[NEWBIE] Advises creating a cnc wood roter

- petekaner

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

31 Jul 2013 22:07 #37299

by petekaner

[NEWBIE] Advises creating a cnc wood roter was created by petekaner

Hello everybody,

Now, first of all, I don't expect a detailed how to, just some advices

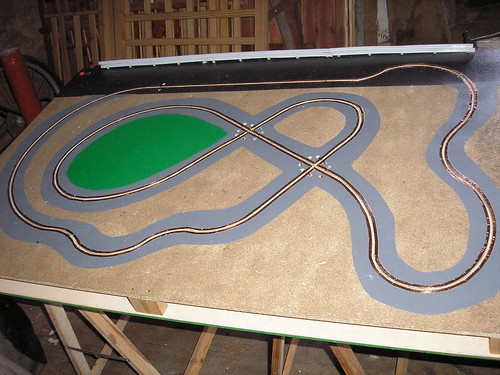

So here's the deal. My brother and I are plannig to build a wood router to create slot car circuits, things like these:

So what we have in mind is:

njdiding.en.made-in-china.com/productima...-1215-1218-1325.html

So my quick questions are:

Any other recommendation you have will be much more appreciate. We are absolutely newbies on this Thanks a lot

Thanks a lot

Ah, and keep in mind this is very important, we're talking about slot cars here

Now, first of all, I don't expect a detailed how to, just some advices

So here's the deal. My brother and I are plannig to build a wood router to create slot car circuits, things like these:

So what we have in mind is:

- A 3 axis router wich can "draw" the slot

- The size of the circuit will be max 120mm x 80mm

- The routing will be done with a router like this: workingwoodplans.files.wordpress.com/201...-working-routers.jpg

njdiding.en.made-in-china.com/productima...-1215-1218-1325.html

So my quick questions are:

- what would recommend? step or lineal motors?

- any recomendations on the controller? I'm thinking on tb6560 3 axis

- we have an old computer which seems just perfet for the job, we will build the bench ourselves as well as everything else, but we will obviously will have to but motors, controllers... how much more or less do you think it will cost?

Any other recommendation you have will be much more appreciate. We are absolutely newbies on this

Ah, and keep in mind this is very important, we're talking about slot cars here

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1744

- Thank you received: 288

31 Jul 2013 23:30 #37300

by cncbasher

Replied by cncbasher on topic [NEWBIE] Advises creating a cnc wood roter

well you certianly will be jumping into probably some of the unknown , but first of all some basics .

depending on your available cash flow , this will not be a cheap fix , expect something in the order of $3,000 - $4,000

or even more , the main point to remember is the heavier you make it , the more force you will need to move it all and then it all falls apart .

is this for only your own use as a hobby or are you looking at building many slot tracks , as this will indeed have a bearing on the way to move forward

stepper motors are the cheaper option , although for reliability i would forgo the tb6560's as a reliable platform , although it may well get you started for the basics , as you progress you will find a better route .

what engineering experience do you guy's have and what tools have you available ?

as this will seriously limit you on the type of machine you can build i presume you mean 1200mm x 800mm ( 4 x 3 )

and also what garage or room do you have to place all this in .. it's suprising how much room they take up , especialy whilst building

i ask these questions to enable more correctly the answers to your main points

all will become clear as i progress your questions

plans etc for this type of machine are plentyfull , some are good , some are darn right dangerous and will just bleed your money

depending on your available cash flow , this will not be a cheap fix , expect something in the order of $3,000 - $4,000

or even more , the main point to remember is the heavier you make it , the more force you will need to move it all and then it all falls apart .

is this for only your own use as a hobby or are you looking at building many slot tracks , as this will indeed have a bearing on the way to move forward

stepper motors are the cheaper option , although for reliability i would forgo the tb6560's as a reliable platform , although it may well get you started for the basics , as you progress you will find a better route .

what engineering experience do you guy's have and what tools have you available ?

as this will seriously limit you on the type of machine you can build i presume you mean 1200mm x 800mm ( 4 x 3 )

and also what garage or room do you have to place all this in .. it's suprising how much room they take up , especialy whilst building

i ask these questions to enable more correctly the answers to your main points

all will become clear as i progress your questions

plans etc for this type of machine are plentyfull , some are good , some are darn right dangerous and will just bleed your money

The following user(s) said Thank You: petekaner

Please Log in or Create an account to join the conversation.

- petekaner

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

01 Aug 2013 01:09 #37302

by petekaner

Replied by petekaner on topic [NEWBIE] Advises creating a cnc wood roter

Hi,

thanks a lot for the quick reply cncbasher

A hobby, there might be some chances for selling some stuff done with it but not in a professional way, more like "hey i would love to have one circuit done with this, can you sell me one?".

I'm a php developer and I also have linux experience. So computer stuff goes on my side. My brother has strong electronic knowledge and he's also a handyman (and I'm kind of too). Tools: we have everything we need I think: every kind of saws to build the bench, soldiering machine (I don't know if that's the name in english), dremels, drillers, etc etc. We also have tons of space, we live (well my brother, where the thing is going to be made) in the country side. Space is not a problem.

yes, sorry

thanks a lot for the quick reply cncbasher

uoooouuu where that money goes? you say tb6560 its not very reliable but... for something so simple (it doesn't need to be extremely precise, its just draw a 3,5mm slot in mdf) i think it will do. Are the motors so expensive? wich ones would you recommend?depending on your available cash flow , this will not be a cheap fix , expect something in the order of $3,000 - $4,000

is this for only your own use as a hobby or are you looking at building many slot tracks , as this will indeed have a bearing on the way to move forwardwhat engineering experience do you guy's have and what tools have you available ?as this will seriously limit you on the type of machine you can build i presume you mean 1200mm x 800mm ( 4 x 3 )Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1744

- Thank you received: 288

01 Aug 2013 02:00 #37303

by cncbasher

Replied by cncbasher on topic [NEWBIE] Advises creating a cnc wood roter

you would probably find just drawing the line freehand and routing it would be far cheaper for such a simple job .

but to answer your question , your probably looking at a guess Electronics 400 -500 Euro , if you use wood as a base of the machine perhaps another 400 -600 Euro , then the cost of the router

etc , the construction of the machine would need to be substantial to withold flex in the gantry and the forces involved against the cutter etc , they are not trivial by any means .

you then need to be able to have some sort of bearings the cheap way is with skate ball bearings and threaded rod etc so add to the above another 100 - 150 Euro

and i'm probably still on the lower cost side .

and you still have a machine that will move and have backlash in the mechanics .

doing this properly with linear bearings , ballscrews will easily treble the cost ..

if you want to look at some plans to get an idea of whats needed send me a pm and i'll forward you a few links that will help

then we can answer specific questions as you work your way through .

the tb6560 is a low cost board which unfortunatly is fraught with being under powered ,if you search the forums you will see many modifications and problems associated with them .

but for a budget start it will get you going , but expect it to fail and be replaced at some time

but to answer your question , your probably looking at a guess Electronics 400 -500 Euro , if you use wood as a base of the machine perhaps another 400 -600 Euro , then the cost of the router

etc , the construction of the machine would need to be substantial to withold flex in the gantry and the forces involved against the cutter etc , they are not trivial by any means .

you then need to be able to have some sort of bearings the cheap way is with skate ball bearings and threaded rod etc so add to the above another 100 - 150 Euro

and i'm probably still on the lower cost side .

and you still have a machine that will move and have backlash in the mechanics .

doing this properly with linear bearings , ballscrews will easily treble the cost ..

if you want to look at some plans to get an idea of whats needed send me a pm and i'll forward you a few links that will help

then we can answer specific questions as you work your way through .

the tb6560 is a low cost board which unfortunatly is fraught with being under powered ,if you search the forums you will see many modifications and problems associated with them .

but for a budget start it will get you going , but expect it to fail and be replaced at some time

The following user(s) said Thank You: petekaner

Please Log in or Create an account to join the conversation.

- petekaner

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

01 Aug 2013 02:18 #37304

by petekaner

but we started to though about a cnc machine and we got into it

About what you sai about the wood... 400-600 euros. I think we can do it for less than 100, after all we only need a 20mm MDF 1200x800mm and the structure. The thing is... this doesn't need to be extremely robust, the router cuts the mdf just like butter. If you take a look at the picture above and notice where the circuit stands, thats exactly where I routed the slot

Anyway I'd love to do this in the most proper way possible, I send you a PM for those links thanks a lot

thanks a lot

Replied by petekaner on topic [NEWBIE] Advises creating a cnc wood roter

Yeah, I know, that's we are doing right now, here's the last rally circuit I've done (scenery on his way):you would probably find just drawing the line freehand and routing it would be far cheaper for such a simple job .

but we started to though about a cnc machine and we got into it

About what you sai about the wood... 400-600 euros. I think we can do it for less than 100, after all we only need a 20mm MDF 1200x800mm and the structure. The thing is... this doesn't need to be extremely robust, the router cuts the mdf just like butter. If you take a look at the picture above and notice where the circuit stands, thats exactly where I routed the slot

Anyway I'd love to do this in the most proper way possible, I send you a PM for those links

Please Log in or Create an account to join the conversation.

Time to create page: 0.070 seconds