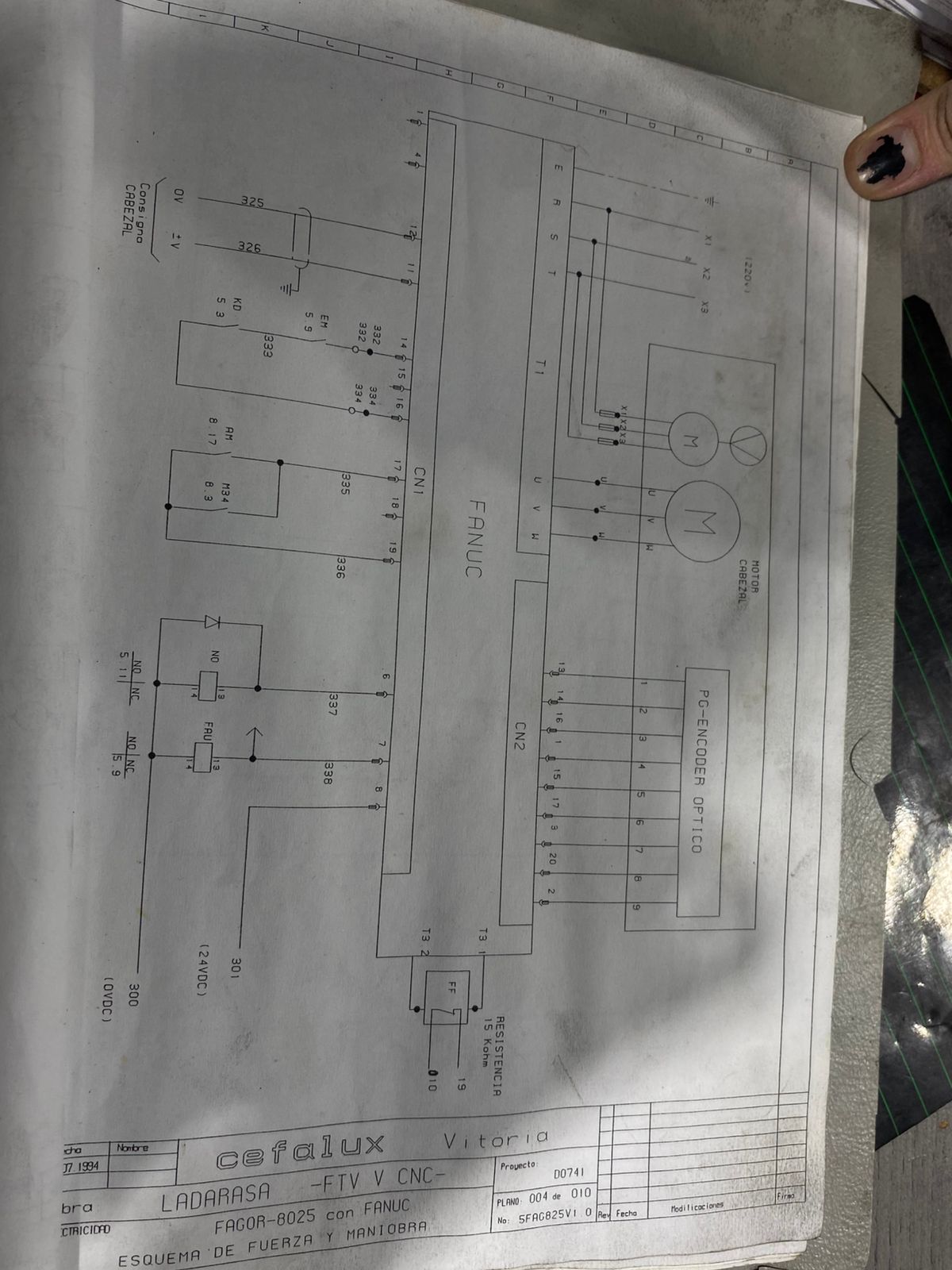

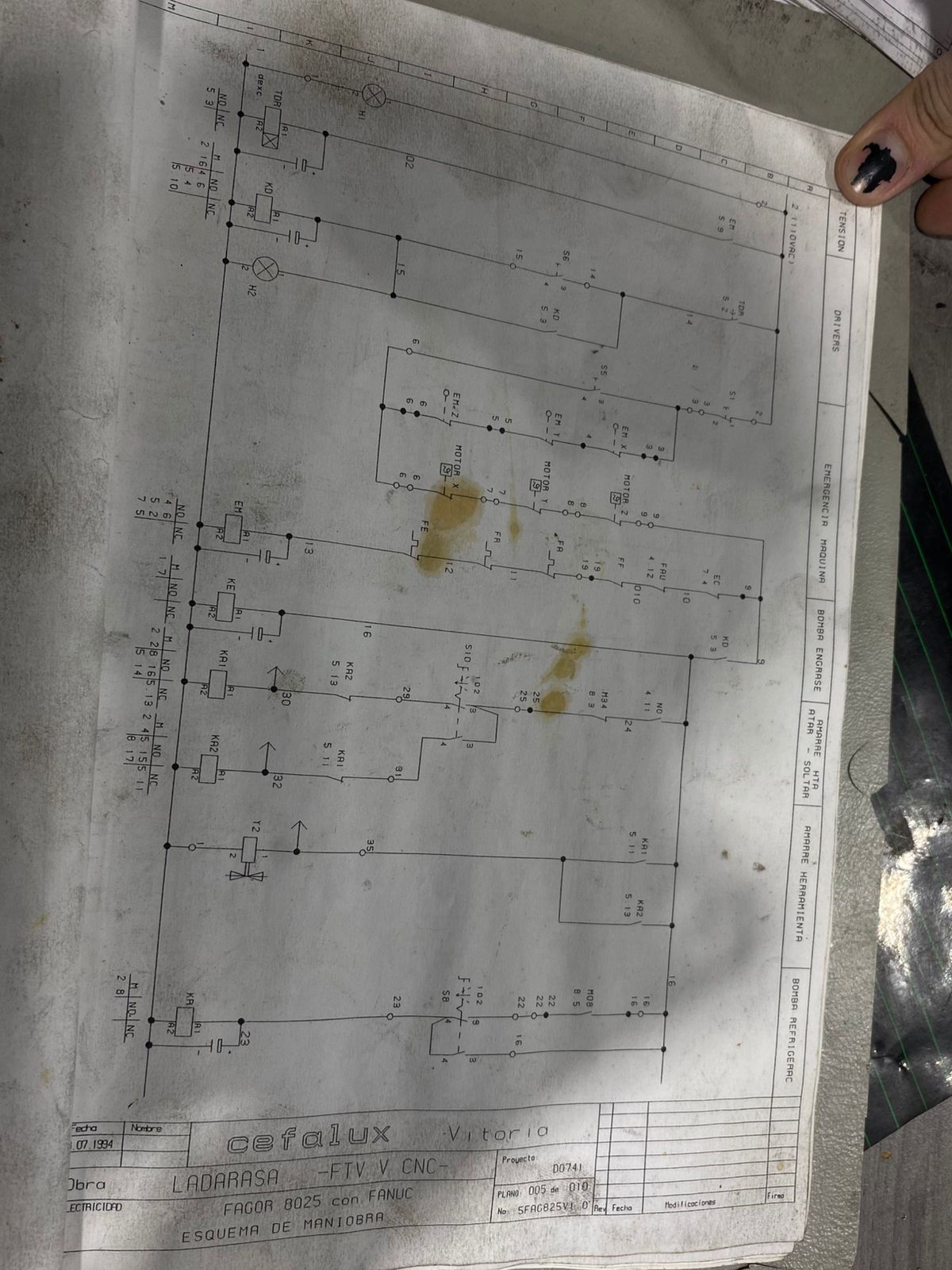

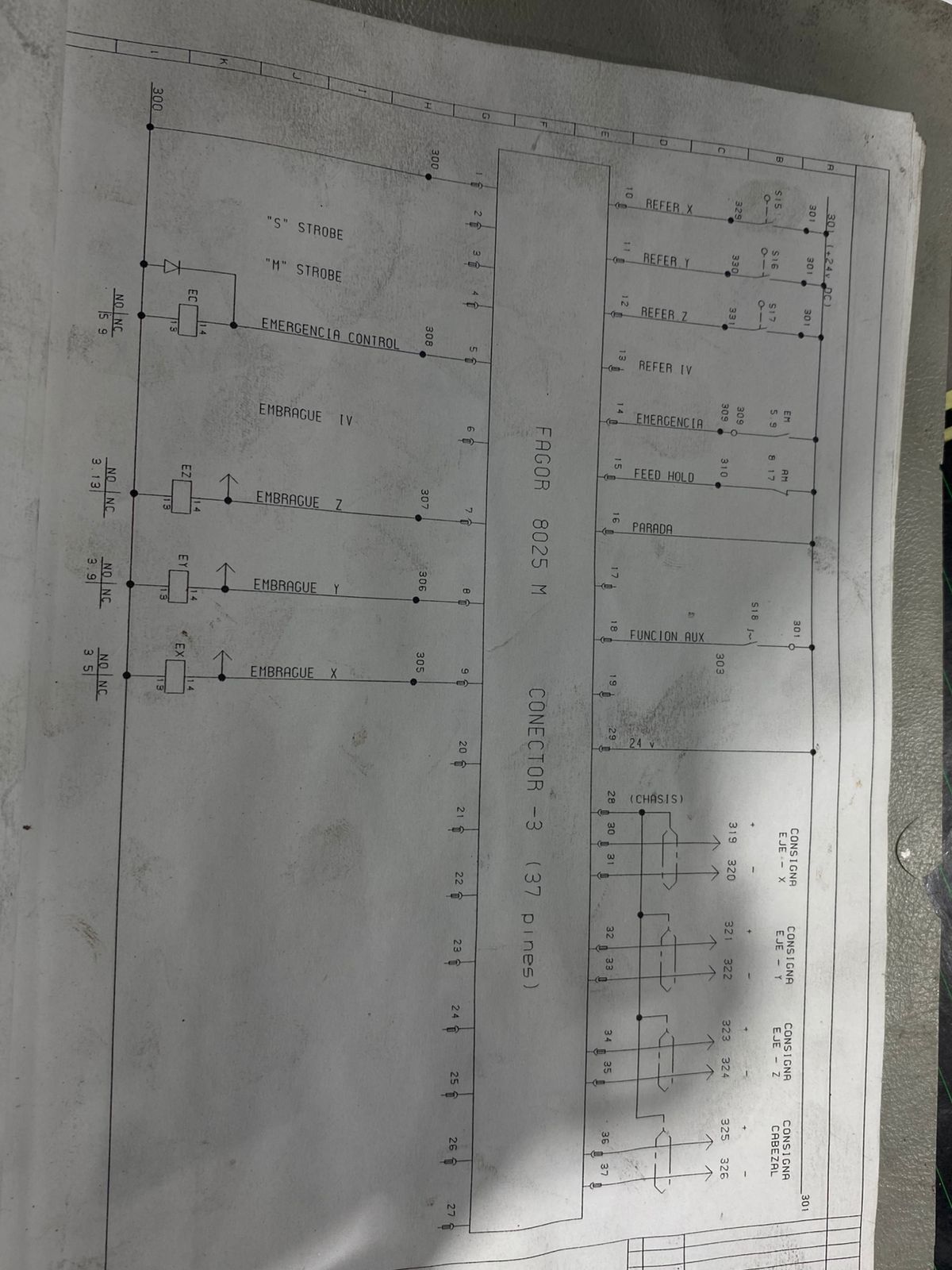

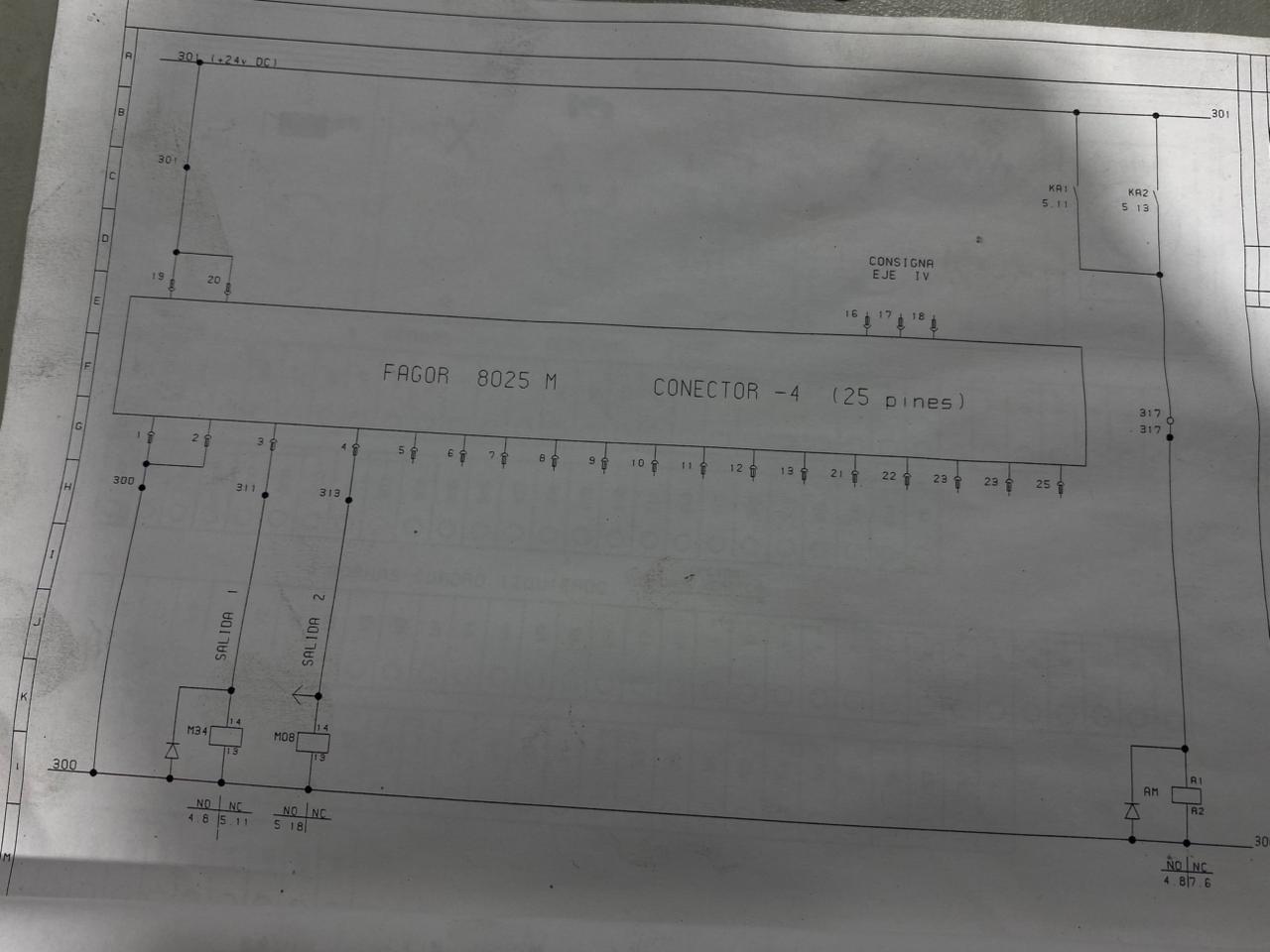

While going through the electrical diagrams of my machine, I noticed something I don’t fully understand. The schematics show a clutch on each axis. Could someone explain what exactly this means and what role the clutch plays? Is it connecting or disconnecting the motor from the ballscrew, or something else?

I’ll attach the diagrams for reference.

The spindle part I’ve already figured out, since I found out how the connections and control signals are set up. Right now, I’m working on counting all the inputs I will need to make sure the Mesa board I choose has enough capacity. Fortunately, the linear scales output 5V signals, so that part looks straightforward too.

Thanks a lot in advance — I’d really appreciate your input and experience on this.

While going through the electrical diagrams of my machine, I noticed something I don’t fully understand. The schematics show a clutch on each axis. Could someone explain what exactly this means and what role the clutch plays? Is it connecting or disconnecting the motor from the ballscrew, or something else?

I’ll attach the diagrams for reference.

The spindle part I’ve already figured out, since I found out how the connections and control signals are set up. Right now, I’m working on counting all the inputs I will need to make sure the Mesa board I choose has enough capacity. Fortunately, the linear scales output 5V signals, so that part looks straightforward too.

Thanks a lot in advance — I’d really appreciate your input and experience on this.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

25 Aug 2025 15:24 #333909

by tommylight

Replied by tommylight on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Maybe brakes? Do the motors have brakes on them?

The brakes on motors work as a clutch, meaning a friction plate pressed by a metal plate with a spring when braked and an electromagnet to pull the metal part away from the friction plate when released.

Electromagnets are usually shown the same in schematics as relays, they are after all the same wounded wire.

The brakes on motors work as a clutch, meaning a friction plate pressed by a metal plate with a spring when braked and an electromagnet to pull the metal part away from the friction plate when released.

Electromagnets are usually shown the same in schematics as relays, they are after all the same wounded wire.

The following user(s) said Thank You: Japoo_Ness

Please Log in or Create an account to join the conversation.

- Japoo_Ness

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 1

29 Aug 2025 14:39 #334091

by Japoo_Ness

Replied by Japoo_Ness on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Yes, I think you’re right. I haven’t been able to check the machine again yet since it’s not mine – I’m just trying to help out a friend – but it probably does have a brake, considering the previous controller was only 2.5 axes.

Now, what I’d like to ask for some advice on: if I want to keep the option of adding more expansions in the future and also a control pendant, would the 7i74 be a good choice? I see that it’s mentioned as a supported configuration in the 6i25 manual, so it seems like it could give me more I/O and flexibility.

Now, what I’d like to ask for some advice on: if I want to keep the option of adding more expansions in the future and also a control pendant, would the 7i74 be a good choice? I see that it’s mentioned as a supported configuration in the 6i25 manual, so it seems like it could give me more I/O and flexibility.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

29 Aug 2025 19:42 #334112

by andypugh

Replied by andypugh on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

The 7i74 is a good start, bit doesn't do much by itself.

The 7i73 is a handy little board for control panels and pendants.

You could also look at the Mesa 50-pin cards. I am a fan of the 6i24

They use different daughter boards to the 25-pin cards (eg 7i44 v 7i74 for smart-serial) but they use the same smart-serial accessory boards.

Just be aware that there are two separate daughter-board ecosystems.

An ethernet-based FPGA card might make for easier PC swaps in the future. My mill recently got a 6i24 side-grade when I couldn't find a PC with a full-size PCI slot to suit the existing 5i23. (they still exist, but I had other constraints like 12V power and M2 slot)

The 7i73 is a handy little board for control panels and pendants.

You could also look at the Mesa 50-pin cards. I am a fan of the 6i24

They use different daughter boards to the 25-pin cards (eg 7i44 v 7i74 for smart-serial) but they use the same smart-serial accessory boards.

Just be aware that there are two separate daughter-board ecosystems.

An ethernet-based FPGA card might make for easier PC swaps in the future. My mill recently got a 6i24 side-grade when I couldn't find a PC with a full-size PCI slot to suit the existing 5i23. (they still exist, but I had other constraints like 12V power and M2 slot)

The following user(s) said Thank You: Japoo_Ness

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7228

29 Aug 2025 20:01 #334118

by tommylight

Replied by tommylight on topic Retrofitting a 3-axis VMC with DC servos - guidance needed

Yes, 7i74 will do perfectly for 6i25 and add 8 more SSerial ports.

And yes, i have used many 7i74 (i have one on my Mazak lathe) as they make for cleaner installs as wiring to 7i70 and/or 7i71 is just a simple network cable.

@Andy,

see if you can source HP Z400 or Z420 or Z600 workstations, all have PCI slots, 420 has 1, 600 has 3 i think, and all have plenty of PCI-E. They are usually very cheap, but struck gold yesterday with 5 of Z600 :

forum.linuxcnc.org/18-computer/57073-hp-...or-use-with-linuxcnc

And yes, i have used many 7i74 (i have one on my Mazak lathe) as they make for cleaner installs as wiring to 7i70 and/or 7i71 is just a simple network cable.

@Andy,

see if you can source HP Z400 or Z420 or Z600 workstations, all have PCI slots, 420 has 1, 600 has 3 i think, and all have plenty of PCI-E. They are usually very cheap, but struck gold yesterday with 5 of Z600 :

forum.linuxcnc.org/18-computer/57073-hp-...or-use-with-linuxcnc

The following user(s) said Thank You: Japoo_Ness

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.233 seconds