5-axis Isel-based machine - Logosol to LinuxCNC?

- NickyDoes

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

23 Oct 2025 04:17 - 23 Oct 2025 04:26 #336932

by NickyDoes

5-axis Isel-based machine - Logosol to LinuxCNC? was created by NickyDoes

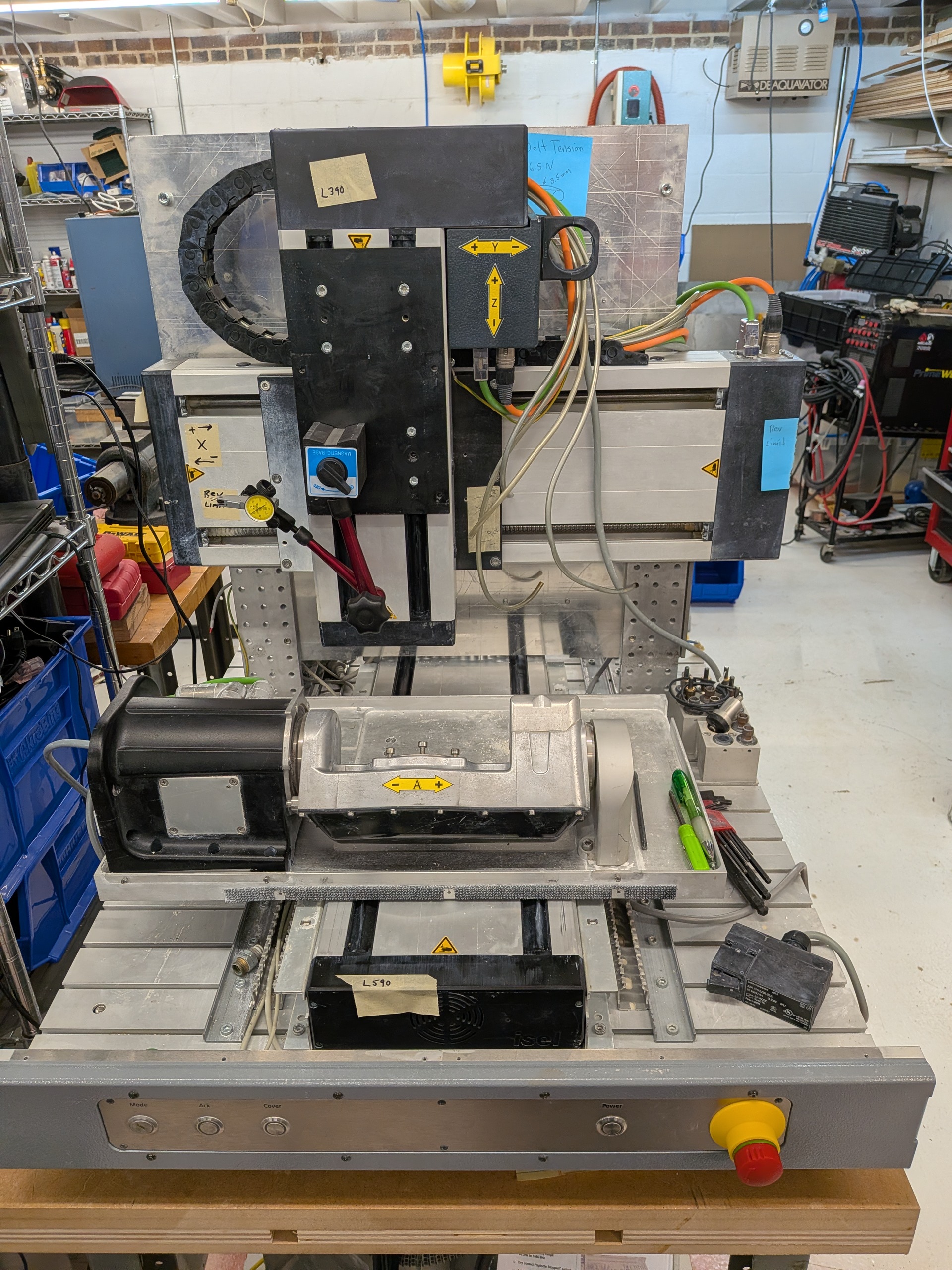

I've been diligently building up a 5-axis machine for machining small analytical instrument parts like fluid manifolds. My work envelope requirement is quite small. It's common to drill 0.5 mm holes 10 mm deep, and have them connect with an intersecting hole on another axis.

The pictured machine is wired with a Logosol CNC package (5 Logosol LS-231 drives + 1 kW spindle drive + a supervisory controller that manages door safety and more). This package is likely in many small specialty CNC machines produced around the world. I've been using Logosol's Windows based CNC program, which is free (Thanks, Logosol!) but is not really supported, updated, or documented. I've been in touch with a Logosol support person, who has been great to work with, but the software feels like a dead end. It's been great for proving the concept, but I'm forecasting a move to LinuxCNC.

The Logosol drives and supervisory controller are nicely wired - so it would be a shame to alter the reliable wiring to use ±10V or step + direction. Logosol's protocol is via RS-485, and includes 256 point path buffering.

My thought is to write HAL components to interface LinuxCNC pins to Logosol's LDCN protocol. The servo drives run a 51.2 microsecond update rate, so 20 servo ticks is 1.024 ms. LinuxCNC's update rate is 1 ms. I can either alter LinuxCNC's rate, or downsample the path points to match (feedback here is appreciated!).

I'm based in Raleigh NC, USA and welcome helpers or onlookers in my shop!

Edit: Isel is the company that made the 3 linear axes and the 2-axis A&B trunnion. They made the vertical brackets, the extruded aluminum base, and many other components. I presume they integrated the whole machine as a 'box builder', and the CNC vendor is more of an applications specialist. The build quality is fantastic.

One more note: The spindle is a Jaeger, and supports tool changes. You can see 12 tool holders dismounted from the bed + a tool height sensor.

The pictured machine is wired with a Logosol CNC package (5 Logosol LS-231 drives + 1 kW spindle drive + a supervisory controller that manages door safety and more). This package is likely in many small specialty CNC machines produced around the world. I've been using Logosol's Windows based CNC program, which is free (Thanks, Logosol!) but is not really supported, updated, or documented. I've been in touch with a Logosol support person, who has been great to work with, but the software feels like a dead end. It's been great for proving the concept, but I'm forecasting a move to LinuxCNC.

The Logosol drives and supervisory controller are nicely wired - so it would be a shame to alter the reliable wiring to use ±10V or step + direction. Logosol's protocol is via RS-485, and includes 256 point path buffering.

My thought is to write HAL components to interface LinuxCNC pins to Logosol's LDCN protocol. The servo drives run a 51.2 microsecond update rate, so 20 servo ticks is 1.024 ms. LinuxCNC's update rate is 1 ms. I can either alter LinuxCNC's rate, or downsample the path points to match (feedback here is appreciated!).

I'm based in Raleigh NC, USA and welcome helpers or onlookers in my shop!

Edit: Isel is the company that made the 3 linear axes and the 2-axis A&B trunnion. They made the vertical brackets, the extruded aluminum base, and many other components. I presume they integrated the whole machine as a 'box builder', and the CNC vendor is more of an applications specialist. The build quality is fantastic.

One more note: The spindle is a Jaeger, and supports tool changes. You can see 12 tool holders dismounted from the bed + a tool height sensor.

Attachments:

Last edit: 23 Oct 2025 04:26 by NickyDoes. Reason: Add details on Isel.

Please Log in or Create an account to join the conversation.

- reboots

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 2

23 Oct 2025 17:47 - 23 Oct 2025 17:48 #336971

by reboots

Replied by reboots on topic 5-axis Isel-based machine - Logosol to LinuxCNC?

I have several simpler LS-173E drives, which only have the RS-485 command interface. I had a project to implement LDCN in a microcontroller for standalone operation, but it's on the back burner this year. No opinion on feasibility with LinuxCNC, but I stumbled across this project that might be useful:

"Linux port of Logosol's LDCN with Python bindings"

github.com/cversek/linux-ldcn

"Linux port of Logosol's LDCN with Python bindings"

github.com/cversek/linux-ldcn

Last edit: 23 Oct 2025 17:48 by reboots.

The following user(s) said Thank You: NickyDoes

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11729

- Thank you received: 3973

24 Oct 2025 08:12 #337031

by rodw

Replied by rodw on topic 5-axis Isel-based machine - Logosol to LinuxCNC?

Good luck with this. There is no reason why you can't run a 1.024 Ms servo thread if that's important to remain synced.. Its just a hal file setting...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4611

26 Oct 2025 18:32 #337235

by andypugh

What bit rate is that at? 115200 bps is quite quick for RS485 (though the internet suggests that 42Mb/s is possible).

At 115200bps 51µs per packet only has space for 6 bits of data, so it either must be running unusually high bit rates or not updating as fast as suggested.

Replied by andypugh on topic 5-axis Isel-based machine - Logosol to LinuxCNC?

My thought is to write HAL components to interface LinuxCNC pins to Logosol's LDCN protocol. The servo drives run a 51.2 microsecond update rate, so 20 servo ticks is 1.024 ms.

What bit rate is that at? 115200 bps is quite quick for RS485 (though the internet suggests that 42Mb/s is possible).

At 115200bps 51µs per packet only has space for 6 bits of data, so it either must be running unusually high bit rates or not updating as fast as suggested.

Please Log in or Create an account to join the conversation.

- NickyDoes

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

28 Oct 2025 07:24 #337331

by NickyDoes

Replied by NickyDoes on topic 5-axis Isel-based machine - Logosol to LinuxCNC?

125000 bits/sec. All LDCN network comms must start at 19200, then get upgraded.

One sets a servo update rate multiplier (e.g. 20x) so the 51.2 µs becomes only the control loop update time, but the commanded position is updated every 1.024 ms. Yes, correct - at 51 µs, the bandwidth would be insufficient.

If interested, I developed HAL components to initialize the LDCN, enumerate the devices, and expose pins to LinuxCNC. Like any software project, it needs experienced eyes to pick apart the architecture.

github.com/ndemarco/linuxcnc-logosol

One sets a servo update rate multiplier (e.g. 20x) so the 51.2 µs becomes only the control loop update time, but the commanded position is updated every 1.024 ms. Yes, correct - at 51 µs, the bandwidth would be insufficient.

If interested, I developed HAL components to initialize the LDCN, enumerate the devices, and expose pins to LinuxCNC. Like any software project, it needs experienced eyes to pick apart the architecture.

github.com/ndemarco/linuxcnc-logosol

Please Log in or Create an account to join the conversation.

Time to create page: 0.147 seconds