G code Generator for Mills

- pi.r

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 0

12 Mar 2014 05:24 - 12 Mar 2014 18:58 #44711

by pi.r

Replied by pi.r on topic G code Generator for Mills

Duplicate post removed. See next post

Last edit: 12 Mar 2014 18:58 by pi.r.

Please Log in or Create an account to join the conversation.

- pi.r

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 0

12 Mar 2014 05:27 - 12 Mar 2014 05:55 #44712

by pi.r

Checked 1.7.04. Export to Axis and save to file works perfectly.

Step over issue:

I enter:

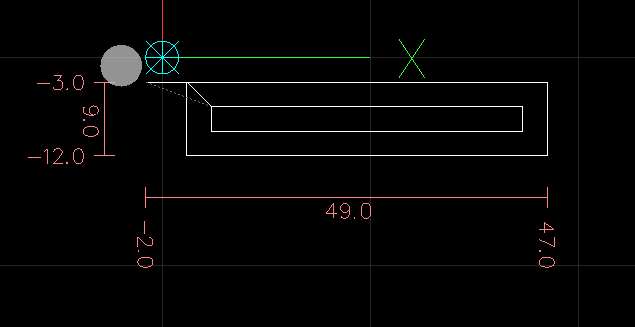

The work piece rear edge is positioned at Y0.0mm

The first horizontal cut will be made at Y-3.0mm

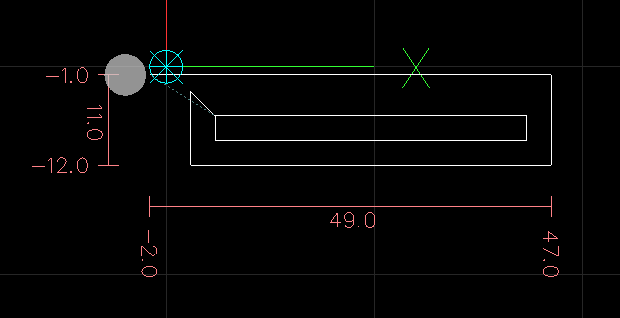

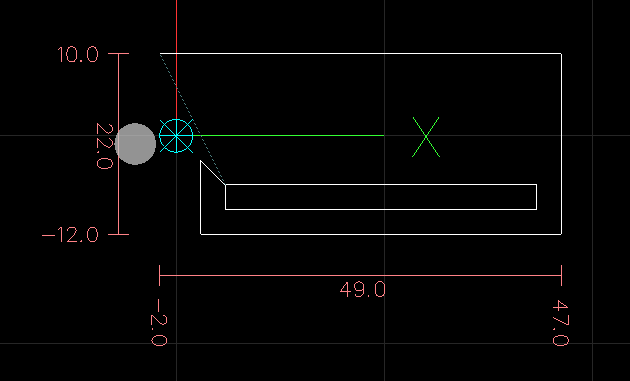

With a tool radius = 2.0mm, the cut area will then range from Y-1.0 to Y-5.0, leaving the first mm from the edge untouched, right..?

The left, right and bottom edges will also be cut, leaving 1mm along the outside uncut in the same way.

I expext:

With a 4mm tool and 75% step over, the tool should cut 3mm into the material in each move. So to me that means the first move should be from X-2.0 Y-1.0 to X49 Y-1.0, and so on.

I assume:

X and Y Length corresponds to the size of my work piece to be cut.

I have to admit that I am a complete newbie in CNC and CAM processing and have a lot to learn, so I might very well be completely lost here. But I really believed I had a fairly good grasp of this...

Replied by pi.r on topic G code Generator for Mills

That's nice. I like that. But I think it would be better to get rid of the separate unit setting, and instead just read the "Preamble" field and look for G20/G21. Maybe that's already in your plan...Actually the inch/mm give sane presets lol.

Checked 1.7.04. Export to Axis and save to file works perfectly.

Step over issue:

I enter:

- Tool Diameter: 4mm

- Step over: 75% (or empty)

- X Length: 50mm

- Y Length: 15mm

- X Reference: 0

- Y Reference: 0

- X Start: (empty)

- Y Start: (empty)

The work piece rear edge is positioned at Y0.0mm

The first horizontal cut will be made at Y-3.0mm

With a tool radius = 2.0mm, the cut area will then range from Y-1.0 to Y-5.0, leaving the first mm from the edge untouched, right..?

The left, right and bottom edges will also be cut, leaving 1mm along the outside uncut in the same way.

I expext:

With a 4mm tool and 75% step over, the tool should cut 3mm into the material in each move. So to me that means the first move should be from X-2.0 Y-1.0 to X49 Y-1.0, and so on.

I assume:

X and Y Length corresponds to the size of my work piece to be cut.

I have to admit that I am a complete newbie in CNC and CAM processing and have a lot to learn, so I might very well be completely lost here. But I really believed I had a fairly good grasp of this...

Last edit: 12 Mar 2014 05:55 by pi.r. Reason: Clarification and misspelling

Please Log in or Create an account to join the conversation.

- pi.r

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 0

12 Mar 2014 05:42 - 12 Mar 2014 05:51 #44713

by pi.r

Replied by pi.r on topic G code Generator for Mills

Last edit: 12 Mar 2014 05:51 by pi.r. Reason: added 2:nd immage

Please Log in or Create an account to join the conversation.

Time to create page: 0.098 seconds