DeskProto releases free CAM software for Linux.

- LexLen

- Offline

- New Member

-

- Posts: 10

- Thank you received: 8

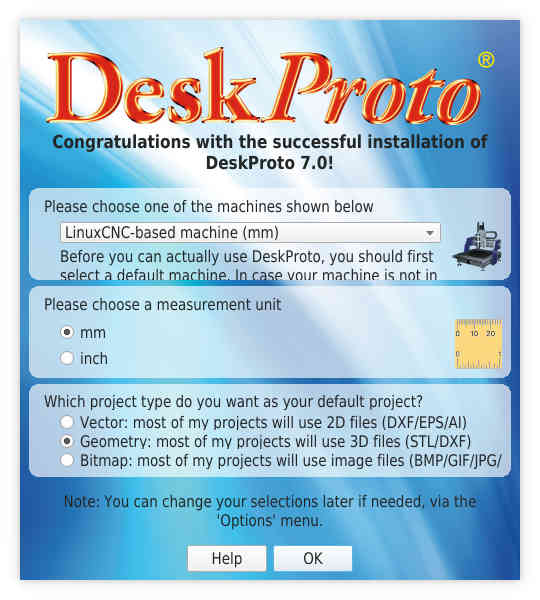

Free CAM software for Linux seems sufficiently relevant to nevertheless post.

The DeskProto CAM software already was available for Windows and MacOS,

last week a version for Linux has been released (distributed as 64 bits AppImage file).

DeskProto uses the "Freemium model": basic CAM functionality is free, more features in the paid editions.

Read more in our Press release message on www.deskproto.com/news-pressreleases/pr_cam-for-linux_2020

Looking forward to getting feedback from the LinuxCNC community.

Please Log in or Create an account to join the conversation.

- Reinhard

- Offline

- Platinum Member

-

- Posts: 508

- Thank you received: 94

Thank you for this post. Guess, this news is worth a seperate newsletter

How about localized variants? Can I download an english version and later change to german?

Your website claims, that german variants have to be downloaded from german website - but that website does not know anything about linux variant

Please Log in or Create an account to join the conversation.

- LexLen

- Offline

- New Member

-

- Posts: 10

- Thank you received: 8

You can install any number of localized variants, on any moment. For each language a new folder will be added to ~/.local/share/Delft Spline Systems/DeskProto/7.0/Language/ (for instance DE for german) with all files that need translation. After that you can simply switch language in the Preferences.

The German translation is special as that has been made by the German distributor. Our plan is to combine all languages in one Setup/DMG/AppImage file for version 7.1

I will email the German distrinutor.

Please Log in or Create an account to join the conversation.

- Reinhard

- Offline

- Platinum Member

-

- Posts: 508

- Thank you received: 94

Congratulation!

You did a really good job

Where former releases crashed on big stl files, this version just works as expected.

Really really great.

I'm so happy about the first "real" CAM for linux systems. I'll buy a license as soon as my machine will be ready. For now, I'm just playing around ...

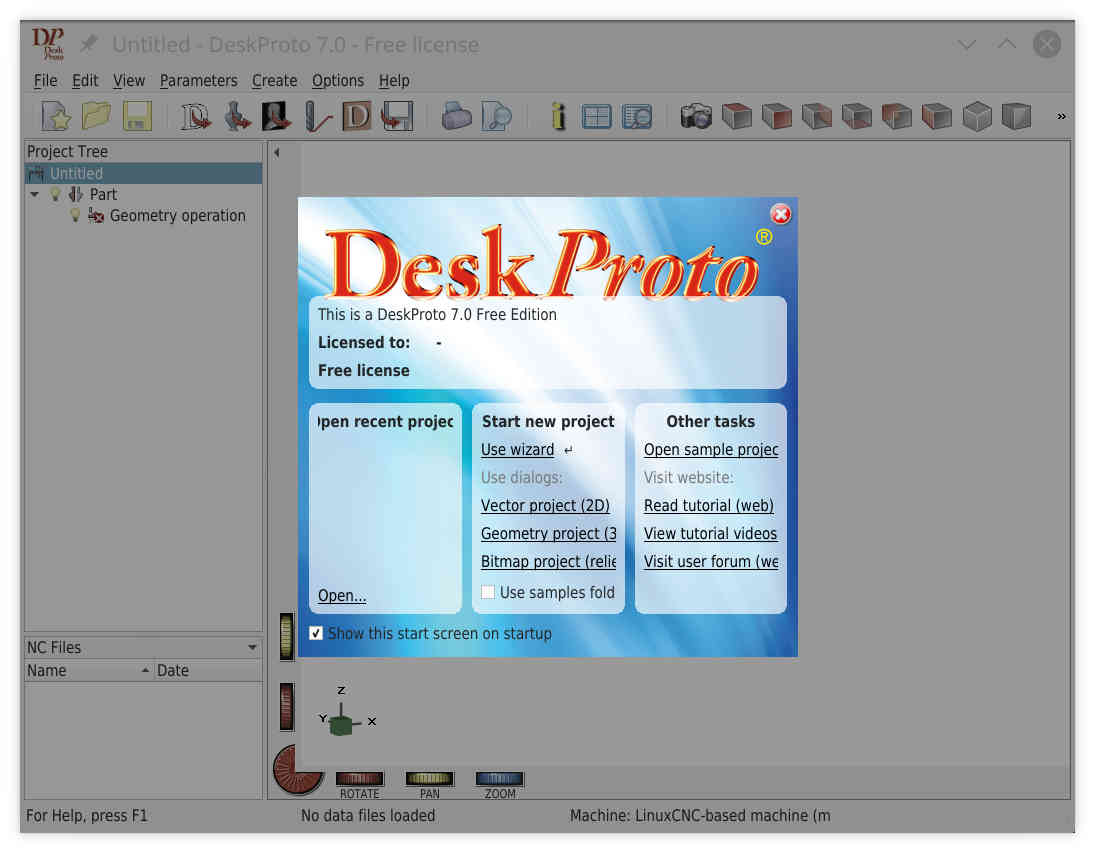

But I could give some feedback. Don't know, which window-toolkit you're using, but some dialogs don't calculate fontmetrics according to used font and fontsize.

I use kde as desktop, where you can change font and fontsize for applications (in system settings) and its possible to scale the desktop.

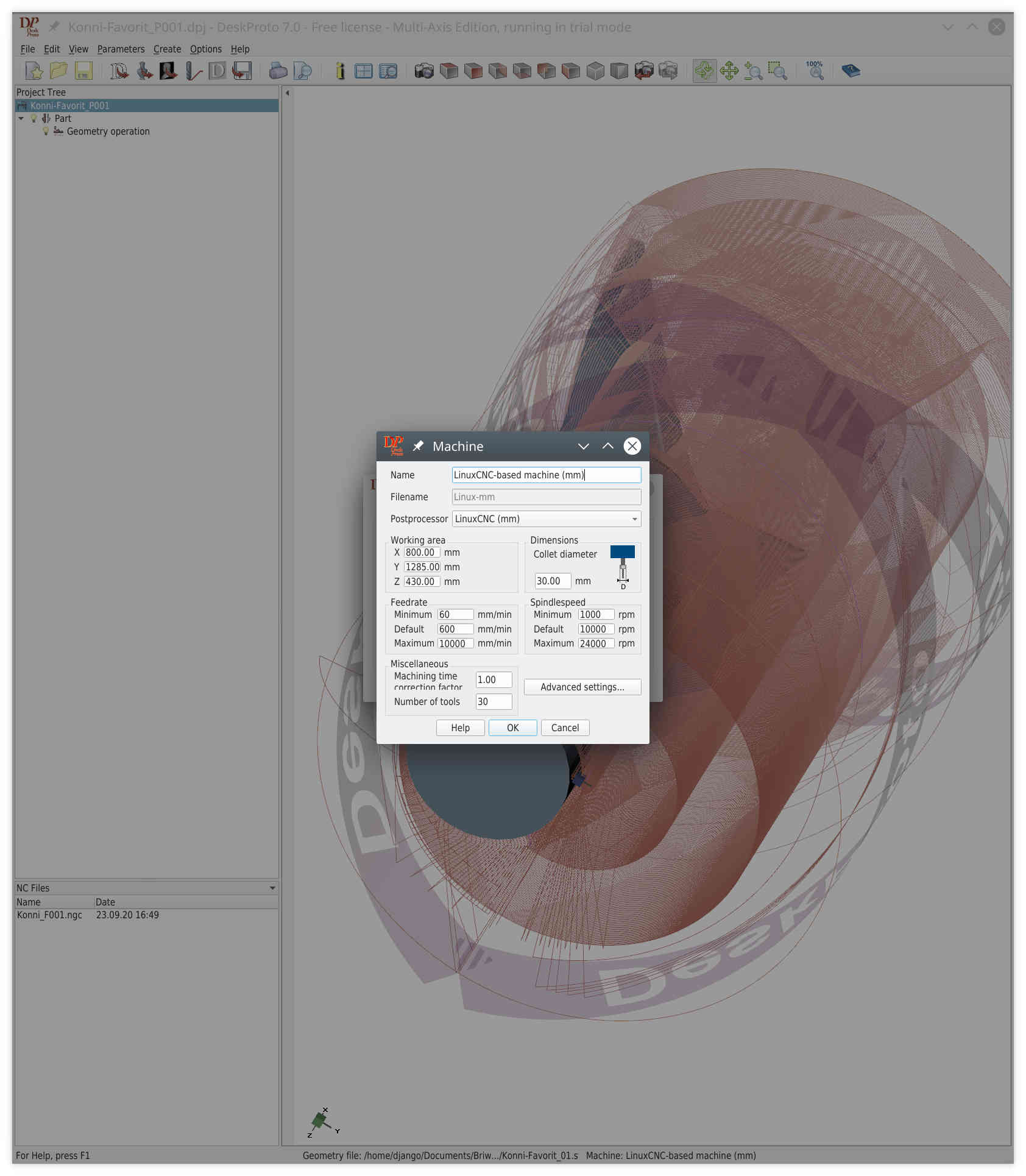

Here a few screenshots:

This dialog says, that DP uses one thread for calculation of workpaths. Don't know, whether that function can use multiple threads. If so, I did not find the option, where to enable multithreading.

Where can I find the list of cutters? I changed some in the application, but could not find the corresponding file.

The point is, I have a tool-manager application, where I manage all my tools. For a specific job I can export a list of tools with properties for DP and another list of tools for use of linuxcnc.

So I'd like to change my tool-exporter to generate the right tool list, that could be used by DP.

Than I have a wish for a future version:

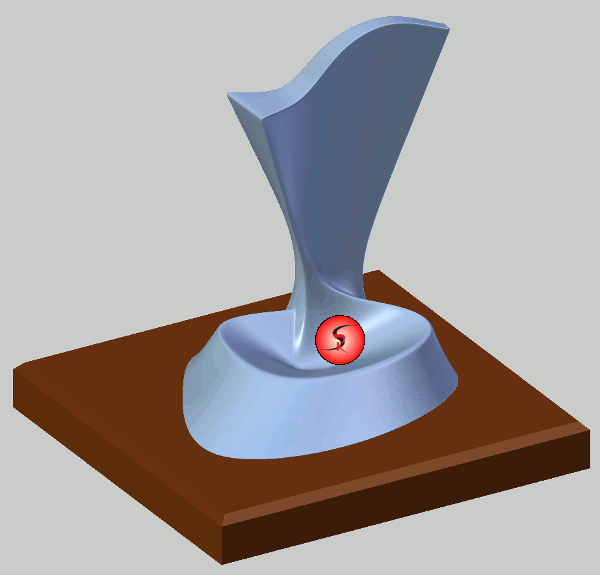

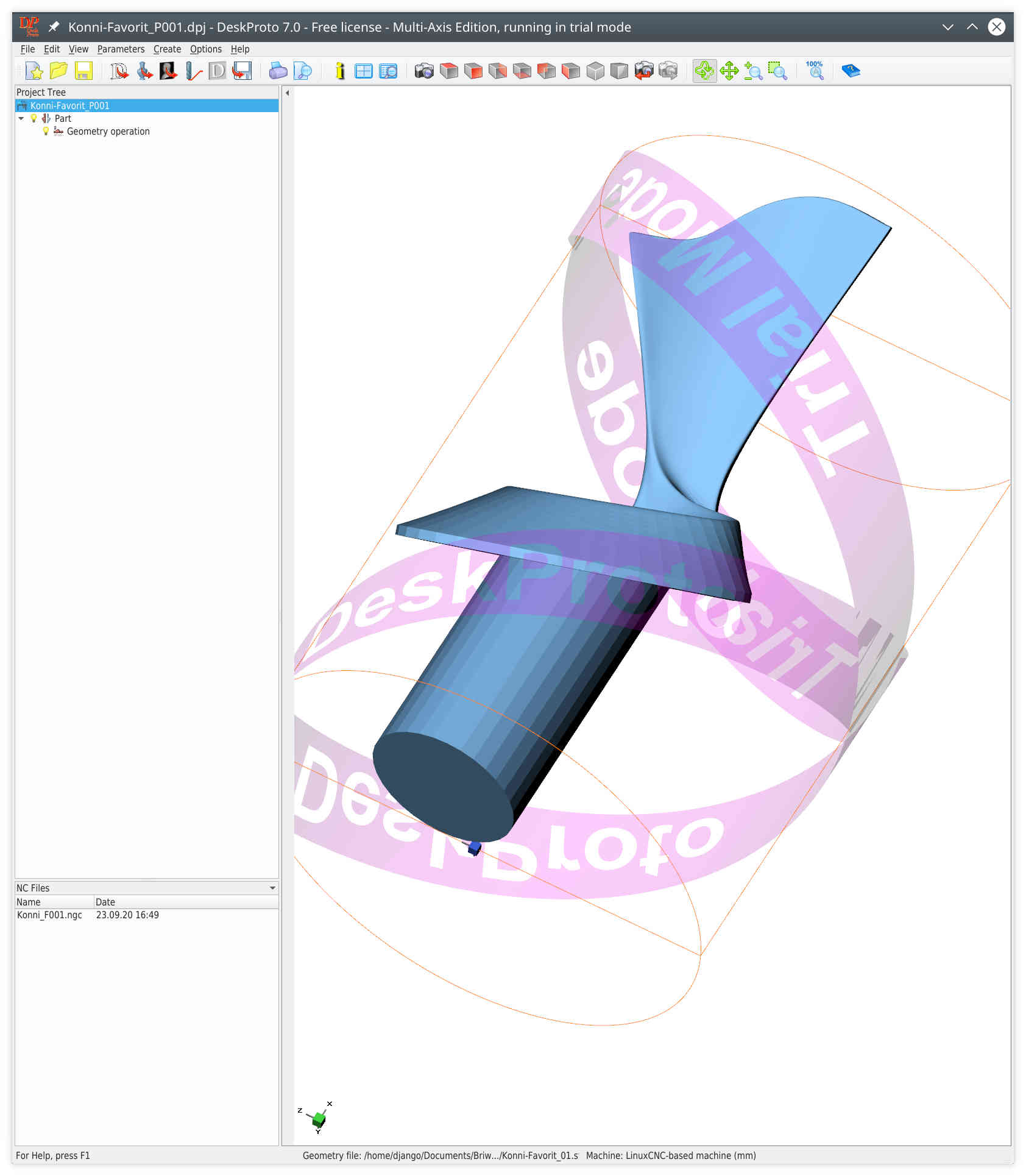

I have a model like this

.

and I added a cylinder for mounting it on a rotary axis like this:

.

Would be nice, if the cylinder could be selected and taken as rotary axis and workpiece zero. Current options don't allow this - except custom zero point, but that is nothing exact - just a guess.

And I miss an option for entering real size of workpiece. Usually the workpiece will be bigger than the cad model. So for rotary workpieces it would be nice to be able to enter diameter and length of the cylinder of the workpiece.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

Seems to be an interesting alternative for me hobbyists, using old mastercam (in vm).

Mike

Please Log in or Create an account to join the conversation.

- LexLen

- Offline

- New Member

-

- Posts: 10

- Thank you received: 8

Happy to hear that the program works well for you.

Except the font size in the user interface: the screenshots show that some dialogs have become quite difficult to understand... We have similar problems on other platforms when a large font is set on a high-res screen. The toolkit that we use is called QT, and the version that we use has a few issues in that area. We plan to use a newer version of QT for the upcoming DeskProto V7.1, and I hope that these problems then will have been solved.

About the multi-threading: DeskProto uses one thread per operation. So when you calculate more operations at the same time it will do so multi-threaded.

The cutters can be found as .CTR files in

~/.local/share/Delft Spline Systems/DeskProto/7.0/Drivers/

(you can change this location in the Preferences)

In V7.1 a button will be added to directly open that location.

For rotary machining DeskProto uses the origin axis as defined in CAD (so the line Y=0 and Z=0). That gives you the option to exactly set the rotation axis (to do so do not use he option "Center geometry"). For more information see the Tips page www.deskproto.com/support-tips-tricks/dp...tion-positioning.php

For the size of the workpiece I assume that you mean the size of the material block ? That can be sent in DeskProto, in the Part parameters (and also in each wizard).

The model that you show provides a real challenge, when you will indeed machine it I am curious to see the result !

Please Log in or Create an account to join the conversation.

- Reinhard

- Offline

- Platinum Member

-

- Posts: 508

- Thank you received: 94

Ah - I see ...The cutters can be found as .CTR files

One file per cutter - not bad at all

.

Hm, the best way is change the origin in cad indeed (I use blender for that).For more information see the Tips page ...

.

Yes, should have used a wizard. Not bad.... and also in each wizard

I did it the manual way - and there the workpiece size is not obvious.

No matter - using a wizard works fine

.

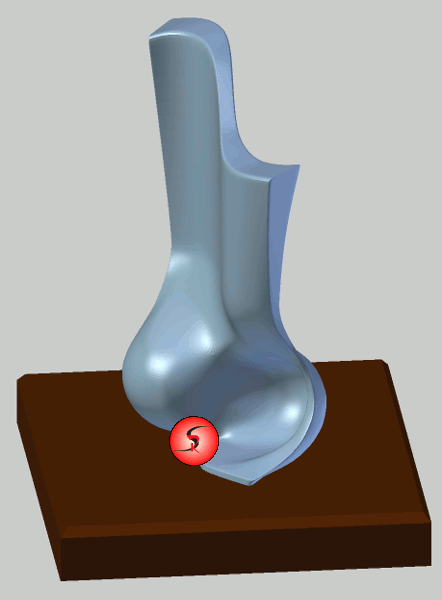

My first model was milled using DP as CAM about 5 years ago. A friend of mine has a mill and he did me a favorThe model that you show provides a real challenge, when you will indeed machine it I am curious to see the result !

.

The challenge was - stl size of 22Mb - DP stumbled from crash to crash. We had to tweak model to get it worked out. That time, support for rotary axis was only indexed axis (if I remember well).

This is the result:

.

Attachments:

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

- Visitor

-

Please Log in or Create an account to join the conversation.

- LexLen

- Offline

- New Member

-

- Posts: 10

- Thank you received: 8

Would it be OK to post these images on our social media pages ? And if yes, what should I mention as source ?

Please Log in or Create an account to join the conversation.

- Reinhard

- Offline

- Platinum Member

-

- Posts: 508

- Thank you received: 94

Sure.Would it be OK to post these images on our social media pages ?

.

Source?And if yes, what should I mention as source ?

Don't know if I understand you right.

Source? - my brain

I model lot of curved surfaces and it was the challenge to create such surfaces in blender. Quite a lot of work, but finally I got it.

So idea and model (both models in this thread) are mine.

Milling happened on a diy-mill build of wood.

... and worth to mention: model came out of milling as is. No grinding.

Just finishing with oil.

Please Log in or Create an account to join the conversation.