Help Setting WJ200 Analog parameters

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

09 Sep 2018 17:59 #117245

by NCPatrol

Help Setting WJ200 Analog parameters was created by NCPatrol

Brief Background: I bought this mill from the original builder so I'm a little behind the curve on the original settings and wiring, settings, etc. Somehow, I managed to burn up the original WJ200. (And somehow two 7i77's when I tried to get a cheap chinese VFD to work in it's place!)

The replacement WJ200 has been sourced and installed, however I'm running in to some difficulties getting it to "talk" the the 7i77.

I have it wired exactly as it was before and I've referenced the original builder's threads on here and other sites, but I think he left out some details.

Here's how it was wired:

L & PLC - tied together at power supply ground

Pin 1 - Output 4 on 7i77

Pin 2 - Output 5 on 7i77

O - Analog Out 5 on 7i77

L - Ground 5 on 7i77

On the VFD I have the following parameters set

C001 - 00

C002 - 01

A002 - 01

I've read mixed statements about the A002 setting - one place he said he had it it at 01 and another he said 002. I've tried both. With 002, I actually get the "run" light to light up, but still no rotation or any other response.

I have reset the VFD to factory settings and tested the terminals manually and it works as it should (i.e.: jumping pins 1 or 2 puts it in fwd or rev) so I'm confident that the VFD is not defective. Since this exact setup worked before with the exact same VFD, I'm confident I'm just missing a parameter in the VFD itself.

The replacement WJ200 has been sourced and installed, however I'm running in to some difficulties getting it to "talk" the the 7i77.

I have it wired exactly as it was before and I've referenced the original builder's threads on here and other sites, but I think he left out some details.

Here's how it was wired:

L & PLC - tied together at power supply ground

Pin 1 - Output 4 on 7i77

Pin 2 - Output 5 on 7i77

O - Analog Out 5 on 7i77

L - Ground 5 on 7i77

On the VFD I have the following parameters set

C001 - 00

C002 - 01

A002 - 01

I've read mixed statements about the A002 setting - one place he said he had it it at 01 and another he said 002. I've tried both. With 002, I actually get the "run" light to light up, but still no rotation or any other response.

I have reset the VFD to factory settings and tested the terminals manually and it works as it should (i.e.: jumping pins 1 or 2 puts it in fwd or rev) so I'm confident that the VFD is not defective. Since this exact setup worked before with the exact same VFD, I'm confident I'm just missing a parameter in the VFD itself.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21157

- Thank you received: 7224

09 Sep 2018 22:09 #117263

by tommylight

Replied by tommylight on topic Help Setting WJ200 Analog parameters

Use halscope or halmeter to check that you actually get something on the analogue output from 7i77.

I am fairly certain that some times due to some yet to be confirmed reason, pncconfig will generate a config that will not power on the spindle ( happened only once ) or will not output anything on any of the analogue outputs ( waisted a full day hunting why this happens, did not find out ). Using over 20 configs made by pncconfig without any issues for testing and running machines, those 2 instances still remain a mystery. The first issue was solved just by editing a single line in the hal file, to much time has passed so i can not recall what was it, but that machine is in use every day since then without a hitch. The second one is a test config so it can wait.

>go to top>

end if

I am fairly certain that some times due to some yet to be confirmed reason, pncconfig will generate a config that will not power on the spindle ( happened only once ) or will not output anything on any of the analogue outputs ( waisted a full day hunting why this happens, did not find out ). Using over 20 configs made by pncconfig without any issues for testing and running machines, those 2 instances still remain a mystery. The first issue was solved just by editing a single line in the hal file, to much time has passed so i can not recall what was it, but that machine is in use every day since then without a hitch. The second one is a test config so it can wait.

>go to top>

end if

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

10 Sep 2018 00:39 #117268

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

Not sure I follow how that would help. This is a known good config of linuxcnc - I just managed to kill a VFD and I dont' know the setting that the previous owner used.

Basically, Linuxcnc via the 7i77 is putting out the correct commands, the VFD just isn't configured properly to receive them.

Basically, Linuxcnc via the 7i77 is putting out the correct commands, the VFD just isn't configured properly to receive them.

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

11 Sep 2018 00:46 #117317

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

More probing tonight - I can confirm that I'm getting 24v to pins 4 and 5 as expected when I put turn the spindle on in forward or reverse.

What I don't get is the "run" light that should come on when I turn the spindle on. The "run command" is either not being sent or the drive is not configured properly to receive it. I *thought* applying 24v to either pins 1 or 2 would give it the run command and tell it what direction to spin.

The Run light above the Run button is lit up, meaning it should be ready to receive external commands. The square "Run" light should turn on when I turn the spindle on in Linux CNC and it's actually being told to run.

If I understand the wiring correctly, the Analog 5 out on the Mesa should be varying resistance to "O" on the drive. I'm not sure how I can test this.

What I don't get is the "run" light that should come on when I turn the spindle on. The "run command" is either not being sent or the drive is not configured properly to receive it. I *thought* applying 24v to either pins 1 or 2 would give it the run command and tell it what direction to spin.

The Run light above the Run button is lit up, meaning it should be ready to receive external commands. The square "Run" light should turn on when I turn the spindle on in Linux CNC and it's actually being told to run.

If I understand the wiring correctly, the Analog 5 out on the Mesa should be varying resistance to "O" on the drive. I'm not sure how I can test this.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

11 Sep 2018 15:14 #117345

by andypugh

The analogout should be a variable voltage, and should be measurable with a multimeter.

You may need to connect VFD analog common to the 7i77 analog common.

Replied by andypugh on topic Help Setting WJ200 Analog parameters

If I understand the wiring correctly, the Analog 5 out on the Mesa should be varying resistance to "O" on the drive. I'm not sure how I can test this.

The analogout should be a variable voltage, and should be measurable with a multimeter.

You may need to connect VFD analog common to the 7i77 analog common.

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

11 Sep 2018 15:54 #117350

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

I believe that's the way it's currently wired.

O on VFD to Analog Out 5 on 7i77

L on VFD to Ground 5 on 7i77

I also know that in the original builder's threads he said he had to connect "L" and "PLC" from the VFD to the ground on the 24v power supply the feeds the 7i77.

O on VFD to Analog Out 5 on 7i77

L on VFD to Ground 5 on 7i77

I also know that in the original builder's threads he said he had to connect "L" and "PLC" from the VFD to the ground on the 24v power supply the feeds the 7i77.

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

11 Sep 2018 16:16 - 11 Sep 2018 16:16 #117352

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

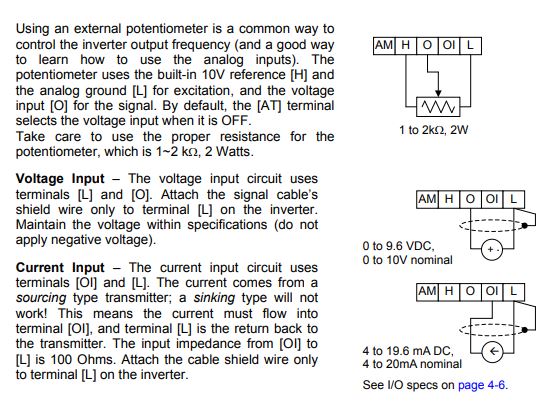

This is from the manual. I'm using the middle scenario - "voltage input", correct? I'll have to test for voltage on O this evening, but I suspect it's there and I'm back to just missing a parameter in the VFD itself.

When I got it, he did have a wire connected to "H" as well. I'm 99% sure that it was not connected to anything on the 7i77 and was likely just left over from a different setup when he initially was wiring it.....but there's that 1% chance that I missed something between replacing the drive and the 7i77.

When I got it, he did have a wire connected to "H" as well. I'm 99% sure that it was not connected to anything on the 7i77 and was likely just left over from a different setup when he initially was wiring it.....but there's that 1% chance that I missed something between replacing the drive and the 7i77.

Last edit: 11 Sep 2018 16:16 by NCPatrol.

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

11 Sep 2018 17:54 #117355

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

Well, that was somewhat easy.

I verified that there was varying voltage between L and O.

Then I re-read the quick reference manual on the "Run" light. As it turns out, that light should only be on when it's actually "armed" and ready to run. The A002 parameter wasn't set properly for an external command. It was waiting for me to physically press the "Run" button instead of using the signal from the 7i77. At some point I had tried it on 02...probably when I had the other wires backwards.

I changed it to 01 and the spindle spins up as expected now.

Now hopefully the first WJ200 burning up was just a fluke and there's not another underlying problem.

This whole fiasco cost me a WJ200 and 2 mesa cards. Granted, the Mesas were from me being stupid, but still wouldn't have happened if the drive hadn't smoked in the first place.

I verified that there was varying voltage between L and O.

Then I re-read the quick reference manual on the "Run" light. As it turns out, that light should only be on when it's actually "armed" and ready to run. The A002 parameter wasn't set properly for an external command. It was waiting for me to physically press the "Run" button instead of using the signal from the 7i77. At some point I had tried it on 02...probably when I had the other wires backwards.

I changed it to 01 and the spindle spins up as expected now.

Now hopefully the first WJ200 burning up was just a fluke and there's not another underlying problem.

This whole fiasco cost me a WJ200 and 2 mesa cards. Granted, the Mesas were from me being stupid, but still wouldn't have happened if the drive hadn't smoked in the first place.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

12 Sep 2018 13:15 #117394

by andypugh

Replied by andypugh on topic Help Setting WJ200 Analog parameters

Fingers crossed.

I have had a WJ200 running for years with no problems.

I have had a WJ200 running for years with no problems.

Please Log in or Create an account to join the conversation.

- NCPatrol

- Offline

- Senior Member

-

Less

More

- Posts: 77

- Thank you received: 1

12 Sep 2018 17:29 #117413

by NCPatrol

Replied by NCPatrol on topic Help Setting WJ200 Analog parameters

This was a really bizarre failure. I had used the mill earlier in the day on a part and was also experimenting with rigid tapping. I stalled the motor a couple times and tripped the VFD (there's a thread about my rigid tapping problems somewhere around here.) Several hours later, the machine was sitting idle but still powered on and I was just cleaning up around the shop when I smelled that telltale odor of burning silicon and then noticed smoke creeping out of the electronics cabinet on the mill.

The only thing that I think could have happened outside of a random/freak internal failure, is that when I was using compressed air to blow chips off the mill, something go inside the cabinet and shorted it. I didn't see any evidence of this when I tore it down, but it's the only possibility I can think of where I could have directly contributed to the failure. The box is pretty well sealed now (ask me how I took out my first Mesa card!) and it's pretty unlikely that a chip could have made it in there, but probably not impossible.

I did find replacement control boards for the VFD from a source in China. If I were a little more brave, I'd try plugging the board from the replacement VFD to the back end of the old one....but I really don't want to risk it right now!

The only thing that I think could have happened outside of a random/freak internal failure, is that when I was using compressed air to blow chips off the mill, something go inside the cabinet and shorted it. I didn't see any evidence of this when I tore it down, but it's the only possibility I can think of where I could have directly contributed to the failure. The box is pretty well sealed now (ask me how I took out my first Mesa card!) and it's pretty unlikely that a chip could have made it in there, but probably not impossible.

I did find replacement control boards for the VFD from a source in China. If I were a little more brave, I'd try plugging the board from the replacement VFD to the back end of the old one....but I really don't want to risk it right now!

Please Log in or Create an account to join the conversation.

Time to create page: 0.090 seconds