- Hardware & Machines

- CNC Machines

- Servo tuning for an axis that behaves different in one direction versus the othe

Servo tuning for an axis that behaves different in one direction versus the othe

- kb0thn

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

13 Dec 2024 14:12 #316579

by kb0thn

Servo tuning for an axis that behaves different in one direction versus the othe was created by kb0thn

Hi Guys,

I've re-controlled a Homag CNC router to use Linux CNC with MESA controls. It's was a complicated project, but for the last year it's been working well enough for me to be running commercial parts on it.

All of the motion hardware (mechanical / servos / drives) is what the Germans put in the machine 20 years ago. It uses Bosch ECODRIVE servo drives and has ball screws on x-axis and z-axis and a rack and pinion on y-axis.

The x-axis and z-axis work fine. The y-axis is "jumpy" when moving in the y+ direction. And smooth in the y- direction. I can clearly the position errors ramp up in halscope and then it appears to catch up and get back into position. With my hand on the gantry I can feel it jump / jump / jump going in the y+ and you can clearly see it in the tool marks. If I rapid at anywhere near full speed in y+ it will get wildly out of control and start slamming back and fourth and attempting to rip the whole 8,000 lb machine apart. But it rapids super smoothly in y-.

Mechanically the axis seems fine and there isn't anything like a dust collection hose that drags differently when going in a different direction. I've manually excessively lubricated the rack and pinion and it perhaps helps a little bit, but certainly doesn't solve the problem.

I recall probably spending about 10 hours attempting to tune the PID parameters and was never able to get it moving smoothly in y+. But I'm at the point now where I need to get it cutting smoother. So I am looking for any suggestions of things to try?

Thank you!

I've re-controlled a Homag CNC router to use Linux CNC with MESA controls. It's was a complicated project, but for the last year it's been working well enough for me to be running commercial parts on it.

All of the motion hardware (mechanical / servos / drives) is what the Germans put in the machine 20 years ago. It uses Bosch ECODRIVE servo drives and has ball screws on x-axis and z-axis and a rack and pinion on y-axis.

The x-axis and z-axis work fine. The y-axis is "jumpy" when moving in the y+ direction. And smooth in the y- direction. I can clearly the position errors ramp up in halscope and then it appears to catch up and get back into position. With my hand on the gantry I can feel it jump / jump / jump going in the y+ and you can clearly see it in the tool marks. If I rapid at anywhere near full speed in y+ it will get wildly out of control and start slamming back and fourth and attempting to rip the whole 8,000 lb machine apart. But it rapids super smoothly in y-.

Mechanically the axis seems fine and there isn't anything like a dust collection hose that drags differently when going in a different direction. I've manually excessively lubricated the rack and pinion and it perhaps helps a little bit, but certainly doesn't solve the problem.

I recall probably spending about 10 hours attempting to tune the PID parameters and was never able to get it moving smoothly in y+. But I'm at the point now where I need to get it cutting smoother. So I am looking for any suggestions of things to try?

Thank you!

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17723

- Thank you received: 5186

13 Dec 2024 15:31 #316581

by PCW

Replied by PCW on topic Servo tuning for an axis that behaves different in one direction versus the othe

Do the motors have tachometers? A dirty tachometer commutator might explain the behaviour

Please Log in or Create an account to join the conversation.

- kb0thn

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

13 Dec 2024 16:04 #316584

by kb0thn

Replied by kb0thn on topic Servo tuning for an axis that behaves different in one direction versus the othe

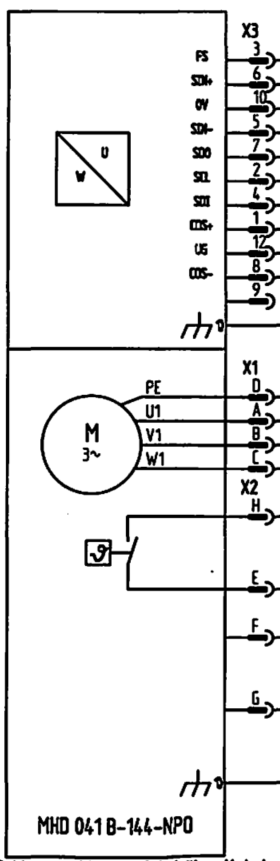

I don't think so. It appears to just be a three phase brushless motor with integral encoder. Here is how the schematic shows the y-axis motor:

Looking up the part number, it is described as:

MHD041B-144-NP0-UN by Rexroth, Indramat, Bosch is a Synchronous Motor in the MHD Series. The MHD041B-144-NP0-UN features a Motor Frame Size of 82mm Flange Size, 50mm Centering Diameter and a Motor Frame Length of 2.7 Nm. This Motor has a Motor Encoder of Digital servo feedback and comes with a Output Shaft of Shaft with keyway according to DIN 6885-1 (with shaft sealing ring).

Thanks

Looking up the part number, it is described as:

MHD041B-144-NP0-UN by Rexroth, Indramat, Bosch is a Synchronous Motor in the MHD Series. The MHD041B-144-NP0-UN features a Motor Frame Size of 82mm Flange Size, 50mm Centering Diameter and a Motor Frame Length of 2.7 Nm. This Motor has a Motor Encoder of Digital servo feedback and comes with a Output Shaft of Shaft with keyway according to DIN 6885-1 (with shaft sealing ring).

Thanks

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21339

- Thank you received: 7282

13 Dec 2024 16:36 #316594

by tommylight

Replied by tommylight on topic Servo tuning for an axis that behaves different in one direction versus the othe

Two things:

-Y axis is the one with rack/pinion? Check and clean the rack and pinion, they collect a lot of dust that gets pressed between the teeth. Use a wire brush. Also check the spring loading parts, they can be stuck and cause that kind of behavior.

-lower the P value for Y axis/joint a bit.

-Y axis is the one with rack/pinion? Check and clean the rack and pinion, they collect a lot of dust that gets pressed between the teeth. Use a wire brush. Also check the spring loading parts, they can be stuck and cause that kind of behavior.

-lower the P value for Y axis/joint a bit.

The following user(s) said Thank You: kb0thn

Please Log in or Create an account to join the conversation.

- kb0thn

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 0

13 Dec 2024 23:37 #316616

by kb0thn

Replied by kb0thn on topic Servo tuning for an axis that behaves different in one direction versus the othe

I am not sure what I was thinking this morning, it is x-axis (the 120" long one) that is rack and pinion. y-axis and z-axis are ball screw and are working fine. (most of my work these days has been on MSY lathes and now a tube laser ... it seems every machine in my shop has different axis names ... and then I screw up the simplest axis named machined I own)

I am going to take tommylight's suggestion and give the rack and pinion a good cleaning. And look at if there is anything that could be lose / binding elsewhere in that axis.

Thanks

I am going to take tommylight's suggestion and give the rack and pinion a good cleaning. And look at if there is anything that could be lose / binding elsewhere in that axis.

Thanks

Please Log in or Create an account to join the conversation.

- Hardware & Machines

- CNC Machines

- Servo tuning for an axis that behaves different in one direction versus the othe

Time to create page: 0.080 seconds