Retrofitting a CharlyRobot 3 axis CNC

- RacingMat

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

11 Jun 2020 17:58 #171159

by RacingMat

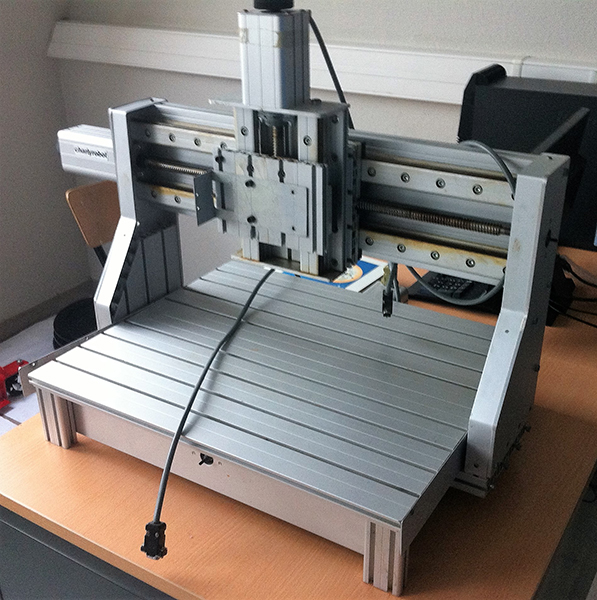

Retrofitting a CharlyRobot 3 axis CNC was created by RacingMat

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

12 Jun 2020 07:55 #171220

by bbsr_5a

Replied by bbsr_5a on topic Retrofitting a CharlyRobot 3 axis CNC

if you trell us the manufactuer of the machine we can help

if you open up the case and tell the PCB reding of the parport Interface we may find the PINout of this

if you alredy got the pinout then you just need to run STEPCONF wizard and the machine will run

is this a ISEL M4030 V1

if you open up the case and tell the PCB reding of the parport Interface we may find the PINout of this

if you alredy got the pinout then you just need to run STEPCONF wizard and the machine will run

is this a ISEL M4030 V1

The following user(s) said Thank You: RacingMat

Please Log in or Create an account to join the conversation.

- RacingMat

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

12 Jun 2020 10:32 #171243

by RacingMat

Replied by RacingMat on topic Retrofitting a CharlyRobot 3 axis CNC

Hi!

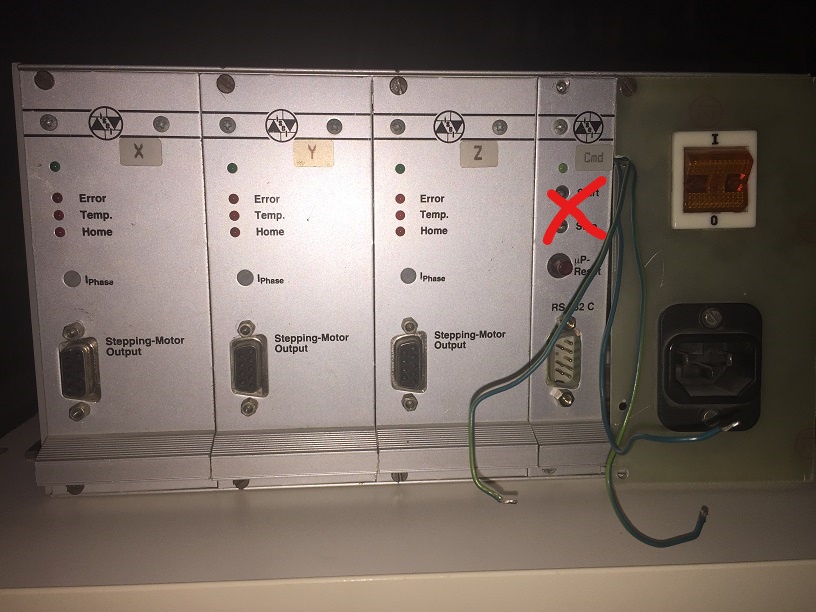

the manufacturer is ISEL/Charlyrobot

reference is unclear maybe PM1 30 with a command control unit C10

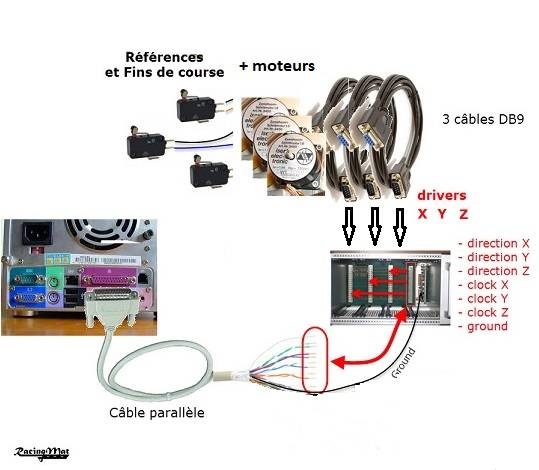

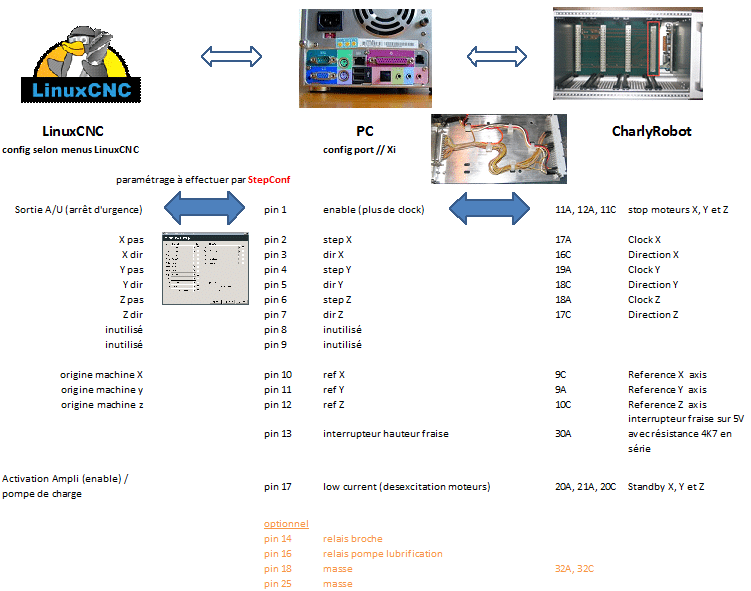

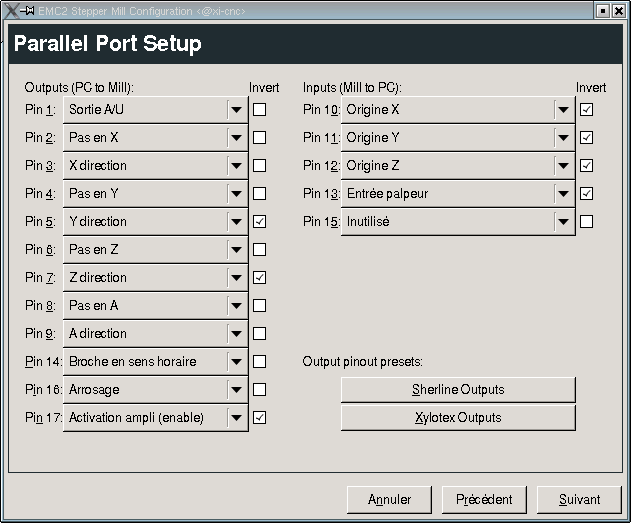

Thanks for your offer, but I have sort out the pinout! And last night, I just connected my parallel port straight to the 3 drivers pins.

And I can move the motors

I may have some questions now:

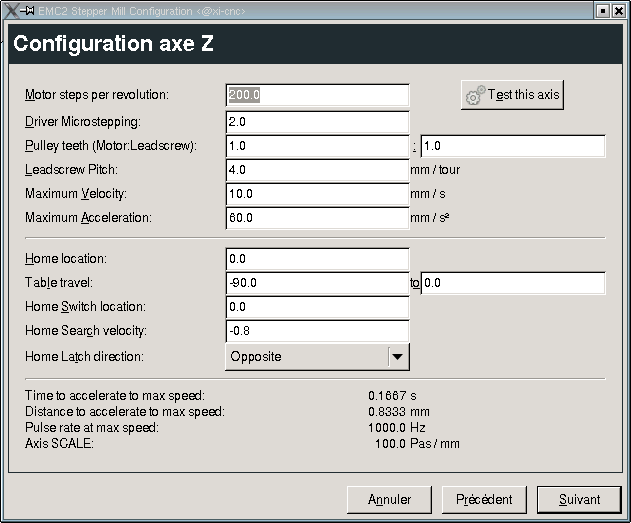

my Z axis can go down but not really up

moving it by hand, the feeling is really fine (smooth, no hard point, no extra effort)

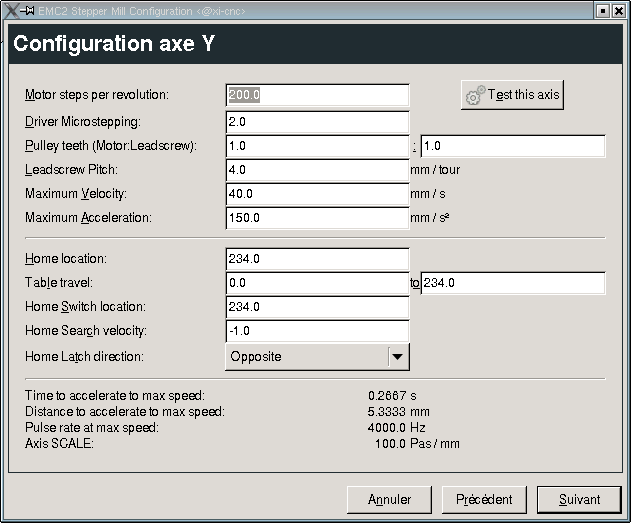

I used an existing similar Charlyrobot setup

here is the Stepconf setup

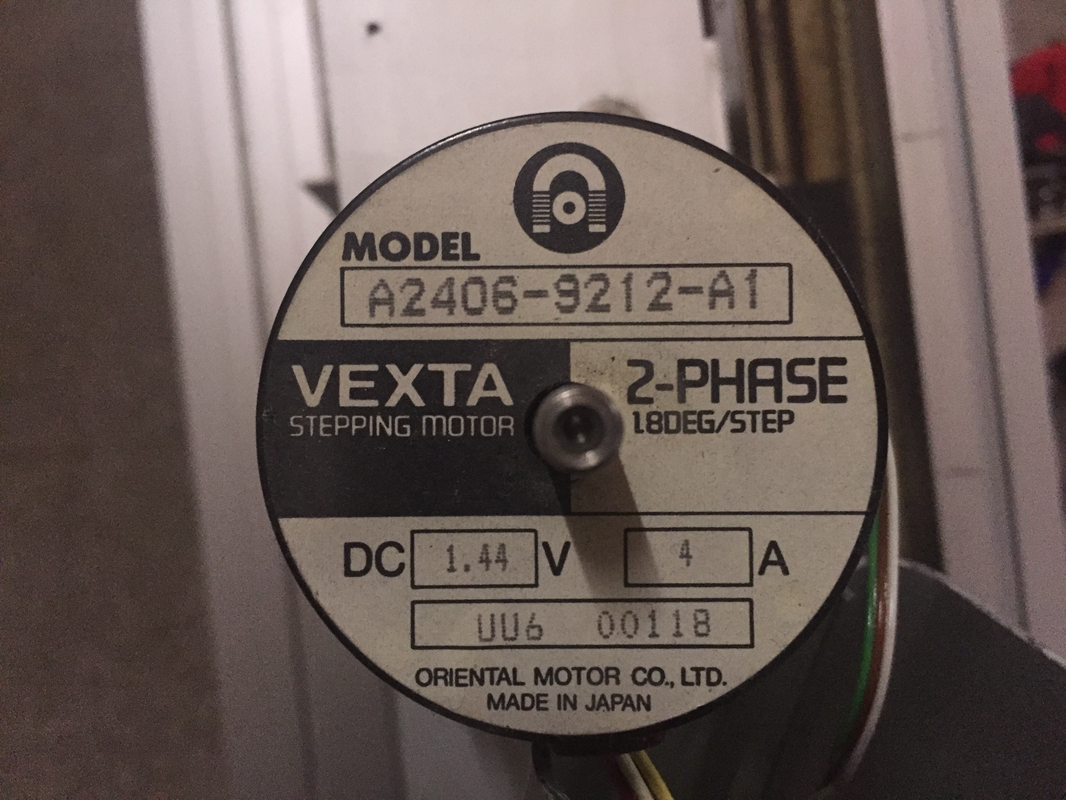

and here is the motor for Z axis:

but maybe it's not suitable with my motors?

the manufacturer is ISEL/Charlyrobot

reference is unclear maybe PM1 30 with a command control unit C10

Thanks for your offer, but I have sort out the pinout! And last night, I just connected my parallel port straight to the 3 drivers pins.

And I can move the motors

I may have some questions now:

my Z axis can go down but not really up

moving it by hand, the feeling is really fine (smooth, no hard point, no extra effort)

I used an existing similar Charlyrobot setup

here is the Stepconf setup

and here is the motor for Z axis:

but maybe it's not suitable with my motors?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

12 Jun 2020 10:52 #171245

by tommylight

Replied by tommylight on topic Retrofitting a CharlyRobot 3 axis CNC

The step timing is to short, so might want to raise that, try 5000.

The following user(s) said Thank You: RacingMat

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

12 Jun 2020 14:22 - 12 Jun 2020 14:24 #171254

by bbsr_5a

Replied by bbsr_5a on topic Retrofitting a CharlyRobot 3 axis CNC

the isel always use a charge pump

in education center i got the same version 2 with Z break

idid get rid of the C10 and went to a standard 5USD Mach3 5Axis bob

this benefits the full RPM controll of the Spindle the extra controll of the CASE Frame Version2

and ofcause the option to go ETH with the 7i92

fast cabeling as plugs to fit isolated cables not the junk of the isel internal

!! ATTANCIAN!!

the isel V1 uses the H-brige as a GND so the motors 8wire got +24V/48 fixed and the drivers pull them down for a step

MAKE shure you are handeling this

in education center i got the same version 2 with Z break

idid get rid of the C10 and went to a standard 5USD Mach3 5Axis bob

this benefits the full RPM controll of the Spindle the extra controll of the CASE Frame Version2

and ofcause the option to go ETH with the 7i92

fast cabeling as plugs to fit isolated cables not the junk of the isel internal

!! ATTANCIAN!!

the isel V1 uses the H-brige as a GND so the motors 8wire got +24V/48 fixed and the drivers pull them down for a step

MAKE shure you are handeling this

Last edit: 12 Jun 2020 14:24 by bbsr_5a. Reason: motor

The following user(s) said Thank You: RacingMat

Please Log in or Create an account to join the conversation.

- RacingMat

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

12 Jun 2020 16:27 - 12 Jun 2020 16:31 #171277

by RacingMat

I tried with custom choice and I had a go at 5000.

Unfortunately, the behaviour is the same... weak Z axis.

I tried the 3 axis with different results:

the Z and X axis are both weak

but gantry Y axis is really beaffy (I can't stop it by hand)

With 500 or 5000, it's the same.

I have to be optimistic if 1 axis is good.

By the way, I have checked the coupling: motor and screw are well linked

I have no budget for MESA conversion.

I have a 5€ BOB but I haven't find any tutorial to use it with ISEL drivers. I made a search into the forum but it doesn't show up your topics, only yours messages...

Replied by RacingMat on topic Retrofitting a CharlyRobot 3 axis CNC

Thanks, step timing value was given by L297 choice.The step timing is to short, so might want to raise that, try 5000.

I tried with custom choice and I had a go at 5000.

Unfortunately, the behaviour is the same... weak Z axis.

I tried the 3 axis with different results:

the Z and X axis are both weak

but gantry Y axis is really beaffy (I can't stop it by hand)

With 500 or 5000, it's the same.

I have to be optimistic if 1 axis is good.

By the way, I have checked the coupling: motor and screw are well linked

Thanks for your help !the isel always use a charge pump

in education center i got the same version 2 with Z break

i did get rid of the C10 and went to a standard 5USD Mach3 5Axis bob

this benefits the full RPM controll of the Spindle the extra controll of the CASE Frame Version2

and of cause the option to go ETH with the 7i92

fast cabeling as plugs to fit isolated cables not the junk of the isel internal

I have no budget for MESA conversion.

I have a 5€ BOB but I haven't find any tutorial to use it with ISEL drivers. I made a search into the forum but it doesn't show up your topics, only yours messages...

I'm not aware of this, nor the consequences... I just plugged the parallel port to the pins of the 3 drivers via the back PCB and socket.!! ATTANCIAN!!

the isel V1 uses the H-brige as a GND so the motors 8wire got +24V/48 fixed and the drivers pull them down for a step

MAKE sure you are handeling this

Last edit: 12 Jun 2020 16:31 by RacingMat. Reason: english translation

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

12 Jun 2020 18:00 #171282

by Mike_Eitel

Replied by Mike_Eitel on topic Retrofitting a CharlyRobot 3 axis CNC

The l297 chip is only the driver chip for a h-bridge and needs those 5000.

But what is used a h-bridge. Can you see the chip? The h-bridge decides the current, means decides the force of the motors. Do they get warm?

I see 4A on the motor and that was difficult to get in chips on those days.

But what is used a h-bridge. Can you see the chip? The h-bridge decides the current, means decides the force of the motors. Do they get warm?

I see 4A on the motor and that was difficult to get in chips on those days.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

12 Jun 2020 18:11 #171284

by tommylight

Replied by tommylight on topic Retrofitting a CharlyRobot 3 axis CNC

With the power off:

-Check plugs and wires going to motors for damage,

-Check drives if they are properly seated in their places,

-Leave the machine ON for 15 minutes, check by hand if the motors are getting warm, they should

After checking that, with the power OFF, replace the Y and X motor plugs, turn on and test.

-Check plugs and wires going to motors for damage,

-Check drives if they are properly seated in their places,

-Leave the machine ON for 15 minutes, check by hand if the motors are getting warm, they should

After checking that, with the power OFF, replace the Y and X motor plugs, turn on and test.

The following user(s) said Thank You: RacingMat

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

12 Jun 2020 18:14 #171285

by tommylight

Replied by tommylight on topic Retrofitting a CharlyRobot 3 axis CNC

L297 is used with an L298 and that is a 2A part, but it can be used in parallel, one chip using both outputs to power 1 winding and another chip for the second winding. Might be that why the motor is 4A, then again it might not be.....The l297 chip is only the driver chip for a h-bridge and needs those 5000.

But what is used a h-bridge. Can you see the chip? The h-bridge decides the current, means decides the force of the motors. Do they get warm?

I see 4A on the motor and that was difficult to get in chips on those days.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

12 Jun 2020 18:22 #171288

by Mike_Eitel

Replied by Mike_Eitel on topic Retrofitting a CharlyRobot 3 axis CNC

Yes, in theory this is possible, also i never saw that.

Next question is if there is some current reduction on, remember that this exists, also switched by a signal.

If i understand correct this same electronc has already controlled the mill corecttly before. So must be capable to drive the motors....

Next question is if there is some current reduction on, remember that this exists, also switched by a signal.

If i understand correct this same electronc has already controlled the mill corecttly before. So must be capable to drive the motors....

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.851 seconds