Brown & Sharpe beast retrofit

- davo727

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

14 Jan 2014 09:41 #42743

by davo727

Replied by davo727 on topic Brown & Sharpe beast retrofit

Very good.

.

An alternative is to use a pneumatic cylinder with a relieving regulator. That gives a constant (and adjustable) force, and minimal extra inertia.

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

14 Jan 2014 12:37 #42746

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

I have some pictures, I need an sd card reader,as they pics are on my phone and I think the usb port is damaged. Ill try for tomorrow. The head really cant be counterweighted with a weight and sporockets like a Fadal, The colunm is a welded box and the top of it is not hollow, no place for the weight... pneumatic, gas charged or even a hydraulic cylinder have been used a counter balances. Right now Ill leave it as is, its been this way for 30 years!!

Ill look seriously at figuring out how to apply bias in the servo tuning. I still think the current loop needs tuning as the motor is noisy and spongy, in current mode(presently in velocity mode using the original tachs), its quiet, but seriously lacks power and is super sloppy. I talked with tech support at AMCI and they pretty much said the same thing. Im not exactly looking forward to the loop tuning, but I would like to know how, as Ive noticed the heavier the load a motor has to move, the spongy-er it becomes.

Ill look seriously at figuring out how to apply bias in the servo tuning. I still think the current loop needs tuning as the motor is noisy and spongy, in current mode(presently in velocity mode using the original tachs), its quiet, but seriously lacks power and is super sloppy. I talked with tech support at AMCI and they pretty much said the same thing. Im not exactly looking forward to the loop tuning, but I would like to know how, as Ive noticed the heavier the load a motor has to move, the spongy-er it becomes.

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

15 Jan 2014 13:17 #42803

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

15 Jan 2014 13:22 #42804

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

Super shakey video, sorry for the bad lighting....

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23377

- Thank you received: 4966

15 Jan 2014 21:11 #42819

by andypugh

Replied by andypugh on topic Brown & Sharpe beast retrofit

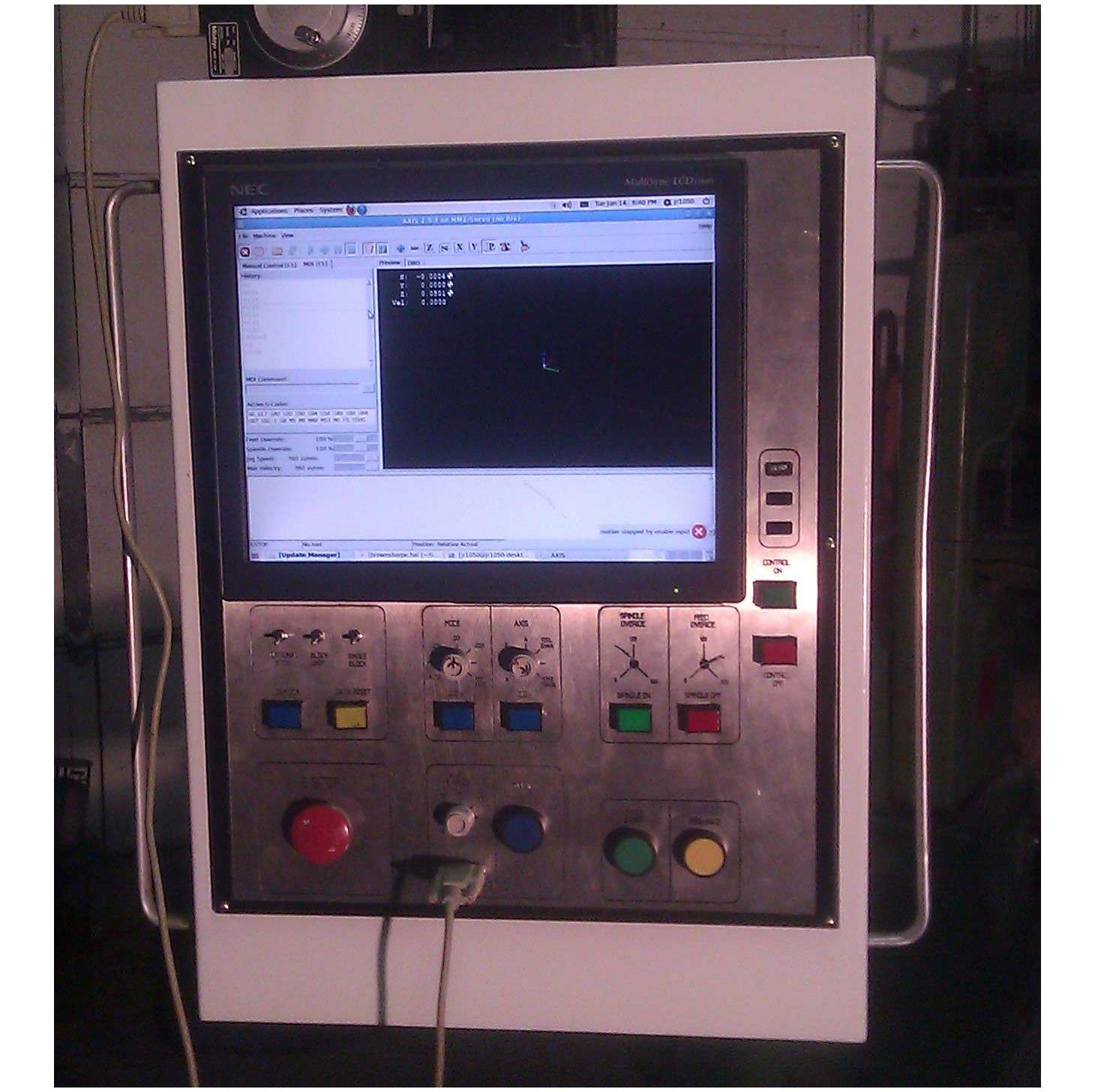

Is that a touchscreen? If it is then I would suggest not using Axis, which is pretty fiddly with a touchscreen.

I am getting on pretty well with "Touchy" on my mill. I like the way that it tends to require an actual physical button press before doing most of the dangerous stuff.

Part of the same philosophy is that it requires a jogwheel or physical buttons to jog, but you look to have those.

I am getting on pretty well with "Touchy" on my mill. I like the way that it tends to require an actual physical button press before doing most of the dangerous stuff.

Part of the same philosophy is that it requires a jogwheel or physical buttons to jog, but you look to have those.

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

16 Jan 2014 03:47 #42847

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

Not a touchscreen, NEC 1560, plain old 15" flat screen. Durable, cheap and the right size!!! I agree with having the ability to interact with the machine with knobs,buttons ect wether they be real on on a touch screen. For running a very small machine, like a sherline, a mouse is ok, you cant do much damage and there is little risk of persersonal injury. On anything else, the mouse has gotta go. Id like to see a gui with tabs that can be switched with a real knob for modes and doesnt require a mouse. Its a matter of perspective I guess...

Please Log in or Create an account to join the conversation.

- newbynobi

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2083

- Thank you received: 415

16 Jan 2014 05:18 #42850

by newbynobi

Replied by newbynobi on topic Brown & Sharpe beast retrofit

Just take a look on my gmoccapy, you can use it without mouse.

It is made to be controled almost with hardware.

Special features you request are wellcome, as there will be also a industrial version in the future.

Norbert

It is made to be controled almost with hardware.

Special features you request are wellcome, as there will be also a industrial version in the future.

Norbert

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

16 Jan 2014 06:09 #42851

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

Ive looked at it before, very nice!! What is required to install it?

Please Log in or Create an account to join the conversation.

- davo727

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

16 Jan 2014 07:32 #42853

by davo727

Replied by davo727 on topic Brown & Sharpe beast retrofit

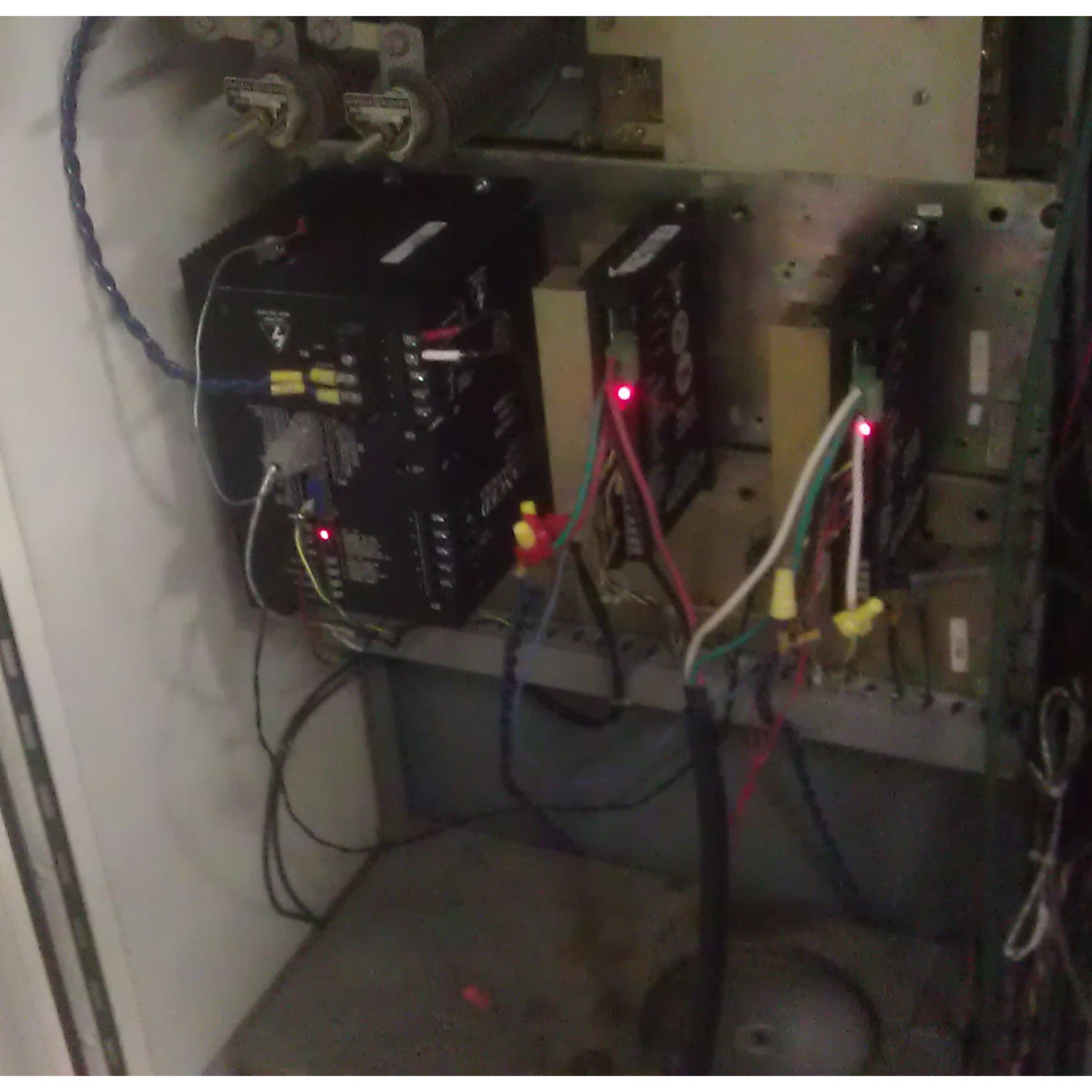

Hi, What are the other boards and modules on your panel please? Thanks

Please Log in or Create an account to join the conversation.

- JR1050

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

16 Jan 2014 07:38 #42854

by JR1050

Replied by JR1050 on topic Brown & Sharpe beast retrofit

The only board in the panel.is a mesa 7i84 serial i/ o board. The rest of it is just buttons, bcd encoders, connections to halui and a program to run it all.

Please Log in or Create an account to join the conversation.

Time to create page: 0.191 seconds