- Hardware & Machines

- Driver Boards

- Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

- GuessWho

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

12 Oct 2025 12:38 - 12 Oct 2025 12:47 #336321

by GuessWho

Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO was created by GuessWho

Hi all and thank you for checking this topic!

Little intro to my project and why I cam here.

I'm here asking for help with upgrading my table. I've bought a CNC plasma cutting table with the hope of starting my own thing and because it looked like a lot of fun. Couple of months down the road it turned out that the table is more on the hobbyist side than I would like. So I decided to start upgrading it in order to have higher quality cuts that I can be proud of.

My current setup.

PLASMA SOURCE

CONTROL

CONTROL AND SOFTWARE

My plan.

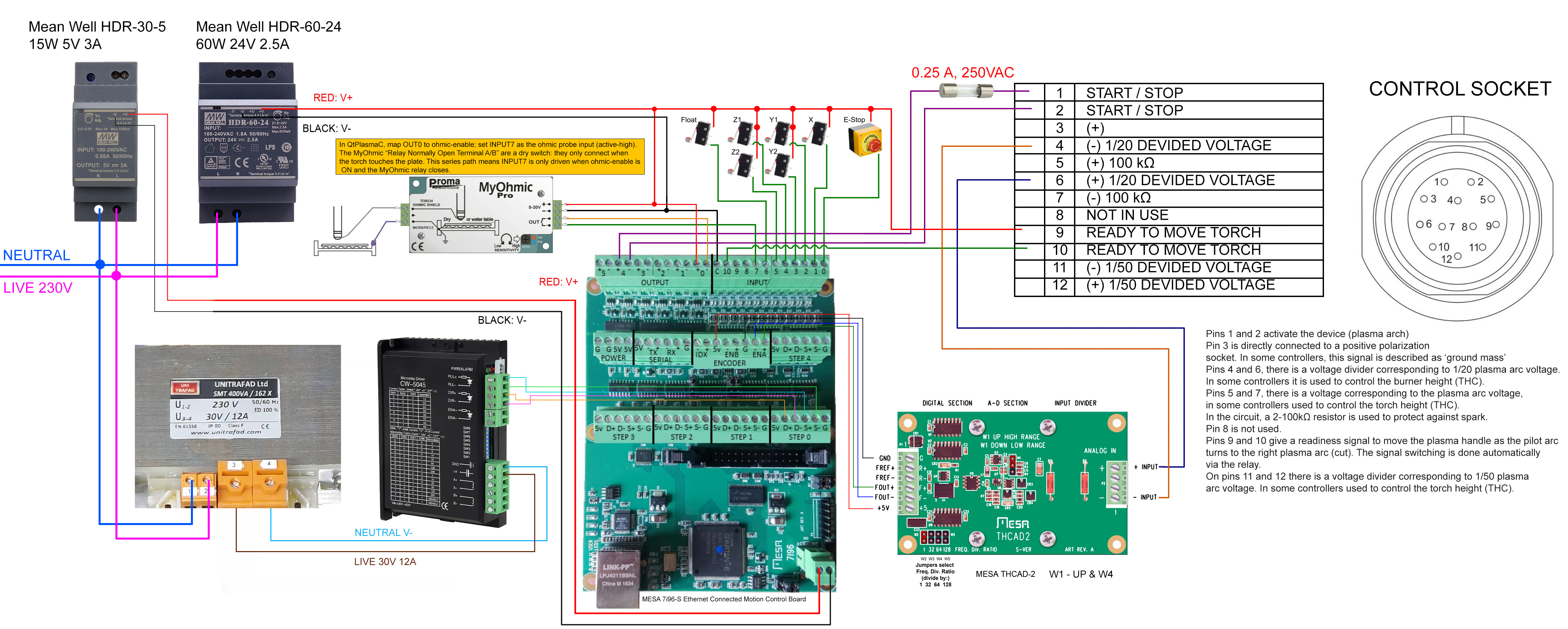

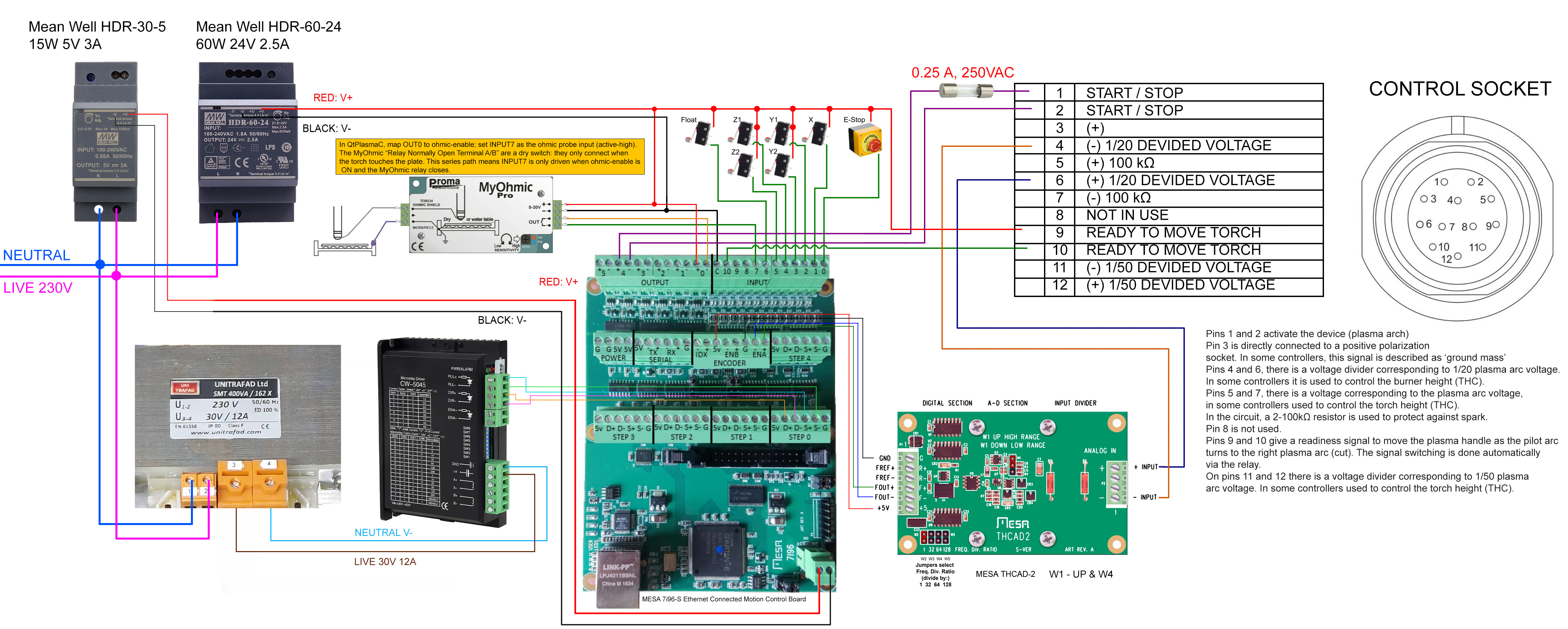

The diagram.

I've reused a diagram from the forum (I believe that it's LOWRIDER3) which turns out to be immense help, I'm not sure I would be able to come up with anything useful if it wasn't for it!

I'm adding the diagram itself so that you good folks can make comments, recommendations, critiques. Thank you all in advance!

Little intro to my project and why I cam here.

I'm here asking for help with upgrading my table. I've bought a CNC plasma cutting table with the hope of starting my own thing and because it looked like a lot of fun. Couple of months down the road it turned out that the table is more on the hobbyist side than I would like. So I decided to start upgrading it in order to have higher quality cuts that I can be proud of.

My current setup.

PLASMA SOURCE

- Unit: Sherman CNC 130 (CNC variant).

- Divided arc output: 1:20 divider present on the machine (available for THC feedback).

CONTROL

- Unknown motion control board

- Unknown THC controller

- Motors: stepper-based system in use - Nema 24 - 60bhh86-300e-24db

- Stepper drivers: 3 × CW-5045 in use for X, Y1/Y2, Z. (

- X/Y motion: rack & pinion,

- Z motion: drive type ballscrew.

- Installed Power: 400VA transformer labeled “230V / 12A” and “SMT 400VA”. This is a step-down transformer: it takes the 230VAC mains in and produces about 30VAC (at up to 12A) on the secondary. After a bridge rectifier and filter capacitor, that 30VAC becomes roughly 42VDC.

CONTROL AND SOFTWARE

- CAM: SheetCam (current workflow).

- Machine control (current): Mach3.

- 3.5 × 2.0 m with water bed.

My plan.

- Move to LinuxCNC with QtPlasmaC.

- Move to Mesa 7i96S: Ethernet motion interface

- Move to Mesa THCAD-2: for 1:20 arc-voltage THC input

- Move to MyOhmic PRO

- Install limit switches

- Use 18 AWG (0.75mm2) shielded cables for the up to 24V connections

- Use 16 AWG (1.5mm2) shielded cables for the connections that are more than 24v

The diagram.

I've reused a diagram from the forum (I believe that it's LOWRIDER3) which turns out to be immense help, I'm not sure I would be able to come up with anything useful if it wasn't for it!

I'm adding the diagram itself so that you good folks can make comments, recommendations, critiques. Thank you all in advance!

Last edit: 12 Oct 2025 12:47 by GuessWho.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

12 Oct 2025 16:04 #336330

by andypugh

Replied by andypugh on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

It looks like you have most of it sorted out, but feel free to ask any questions if you get stuck.

Depending on what the mystery control board is, it might be compatible with Remora firmware.

Depending on what the mystery control board is, it might be compatible with Remora firmware.

The following user(s) said Thank You: GuessWho

Please Log in or Create an account to join the conversation.

- Hakan

- Away

- Platinum Member

-

Less

More

- Posts: 1240

- Thank you received: 436

12 Oct 2025 18:32 #336340

by Hakan

Replied by Hakan on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

I thought the THCAD can do the job of the Promo Ohmic sensing system?

Or perhaps one need an additional THCAD arc-voltage reader.

Plasma-guys, you know this.

Or perhaps one need an additional THCAD arc-voltage reader.

Plasma-guys, you know this.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

12 Oct 2025 19:08 #336341

by rodw

Replied by rodw on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Looks great. I will be interested in how you go with the My Ohmic Pro. I was sent an evaluation one and its beautifully engineered. I just had nothing to try it out on. The THCAD for Ohmic struggles on Water tables so hopefully it proves a more robust solution. Lukaz at Proma said he was very proud of the water handling of the My Ohmic Pro

Be sure to add an EMI filter on your mains input to avoid electrical noise. You can get them built into an IEC connector. even with a power switch and fuse built in.

Be sure to add an EMI filter on your mains input to avoid electrical noise. You can get them built into an IEC connector. even with a power switch and fuse built in.

The following user(s) said Thank You: GuessWho

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17728

- Thank you received: 5186

12 Oct 2025 20:00 #336345

by PCW

Replied by PCW on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

If using a THCAD for ohmic sensing has issues with water. the most likely issue

is that the sense resistor is too high a value.

is that the sense resistor is too high a value.

The following user(s) said Thank You: GuessWho

Please Log in or Create an account to join the conversation.

- GuessWho

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

13 Oct 2025 08:11 #336364

by GuessWho

Replied by GuessWho on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Thanks everyone for the feedback. I’ll keep you posted as things progress.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21345

- Thank you received: 7284

13 Oct 2025 09:03 #336365

by tommylight

Replied by tommylight on topic Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

I agree and I am pretty sure i mentioned somewhere a long time ago that a lower value resistor should be used for sensing. Something that will result in 20-50mA current should do just fine, maybe more as the water used will get lower resistance the more cuts are done and as it evaporates.If using a THCAD for ohmic sensing has issues with water. the most likely issue

is that the sense resistor is too high a value.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

- Hardware & Machines

- Driver Boards

- Upgrade of CNC Plasma Cutting Table with Mesa 7i96S, THCAD-2 And MyOhmic PRO

Time to create page: 0.088 seconds