New to CNC's, recommendation for 2D wood cutting

- Karks13

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

10 Apr 2022 18:54 - 10 Apr 2022 18:56 #239841

by Karks13

New to CNC's, recommendation for 2D wood cutting was created by Karks13

Hello, I am new to this forum as I am starting a woodworking craft that is taking off and I need help with a CNC recommendation. I cut (Thickness) 3/4" pine designs with a max width of 18”/length 25". I have done some research regarding CNC's but not sure if they are suitable for cutting ¾” pine designs. Can you please look at the 3 machine below and let me know if one is better cutting out my designs, or suggestions? I will mostly use this for CNC 2D Cutting. Any suggestions/recommendations would be great! I would like to keep my budget round 3k. See my attached pictures.

I also need to weigh out software and what would be best for my 2D cuts.

CNC's I am looking at:

Inventables X-Carve

X-Carve | Affordable CNC Machine | 3D Carving Machine | Inventables

Bob’s Evolution 5

Evolution 5 CNC Router Kit – BobsCNC

Mill Right – Mega V Router

Mega V Router - MillRight CNC, LLC

I also need to weigh out software and what would be best for my 2D cuts.

CNC's I am looking at:

Inventables X-Carve

X-Carve | Affordable CNC Machine | 3D Carving Machine | Inventables

Bob’s Evolution 5

Evolution 5 CNC Router Kit – BobsCNC

Mill Right – Mega V Router

Mega V Router - MillRight CNC, LLC

Attachments:

Last edit: 10 Apr 2022 18:56 by Karks13.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21167

- Thank you received: 7231

10 Apr 2022 20:33 #239855

by tommylight

Replied by tommylight on topic New to CNC's, recommendation for 2D wood cutting

I might not be the right person to answer this but the short answer would be neither.

Personally i would not consider any of those as "hobby", plastic wheels, direct driven belt or rack, etc, or in other words, the same thing is buying a 3D printer and mounting a spindle on.

They all probably work, very, very slow, with very soft wood, and wont last.

The best and cheapest (although still out of your range) would be to find an old industrial machine and retrofit it, not sure where you are, but here for 7 to 12K will get you an very nice machine that will make those parts by the hundreds per day.

I did say i am not the right person ...

Personally i would not consider any of those as "hobby", plastic wheels, direct driven belt or rack, etc, or in other words, the same thing is buying a 3D printer and mounting a spindle on.

They all probably work, very, very slow, with very soft wood, and wont last.

The best and cheapest (although still out of your range) would be to find an old industrial machine and retrofit it, not sure where you are, but here for 7 to 12K will get you an very nice machine that will make those parts by the hundreds per day.

I did say i am not the right person ...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

10 Apr 2022 21:27 #239859

by andypugh

Replied by andypugh on topic New to CNC's, recommendation for 2D wood cutting

Firstly, looking at your samples, none of the CNCs shown can make them, as they all have sharp internal corners that can not be made with a rotating tool.

I would avoid anything that uses an off-the-shelf router as a spindle too, they are _very_ noisy.

They all seem to use some form of GRBL (3D printer) controller, so are not compatible with LinuxCNC.

You might actually be better off with a laser, and cutting the parts in several layers then gluing in stacks. (I don't see a $3k laser cutting 3/4 material)

I would avoid anything that uses an off-the-shelf router as a spindle too, they are _very_ noisy.

They all seem to use some form of GRBL (3D printer) controller, so are not compatible with LinuxCNC.

You might actually be better off with a laser, and cutting the parts in several layers then gluing in stacks. (I don't see a $3k laser cutting 3/4 material)

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

10 Apr 2022 22:47 #239867

by BigJohnT

Replied by BigJohnT on topic New to CNC's, recommendation for 2D wood cutting

Welcome to the LinuxCNC forum, I spoke to you on the patriot wood working forum.

I see now you have a lot more items to make, I was thinking about making patterns and using a pattern bit but that thought went out the window.

Do you think you could build your own router table with 8020 material?

JT

I see now you have a lot more items to make, I was thinking about making patterns and using a pattern bit but that thought went out the window.

Do you think you could build your own router table with 8020 material?

JT

Please Log in or Create an account to join the conversation.

- tallerseverino

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 2

11 Apr 2022 08:26 #239901

by tallerseverino

Replied by tallerseverino on topic New to CNC's, recommendation for 2D wood cutting

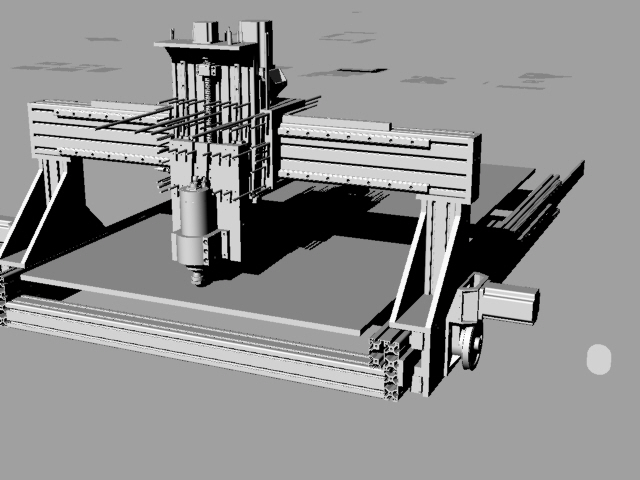

Only an idea. All those routers seem, I don't know, "thin" (english is not my first language), I'm building one with several different aluminum profiles, sheets, etc. But mine is for a router, for your designs I think a laser will do OK.

I also went not long ago to a local laser cnc cutter for a "very accurate" fret slots cutting template (for guitars) and was very displeased with the results, maybe the machine was not well tuned, I don't know, It went directly to the chimney pile.

However you must do trial and error with thick wood, the laser is literally burning the wood.

I attach a work in progress of my design just for fun.

I also went not long ago to a local laser cnc cutter for a "very accurate" fret slots cutting template (for guitars) and was very displeased with the results, maybe the machine was not well tuned, I don't know, It went directly to the chimney pile.

However you must do trial and error with thick wood, the laser is literally burning the wood.

I attach a work in progress of my design just for fun.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4601

11 Apr 2022 09:09 #239907

by andypugh

Replied by andypugh on topic New to CNC's, recommendation for 2D wood cutting

If you need square corners. (And if you want a project, more than you want to make parts

The following user(s) said Thank You: tallerseverino

Please Log in or Create an account to join the conversation.

Time to create page: 0.299 seconds