Firmware Request for 7i92 – Plasma CNC Build

- souh-hil

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

18 Sep 2025 19:07 #335164

by souh-hil

Firmware Request for 7i92 – Plasma CNC Build was created by souh-hil

Hello everyone,This is my first post here on the LinuxCNC forum, and also my very first CNC build — so please forgive any mistakes or lack of experience on my part. I'm doing my best to learn as I go.I'm building a plasma CNC machine and using a Mesa 7i92 card. For my setup, I’ll be connecting two 5-axis breakout boards — one on P1 and one on P2. I’m looking for a suitable firmware that would allow me to:

- Use 4 or 5 encoder inputs (for THCAD and potentially other uses)

- Have at least 10 inputs and 5 outputs for general machine control

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

18 Sep 2025 20:51 #335170

by PCW

Replied by PCW on topic Firmware Request for 7i92 – Plasma CNC Build

For a 7I92:

7i92_5ABOBx2D.bit

for a 7I92T:

7i92t_5abobx2d.bin

Would be closest If you are using the common "Mach 5 Axis" Sainsmart parallel port BOB

Note that the inputs of the common 5 Axis breakouts are not really suitable for encoder use

as they are quite slow and require 12 V signals.

7i92_5ABOBx2D.bit

for a 7I92T:

7i92t_5abobx2d.bin

Would be closest If you are using the common "Mach 5 Axis" Sainsmart parallel port BOB

Note that the inputs of the common 5 Axis breakouts are not really suitable for encoder use

as they are quite slow and require 12 V signals.

The following user(s) said Thank You: souh-hil

Please Log in or Create an account to join the conversation.

- souh-hil

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

18 Sep 2025 23:26 #335177

by souh-hil

Replied by souh-hil on topic Firmware Request for 7i92 – Plasma CNC Build

Yes, I'm using the common 5-axis BOBs from china, one on each port (P1 and P2).

That said, I don’t actually need all 10 StepGen channels. My machine only uses 4 axes, so I’m hoping to free up many of the StepGen-related I/O pins and use them as general-purpose I/Os instead.

Also, since the 7i92 headers are mirrored (P1 and P2), both BOBs give access to the same type of GPIO pins. I’m hoping to take advantage of that symmetry and assign more pins for inputs (e.g., limit switches, ArcOK, ohmic probe, thc UP /down etc.), and just a few for outputs (torch on/off, float switch reset, laser etc.).

Ideally, I'd like a bitfile that allows:

At least 10 inputs and 5 outputs for general machine control

Fewer StepGen channels (maybe 4 or 5 max)

If a bitfile like that exists — or if modifying an existing one is straightforward — I’d really appreciate the guidance.

Thanks again for your help!

Best regards,

That said, I don’t actually need all 10 StepGen channels. My machine only uses 4 axes, so I’m hoping to free up many of the StepGen-related I/O pins and use them as general-purpose I/Os instead.

Also, since the 7i92 headers are mirrored (P1 and P2), both BOBs give access to the same type of GPIO pins. I’m hoping to take advantage of that symmetry and assign more pins for inputs (e.g., limit switches, ArcOK, ohmic probe, thc UP /down etc.), and just a few for outputs (torch on/off, float switch reset, laser etc.).

Ideally, I'd like a bitfile that allows:

At least 10 inputs and 5 outputs for general machine control

Fewer StepGen channels (maybe 4 or 5 max)

If a bitfile like that exists — or if modifying an existing one is straightforward — I’d really appreciate the guidance.

Thanks again for your help!

Best regards,

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7227

18 Sep 2025 23:37 #335178

by tommylight

Replied by tommylight on topic Firmware Request for 7i92 – Plasma CNC Build

Any stepgen or encoder that is not in use, it's pins can be used as IO, so if you just load

loadrt num_stepgens = 4

that will enable 4 stepgens on the first port (no idea exactly if P1 or P2) and the rest of the 26 pins can be used freely as inputs or as outputs.

Use

mesaflash --card_name --IP --readhmid

replace name and IP with what you have and check the resulting pin assignment so you can decide how many stepgens and encoders you need and what pins they use, from that you know what pin numbers remain for inputs and outputs.

BUT, since you are using BOB's, you will be limited to what the BOB uses as inputs ( 10 in total for encoders and switches) and 24 as outputs.

loadrt num_stepgens = 4

that will enable 4 stepgens on the first port (no idea exactly if P1 or P2) and the rest of the 26 pins can be used freely as inputs or as outputs.

Use

mesaflash --card_name --IP --readhmid

replace name and IP with what you have and check the resulting pin assignment so you can decide how many stepgens and encoders you need and what pins they use, from that you know what pin numbers remain for inputs and outputs.

BUT, since you are using BOB's, you will be limited to what the BOB uses as inputs ( 10 in total for encoders and switches) and 24 as outputs.

The following user(s) said Thank You: souh-hil

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17586

- Thank you received: 5142

19 Sep 2025 00:30 #335180

by PCW

Replied by PCW on topic Firmware Request for 7i92 – Plasma CNC Build

A picture or link to the actual breakout board you have would be helpful.

As tommylight noted, the common "5 Axis CNC" breakout has 12 outputs

and 5 inputs and this is fixed by the breakout board hardware.

As tommylight noted, the common "5 Axis CNC" breakout has 12 outputs

and 5 inputs and this is fixed by the breakout board hardware.

The following user(s) said Thank You: tommylight, souh-hil

Please Log in or Create an account to join the conversation.

- souh-hil

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

19 Sep 2025 13:50 #335191

by souh-hil

Replied by souh-hil on topic Firmware Request for 7i92 – Plasma CNC Build

Hi all,Thanks in advance to everyone who responds!I’m using the following HostMot2 bitfile for my Mesa 7i92:

BoardName : MESA7I92

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 2

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 2 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 6 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 5 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 1 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 200.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort PWM 0 PWM (Out)

14 1 IOPort None

2 2 IOPort StepGen 0 Step/Table1 (Out)

15 3 IOPort None

3 4 IOPort StepGen 0 Dir/Table2 (Out)

16 5 IOPort StepGen 4 Step/Table1 (Out)

4 6 IOPort StepGen 1 Step/Table1 (Out)

17 7 IOPort StepGen 4 Dir/Table2 (Out)

5 8 IOPort StepGen 1 Dir/Table2 (Out)

6 9 IOPort StepGen 2 Step/Table1 (Out)

7 10 IOPort StepGen 2 Dir/Table2 (Out)

8 11 IOPort StepGen 3 Step/Table1 (Out)

9 12 IOPort StepGen 3 Dir/Table2 (Out)

10 13 IOPort None

11 14 IOPort QCount 0 Quad-A (In)

12 15 IOPort QCount 0 Quad-B (In)

13 16 IOPort QCount 0 Quad-IDX (In)

IO Connections for P1

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 17 IOPort QCount 1 Quad-A (In)

14 18 IOPort QCount 1 Quad-B (In)

2 19 IOPort QCount 1 Quad-IDX (In)

15 20 IOPort QCount 2 Quad-A (In)

3 21 IOPort QCount 2 Quad-B (In)

16 22 IOPort QCount 2 Quad-IDX (In)

4 23 IOPort QCount 3 Quad-A (In)

17 24 IOPort QCount 3 Quad-B (In)

5 25 IOPort QCount 3 Quad-IDX (In)

6 26 IOPort QCount 4 Quad-A (In)

7 27 IOPort QCount 4 Quad-B (In)

8 28 IOPort QCount 4 Quad-IDX (In)

9 29 IOPort QCount 5 Quad-A (In)

10 30 IOPort QCount 5 Quad-B (In)

11 31 IOPort QCount 5 Quad-IDX (In)

12 32 IOPort None

13 33 IOPort None

BoardName : MESA7I92

FPGA Size: 9 KGates

FPGA Pins: 144

Number of IO Ports: 2

Width of one I/O port: 17

Clock Low frequency: 100.0000 MHz

Clock High frequency: 200.0000 MHz

IDROM Type: 3

Instance Stride 0: 4

Instance Stride 1: 64

Register Stride 0: 256

Register Stride 1: 256

Modules in configuration:

Module: DPLL

There are 1 of DPLL in configuration

Version: 0

Registers: 7

BaseAddress: 7000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: WatchDog

There are 1 of WatchDog in configuration

Version: 0

Registers: 3

BaseAddress: 0C00

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: IOPort

There are 2 of IOPort in configuration

Version: 0

Registers: 5

BaseAddress: 1000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: QCount

There are 6 of QCount in configuration

Version: 2

Registers: 5

BaseAddress: 3000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: StepGen

There are 5 of StepGen in configuration

Version: 2

Registers: 10

BaseAddress: 2000

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: PWM

There are 1 of PWM in configuration

Version: 0

Registers: 5

BaseAddress: 4100

ClockFrequency: 200.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Module: LED

There are 1 of LED in configuration

Version: 0

Registers: 1

BaseAddress: 0200

ClockFrequency: 100.000 MHz

Register Stride: 256 bytes

Instance Stride: 4 bytes

Configuration pin-out:

IO Connections for P2

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 0 IOPort PWM 0 PWM (Out)

14 1 IOPort None

2 2 IOPort StepGen 0 Step/Table1 (Out)

15 3 IOPort None

3 4 IOPort StepGen 0 Dir/Table2 (Out)

16 5 IOPort StepGen 4 Step/Table1 (Out)

4 6 IOPort StepGen 1 Step/Table1 (Out)

17 7 IOPort StepGen 4 Dir/Table2 (Out)

5 8 IOPort StepGen 1 Dir/Table2 (Out)

6 9 IOPort StepGen 2 Step/Table1 (Out)

7 10 IOPort StepGen 2 Dir/Table2 (Out)

8 11 IOPort StepGen 3 Step/Table1 (Out)

9 12 IOPort StepGen 3 Dir/Table2 (Out)

10 13 IOPort None

11 14 IOPort QCount 0 Quad-A (In)

12 15 IOPort QCount 0 Quad-B (In)

13 16 IOPort QCount 0 Quad-IDX (In)

IO Connections for P1

Pin# I/O Pri. func Sec. func Chan Pin func Pin Dir

1 17 IOPort QCount 1 Quad-A (In)

14 18 IOPort QCount 1 Quad-B (In)

2 19 IOPort QCount 1 Quad-IDX (In)

15 20 IOPort QCount 2 Quad-A (In)

3 21 IOPort QCount 2 Quad-B (In)

16 22 IOPort QCount 2 Quad-IDX (In)

4 23 IOPort QCount 3 Quad-A (In)

17 24 IOPort QCount 3 Quad-B (In)

5 25 IOPort QCount 3 Quad-IDX (In)

6 26 IOPort QCount 4 Quad-A (In)

7 27 IOPort QCount 4 Quad-B (In)

8 28 IOPort QCount 4 Quad-IDX (In)

9 29 IOPort QCount 5 Quad-A (In)

10 30 IOPort QCount 5 Quad-B (In)

11 31 IOPort QCount 5 Quad-IDX (In)

12 32 IOPort None

13 33 IOPort None

- I only need 4 axes (X, Y1, Y2, Z). Can I use the last StepGen for torch on and laser pointer outputs?

- I do not need encoders. Can I use the QCount pins as general-purpose inputs?

- Can I use the pins labeled “None” or “unassigned” in the bitfile as inputs or outputs, depending on their pin direction?For example, pins 10 and 15 as inputs, and pin 14 as output?

- Are pins 13 and 15 on P2 free to use as I/O?

- My breakout board has 5 inputs labeled P10, P11, P12, P13, and P15. Can I use all of them as inputs

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7227

19 Sep 2025 13:57 #335192

by tommylight

Replied by tommylight on topic Firmware Request for 7i92 – Plasma CNC Build

1 Yes

2 Yes

3 Yes

4 Yes, if you do not use any encoders

5 Yes

2 Yes

3 Yes

4 Yes, if you do not use any encoders

5 Yes

Please Log in or Create an account to join the conversation.

- souh-hil

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

26 Sep 2025 09:57 #335448

by souh-hil

Replied by souh-hil on topic Firmware Request for 7i92 – Plasma CNC Build

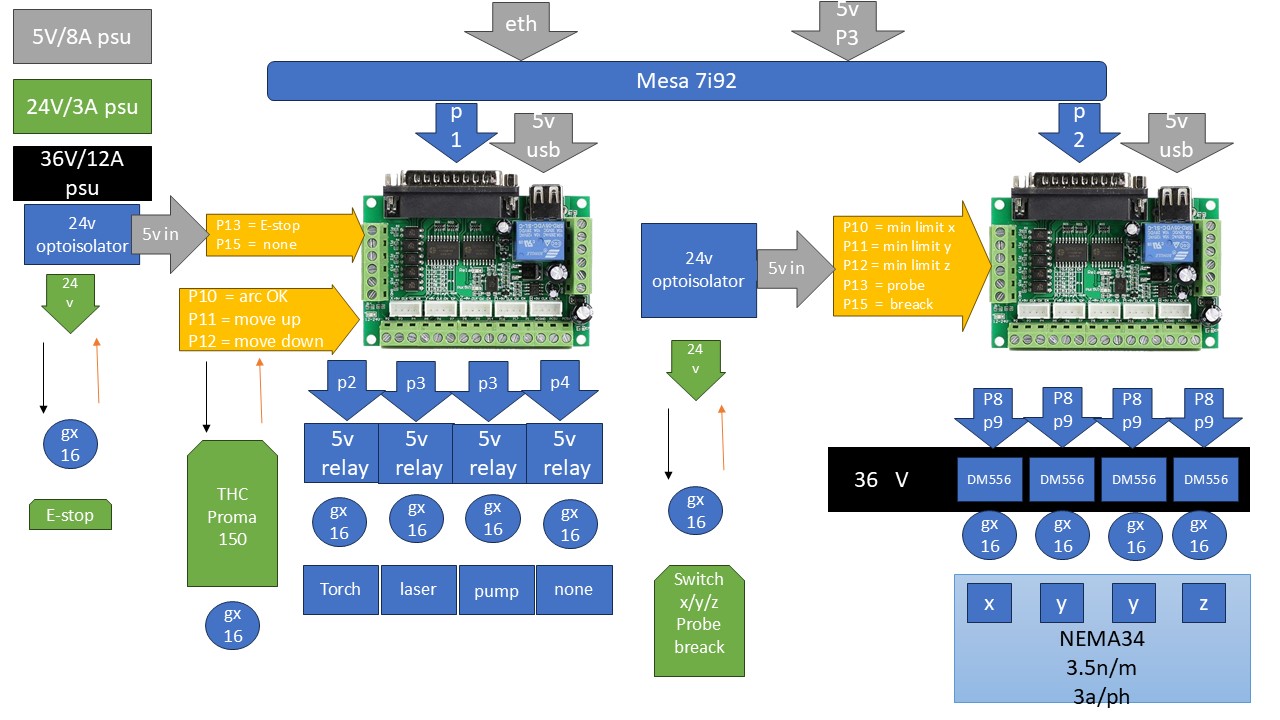

Hello again everyone,First, I apologize for the late reply — I’ve been working on revising my plan and wiring, and it took longer than expected.I’ve updated my wiring/architecture plan (see attached diagram), and here’s where I’m at:

- Mesa 7i92 over Ethernet

- Two 5-axis breakout boards (5ABOB ×2)

- DM556 drivers for NEMA34 motors (3.5 Nm, 3 A/phase)

- THC Proma 150 for torche height control (Arc OK, Up, Down signals)

- Relays for torch, laser, pump, etc.

- E-stop, limits, probe via optoisolators

- Power supplies: 5 V/8 A, 24 V/3 A, 36 V/12 A

- With that setup (7i92 + 2 × 5ABOB), is the wiring architecture I’m proposing feasible?

- I was thinking of starting with the G540 HAL/INI config in pncconf as a base, then editing it . Is that a sensible approach, or is there a better workflow to generate a clean HAL/INI for this sort of layout?

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21163

- Thank you received: 7227

26 Sep 2025 12:42 #335453

by tommylight

Replied by tommylight on topic Firmware Request for 7i92 – Plasma CNC Build

1. yes

2. yes

2. yes

The following user(s) said Thank You: souh-hil

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.127 seconds