hot wire cutting

- Tniejadek

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

17 Feb 2025 21:04 #321872

by Tniejadek

hot wire cutting was created by Tniejadek

Hello,

The forum I often browsed and for most problems I found help. Now, unfortunately, the issue has outgrown me. I have a plotter for cutting styrofoam with hot wire.

I need a wire break control in it. The wire is controlled by PWM. The problem is that I would like the control to take place only in a specific case, i.e. when the machine executes a program with (M3) on, the wire breakage would cause the machine to pause or e-stop. My control system works only when current flows through the wire then there is a high state on the sensor output. Can anyone help me solve this problem?

Translated with DeepL.com (free version)

The forum I often browsed and for most problems I found help. Now, unfortunately, the issue has outgrown me. I have a plotter for cutting styrofoam with hot wire.

I need a wire break control in it. The wire is controlled by PWM. The problem is that I would like the control to take place only in a specific case, i.e. when the machine executes a program with (M3) on, the wire breakage would cause the machine to pause or e-stop. My control system works only when current flows through the wire then there is a high state on the sensor output. Can anyone help me solve this problem?

Translated with DeepL.com (free version)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20200

- Thank you received: 6874

17 Feb 2025 21:49 #321874

by tommylight

Replied by tommylight on topic hot wire cutting

More info

How is the wire break sensor included in LinuxCNC?

Is that a normal hi/low signal that LinuxCNC sees?

If yes, wiring that signal to amplifier fault in hal would disable the machine, not e-stop, so you can change the wire and continue working.

You can also wire it to feed hold or motion inhibit, but both will just stop motion and wait while the drives will remain enabled, actually this might be better if the machine has something that can move when motors are disabled.

How is the wire break sensor included in LinuxCNC?

Is that a normal hi/low signal that LinuxCNC sees?

If yes, wiring that signal to amplifier fault in hal would disable the machine, not e-stop, so you can change the wire and continue working.

You can also wire it to feed hold or motion inhibit, but both will just stop motion and wait while the drives will remain enabled, actually this might be better if the machine has something that can move when motors are disabled.

Please Log in or Create an account to join the conversation.

- Tniejadek

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

18 Feb 2025 05:41 #321893

by Tniejadek

Replied by Tniejadek on topic hot wire cutting

At the moment the sensor is not connected in any way because it did not work for me under e-stop, I had to have at least a minimum current in the wire at all times, even when stationary.

The high signal from the sensor activates the relay so I can give any signal.

The machine is supposed to stop, because often when it breaks the wire sticks to the material and pulls it.

Apart from the movement of the wire frames, the machine does not make any other movements.

I wanted to associate this control with the M3 code because my G-code generator allows quick passes past the material without heating the wire.

Translated with DeepL.com (free version)

The high signal from the sensor activates the relay so I can give any signal.

The machine is supposed to stop, because often when it breaks the wire sticks to the material and pulls it.

Apart from the movement of the wire frames, the machine does not make any other movements.

I wanted to associate this control with the M3 code because my G-code generator allows quick passes past the material without heating the wire.

Translated with DeepL.com (free version)

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 901

- Thank you received: 377

18 Feb 2025 11:04 #321910

by my1987toyota

Replied by my1987toyota on topic hot wire cutting

Some pictures of your machine would help. tommylight and I have both built hot wire foam machines.

Personally I would use ladder logic for the pause control. I am confused however as

to why your wire breaks often enough that you need a system to pause the program when it happens.

Some questions.-

What type of wire are you using Titanium? NiChrome?

How much tension is the wire kept under?

What gauge is the wire?

How hot are you running the wire?

What voltage is the wire powered with?

What frequency is your PWM signal?

Personally I would use ladder logic for the pause control. I am confused however as

to why your wire breaks often enough that you need a system to pause the program when it happens.

Some questions.-

What type of wire are you using Titanium? NiChrome?

How much tension is the wire kept under?

What gauge is the wire?

How hot are you running the wire?

What voltage is the wire powered with?

What frequency is your PWM signal?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Tniejadek

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

18 Feb 2025 19:06 #321930

by Tniejadek

Replied by Tniejadek on topic hot wire cutting

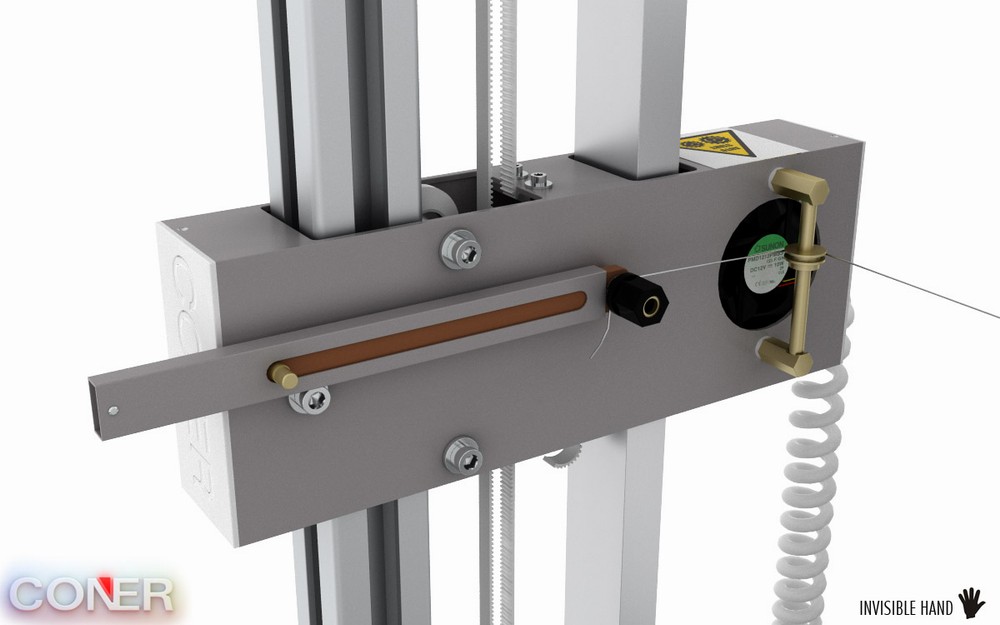

I converted the controller of an old plotter that was burned out. By trial and error method we managed to get it working.

I use 0.3mm kanthal wire.The length of the wire is 1.5 meters.

It does not break very often but it is almost always the least appropriate moment when cutting large files. And my works can be cut even 1,5 h. I use styrofoam for initial molds for plaster decorations. (Maybe a little from exaggerated economy I use it too long).

I don't know the tension force of the wire and it will be difficult for me to measure it.

I don't know the temperature of the wire either, but I know that with the hardest materials in the dark it doesn't glow. At least that's the setting I use.

The wire is powered by 90V.

I have the PWM set to 100Hz.

Whether the control is needed I don't know now I work without it, but in the old machine it was and sometimes I saved a large piece of material.

I am also attaching two photos from the manufacturer's website of my own now I don't have until the weekend I will be in the workshop.

Translated with DeepL.com (free version)

I use 0.3mm kanthal wire.The length of the wire is 1.5 meters.

It does not break very often but it is almost always the least appropriate moment when cutting large files. And my works can be cut even 1,5 h. I use styrofoam for initial molds for plaster decorations. (Maybe a little from exaggerated economy I use it too long).

I don't know the tension force of the wire and it will be difficult for me to measure it.

I don't know the temperature of the wire either, but I know that with the hardest materials in the dark it doesn't glow. At least that's the setting I use.

The wire is powered by 90V.

I have the PWM set to 100Hz.

Whether the control is needed I don't know now I work without it, but in the old machine it was and sometimes I saved a large piece of material.

I am also attaching two photos from the manufacturer's website of my own now I don't have until the weekend I will be in the workshop.

Translated with DeepL.com (free version)

Attachments:

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 901

- Thank you received: 377

19 Feb 2025 00:12 #321952

by my1987toyota

Replied by my1987toyota on topic hot wire cutting

I will admit I haven't herd of Kanthal wire before. From what I could find online it is an iron chromium aluminum

wire. I would have concerns with a wire that is heated and flexed repeatedly when it contains aluminum . That

would generally be a recipe for stress cracking. Hence why I like NiChrome wire. I would venture a guess that

the wire on your machine usually breaks at the pulley. Correct? At least if it's the same as the picture.

wire. I would have concerns with a wire that is heated and flexed repeatedly when it contains aluminum . That

would generally be a recipe for stress cracking. Hence why I like NiChrome wire. I would venture a guess that

the wire on your machine usually breaks at the pulley. Correct? At least if it's the same as the picture.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20200

- Thank you received: 6874

19 Feb 2025 00:20 #321953

by tommylight

Replied by tommylight on topic hot wire cutting

We use NiChrome, they last looooooong

Sometimes, when i can not find that i use the two thinnest guitar wires, perfectly usable but do not last as long.

Sometimes, when i can not find that i use the two thinnest guitar wires, perfectly usable but do not last as long.

Please Log in or Create an account to join the conversation.

- Tniejadek

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

27 Feb 2025 17:39 #322804

by Tniejadek

Replied by Tniejadek on topic hot wire cutting

Yes the wire breaks most often just in the area of the wheel.

Now we bought wire still kanthal from another source is more expensive than the previous one and it is much better.

The machine currently works without the sensor. However, in the future I would like to have this function anyway. I was wondering if it is possible to use one of the inputs as a digital input (because I saw in stepconf that such a function can be assigned) and connect it programmatically to the pause?

Now we bought wire still kanthal from another source is more expensive than the previous one and it is much better.

The machine currently works without the sensor. However, in the future I would like to have this function anyway. I was wondering if it is possible to use one of the inputs as a digital input (because I saw in stepconf that such a function can be assigned) and connect it programmatically to the pause?

Please Log in or Create an account to join the conversation.

- my1987toyota

-

- Offline

- Platinum Member

-

Less

More

- Posts: 901

- Thank you received: 377

28 Feb 2025 13:59 - 28 Feb 2025 14:00 #322869

by my1987toyota

Replied by my1987toyota on topic hot wire cutting

What type of sensor is it?

Inductive?

Continuity?

Voltage?

Thermocoupled?

Wire tension? ( basically a normally closed switch and spring )

At least those are the types I could think of being used. Their probably more.

Inductive?

Continuity?

Voltage?

Thermocoupled?

Wire tension? ( basically a normally closed switch and spring )

At least those are the types I could think of being used. Their probably more.

Last edit: 28 Feb 2025 14:00 by my1987toyota. Reason: adding info

Please Log in or Create an account to join the conversation.

- Tniejadek

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

28 Feb 2025 19:29 - 28 Feb 2025 19:44 #322882

by Tniejadek

Replied by Tniejadek on topic hot wire cutting

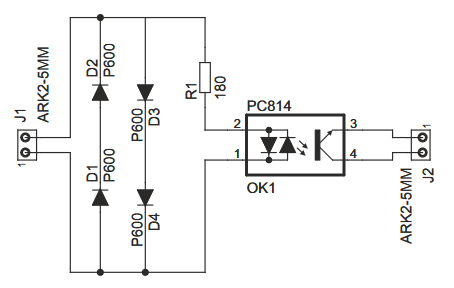

The sensor controls the flow of current through the wire, a simple electronic circuit that operates over a wide range of voltages and gives a low state at the output when the current flow disappears. See diagram.The connectors on the left side 1 and J1 are connected to the wire and the connectors 1 and J2 on the right side are the output.

Attachments:

Last edit: 28 Feb 2025 19:44 by Tniejadek.

The following user(s) said Thank You: my1987toyota

Please Log in or Create an account to join the conversation.

Time to create page: 0.112 seconds