Novakon Mill Conversion - Getting Started

- Whizbang

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

21 Feb 2024 22:30 - 21 Feb 2024 23:48 #293932

by Whizbang

Novakon Mill Conversion - Getting Started was created by Whizbang

I have a Novakon CNC mill (similar to early Tormach machines). It is from 2009-ish, I bought it used for a great price in 2012 but have not put much time on it. It runs Mach3 and was always glitchy. Shortly after I purchased it, I got the idea I would do a Linux CNC conversion based on some others I saw doing it on CNCZone back in the day using the Tormach GUI (pathpilot), but I never actually got around to doing it. Also – I have little to no experience with Linux anything.

The current CNC Mill

Novakon NM-200 series CNC Mill, circa 2009

-Still functional, but still glitchy with Mach software

-3 Axis

-4th axis capable with rotary table, which I also have.

-Runs Mach 3

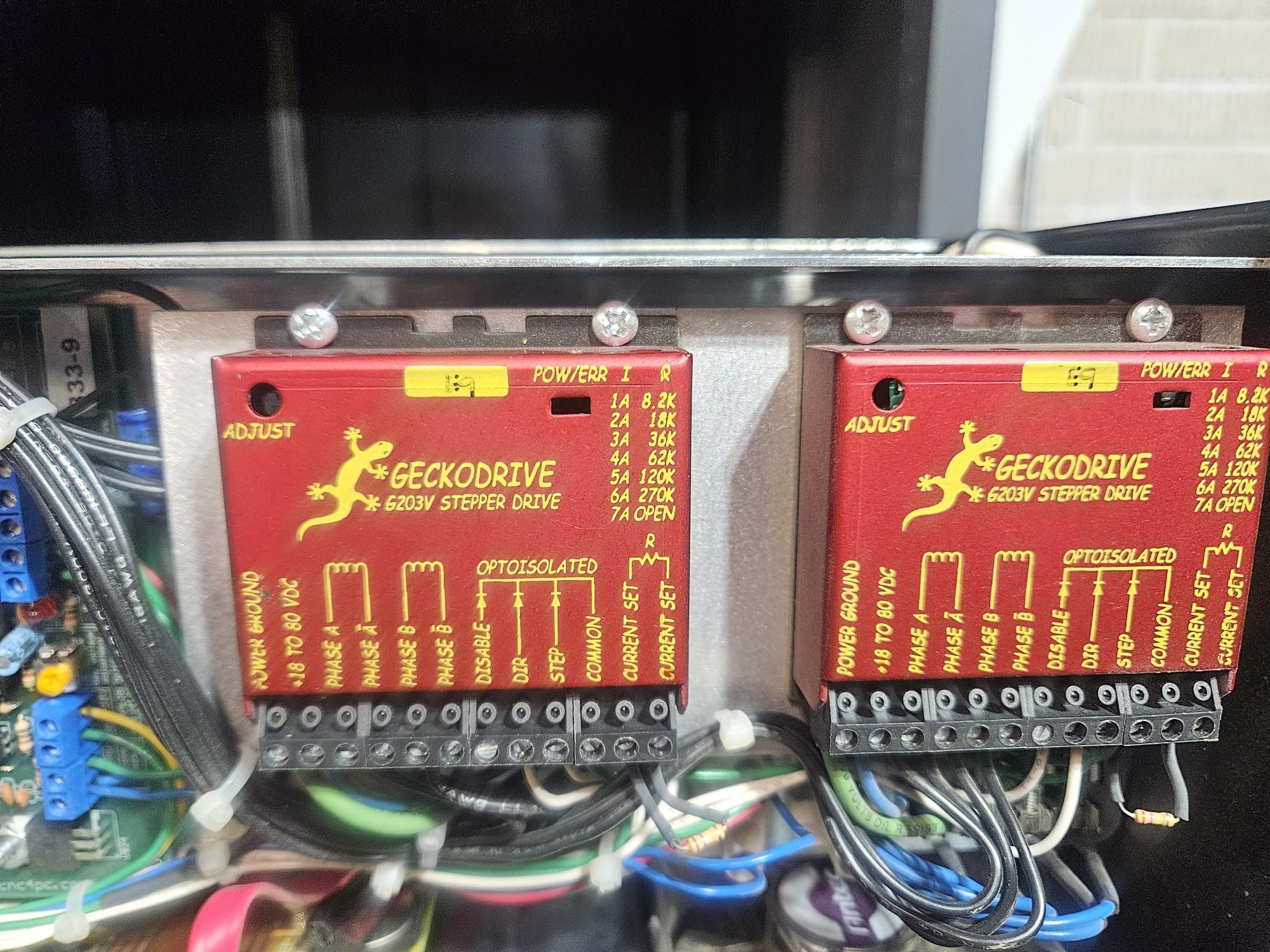

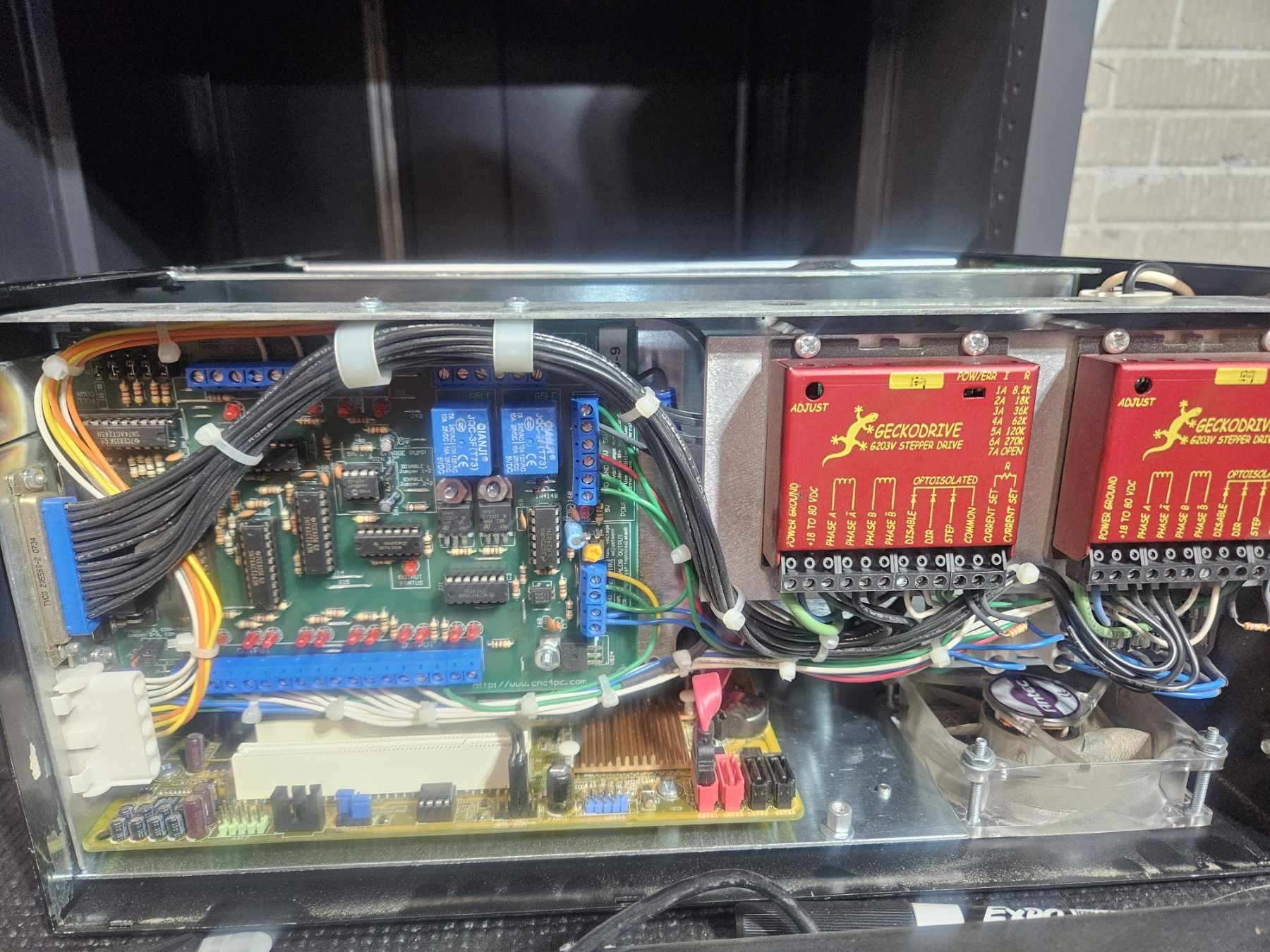

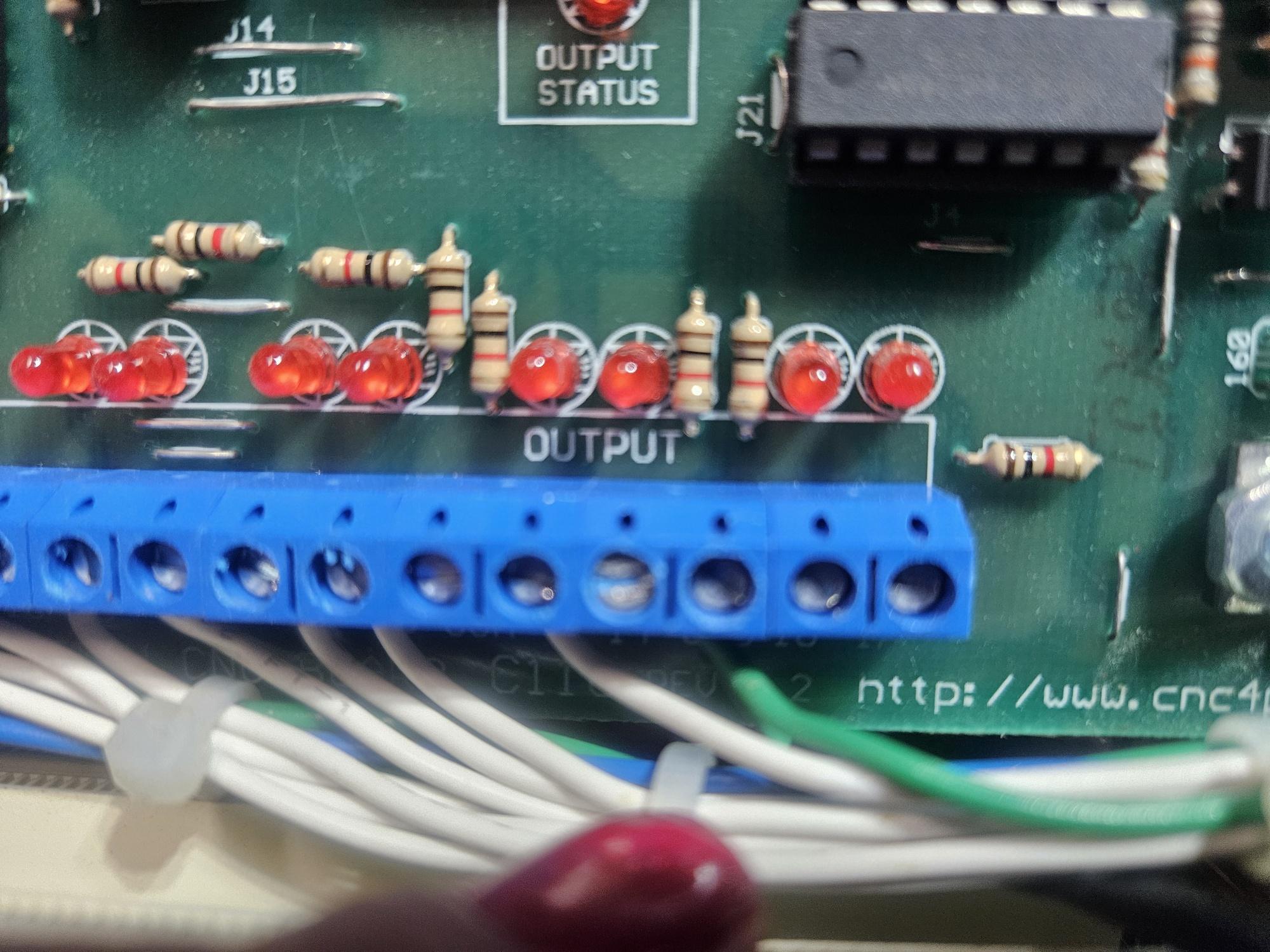

-Has C11 G rev 8.2 breakout board

-G203V Gecko Stepper Drivers

-iMach P2S Pendant (I added this)

Conversion Targets

-Keep costs minimal until concept is proven.

-New (to Novakon Machine) computer to run Linux CNC

-Want to keep original computer unmodified and functional

-The C11 breakout board and gecko drivers are still in the original

computer case and the ideal plan would be to jumper from them to the

new computer/Mesa card

-Run Linux CNC with Mesa card

-Currently have new, never used 6i25 Mesa planning to use

-After reading about others who did conversion Tormach GUI

(pathpilot) with mesa cards I bought one, then didn’t dive into the

project, so it’s a little older

-Is there a better/simpler solution that would be smarter to invest in now?

I want to keep costs down, but if there is another simpler solution to still hit

my targets and potentially save A LOT of time then I am willing to consider

the investment.

-Maintain functionality with iMach P2S Pendant

-Assuming this will be a relatively simply config option.

-Bonus – 4th axis capability

Linux CNC

I originally installed Debian 12 Linux CNC.iso from linux website and at first struggled with high latency issues

-Original ISO was buggy and caused issues

- A helpful member in IRC traced it back to raspberry pi.

-Got on IRC and got great feedback, informing me that because I am using

Mesa card latency does not matter because the card compensates for it.

-Installing new ISO was recommended

-Installed Debian Mate from USB

-Installed Linux CNC

-Tried to import MACH.xml

-Would not import using step.config

-None of the ports & pins came through

-I do have record of all the ports and pins and other MACH config settings

-None of the commands I was directed to use to fix the issues could be “found”

-Got into IRC channel in hopes of finding solutions

-Was told about Github convertor

-Its Python and I can’t get it to work.

Thanks in advance for any feedback. I appreciate any and all suggestions or guidance.

The current CNC Mill

Novakon NM-200 series CNC Mill, circa 2009

-Still functional, but still glitchy with Mach software

-3 Axis

-4th axis capable with rotary table, which I also have.

-Runs Mach 3

-Has C11 G rev 8.2 breakout board

-G203V Gecko Stepper Drivers

-iMach P2S Pendant (I added this)

Conversion Targets

-Keep costs minimal until concept is proven.

-New (to Novakon Machine) computer to run Linux CNC

-Want to keep original computer unmodified and functional

-The C11 breakout board and gecko drivers are still in the original

computer case and the ideal plan would be to jumper from them to the

new computer/Mesa card

-Run Linux CNC with Mesa card

-Currently have new, never used 6i25 Mesa planning to use

-After reading about others who did conversion Tormach GUI

(pathpilot) with mesa cards I bought one, then didn’t dive into the

project, so it’s a little older

-Is there a better/simpler solution that would be smarter to invest in now?

I want to keep costs down, but if there is another simpler solution to still hit

my targets and potentially save A LOT of time then I am willing to consider

the investment.

-Maintain functionality with iMach P2S Pendant

-Assuming this will be a relatively simply config option.

-Bonus – 4th axis capability

Linux CNC

I originally installed Debian 12 Linux CNC.iso from linux website and at first struggled with high latency issues

-Original ISO was buggy and caused issues

- A helpful member in IRC traced it back to raspberry pi.

-Got on IRC and got great feedback, informing me that because I am using

Mesa card latency does not matter because the card compensates for it.

-Installing new ISO was recommended

-Installed Debian Mate from USB

-Installed Linux CNC

-Tried to import MACH.xml

-Would not import using step.config

-None of the ports & pins came through

-I do have record of all the ports and pins and other MACH config settings

-None of the commands I was directed to use to fix the issues could be “found”

-Got into IRC channel in hopes of finding solutions

-Was told about Github convertor

-Its Python and I can’t get it to work.

Thanks in advance for any feedback. I appreciate any and all suggestions or guidance.

Attachments:

Last edit: 21 Feb 2024 23:48 by Whizbang.

Please Log in or Create an account to join the conversation.

- Whizbang

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

21 Feb 2024 23:56 #293939

by Whizbang

Replied by Whizbang on topic Novakon Mill Conversion - Getting Started

Update: I tried to use a python script i was linked to in the #linuxcnc chat by another user. i was able to cd to the proper directory but keep getting running into an issue of it getting hung up on line 32 of the script where it identifies the .xml you want to convert. I have attached the .xml here but may have to attach the .py separately for maximum file size reasons.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

22 Feb 2024 04:36 #293955

by spumco

Replied by spumco on topic Novakon Mill Conversion - Getting Started

Don't worry about a Mach3 conversion script. It's easy enough to use one of the LCNC wizards (PNCconf or Mesact) to set up a pretty simple 4-axis Mesa config.

Regarding the 6i25 vs an ethernet Mesa (like 7i96S), that's up to you. The biggest consideration is the footprint. A USFF mini-PC and an eth-Mesa will likely take up less space (or be easier to mount/stash) than a PC with PCI slots, plus a daughter board to break out the 6i25's pins.

You can pick up a nice, used USFF mini-PC off ebay for $40-$75 plug a 7i96S in to it, and possibly be done at that point (depends on how much IO you need). You could gut the existing enclosure, keep the drives and power supply, and fit the PC & 7i96s inside the box - no external components beyond a monitor, keyboard, and pendant.

On the other hand, if you have a PC now that will accept the 6i25, it'll work just fine... but you'll need a breakout board of some sort - and the typical 7i76 is out of stock. (but a 7i78 + 7i84 are in stock).

Either way, stay away from laptop-based PC's (mini or otherwise). They tend to have power-saving features that can interfere with both LCNC latency as well as ethernet latency. Same thing for cutting edge single-board computers... some work, some dont, you don't need a headache or have to trouble-shoot the hardware to get it working with LCNC.

An HP Elitedesk 800 G2 or G3 mini are cheap on ebay, and a number of people have reported good results with those. HOWEVER... if you do buy one, stay away from the 35w version and make sure you get a 65w model. The 35w ones use a laptop processor and have built-in crap that may cause latency spikes.

Your iMach pendant can be firmware-flashed to LCNC, so you won't need a bunch of IO for those functions. Keep in mind that the iMach is still USB with LCNC, so the pendant latency glitches you may experience now with Mach3 will still be present in LCNC if you use the iMach. They aren't broken... they just aren't 'real-time' even when working as designed. Mine is sitting in a box somewhere for just that reason.

So... figure out the PC based on which Mesa interface you want. Then install LCNC and test-drive the various user interfaces, but don't worry about a 'conversion script'.

Once you have a PC with LCNC running we can help you plan out the rest of the conversion.

Regarding the 6i25 vs an ethernet Mesa (like 7i96S), that's up to you. The biggest consideration is the footprint. A USFF mini-PC and an eth-Mesa will likely take up less space (or be easier to mount/stash) than a PC with PCI slots, plus a daughter board to break out the 6i25's pins.

You can pick up a nice, used USFF mini-PC off ebay for $40-$75 plug a 7i96S in to it, and possibly be done at that point (depends on how much IO you need). You could gut the existing enclosure, keep the drives and power supply, and fit the PC & 7i96s inside the box - no external components beyond a monitor, keyboard, and pendant.

On the other hand, if you have a PC now that will accept the 6i25, it'll work just fine... but you'll need a breakout board of some sort - and the typical 7i76 is out of stock. (but a 7i78 + 7i84 are in stock).

Either way, stay away from laptop-based PC's (mini or otherwise). They tend to have power-saving features that can interfere with both LCNC latency as well as ethernet latency. Same thing for cutting edge single-board computers... some work, some dont, you don't need a headache or have to trouble-shoot the hardware to get it working with LCNC.

An HP Elitedesk 800 G2 or G3 mini are cheap on ebay, and a number of people have reported good results with those. HOWEVER... if you do buy one, stay away from the 35w version and make sure you get a 65w model. The 35w ones use a laptop processor and have built-in crap that may cause latency spikes.

Your iMach pendant can be firmware-flashed to LCNC, so you won't need a bunch of IO for those functions. Keep in mind that the iMach is still USB with LCNC, so the pendant latency glitches you may experience now with Mach3 will still be present in LCNC if you use the iMach. They aren't broken... they just aren't 'real-time' even when working as designed. Mine is sitting in a box somewhere for just that reason.

So... figure out the PC based on which Mesa interface you want. Then install LCNC and test-drive the various user interfaces, but don't worry about a 'conversion script'.

Once you have a PC with LCNC running we can help you plan out the rest of the conversion.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11660

- Thank you received: 3928

22 Feb 2024 06:10 #293956

by rodw

Replied by rodw on topic Novakon Mill Conversion - Getting Started

I have never used Mach but I did help a guy get rolling on a Mesa 7i96

I set up a very rough rolling 4 motor gantry config in pncconf then edited by hand from the Mach data.. Mach's stepsPer is the same as Lcnc's step_scale. We got this machine working in about 3 hours one afternoon that included wiring in the limit switches which Mach did not use.

I set up a very rough rolling 4 motor gantry config in pncconf then edited by hand from the Mach data.. Mach's stepsPer is the same as Lcnc's step_scale. We got this machine working in about 3 hours one afternoon that included wiring in the limit switches which Mach did not use.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Whizbang

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

22 Feb 2024 12:50 - 22 Feb 2024 12:54 #293978

by Whizbang

Replied by Whizbang on topic Novakon Mill Conversion - Getting Started

Thanks for the information spumco.

Couple additional questions:

-With the 6i25 I have is it worth trying to connect to my existing c11 bob that is in the current setup machine. It appears it's from cnc4pc. Can I avoid buying the additional card or cards from mesa.

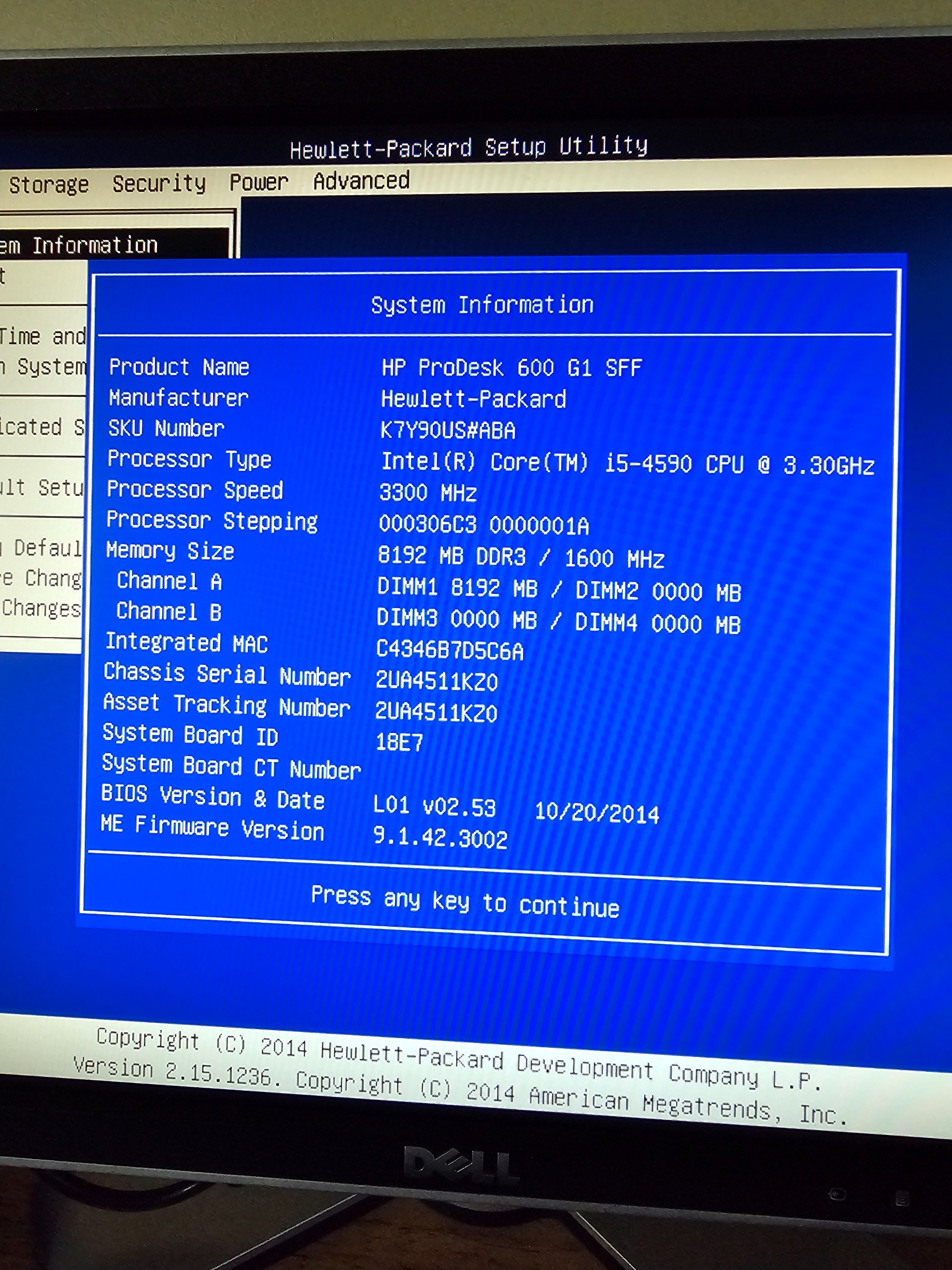

- I snagged a deal on a hp pro desk 600 is this OK? Specs in attached photos.

- Lastly I'd prefer to not gut my old setup that runs mach3 if possible cause it's still functional and I can fall back on it if I can't figure out this linx stuff. I was hoping to just link into that c11 board and geckos as it is currently configured. If not I would prefer to buy modest setup and setup another controller box. For this I am guessing I would need 7i96s, new drivers for each axis and new powersupply(s). At that point should I just upgrade to hybrid steppers?

Couple additional questions:

-With the 6i25 I have is it worth trying to connect to my existing c11 bob that is in the current setup machine. It appears it's from cnc4pc. Can I avoid buying the additional card or cards from mesa.

- I snagged a deal on a hp pro desk 600 is this OK? Specs in attached photos.

- Lastly I'd prefer to not gut my old setup that runs mach3 if possible cause it's still functional and I can fall back on it if I can't figure out this linx stuff. I was hoping to just link into that c11 board and geckos as it is currently configured. If not I would prefer to buy modest setup and setup another controller box. For this I am guessing I would need 7i96s, new drivers for each axis and new powersupply(s). At that point should I just upgrade to hybrid steppers?

Attachments:

Last edit: 22 Feb 2024 12:54 by Whizbang.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

22 Feb 2024 17:13 #294000

by spumco

Replied by spumco on topic Novakon Mill Conversion - Getting Started

My guess is the the HP will be just fine for LCNC.

While the 6i25 and C11 both have DB25 connectors, I don't know what the C11 DB25 pins are.

The C11g user manual isn't clear which DB25 pin is connected to which terminal. I _think_ it's duplicating a standard parallel port, but I'm not sure... nor am I sure if you'd need to cobble up a custom DB25 cable that makes the desired 6i25=>C11 connections.

If you really want to plug the C11 in to the 6i25, you might get a better response if you start a new thread under 'Driver Boards' with that specific question. That would certainly make it easy to revert back if such is the case.

If not, you're back to the decision of using the 6i25 with a daughterboard(s), or buying an ethernet Mesa card and maybe a second board for more IO.

While the 6i25 and C11 both have DB25 connectors, I don't know what the C11 DB25 pins are.

The C11g user manual isn't clear which DB25 pin is connected to which terminal. I _think_ it's duplicating a standard parallel port, but I'm not sure... nor am I sure if you'd need to cobble up a custom DB25 cable that makes the desired 6i25=>C11 connections.

If you really want to plug the C11 in to the 6i25, you might get a better response if you start a new thread under 'Driver Boards' with that specific question. That would certainly make it easy to revert back if such is the case.

If not, you're back to the decision of using the 6i25 with a daughterboard(s), or buying an ethernet Mesa card and maybe a second board for more IO.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

22 Feb 2024 17:17 #294001

by spumco

Replied by spumco on topic Novakon Mill Conversion - Getting Started

Another thing I missed in your last post: you don't need new drivers. The 6i25 w/daughter board or 7i96s will connect to the Geckos and control them just fine.

How many IO points do you need, and what type? Make a shopping list and we'll see if a 7i96S can handle everything by itself.

How many IO points do you need, and what type? Make a shopping list and we'll see if a 7i96S can handle everything by itself.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5156

22 Feb 2024 18:22 #294008

by PCW

Replied by PCW on topic Novakon Mill Conversion - Getting Started

There is firmware for a 5i25/6i25 and the C11 (and C11G)

so its a direct connection.

so its a direct connection.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1973

- Thank you received: 807

22 Feb 2024 19:48 #294013

by spumco

Thanks PCW. Is that for 6i25's P2 or P3?

Replied by spumco on topic Novakon Mill Conversion - Getting Started

There is firmware for a 5i25/6i25 and the C11 (and C11G)

so its a direct connection.

Thanks PCW. Is that for 6i25's P2 or P3?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5156

22 Feb 2024 20:53 #294016

by PCW

Replied by PCW on topic Novakon Mill Conversion - Getting Started

First C11 on P3 (DB25) second C11 (if used) on P2 (HDR26)

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

Time to create page: 0.246 seconds