Matching existing AC servos to new drives.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

28 Aug 2019 04:06 #143391

by DaOne

Matching existing AC servos to new drives. was created by DaOne

I have a Kitamura Mycenter 0 I am contemplating on retrofitting. I looked into the drives (CACR-IR-151515EBY33) and they appear to be incompatible with Mesa hardware. So now I am wondering if I can just replace the drives or do I really need a matched set (Servo + drive)? The drives I am looking at are these...

www.cnc4pc.com/dyn4-ac-servo-drive-t01-frame.html

Anyone happen to have any info on this?

My servos are...

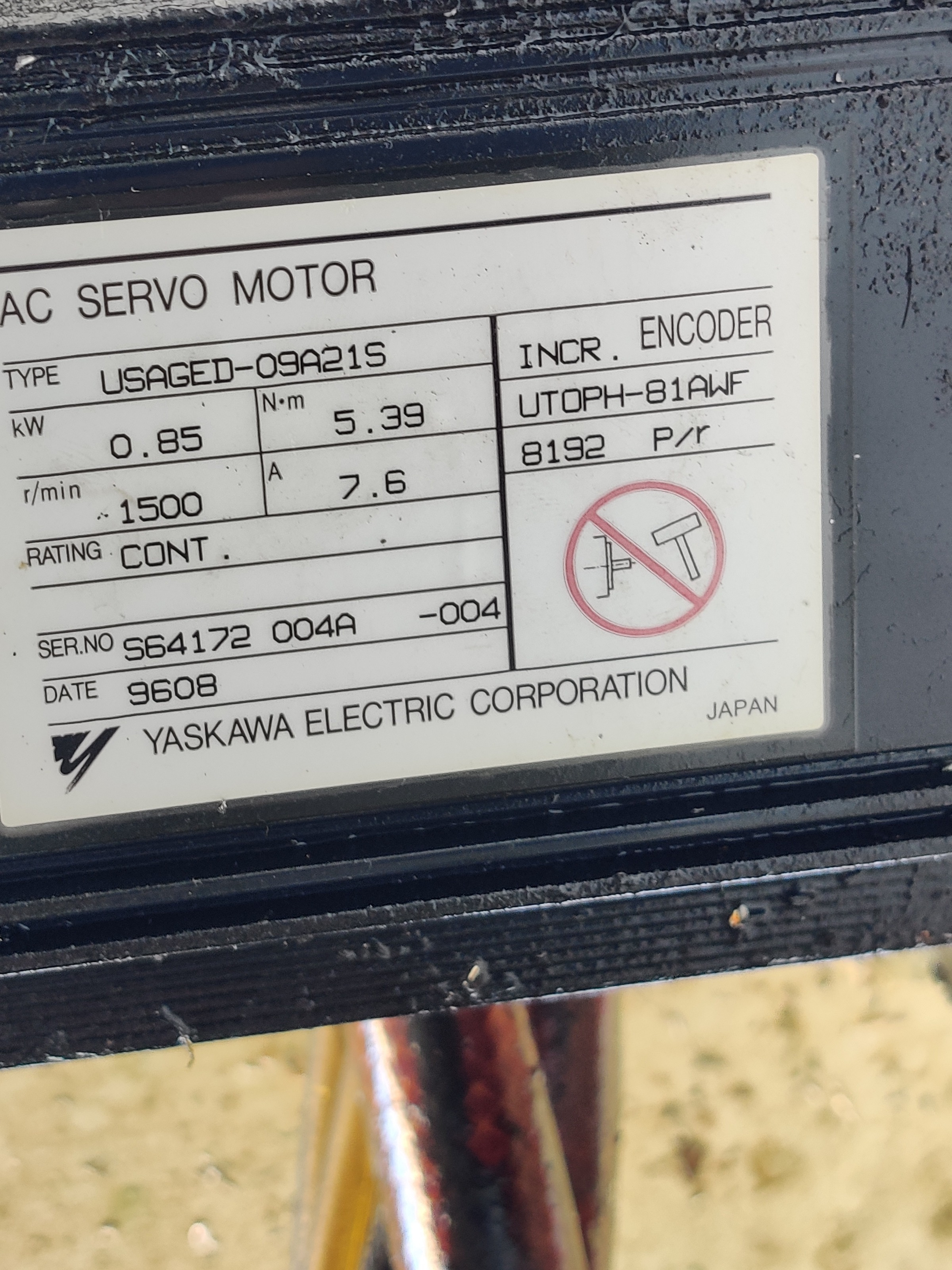

X / Y..

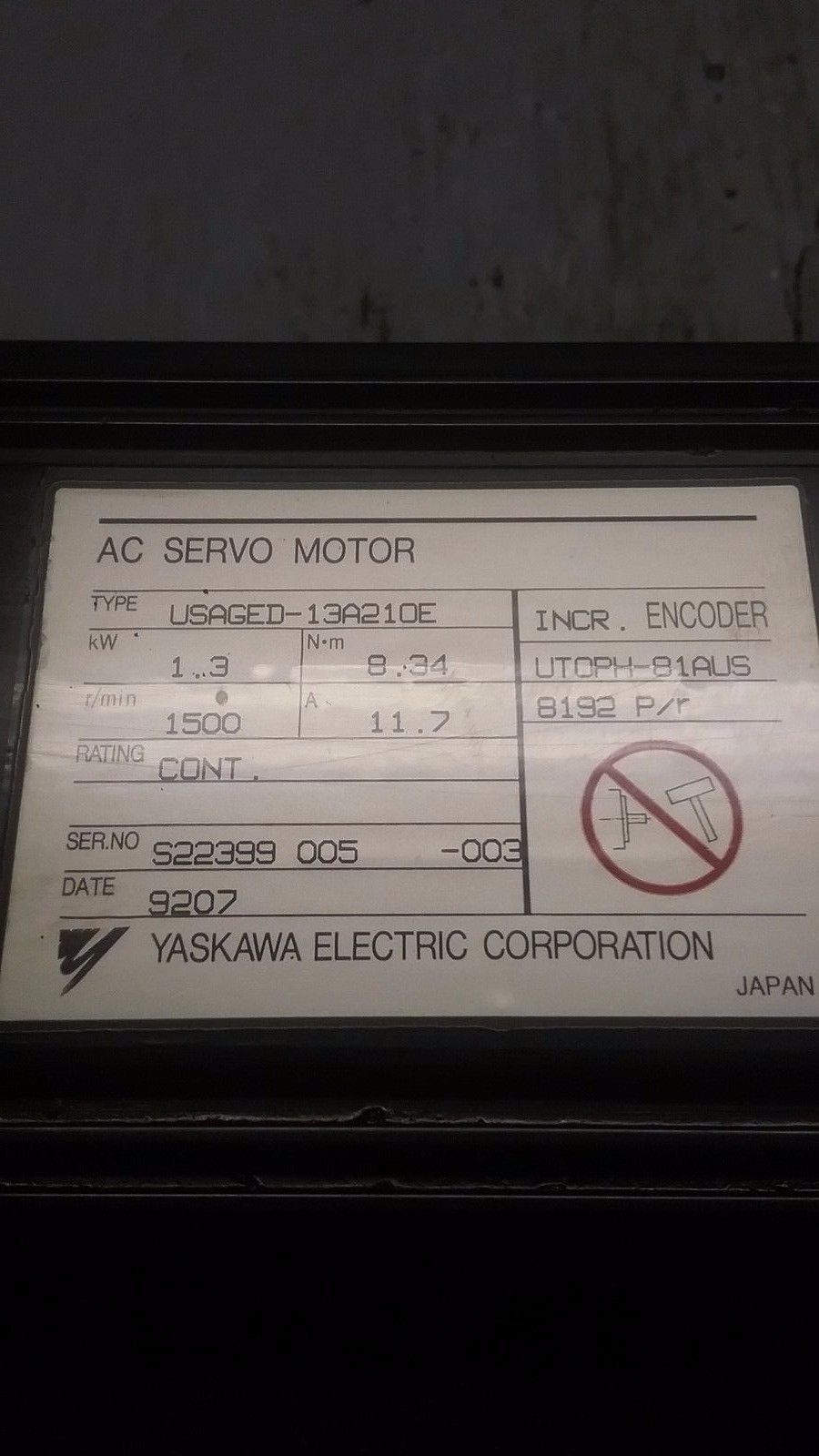

Z..

Basically looking for recommendations.

www.cnc4pc.com/dyn4-ac-servo-drive-t01-frame.html

Anyone happen to have any info on this?

My servos are...

X / Y..

Z..

Basically looking for recommendations.

Attachments:

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

28 Aug 2019 05:48 #143396

by DaOne

Replied by DaOne on topic Matching existing AC servos to new drives.

The datasheet on the servos is here...

www.yaskawa.com/delegate/getAttachment?d...me=TSE-S800-4.1E.pdf

Looks like I can just input the info into the drive and I should be good to go. Hoping to have someone with more experience take a look at it for me.

www.yaskawa.com/delegate/getAttachment?d...me=TSE-S800-4.1E.pdf

Looks like I can just input the info into the drive and I should be good to go. Hoping to have someone with more experience take a look at it for me.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21365

- Thank you received: 7288

28 Aug 2019 07:10 #143405

by tommylight

Replied by tommylight on topic Matching existing AC servos to new drives.

The drives should have a normal encoder output on one of the connectors, with 2000 PPR so you can use that as feedback.

If the drives work, use them, they are very good and after wiring the tuning should take about 5 minutes in total.

On the other side, changing the drives would require changing motors, or changing the encoders on the motors together with commutation that is built in with the encoders.

The original encoders output incremental signals on all 3 outputs that change the distance between pulses in corelation to one and the other, something like looking at a 3 phase PWM signal.

Also the commutation signals, the Argon drives from Granite devices complained about signals, forgot what exactly but those drives can work with no commutation, so all was good.

IF you plan on changing the encoders, most probably you will have to destroy them as i could not get them out.

Again, try to use the original drives, they work perfectly with Mesa 7i77 and Linuxcnc.

If the drives work, use them, they are very good and after wiring the tuning should take about 5 minutes in total.

On the other side, changing the drives would require changing motors, or changing the encoders on the motors together with commutation that is built in with the encoders.

The original encoders output incremental signals on all 3 outputs that change the distance between pulses in corelation to one and the other, something like looking at a 3 phase PWM signal.

Also the commutation signals, the Argon drives from Granite devices complained about signals, forgot what exactly but those drives can work with no commutation, so all was good.

IF you plan on changing the encoders, most probably you will have to destroy them as i could not get them out.

Again, try to use the original drives, they work perfectly with Mesa 7i77 and Linuxcnc.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

28 Aug 2019 23:10 #143502

by andypugh

In what way are they incompatible?

If they really are incompatible with Mesa, then perhaps General Mechatronics have something?

Replied by andypugh on topic Matching existing AC servos to new drives.

I have a Kitamura Mycenter 0 I am contemplating on retrofitting. I looked into the drives (CACR-IR-151515EBY33) and they appear to be incompatible with Mesa hardware.

In what way are they incompatible?

If they really are incompatible with Mesa, then perhaps General Mechatronics have something?

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

28 Aug 2019 23:46 #143506

by JR1050

Replied by JR1050 on topic Matching existing AC servos to new drives.

A while back I was trying to use similar yaskawa motors with AMC 25a20 brushless drives. I did get the motors to run with the bldc component, it wasn’t easy and really didn’t work that well. There are some other drives by AMC that would might work , I suspect a digitech model would , problem is they are not cheap. You could look around for a compatible analog yaskawa drive. I take it your Kitamura has an I-80 control ?

Please Log in or Create an account to join the conversation.

- DaOne

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 155

- Thank you received: 6

30 Aug 2019 02:08 #143626

by DaOne

Replied by DaOne on topic Matching existing AC servos to new drives.

I would love to re-use these drives. They work great. The control is just constantly having issues and is very out dated. Yes its the I-80 control. The drives use PWM (PWMU / PWMV). I am not familiar with this type of input. If there is hardware that will adapt this to the +-10v or some kinda hardware that works with these I am all ears. It would save a ton of time and $.

Here is the manual...

www.yaskawa.com/delegate/getAttachment?c...20Servo%20Manual.pdf

Here is the manual...

www.yaskawa.com/delegate/getAttachment?c...20Servo%20Manual.pdf

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

30 Aug 2019 12:15 #143654

by andypugh

Replied by andypugh on topic Matching existing AC servos to new drives.

The drives require a PWm to drive 2 out of 3 phases. Presumably the other phase is calculated as what is left over.

Mesa have a 3-phase PWM module, look for firmwares for the 7i39 as an example.

(you would just ignore the PWMW output of the card)

Mesa have a 3-phase PWM module, look for firmwares for the 7i39 as an example.

(you would just ignore the PWMW output of the card)

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17735

- Thank you received: 5187

30 Aug 2019 15:19 #143666

by PCW

Replied by PCW on topic Matching existing AC servos to new drives.

Yes, you should be able to control the drive with LinuxCNC and 2 PWM generators and the BLDC component

If using Mesa hardware, Ideally rather than bare PWM generators, a module that generates

sine wave PWM at requested frequencies and amplitudes would be better since it would

have better waveform accuracy at high speeds

If using Mesa hardware, Ideally rather than bare PWM generators, a module that generates

sine wave PWM at requested frequencies and amplitudes would be better since it would

have better waveform accuracy at high speeds

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

01 Sep 2019 19:33 #143805

by andypugh

Replied by andypugh on topic Matching existing AC servos to new drives.

Would it be best to use the Three Phase PWM module, just in case the drives care about the relative phase of the PWM? Or is that unlikely?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17735

- Thank you received: 5187

01 Sep 2019 23:01 #143818

by PCW

Replied by PCW on topic Matching existing AC servos to new drives.

Pretty sure it needs 2 phases 120 degrees apart synced to the rotor like a AMC drives

(the third phase is just the difference between U and V) so using the 3 phase PWMgen should work

it would be better if the hardware did some interpolation like a velocity mode stepgen

I may take a look at this since I need to support the XY100 galvanometer interface

firmware and it deliberately looks very much like a (2 axis) stepgen

(the third phase is just the difference between U and V) so using the 3 phase PWMgen should work

it would be better if the hardware did some interpolation like a velocity mode stepgen

I may take a look at this since I need to support the XY100 galvanometer interface

firmware and it deliberately looks very much like a (2 axis) stepgen

Please Log in or Create an account to join the conversation.

Time to create page: 0.177 seconds