CNC for a pattern torch.

- Galane

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

15 Apr 2013 18:13 - 15 Apr 2013 18:17 #32738

by Galane

CNC for a pattern torch. was created by Galane

It's a simple machine, a gas cutting torch at the end of a passive two joint arm. Above the torch is a motor and gearbox driving a 1/4" diameter, knurled, magnetic shaft. That shaft rolls around the edge of a steel pattern so the torch moves and cuts steel plate into the shape of the pattern.

It's simple and pretty much foolproof, as long as you have or can make patterns.

The problems, the patterns have to be 1/8" smaller all around than the pieces being cut and sharp corners aren't possible due to the way the magnet rolls around. Too sharp inside and the magnet gets stuck. Too sharp outside and it can come loose from the pattern. For every new shape a new pattern has to be made. It's time consuming and inefficient for small numbers of cutouts, especially for when only a couple of parts need made. It'll cut two (or three or more) parts identically but if the pattern is never needed again it's scrap.

There's two ways I can think of to add CNC without altering the arm and torch mounting at all.

One is to attach a square shape frame to the arm support post with a motor at each corner. Each motor winds/unwinds a cable and each cable has a ring that fits over the drive magnet. Switching to pattern following is easy, simply take the rings off and hang them onto pegs somewhere out of the way. Search for IPAnema robot on YouTube. Reduce that to four cables and movement in only a 2D plane. Or a Skycam with all the cables pulled in so there's no up and down movement. (I was watching a NASCAR race with one of those cameras when I thought it could be a way to CNC the torch.)

The other is a CoreXY drive with a tight cable or belt and a lightweight gantry arm. The carriage could have a single ball bearing in its bottom side with an ID sized to fit over the drive magnet. To switch to pattern following pick the gantry up a bit, move the arm then jog the gantry back towards the support post.

CoreXY doesn't need rigid rails to keep the gantry from racking. It's similar in design to what's inside an Etch-a-Sketch, which uses two crossed rails supported by a tight cable running around several pulleys and crossing itself at least once so the rails can't rack.

The torch doesn't need to move fast. It doesn't have controllable on/off. It's lit with a striker and turned off manually with a gas valve. It doesn't need automatic height control because it's only used to cut thick steel plate. The drive doesn't need monster torque motors, I can easily push it around with light pressure on the tip of one little finger. If it was perfectly level (in its present location it's not quite) I could probably just about move it by blowing on the end of the arm.

Since the motors can be light and there's zero cutting force, the supporting structure for the drive can be fairly light. The system only needs to be able to move a low inertia mass at speeds up to a few inches per second. I suspect that NEMA17 motors with 100 or so oz-in torque might be grossly overpowered for this application.

Pros and cons of each method.

Four cable drive.

Pros. Mechanically simple. Needs no rails or rigid guides. Very easy switch between CNC and pattern mode. Non-electronic hardware parts inexpensive.

Cons. More expensive for motors and drivers. I've spent hours searching and found only some very slow 2 and 3 motor designs, mostly student experiments, vertical wall plotter art installations and a few fledgling DIY mini-skycam experiments where they're attempting to merge two 2 motor wall plotter drives. Fast ones are made by companies or R&D firms with huge budgets and they're all 3D motion like IPAnema. In other words nobody has bothered to even try to build a reasonably fast two dimensional version. (Look! A college thesis paper just waiting to be written!)

CoreXY

Pros. Needs only one lightweight rigid rail. Needs only two motors and electronics VS 4 for Four cable system. Easy switch between CNC and pattern mode if the gantry rail isn't rigidly mounted at the ends. There's actually been some use of the similar rigid rail H-Bot or Hbot drive in CNC (but has it been done with LinuxCNC?), the CoreXY drive should be able to use the same software setup.

Cons. More complex for the drive hardware. Requires 8 idlers plus whatever is used for bearings on the carriage and it needs a rigid gantry rail.

Either way, the electronics and motors won't break the bank for this. One of those ~$200 power supply, integrated driver board and motor kits should work. A 2 axis board with two motors is even less. My aesthetic sense (such as it is) leans toward the four cable for its elegant mechanical simplicity, but I don't have the math skills to even begin to to attempt figuring out a way to convert G-code to what it would need for movement commands.

I'm dependent on someone else being interested enough in figuring out how to make LinuxCNC operate one of these types of drive systems. Either way, it would make for a very inexpensive method of using fire to cut thick slabs of metal, while rescuing more 'obsolete' old tools from being scrapped.

Who doesn't like fire and cutting thick slabs of metal with it?

It's simple and pretty much foolproof, as long as you have or can make patterns.

The problems, the patterns have to be 1/8" smaller all around than the pieces being cut and sharp corners aren't possible due to the way the magnet rolls around. Too sharp inside and the magnet gets stuck. Too sharp outside and it can come loose from the pattern. For every new shape a new pattern has to be made. It's time consuming and inefficient for small numbers of cutouts, especially for when only a couple of parts need made. It'll cut two (or three or more) parts identically but if the pattern is never needed again it's scrap.

There's two ways I can think of to add CNC without altering the arm and torch mounting at all.

One is to attach a square shape frame to the arm support post with a motor at each corner. Each motor winds/unwinds a cable and each cable has a ring that fits over the drive magnet. Switching to pattern following is easy, simply take the rings off and hang them onto pegs somewhere out of the way. Search for IPAnema robot on YouTube. Reduce that to four cables and movement in only a 2D plane. Or a Skycam with all the cables pulled in so there's no up and down movement. (I was watching a NASCAR race with one of those cameras when I thought it could be a way to CNC the torch.)

The other is a CoreXY drive with a tight cable or belt and a lightweight gantry arm. The carriage could have a single ball bearing in its bottom side with an ID sized to fit over the drive magnet. To switch to pattern following pick the gantry up a bit, move the arm then jog the gantry back towards the support post.

CoreXY doesn't need rigid rails to keep the gantry from racking. It's similar in design to what's inside an Etch-a-Sketch, which uses two crossed rails supported by a tight cable running around several pulleys and crossing itself at least once so the rails can't rack.

The torch doesn't need to move fast. It doesn't have controllable on/off. It's lit with a striker and turned off manually with a gas valve. It doesn't need automatic height control because it's only used to cut thick steel plate. The drive doesn't need monster torque motors, I can easily push it around with light pressure on the tip of one little finger. If it was perfectly level (in its present location it's not quite) I could probably just about move it by blowing on the end of the arm.

Since the motors can be light and there's zero cutting force, the supporting structure for the drive can be fairly light. The system only needs to be able to move a low inertia mass at speeds up to a few inches per second. I suspect that NEMA17 motors with 100 or so oz-in torque might be grossly overpowered for this application.

Pros and cons of each method.

Four cable drive.

Pros. Mechanically simple. Needs no rails or rigid guides. Very easy switch between CNC and pattern mode. Non-electronic hardware parts inexpensive.

Cons. More expensive for motors and drivers. I've spent hours searching and found only some very slow 2 and 3 motor designs, mostly student experiments, vertical wall plotter art installations and a few fledgling DIY mini-skycam experiments where they're attempting to merge two 2 motor wall plotter drives. Fast ones are made by companies or R&D firms with huge budgets and they're all 3D motion like IPAnema. In other words nobody has bothered to even try to build a reasonably fast two dimensional version. (Look! A college thesis paper just waiting to be written!)

CoreXY

Pros. Needs only one lightweight rigid rail. Needs only two motors and electronics VS 4 for Four cable system. Easy switch between CNC and pattern mode if the gantry rail isn't rigidly mounted at the ends. There's actually been some use of the similar rigid rail H-Bot or Hbot drive in CNC (but has it been done with LinuxCNC?), the CoreXY drive should be able to use the same software setup.

Cons. More complex for the drive hardware. Requires 8 idlers plus whatever is used for bearings on the carriage and it needs a rigid gantry rail.

Either way, the electronics and motors won't break the bank for this. One of those ~$200 power supply, integrated driver board and motor kits should work. A 2 axis board with two motors is even less. My aesthetic sense (such as it is) leans toward the four cable for its elegant mechanical simplicity, but I don't have the math skills to even begin to to attempt figuring out a way to convert G-code to what it would need for movement commands.

I'm dependent on someone else being interested enough in figuring out how to make LinuxCNC operate one of these types of drive systems. Either way, it would make for a very inexpensive method of using fire to cut thick slabs of metal, while rescuing more 'obsolete' old tools from being scrapped.

Who doesn't like fire and cutting thick slabs of metal with it?

Last edit: 15 Apr 2013 18:17 by Galane.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

15 Apr 2013 18:46 - 15 Apr 2013 18:47 #32741

by BigJohnT

Replied by BigJohnT on topic CNC for a pattern torch.

Last edit: 15 Apr 2013 18:47 by BigJohnT.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23485

- Thank you received: 4994

15 Apr 2013 19:58 #32749

by andypugh

Have you seen ?

That's another 3-D one though.

I think corexy can be simplified to just a spreader bar for the x-direction pulleys. it would probably be stiffer with a single slide at the back though.

Thinking about it, the mechanism from a flatbed plotter would be ideal, that could just park completely out of the way. I think those use two belts/cables but the pen arm runs on a single slide at the back.

the steppers are fixed on the plotter setup. I will have a look at mine tonight to see what the cable runs are.

If you look at the CoreXY pictures: www.corexy.com/theory.html then it seems that the right-hand stepper and pulley could be moved to the left-hand side (and the pulleys could share shafts) to give a similar 2-open-sides setup.

I like the 4-cable idea, but if you do want to be able to unhook it then I can imagine the spools all unspooling in an annoying way. with a mechanical arrangement you could just unclip the torch head.

Replied by andypugh on topic CNC for a pattern torch.

Cons. More expensive for motors and drivers. I've spent hours searching and found only some very slow 2 and 3 motor designs, mostly student experiments, vertical wall plotter art installations and a few fledgling DIY mini-skycam experiments where they're attempting to merge two 2 motor wall plotter drives. Fast ones are made by companies or R&D firms with huge budgets and they're all 3D motion like IPAnema. In other words nobody has bothered to even try to build a reasonably fast two dimensional version. (Look! A college thesis paper just waiting to be written!)

Have you seen ?

That's another 3-D one though.

I think corexy can be simplified to just a spreader bar for the x-direction pulleys. it would probably be stiffer with a single slide at the back though.

Thinking about it, the mechanism from a flatbed plotter would be ideal, that could just park completely out of the way. I think those use two belts/cables but the pen arm runs on a single slide at the back.

the steppers are fixed on the plotter setup. I will have a look at mine tonight to see what the cable runs are.

If you look at the CoreXY pictures: www.corexy.com/theory.html then it seems that the right-hand stepper and pulley could be moved to the left-hand side (and the pulleys could share shafts) to give a similar 2-open-sides setup.

I like the 4-cable idea, but if you do want to be able to unhook it then I can imagine the spools all unspooling in an annoying way. with a mechanical arrangement you could just unclip the torch head.

Please Log in or Create an account to join the conversation.

- Galane

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

16 Apr 2013 06:17 #32775

by Galane

It's quite a bit like this one www.hellotrade.com/esab-usa/ultra-graph-...-pattern-cutter.html

Replied by Galane on topic CNC for a pattern torch.

So the existing mechanics function is to support the torch in the vertical and provide free movement in the X and Y axis? A photo would be nice to see...

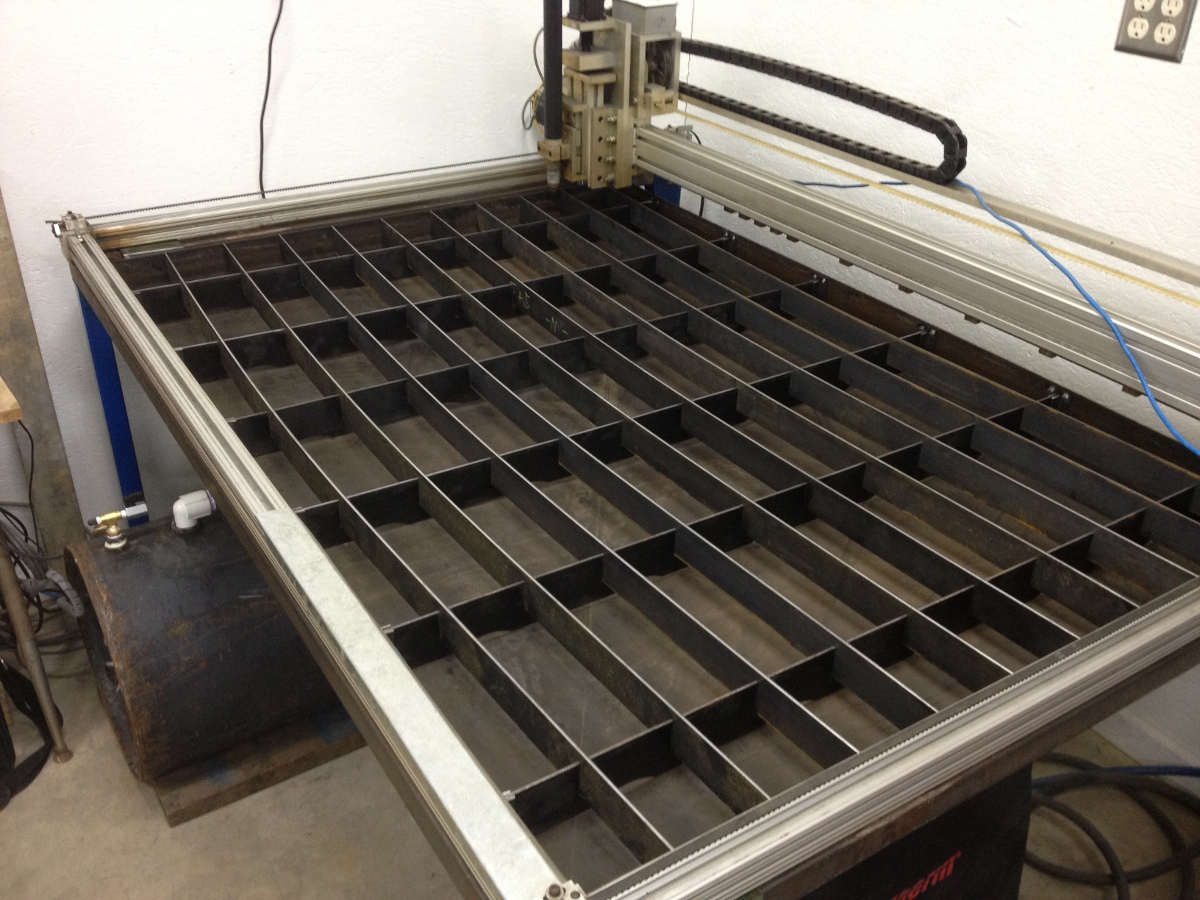

Even the CoreXY would need supporting structure as I see it. The simple thing to construct and use would be something like my plasma cutter.

John

It's quite a bit like this one www.hellotrade.com/esab-usa/ultra-graph-...-pattern-cutter.html

Please Log in or Create an account to join the conversation.

Time to create page: 0.072 seconds