CNC machine B64-S-ATC

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

19 May 2024 05:06 #300953

by Mr. Mass

CNC machine B64-S-ATC was created by Mr. Mass

I've started a new project, this time a CNC machine. I did a little design review video. I want to try to make a machine with auto tool change. Setting up the ATC will probably be the hardest part of this project for me. So get ready, I will ask nub questions)

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

21 May 2024 00:20 #301044

by andypugh

Replied by andypugh on topic CNC machine B64-S-ATC

If you think that the control cabinet will be too small, them you are bound to be right. (In fact, it's probably too small even if you don't think it is)

Maybe if you take out the diagonal braces that interfere with a bigger cabinet you can use the control cabinet itself to brace that face?

Maybe if you take out the diagonal braces that interfere with a bigger cabinet you can use the control cabinet itself to brace that face?

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

06 Jun 2024 11:35 #302461

by Mr. Mass

Replied by Mr. Mass on topic CNC machine B64-S-ATC

Hmm, that's a fresh thought. I hadn't thought of using the electronics box as one big stiffener. Of course, it would be difficult to make the welded base itself quite accurately so that the box would fit with minimal gaps. But I'll definitely give it some thought, thanks.

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

19 Aug 2024 10:56 - 19 Aug 2024 10:58 #308128

by Mr. Mass

Replied by Mr. Mass on topic CNC machine B64-S-ATC

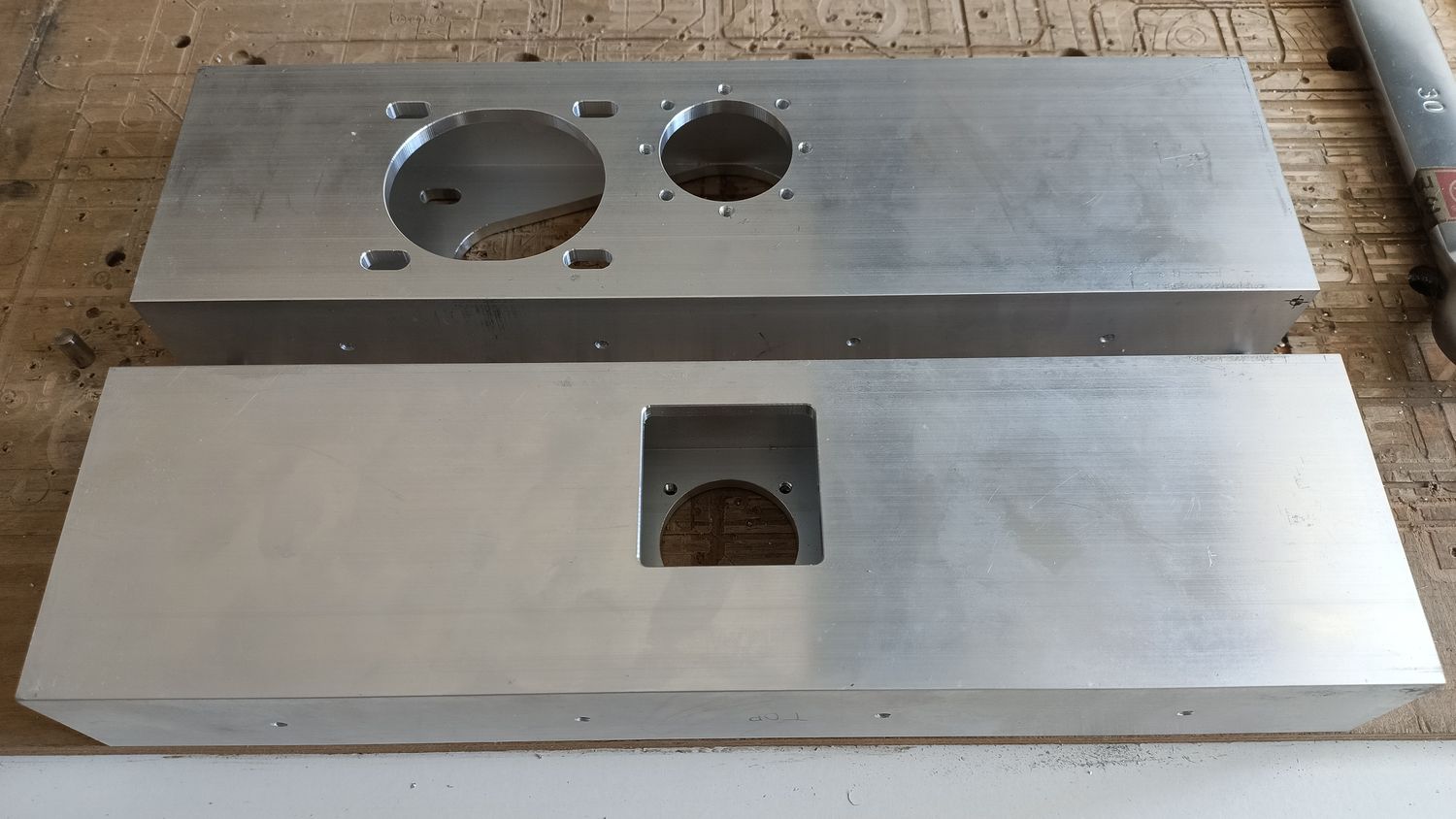

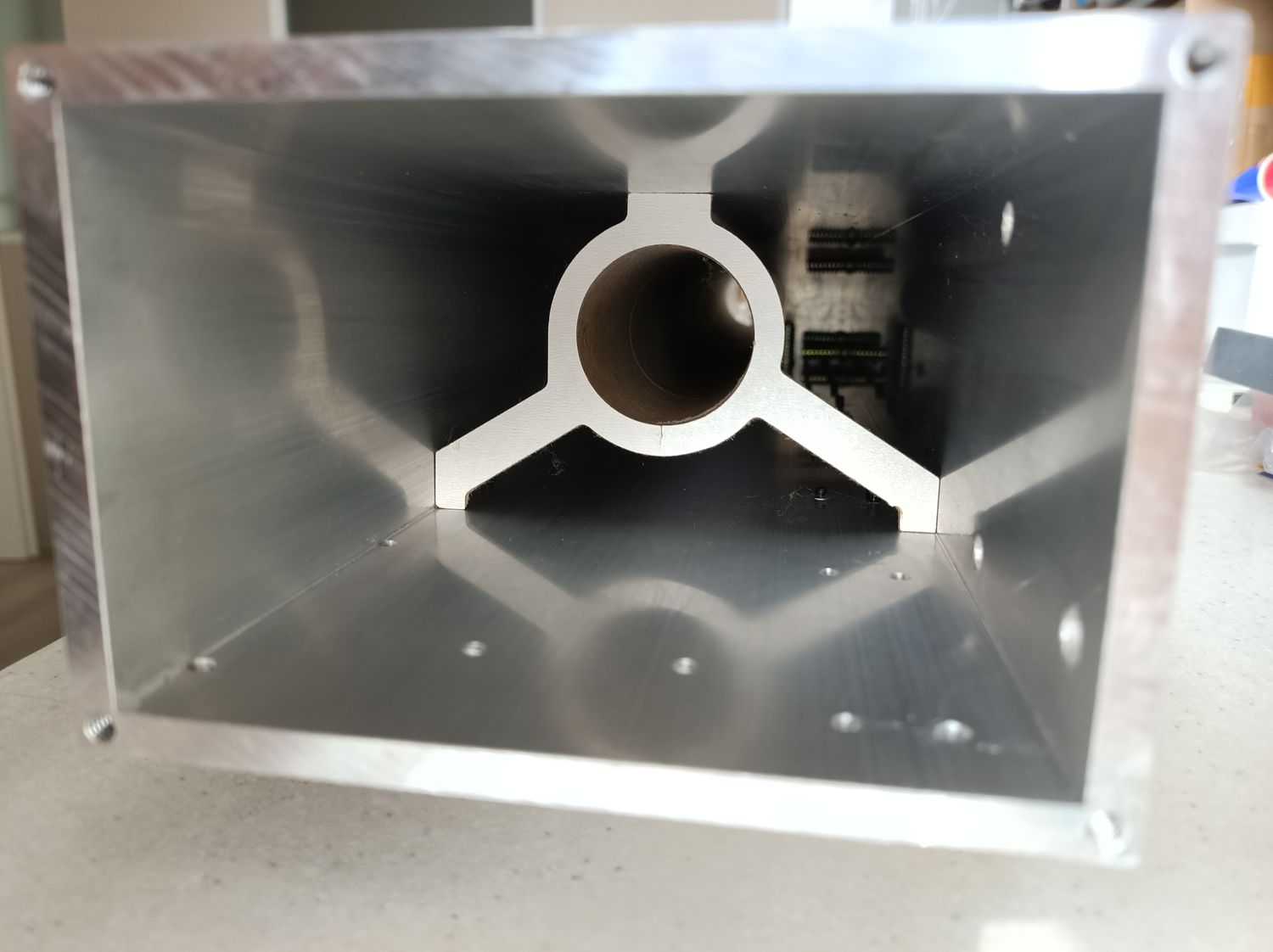

Attachments:

Last edit: 19 Aug 2024 10:58 by Mr. Mass.

The following user(s) said Thank You: tommylight, besriworld

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

22 Oct 2024 06:15 - 22 Oct 2024 06:18 #312826

by Mr. Mass

Replied by Mr. Mass on topic CNC machine B64-S-ATC

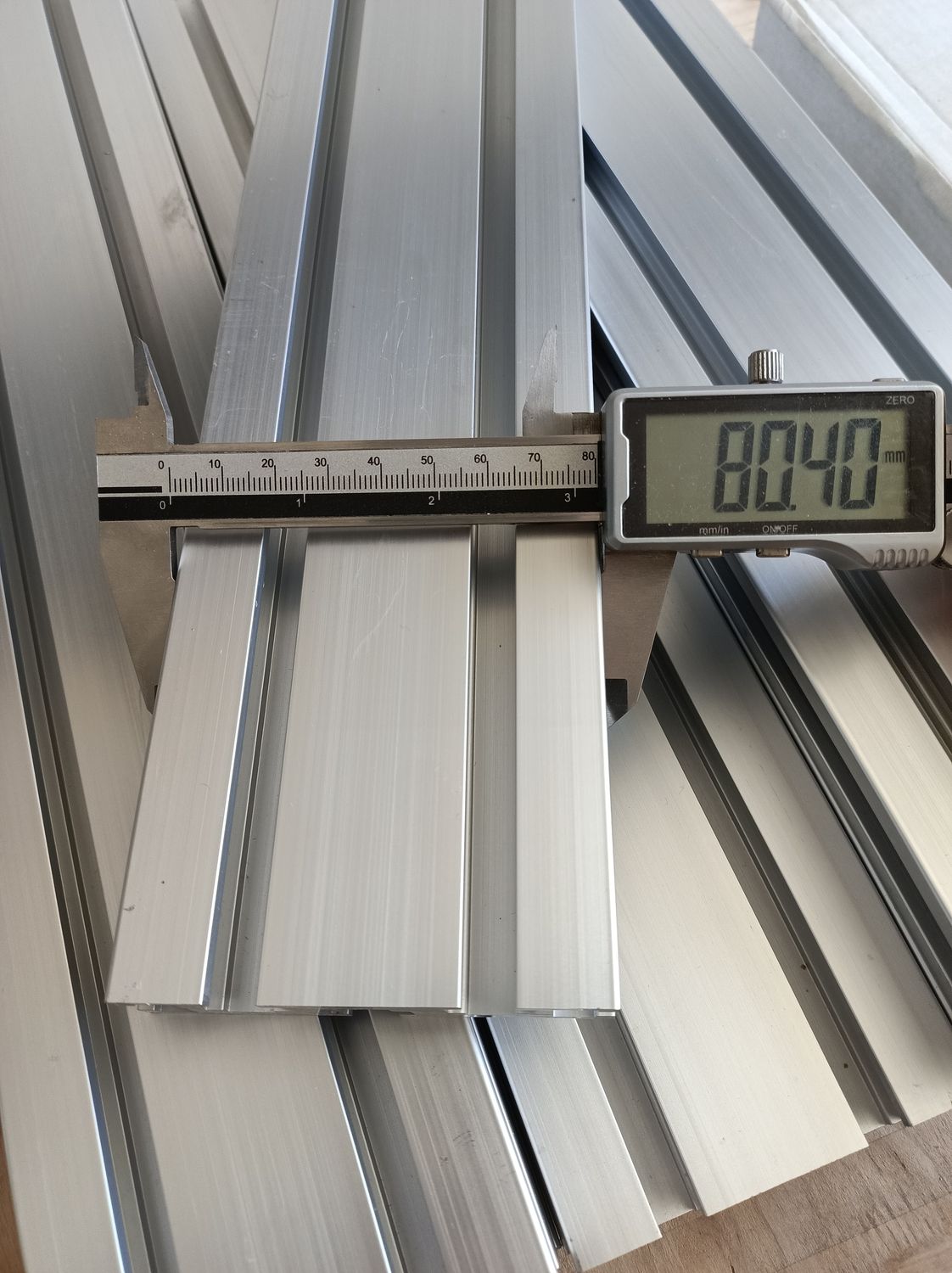

Some progress here. I continued making the base and found out that the profiles with t-slot are slightly larger. Since they fit one to the other and there are 10 of them, this error will not allow to assemble everything.

So I had to fix it.

Finished all the profiles and parts for the base.

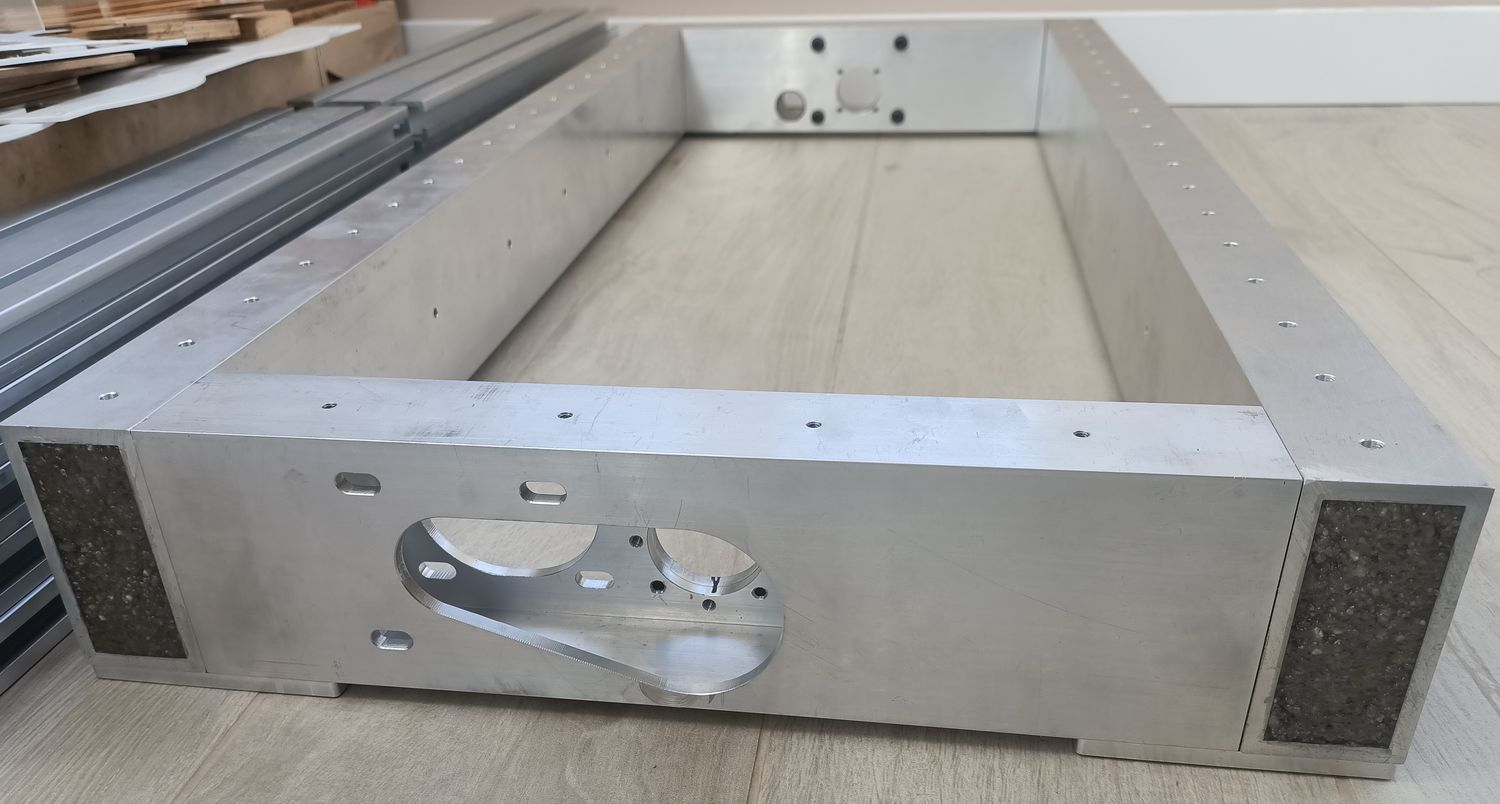

Now for the fun part. I've been wanting to try using profile filler for a long time and now I've finally made up my mind. I decided to use epoxy granite, it's easy to make and adds quite a bit of stiffness and most importantly, dampens vibrations very well. I made some samples to check the composition of the mix, everything went well with the calculation.

Then I decided that it would be easy to put the tabs in the profile with an internal cross-section of 70*30mm. But it turned out to be very difficult, don't do it like that.

Laying the mixture inside and tamping it down through all those tabs wasn't easy either. Now while the epoxy granite is gaining its strength I can do the other parts.

So I had to fix it.

Finished all the profiles and parts for the base.

Now for the fun part. I've been wanting to try using profile filler for a long time and now I've finally made up my mind. I decided to use epoxy granite, it's easy to make and adds quite a bit of stiffness and most importantly, dampens vibrations very well. I made some samples to check the composition of the mix, everything went well with the calculation.

Then I decided that it would be easy to put the tabs in the profile with an internal cross-section of 70*30mm. But it turned out to be very difficult, don't do it like that.

Laying the mixture inside and tamping it down through all those tabs wasn't easy either. Now while the epoxy granite is gaining its strength I can do the other parts.

Attachments:

Last edit: 22 Oct 2024 06:18 by Mr. Mass.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21339

- Thank you received: 7282

22 Oct 2024 12:57 #312847

by tommylight

Replied by tommylight on topic CNC machine B64-S-ATC

Looking good

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

22 Nov 2024 11:42 #315027

by Mr. Mass

Replied by Mr. Mass on topic CNC machine B64-S-ATC

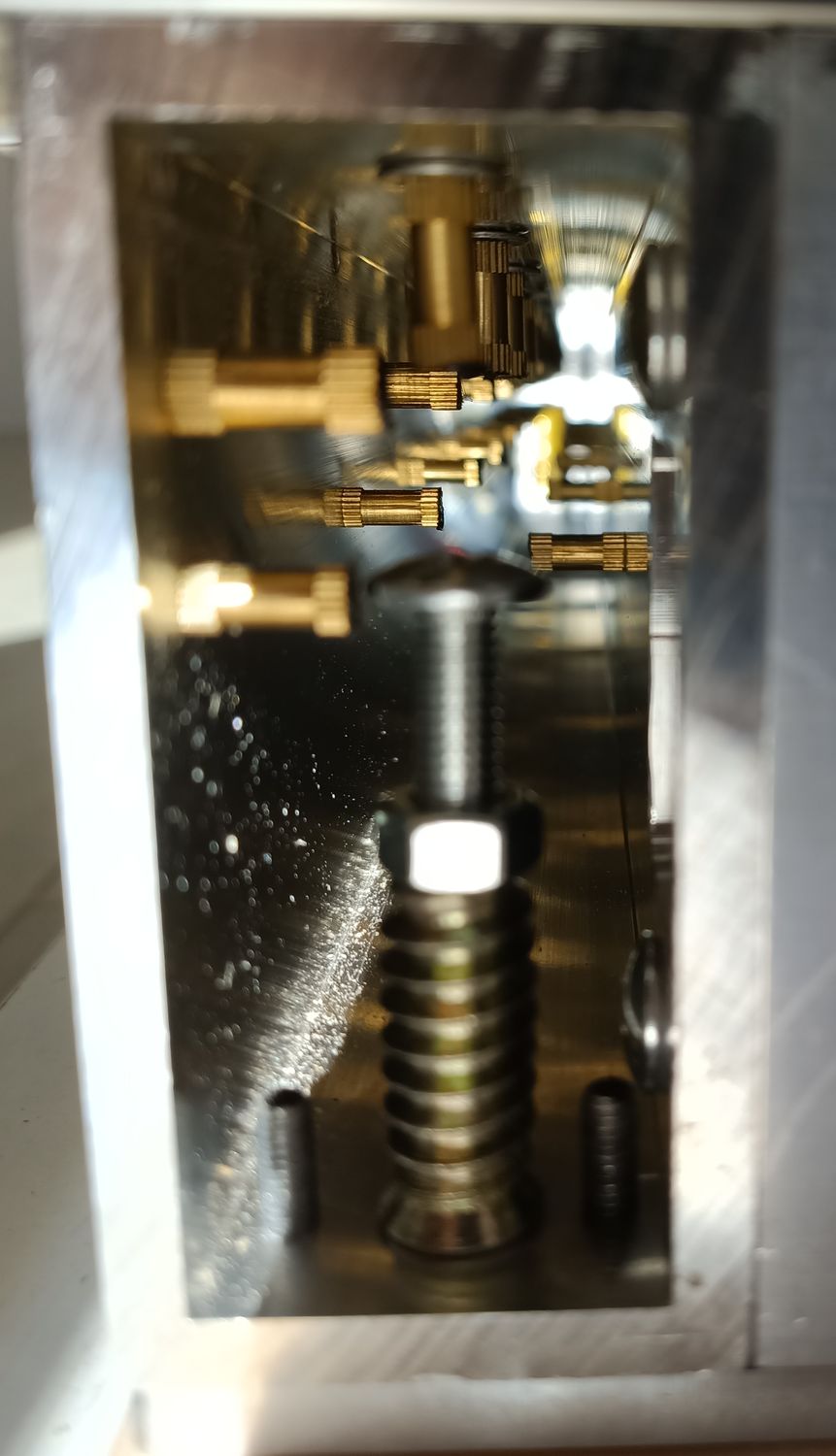

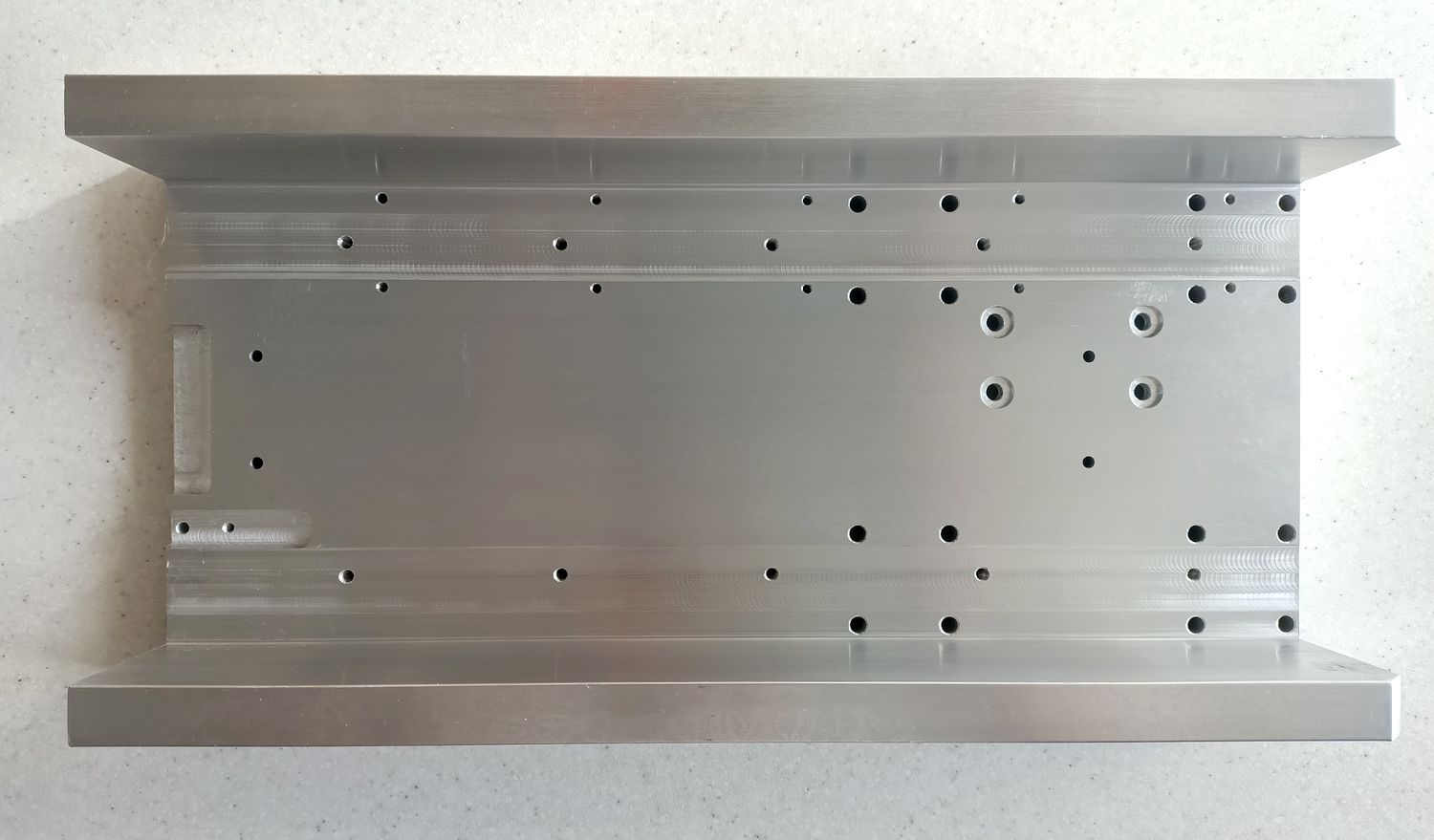

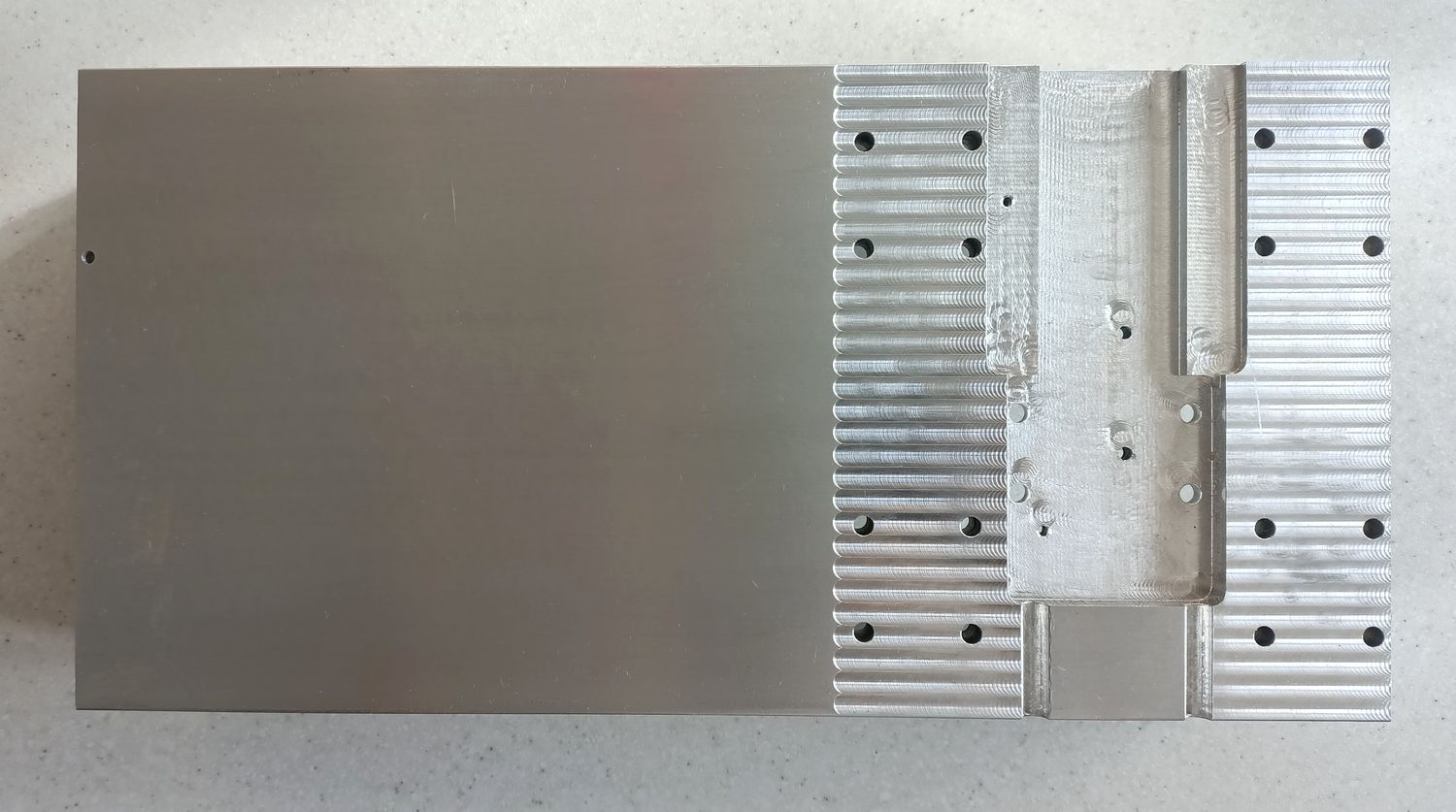

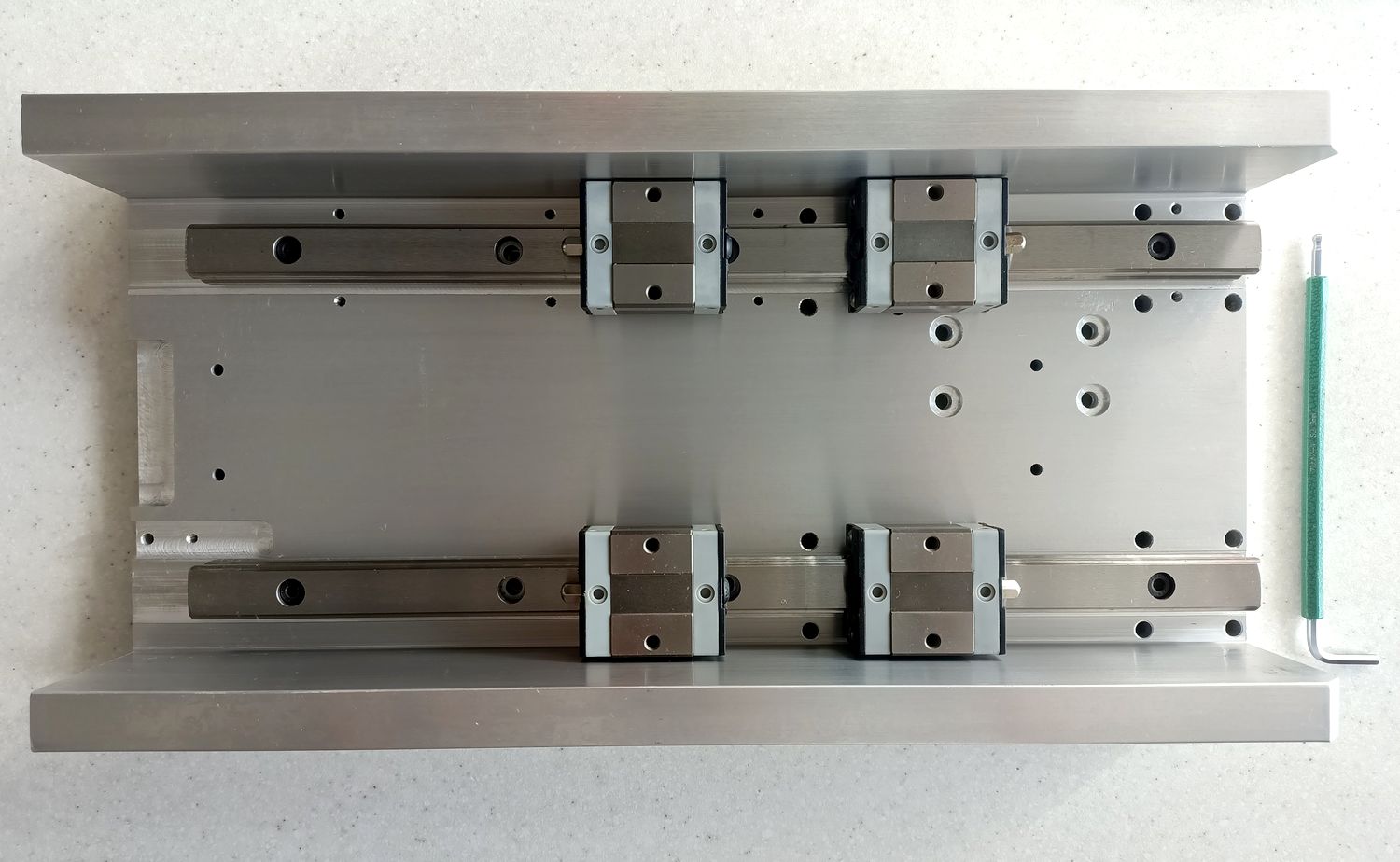

Now it's time for the portal beam. I milled seats for the rails (the profile itself was bent by about 0.2mm) and drilled all the holes.

I also decided to fill this profile with polymer granite.

Remembering not very successful variant with tabs in the base this time I decided to try a different way. I cut all the threads directly into the profile and then screwed the screws in. Then I poured the polymer granite and after a few hours, when the mixture began to harden, I carefully unscrewed it all. It was much quicker and easier than with tabs.

There will be a motor on one side, so the fill will not be full volume. I also decided to put the wires from the motor through the profile, so I used a cardboard tube for this. On one side it is held by an aluminum plate. When pouring the polymer granite to have support inside, I made a piece of thin MDF.

I also decided to fill this profile with polymer granite.

Remembering not very successful variant with tabs in the base this time I decided to try a different way. I cut all the threads directly into the profile and then screwed the screws in. Then I poured the polymer granite and after a few hours, when the mixture began to harden, I carefully unscrewed it all. It was much quicker and easier than with tabs.

There will be a motor on one side, so the fill will not be full volume. I also decided to put the wires from the motor through the profile, so I used a cardboard tube for this. On one side it is held by an aluminum plate. When pouring the polymer granite to have support inside, I made a piece of thin MDF.

Attachments:

Please Log in or Create an account to join the conversation.

- Mr. Mass

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 45

20 Dec 2024 07:05 #317029

by Mr. Mass

Replied by Mr. Mass on topic CNC machine B64-S-ATC

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.422 seconds