CNC Sewing machine question

- rjd1234

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

03 Aug 2019 23:02 #141306

by rjd1234

CNC Sewing machine question was created by rjd1234

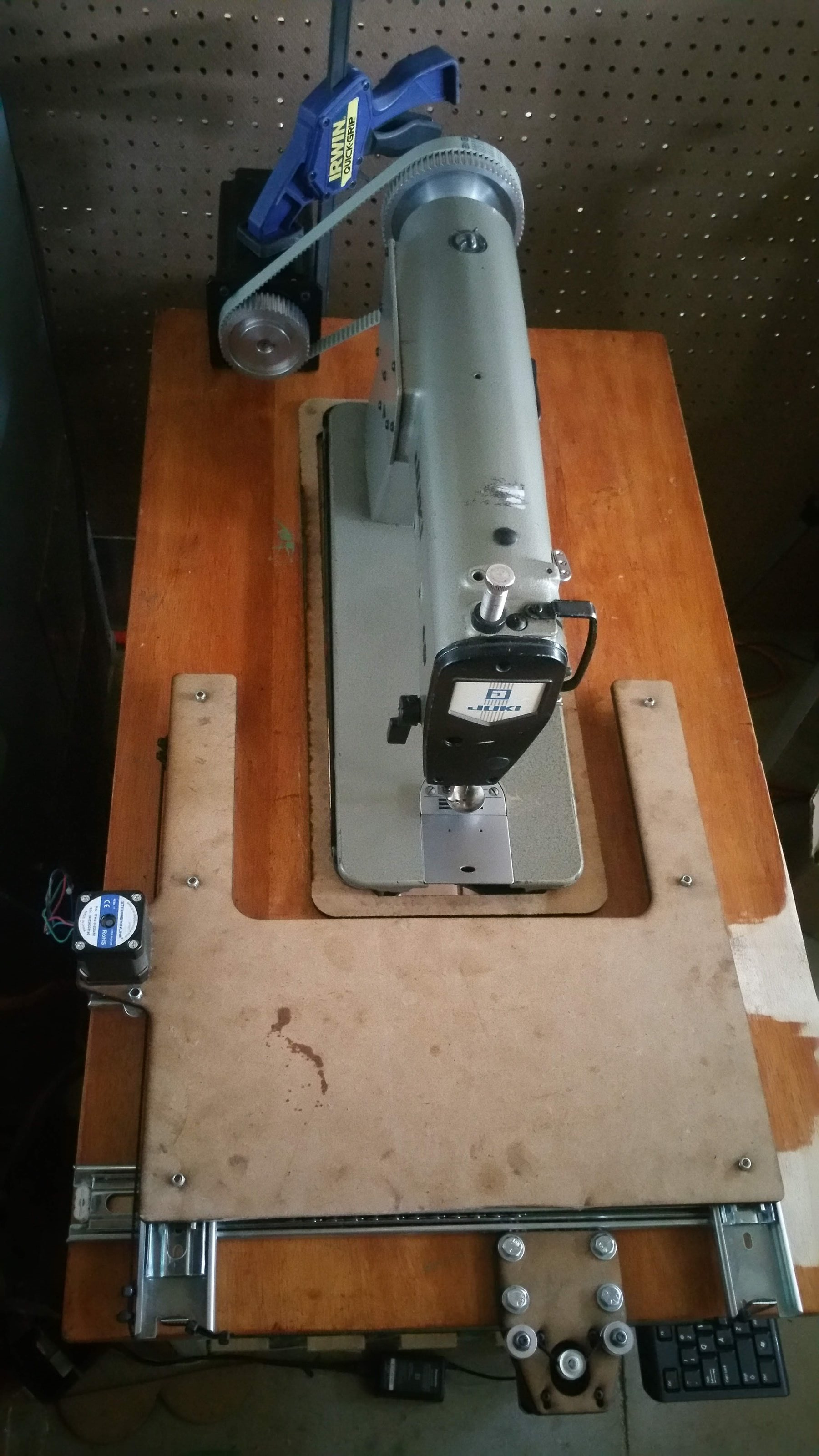

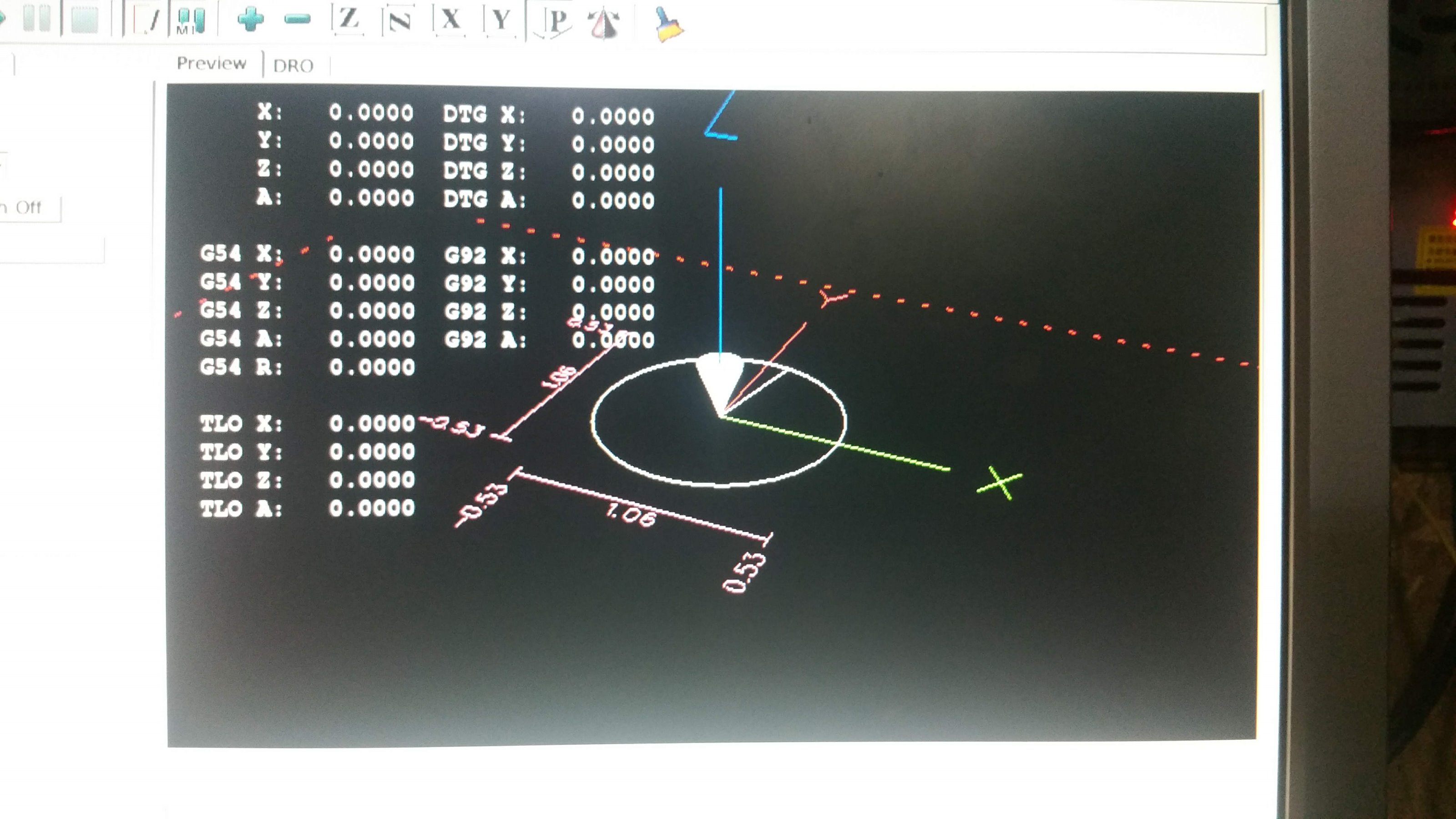

I have taken an old sewing machine and given it some computer controls using LinuxCNC. See attached pictures.

While it is working, it is not fast enough.

I am building on ideas from several others who have built similar machines. Basically, the strategy is to move x and y to the right point and then advance the A axis 360 degrees - this is one cycle of the needle going down, up, then back into position. I have attached some G Code that I am using for testing... it is a circle roughly 1 in diameter broken into 33 segments. The A axis is set to wrapped rotary in the .ini file. I have pushed the accel and velocity as fast as possible before skipping and the time to sew this circle is about 13 sec... it should be like 3 secs.

Here is a segment of code:

N18 G90 G1 X0.1007 Y0.5217

N19 G91 G00 A360

N20 G90 G1 X0.1978 Y0.4932

N21 G91 G00 A360

N22 G90 G1 X0.2878 Y0.4468

N23 G91 G00 A360

... etc

After I got the accel as fast as is reasonable, I tried speeding things up by having the A axis move as much as possible while the X and Y are moving.

Here is a segment of that code:

N18 G90 G1 X0.1007 Y0.5217 A160

N19 G91 G00 A200

N20 G90 G1 X0.1978 Y0.4932 A160

N21 G91 G00 A200

N22 G90 G1 X0.2878 Y0.4468 A160

N23 G91 G00 A200

... etc

This actually slowed the cycle down to about 15 sec.

I'm wondering if there is a way to write the program so that the A axis doesn't start and stop, but continues to spin and the X and Y move when the A axis is between 0 and 160 degrees.

I've never worked with servos before... and I'm pretty sure they would be very expensive... so I'm hoping to find a solution using the steppers that I already have.

I appreciate any thoughts and feedback.

While it is working, it is not fast enough.

I am building on ideas from several others who have built similar machines. Basically, the strategy is to move x and y to the right point and then advance the A axis 360 degrees - this is one cycle of the needle going down, up, then back into position. I have attached some G Code that I am using for testing... it is a circle roughly 1 in diameter broken into 33 segments. The A axis is set to wrapped rotary in the .ini file. I have pushed the accel and velocity as fast as possible before skipping and the time to sew this circle is about 13 sec... it should be like 3 secs.

Here is a segment of code:

N18 G90 G1 X0.1007 Y0.5217

N19 G91 G00 A360

N20 G90 G1 X0.1978 Y0.4932

N21 G91 G00 A360

N22 G90 G1 X0.2878 Y0.4468

N23 G91 G00 A360

... etc

After I got the accel as fast as is reasonable, I tried speeding things up by having the A axis move as much as possible while the X and Y are moving.

Here is a segment of that code:

N18 G90 G1 X0.1007 Y0.5217 A160

N19 G91 G00 A200

N20 G90 G1 X0.1978 Y0.4932 A160

N21 G91 G00 A200

N22 G90 G1 X0.2878 Y0.4468 A160

N23 G91 G00 A200

... etc

This actually slowed the cycle down to about 15 sec.

I'm wondering if there is a way to write the program so that the A axis doesn't start and stop, but continues to spin and the X and Y move when the A axis is between 0 and 160 degrees.

I've never worked with servos before... and I'm pretty sure they would be very expensive... so I'm hoping to find a solution using the steppers that I already have.

I appreciate any thoughts and feedback.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

03 Aug 2019 23:12 #141308

by jmelson

Replied by jmelson on topic CNC Sewing machine question

Ugh! Why do you think you need to program the needle crank in degrees?

All you want is for the needle to be up when you make LARGE moves of the material.

Why not set up the sewing motor to be the spindle (maybe even have programmable "spindle" speed, and then have a circuit that always stops the needle at full up.

You could program a pause after every spindle stop to allow the needle to get to full-up.

Jon

All you want is for the needle to be up when you make LARGE moves of the material.

Why not set up the sewing motor to be the spindle (maybe even have programmable "spindle" speed, and then have a circuit that always stops the needle at full up.

You could program a pause after every spindle stop to allow the needle to get to full-up.

Jon

Please Log in or Create an account to join the conversation.

- rjd1234

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

04 Aug 2019 07:33 #141312

by rjd1234

Replied by rjd1234 on topic CNC Sewing machine question

Can a stepper be run like a spindle?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

04 Aug 2019 08:13 #141314

by tommylight

Replied by tommylight on topic CNC Sewing machine question

Yes. The stepgen has to be set in velociry mode, i think as i never done it.

From what others mentioned in this thread, you will need to add a sensor to the machine pulley so it always stops at the top position of the needle.

There is also the issue of the X and Y axis moving the material while the needle is inserted in the material. I am aware that the machine clamps the material when in normal use and pushes it back. That can normally be disabled.

From what others mentioned in this thread, you will need to add a sensor to the machine pulley so it always stops at the top position of the needle.

There is also the issue of the X and Y axis moving the material while the needle is inserted in the material. I am aware that the machine clamps the material when in normal use and pushes it back. That can normally be disabled.

Please Log in or Create an account to join the conversation.

- rjd1234

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

04 Aug 2019 13:48 #141328

by rjd1234

Replied by rjd1234 on topic CNC Sewing machine question

Right - I have disabled the machine clamping so that the X and Y movements are done only by my steppers.

If I run the stepper like a spindle, will I still have access to know the position?

If I run the stepper like a spindle, will I still have access to know the position?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

04 Aug 2019 14:09 #141333

by tommylight

Replied by tommylight on topic CNC Sewing machine question

From what i know about those machines, the material can not be moved while the needle is in the material, that is why i think you would need two sensors on the machine pulley so it can know when the needle is out to start moving the material and when to stop moving just before the needle is inserted into the material.

All that is not very important for very high thread count as a litle flex to the needle is OK. That problem becomes very obvious when you try to stitch letters at 2 or more mm apart, that will break the needle or in your case most probably lose position.

Do a search for "rugbot" here on the forum maybe there is some info there on how to do that.

All that is not very important for very high thread count as a litle flex to the needle is OK. That problem becomes very obvious when you try to stitch letters at 2 or more mm apart, that will break the needle or in your case most probably lose position.

Do a search for "rugbot" here on the forum maybe there is some info there on how to do that.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

04 Aug 2019 15:49 #141344

by jmelson

Replied by jmelson on topic CNC Sewing machine question

The frame to hold the material is pretty large. When the CNC program is in the sewing mode, it will be moving at a very slow rate, and should not break the needle, as the fabric has some stretch to it. When making larger moves, as between letters, the "spindle" should be stopped with a timed pause command to allow the needle to go fully up before moving. I think this will really solve the problem.

Jon

Jon

The following user(s) said Thank You: tommylight, pinder

Please Log in or Create an account to join the conversation.

- rjd1234

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

05 Aug 2019 14:24 #141418

by rjd1234

Replied by rjd1234 on topic CNC Sewing machine question

Good suggestion on the Rugbot. I downloaded his .hal and .ini files. He is using hypot and a DMM servo. I am not familiar with either of these things... so I will do some research. From what I read, the hypot makes the speed of the "spindle" correlate with the speed of the x and y.

I will study this a bit more... hopefully I don't need to get a servo. With a servo I'm sure I could program everything so that the x and y only move when the needle pulley is between 160 and 360 degrees.

I will study this a bit more... hopefully I don't need to get a servo. With a servo I'm sure I could program everything so that the x and y only move when the needle pulley is between 160 and 360 degrees.

Please Log in or Create an account to join the conversation.

- rjd1234

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

05 Aug 2019 14:31 #141420

by rjd1234

Replied by rjd1234 on topic CNC Sewing machine question

Jon,

I understand what you mean. The reason I was trying to time everything so that it doesn't move while the needle is down is to avoid bending it into the hook on the underside. The slot on the spinning hook is pretty narrow that the needle goes into. I think it could tolerate more bending in the x than the y.

It is a good suggestion though. I will try it and see what happens. Worse case scenario, I have to replace the hook.

Thanks,

Rick

I understand what you mean. The reason I was trying to time everything so that it doesn't move while the needle is down is to avoid bending it into the hook on the underside. The slot on the spinning hook is pretty narrow that the needle goes into. I think it could tolerate more bending in the x than the y.

It is a good suggestion though. I will try it and see what happens. Worse case scenario, I have to replace the hook.

Thanks,

Rick

Please Log in or Create an account to join the conversation.

- SPH

-

- Offline

- Premium Member

-

Less

More

- Posts: 109

- Thank you received: 6

05 Aug 2019 23:34 - 05 Aug 2019 23:34 #141462

by SPH

Replied by SPH on topic CNC Sewing machine question

I've no experience with cnc sewing machines but plenty with conventional ones. I can say that you'll need to make sure the bed isn't moving when the needle is down. Best scenario it will just give you rubbish results because the stitches will be in the wrong place, worst case you'll get constant broken needles.

You should have the best part of 180 degrees of spindle movement to do the bed moves. Perhaps a little less for reliable results. I suspect you'll need really high speed and torque on your x/y to get good results.

You should have the best part of 180 degrees of spindle movement to do the bed moves. Perhaps a little less for reliable results. I suspect you'll need really high speed and torque on your x/y to get good results.

Last edit: 05 Aug 2019 23:34 by SPH.

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds