Z-axis coördinates problem after running program

- remon_v

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 7

22 May 2022 08:47 - 22 May 2022 08:58 #243535

by remon_v

Replied by remon_v on topic Z-axis coördinates problem after running program

I just did that… and didn’t work.

What did work is when I clicked ‘Tool touch off’

What did work is when I clicked ‘Tool touch off’

Last edit: 22 May 2022 08:58 by remon_v.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

22 May 2022 09:10 #243537

by andypugh

Replied by andypugh on topic Z-axis coördinates problem after running program

Can you post the first 20 or 30 lines of the G-code?

Please Log in or Create an account to join the conversation.

- remon_v

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 7

22 May 2022 09:18 - 22 May 2022 09:19 #243539

by remon_v

Replied by remon_v on topic Z-axis coördinates problem after running program

I’m sorry I does work…

I only changed the Z-limit max of the joint and not the axis.

Now I changed both and it works!

Thanks for the help!

I only changed the Z-limit max of the joint and not the axis.

Now I changed both and it works!

Thanks for the help!

Last edit: 22 May 2022 09:19 by remon_v.

Please Log in or Create an account to join the conversation.

- remon_v

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 7

22 May 2022 16:31 #243563

by remon_v

Replied by remon_v on topic Z-axis coördinates problem after running program

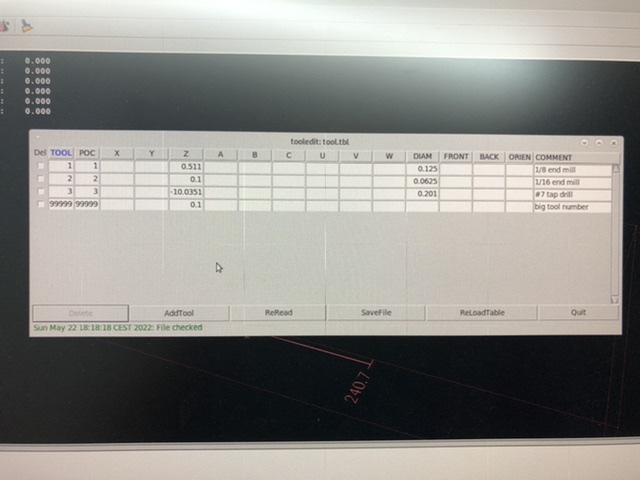

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

23 May 2022 22:21 #243647

by andypugh

Replied by andypugh on topic Z-axis coördinates problem after running program

I thought that I answered this.

Fusion has an option to use tool diameter compensation in the CAM or in the controller.

But the tool length is just assumed to be correct, ie Fusion assumes that after a G43 the tool point is at the controlled point.

The tool length data in Fusion is only for the graphics. The tool length data in LinuxCNC is the important one. (and should be set by touch-off or tool-probe, not from measuring the tool)

Fusion has an option to use tool diameter compensation in the CAM or in the controller.

But the tool length is just assumed to be correct, ie Fusion assumes that after a G43 the tool point is at the controlled point.

The tool length data in Fusion is only for the graphics. The tool length data in LinuxCNC is the important one. (and should be set by touch-off or tool-probe, not from measuring the tool)

Please Log in or Create an account to join the conversation.

- OliverLSedlacek

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 1

07 Feb 2023 09:38 #263905

by OliverLSedlacek

Replied by OliverLSedlacek on topic Z-axis coördinates problem after running program

I don't want this to be a thread hijack, but I'm a newbie and also struggling with Z limits. What's the convention for Z limits, 0 (table) to 100 (fully up) or -100 for table and 0 for fully up?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21370

- Thank you received: 7288

07 Feb 2023 11:07 #263917

by tommylight

Replied by tommylight on topic Z-axis coördinates problem after running program

Usually for mills it is 0 up and -100 down to the table, then use G54 offset to set 0 at the top of the workpiece.

The following user(s) said Thank You: OliverLSedlacek

Please Log in or Create an account to join the conversation.

Time to create page: 0.165 seconds