Sinumerik controlpanel with Linux CNC

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

03 Mar 2021 20:19 #200936

by andypugh

Typically you cycle between them very rapidly (and over-drive them) and use persistence of vision to make it look like they are all lit.

Replied by andypugh on topic Sinumerik controlpanel with Linux CNC

Charlieplexing sounds interesting - but it has the limitation for one led at a time.

Typically you cycle between them very rapidly (and over-drive them) and use persistence of vision to make it look like they are all lit.

Please Log in or Create an account to join the conversation.

- JimPanski

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 3

08 Mar 2021 18:31 #201459

by JimPanski

Replied by JimPanski on topic Sinumerik controlpanel with Linux CNC

Yes of course. Like on the 7 seg. LED displays..

Do you may have ideas how its possible to use this mpi bus type of panel?

BR

Conny

Do you may have ideas how its possible to use this mpi bus type of panel?

BR

Conny

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4598

08 Mar 2021 19:03 #201467

by andypugh

Replied by andypugh on topic Sinumerik controlpanel with Linux CNC

Google tells me that MPI is RS485. So some sort of protocol analyser (wireshark?) might help figure it out.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

09 Mar 2021 07:13 #201520

by Mike_Eitel

Replied by Mike_Eitel on topic Sinumerik controlpanel with Linux CNC

Mpi has quite some common part with old profibus. Can't remember witch one is a subset of the other. Mpi is newer, think it has more possibilities.

Please Log in or Create an account to join the conversation.

- JimPanski

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 3

09 Mar 2021 17:47 #201572

by JimPanski

Replied by JimPanski on topic Sinumerik controlpanel with Linux CNC

As far a I could read MPI and PB profocols are mostly the same and only few bits should different. On the MPI HW side there is mostly no galvanic isolation as found in PB.

After lot of googling I think this is way over my head. As the programmer of pyprofibus stated this MPI connection will surely not work with his software. Wireshark will also not work. If my understanding is correct a RS485 sniffer tool is needed. Problem is also that I dont know how this would be used :/

So I am afraid I have to go the Mesa way...

After lot of googling I think this is way over my head. As the programmer of pyprofibus stated this MPI connection will surely not work with his software. Wireshark will also not work. If my understanding is correct a RS485 sniffer tool is needed. Problem is also that I dont know how this would be used :/

So I am afraid I have to go the Mesa way...

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

09 Mar 2021 19:38 #201590

by Mike_Eitel

Replied by Mike_Eitel on topic Sinumerik controlpanel with Linux CNC

Don't know how it is today, but in the old (Siemens) days these protokoll have been kept for few eyes only behind locked doors. I remember they are subset of the secret s5 programming interface.

Please Log in or Create an account to join the conversation.

- Mud

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 25

09 Mar 2021 22:17 #201607

by Mud

Replied by Mud on topic Sinumerik controlpanel with Linux CNC

Beckhoff manage both profibus and profinet.

Please Log in or Create an account to join the conversation.

- JimPanski

- Offline

- Senior Member

-

Less

More

- Posts: 60

- Thank you received: 3

11 Mar 2021 07:23 #201778

by JimPanski

Replied by JimPanski on topic Sinumerik controlpanel with Linux CNC

Thats right, but those communication terminals are hard to get working with lcec first of all. Then on this particular machine I am using Mesa Hardware, so it´s also not the straight forward soution. Maybe in this case better to use sserial HW (maybe Mesa or even arduino/stm stuff with a matrix type panel).

Nevertheless it would be very interesting to get those types of panels working with lcnc.

Nevertheless it would be very interesting to get those types of panels working with lcnc.

Please Log in or Create an account to join the conversation.

- beakersBestFriend

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 0

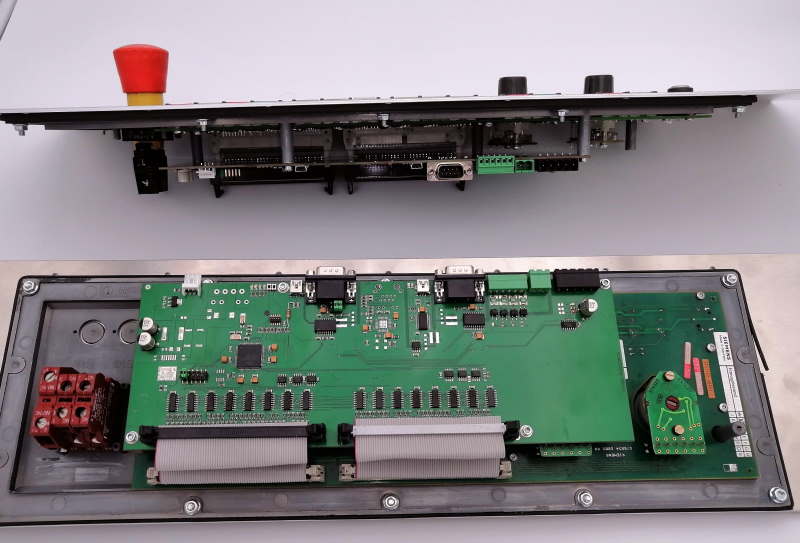

08 Dec 2022 19:23 - 08 Dec 2022 21:04 #258911

by beakersBestFriend

Replied by beakersBestFriend on topic Sinumerik controlpanel with Linux CNC

Hi Onkelmat,

I picked the Sinumerik panel because I like the touch and feel and the bunch of user knobs avail.

And it is quite affordable (at least here in Europe).

Profibus needs a hard realtime capable master and protocol is patented by Siemens. So i picked the passive one, without any electronics. It is simple as it can be. It is not multiplexed. Every key has its own signal, the LEDs also. The multi position knobs for feed and spindle speed are binary coded.

Only the stop keys are kind of special. They have a pullup and a resistor to allow fail state detection with a window discriminator curcuit.

So you only need 80 digital TTL level inputs, three window discriminator curcuit and 48 outputs and you are ready to go.

I decided to make a PCB to interface the Machine Control Panel from its two 64pin ribbon cables with all the key, knob and LED signals to

It is powered by a 24V supply or by a floppy power connector.

Because there was some space left on the PCB I added 4 isolated 12-24V 300mA outputs for a stacked signal light and a TTL quadraturencoder input with index for a jog wheel.

The software side looks like this:

MB2Hal uses a RS485 (USB Dongle) to communicate with the board. I grouped the keys and LEDs into three modus groups each OpMode, Axis and User.

The Signals from MB2Hal are connected to halui.

The quadratur signal is not supported yet.

The Sinumerik keys match the LinuxCNC functions quite good, only the teach in key has no equivalent. (But of course can dedicate it to an other signal.)

In addition to the feed stop Sinumerik has a spindle start/stop that stops the feedrate followed by the spindel.

(at least our old Sinumerik 810 does it this way)

I think that can be emulated by a small sequencer.

What I do miss is the Sinumerik style single stepping, that LinuxCNC handles completly different.

On the other side LinuxCNC can override jog feedrate, what the Sinumerik panel does not support with a knob.

I think about using keys so set jog feedrate 10, 20, 50 , 80 and 100%

I used the component toggle2nist (which actually has a bug) to convert e.g. the coolant on and off switch to a toggle switch.But this is a matter of taste.

For the stacked light i wrote a simple component that combines halui.mode.is-auto, halui.program.is-running and halui.machine.is-on to some (blinking) light states.

I love the result. Build it in a Brother TC211 retrofit. Others will come.

Feels much better to control the machine using dedicated keys and indicators.

( The picture shows two boards mounted on two different MCPs. Some communication interfaces are not mounted. Due to the chip shortage I only populated them when needed.)

attached the modbus.hal and modbus.ini

cheers

Rainer

modbus.hal

modbus.ini

I picked the Sinumerik panel because I like the touch and feel and the bunch of user knobs avail.

And it is quite affordable (at least here in Europe).

Profibus needs a hard realtime capable master and protocol is patented by Siemens. So i picked the passive one, without any electronics. It is simple as it can be. It is not multiplexed. Every key has its own signal, the LEDs also. The multi position knobs for feed and spindle speed are binary coded.

Only the stop keys are kind of special. They have a pullup and a resistor to allow fail state detection with a window discriminator curcuit.

So you only need 80 digital TTL level inputs, three window discriminator curcuit and 48 outputs and you are ready to go.

I decided to make a PCB to interface the Machine Control Panel from its two 64pin ribbon cables with all the key, knob and LED signals to

- Modbus RTU over isolated RS485 and isolated USB

- Modbus over Ethernet (that is isolated by definition)

- CAN/CANOpen over isolated CAN.

It is powered by a 24V supply or by a floppy power connector.

Because there was some space left on the PCB I added 4 isolated 12-24V 300mA outputs for a stacked signal light and a TTL quadraturencoder input with index for a jog wheel.

The software side looks like this:

MB2Hal uses a RS485 (USB Dongle) to communicate with the board. I grouped the keys and LEDs into three modus groups each OpMode, Axis and User.

The Signals from MB2Hal are connected to halui.

The quadratur signal is not supported yet.

The Sinumerik keys match the LinuxCNC functions quite good, only the teach in key has no equivalent. (But of course can dedicate it to an other signal.)

In addition to the feed stop Sinumerik has a spindle start/stop that stops the feedrate followed by the spindel.

(at least our old Sinumerik 810 does it this way)

I think that can be emulated by a small sequencer.

What I do miss is the Sinumerik style single stepping, that LinuxCNC handles completly different.

On the other side LinuxCNC can override jog feedrate, what the Sinumerik panel does not support with a knob.

I think about using keys so set jog feedrate 10, 20, 50 , 80 and 100%

I used the component toggle2nist (which actually has a bug) to convert e.g. the coolant on and off switch to a toggle switch.But this is a matter of taste.

For the stacked light i wrote a simple component that combines halui.mode.is-auto, halui.program.is-running and halui.machine.is-on to some (blinking) light states.

I love the result. Build it in a Brother TC211 retrofit. Others will come.

Feels much better to control the machine using dedicated keys and indicators.

( The picture shows two boards mounted on two different MCPs. Some communication interfaces are not mounted. Due to the chip shortage I only populated them when needed.)

attached the modbus.hal and modbus.ini

cheers

Rainer

modbus.hal

# http://linuxcnc.org/docs/html/man/man1/halui.1.html

loadusr -W mb2hal config=./hallib/modbus.ini

loadrt toggle2nist names=BlockToggle,CoolantToggle,MistToggle,OptionalStopToggle

addf BlockToggle base-thread

addf CoolantToggle base-thread

addf MistToggle base-thread

addf OptionalStopToggle base-thread

loadrt jogbykeys count=1

addf jogbykeys.0 servo-thread

loadrt nothomedwarning names=nothomedwarn

addf nothomedwarn base-thread

net MaschinenstatusRot stackedsignal.0.red => mb2hal.StackedLight.00

net MaschinenstatusGelb stackedsignal.0.yellow => mb2hal.StackedLight.01

net MaschinenstatusGruen stackedsignal.0.green => mb2hal.StackedLight.02

net Abort halui.abort mb2hal.OpmodeKey.00

net AutoModeReq halui.mode.auto mb2hal.OpmodeKey.04

net JogModeReq halui.mode.joint mb2hal.OpmodeKey.01

net MDIModeReq halui.mode.mdi mb2hal.OpmodeKey.03

net PRGStopReq halui.program.stop mb2hal.OpmodeKey.06

net programIsIdle halui.program.is-idle mb2hal.OpmodeLed.06

net PRGStartReq halui.program.run => mb2hal.OpmodeKey.07

net programIsRunning mb2hal.OpmodeLed.07

net FEEDPauseReq halui.program.pause mb2hal.AxisKey.17

net FEEDPauseAct halui.program.is-paused mb2hal.AxisLed.17

net FEEDResumeReq halui.program.resume mb2hal.AxisKey.18

net HomeAllRequest mb2hal.OpmodeKey.09 halui.home-all

setp nothomedwarn.chanelcount 3

net join0homed halui.joint.0.is-homed nothomedwarn.is-homed0

net join1homed halui.joint.1.is-homed nothomedwarn.is-homed1

net join2homed halui.joint.2.is-homed nothomedwarn.is-homed2

net jointshomed nothomedwarn.all-homed mb2hal.OpmodeLed.09

net JogINCVAR mb2hal.OpmodeKey.10 jogbykeys.0.req-jog-var

net JogINC1 mb2hal.OpmodeKey.11 jogbykeys.0.req-jog-inc-1

net JogINC10 mb2hal.OpmodeKey.12 jogbykeys.0.req-jog-inc-10

net JogINC100 mb2hal.OpmodeKey.13 jogbykeys.0.req-jog-inc-100

net JogINC1000 mb2hal.OpmodeKey.14 jogbykeys.0.req-jog-inc-1000

net JogINC10000 mb2hal.OpmodeKey.15 jogbykeys.0.req-jog-inc-10000

net IsJogINCVAR jogbykeys.0.is-jog-var mb2hal.OpmodeLed.10

net IsJogINC1 jogbykeys.0.is-jog-inc-1 mb2hal.OpmodeLed.11

net IsJogINC10 jogbykeys.0.is-jog-inc-10 mb2hal.OpmodeLed.12

net IsJogINC100 jogbykeys.0.is-jog-inc-100 mb2hal.OpmodeLed.13

net IsJogINC1000 jogbykeys.0.is-jog-inc-1000 mb2hal.OpmodeLed.14

net IsJogINC10000 jogbykeys.0.is-jog-inc-10000 mb2hal.OpmodeLed.15

setp jogbykeys.0.jog-set-low-speed 100

setp jogbykeys.0.jog-set-hi-speed 600

net JogVarSpeedValue halui.joint.jog-speed jogbykeys.0.jog-set-var-speed

net JogVarIncValue halui.joint.selected.increment jogbykeys.0.jog-set-inc

net JogKeyInMinus jogbykeys.0.jog-minus mb2hal.AxisKey.12 mb2hal.AxisLed.12

net JogKeyInSPUP jogbykeys.0.jog-speedup mb2hal.AxisKey.13

net JogKeyInPlus jogbykeys.0.jog-plus mb2hal.AxisKey.14 mb2hal.AxisLed.14

net JogMinusInc halui.joint.selected.increment-minus jogbykeys.0.jog-inc-minus

net JogPlusInc halui.joint.selected.increment-plus jogbykeys.0.jog-inc-plus

net JogMinus halui.joint.selected.minus jogbykeys.0.jog-var-minus

net JogPlus halui.joint.selected.plus jogbykeys.0.jog-var-plus

net JointSelXreq halui.joint.0.select mb2hal.AxisKey.00

net JointSelYreq halui.joint.1.select mb2hal.AxisKey.01

net JointSelZreq halui.joint.2.select mb2hal.AxisKey.02

#net JointSelAreq halui.joint.3.select mb2hal.AxisKey.03

net JointSelXAct halui.joint.0.is-selected mb2hal.AxisLed.00

net JointSelYAct halui.joint.1.is-selected mb2hal.AxisLed.01

net JointSelZAct halui.joint.2.is-selected mb2hal.AxisLed.02

#net JointSelAAct halui.joint.3.is-selected mb2hal.AxisLed.03

net modeIsAuto mb2hal.OpmodeLed.04

net JointModeAct halui.mode.is-joint or2_manual_joint_mode.in0

net ManModeAct halui.mode.is-manual or2_manual_joint_mode.in1

net ManOrJogModeAct or2_manual_joint_mode.out mb2hal.OpmodeLed.01

net MDIModeAct halui.mode.is-mdi mb2hal.OpmodeLed.03

# BlockToggle,CoolantToggle

net FloodTogIn mb2hal.UserKey.00 CoolantToggle.in

net FloodOnReq CoolantToggle.on halui.flood.on

net FloodOffReq CoolantToggle.off halui.flood.off

net FloodIsOn halui.flood.is-on CoolantToggle.is-on mb2hal.UserLed.00

net MistTogIn mb2hal.UserKey.01 MistToggle.in

net MistOnReq MistToggle.on halui.mist.on

net MistOffReq MistToggle.off halui.mist.off

net MistIsOn halui.mist.is-on MistToggle.is-on mb2hal.UserLed.01

net OptStopTogIn mb2hal.UserKey.03 OptionalStopToggle.in

net OptStopOnReq OptionalStopToggle.on halui.program.optional-stop.on

net OptStopOffReq OptionalStopToggle.off halui.program.optional-stop.off

net OptStopIsOn halui.program.optional-stop.is-on OptionalStopToggle.is-on mb2hal.UserLed.03

net BLOCKMODETogIn mb2hal.UserKey.04 BlockToggle.in

net BLOCKMODEOnReq BlockToggle.on halui.program.block-delete.on

net BLOCKMODEOffReq BlockToggle.off halui.program.block-delete.off

net BLOCKMODEIsOn halui.program.block-delete.is-on => BlockToggle.is-on => mb2hal.UserLed.04

net SpindleStop halui.spindle.0.stop mb2hal.AxisKey.15

net SpindleStart halui.spindle.0.start mb2hal.AxisKey.16

setp halui.spindle.0.override.direct-value 1

setp halui.spindle.0.override.count-enable 1

setp halui.spindle.0.override.scale 0.01

setp halui.feed-override.direct-value 1

setp halui.feed-override.count-enable 1

setp halui.feed-override.scale 0.01

setp halui.rapid-override.direct-value 1

setp halui.rapid-override.count-enable 1

setp halui.rapid-override.scale 0.01

net SpindleSet mb2hal.Knob.00.int => halui.spindle.0.override.counts

net FeedSet mb2hal.Knob.01.int => halui.feed-override.counts => halui.rapid-override.counts

modbus.ini

[MB2HAL_INIT]

INIT_DEBUG=3

HAL_MODULE_NAME=mb2hal

SLOWDOWN=0.0

TOTAL_TRANSACTIONS=8

[TRANSACTION_00]

LINK_TYPE=serial

SERIAL_PORT=/dev/ttyUSB0

SERIAL_BAUD=115200

SERIAL_BITS=8

SERIAL_PARITY=even

SERIAL_STOP=1

SERIAL_DELAY_MS=1

MB_SLAVE_ID=10

MB_TX_CODE=fnct_02_read_discrete_inputs

FIRST_ELEMENT=0

NELEMENTS=16

HAL_TX_NAME=OpmodeKey

MAX_UPDATE_RATE=8.0

MB_RESPONSE_TIMEOUT_MS=50

MB_BYTE_TIMEOUT_MS=50

DEBUG=0

[TRANSACTION_01]

MB_TX_CODE=fnct_02_read_discrete_inputs

FIRST_ELEMENT=16

NELEMENTS=19

HAL_TX_NAME=AxisKey

DEBUG=0

[TRANSACTION_02]

MB_TX_CODE=fnct_02_read_discrete_inputs

FIRST_ELEMENT=40

NELEMENTS=15

HAL_TX_NAME=UserKey

DEBUG=0

[TRANSACTION_03]

MB_TX_CODE=fnct_15_write_multiple_coils

FIRST_ELEMENT=0

NELEMENTS=16

HAL_TX_NAME=OpmodeLed

DEBUG=0

[TRANSACTION_04]

MB_TX_CODE=fnct_15_write_multiple_coils

FIRST_ELEMENT=16

NELEMENTS=19

HAL_TX_NAME=AxisLed

DEBUG=0

[TRANSACTION_05]

MB_TX_CODE=fnct_15_write_multiple_coils

FIRST_ELEMENT=40

NELEMENTS=15

HAL_TX_NAME=UserLed

DEBUG=0

[TRANSACTION_06]

MB_TX_CODE=fnct_03_read_holding_registers

FIRST_ELEMENT=0

NELEMENTS=2

HAL_TX_NAME=Knob

DEBUG=0

[TRANSACTION_07]

MB_TX_CODE=fnct_15_write_multiple_coils

FIRST_ELEMENT=56

NELEMENTS=4

HAL_TX_NAME=StackedLight

DEBUG=0Attachments:

Last edit: 08 Dec 2022 21:04 by beakersBestFriend.

Please Log in or Create an account to join the conversation.

- AlpineCNCFlo

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

26 Dec 2024 22:07 #317436

by AlpineCNCFlo

Replied by AlpineCNCFlo on topic Sinumerik controlpanel with Linux CNC

Hello @beakersBestFriend, i would realy love to use the same sinumerik panel as you did. Is there any way to get the PCB you made?

Thank you.

Thank you.

Please Log in or Create an account to join the conversation.

Time to create page: 0.122 seconds